$34

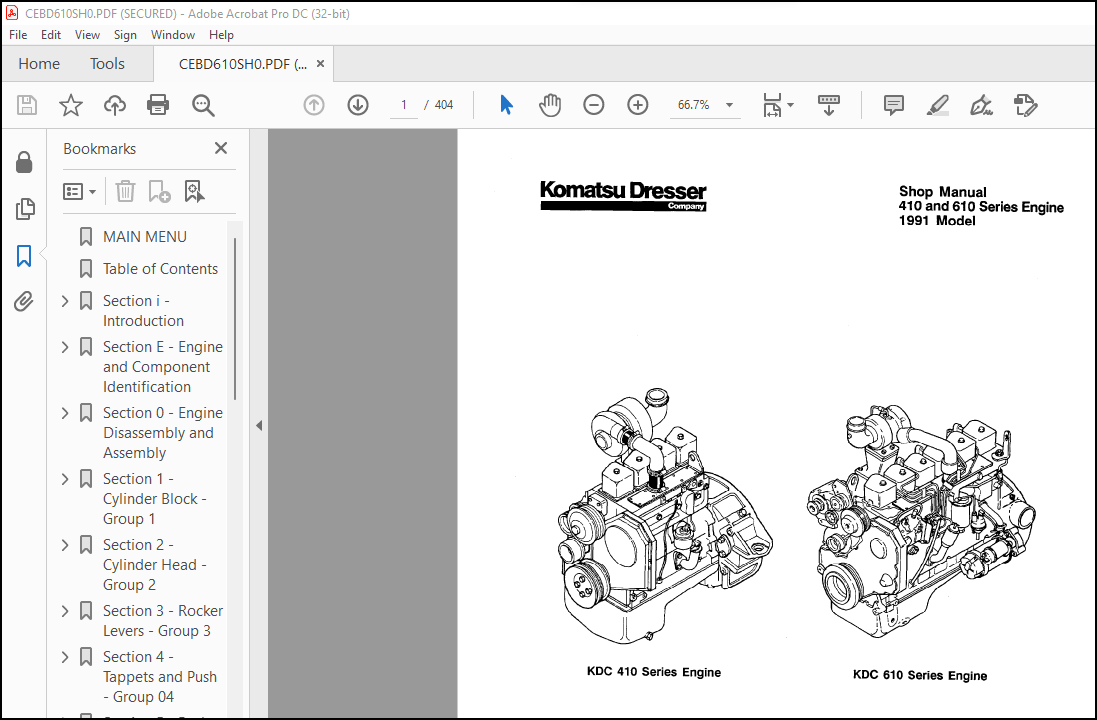

1991 Komatsu Dresser 410 & 610 Series Engine Shop Manual – PDF DOWNLOAD

1991 Komatsu Dresser 410 & 610 Series Engine Shop Manual – PDF DOWNLOAD

FILE DETAILS:

1991 Komatsu Dresser 410 & 610 Series Engine Shop Manual – PDF DOWNLOAD

Language : English

Pages : 404

Downloadable : Yes

File Type : PDF

Size: 63.2 MB

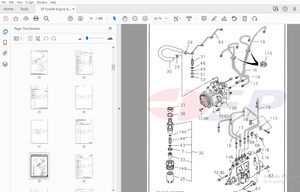

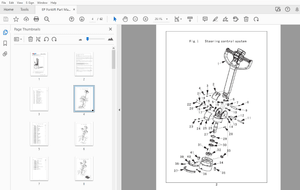

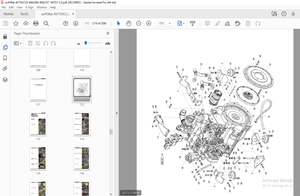

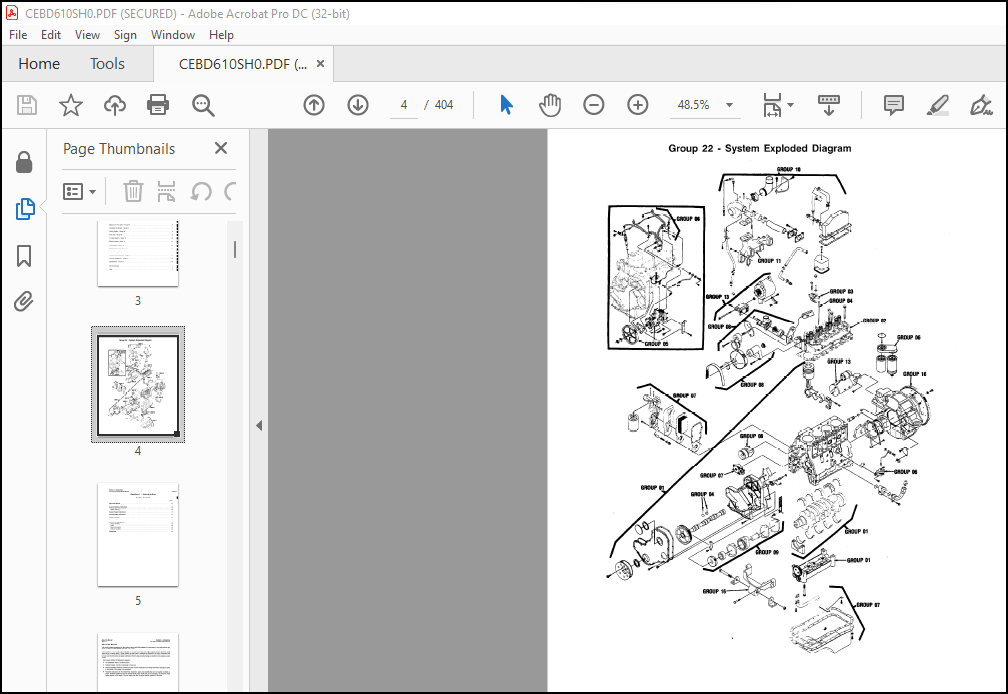

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

1991 Komatsu Dresser 410 & 610 Series Engine Shop Manual – PDF DOWNLOAD

- The 1991 Komatsu Dresser 410 & 610 Series Engine Shop Manual is a comprehensive guide that provides detailed information on the maintenance, repair, and overhaul of the engines used in the Komatsu Dresser 410 and 610 series of industrial wheel loaders. This manual is intended for use by mechanics, technicians, and individuals who are knowledgeable in engine repair.

- The manual is organized into several sections, each covering a different aspect of the engine. The first section provides an overview of the engine and its components, including the specifications and performance data. This section also includes a table of contents, a list of illustrations, and a list of symbols and abbreviations used throughout the manual.

- The second section of the manual covers engine inspection and measurement procedures. This section provides step-by-step instructions for checking and measuring various components of the engine, including the cylinder block, crankshaft, and connecting rods. The manual includes detailed illustrations to help the reader understand the procedures.

- The third section covers engine disassembly and assembly procedures. This section provides instructions for removing and installing various components of the engine, including the cylinder head, pistons, and crankshaft. The manual also includes torque specifications for each component.

- The fourth section covers engine testing and adjusting procedures. This section provides instructions for testing and adjusting various components of the engine, including the fuel injection system, the turbocharger, and the valve clearance. The manual includes detailed illustrations to help the reader understand the procedures.

- The fifth section covers engine maintenance procedures, including routine maintenance and inspections. This section provides instructions for maintaining the engine to ensure its continued performance and longevity.

- The sixth section covers engine troubleshooting and diagnosis procedures. This section provides instructions for diagnosing and troubleshooting various engine problems, including starting problems, low power output, and excessive smoke. The manual includes a troubleshooting chart and detailed illustrations to help the reader diagnose and fix the problem.

- Overall, the 1991 Komatsu Dresser 410 & 610 Series Engine Shop Manual is a comprehensive guide that provides detailed information on the maintenance, repair, and overhaul of the engines used in the Komatsu Dresser 410 and 610 series of industrial wheel loaders. It is an essential tool for anyone working on or maintaining these engines. The manual is available in print or digital formats, making it a convenient and accessible resource for mechanics and technicians.

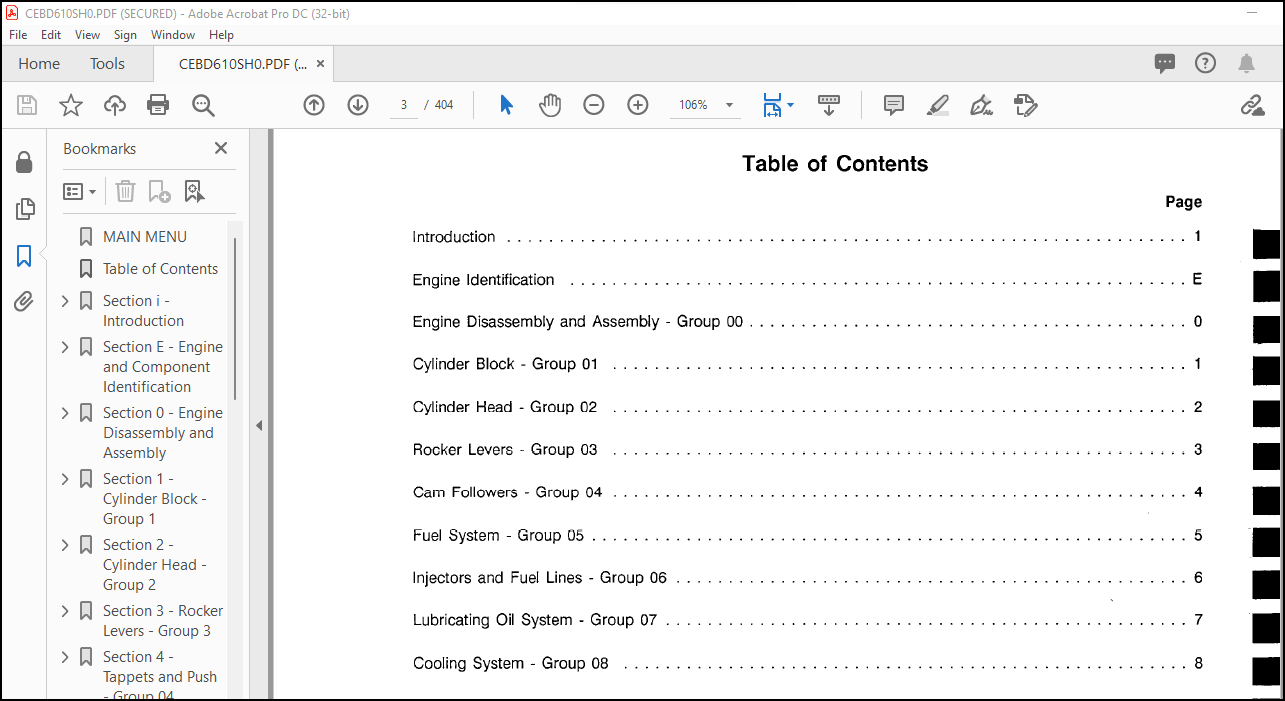

TABLE OF CONTENTS:

1991 Komatsu Dresser 410 & 610 Series Engine Shop Manual – PDF DOWNLOAD

MAIN MENU………………………………………………….. 0

Table of Contents…………………………………………… 3

Section i – Introduction…………………………………….. 5

About the Manual ……………………………………….. 6

General Cleaning Instructions ……………………………. 12

Solvent and Acid Cleaning…………………………….. 12

Steam Cleaning………………………………………. 12

General Repair Instructions ……………………………… 11

General Safety Instructions …………………………….. 10

Generic Symbols ………………………………………… 8

Glossary of Terms ………………………………………. 13

How To Use This Manual ………………………………….. 7

Group Contents………………………………………. 7

Index………………………………………………. 7

Metric Information…………………………………… 7

Table of Contents……………………………………. 7

Illustrations ………………………………………….. 9

Section E – Engine and Component Identification………………… 15

Engine Diagram …………………………………………. 20

Engine Identification …………………………………… 16

Engine Dataplate ……………………………………. 16

Injection Pump Dataplate ………………………………… 17

Cooling System………………………………………. 19

Fuel System…………………………………………. 19

General Engine Data………………………………….. 18

Intake Air and Exhaust System…………………………. 19

Lubrication System…………………………………… 18

Lucas CAV DPA dataplate location………………………. 17

Robert Bosch VE dataplate location…………………….. 17

Section 0 – Engine Disassembly and Assembly……………………. 23

Accessories – Installation ………………………………. 97

Accessories – Removal……………………………………. 44

Alternator – Installation…………………………………119

Alternator – Removal ……………………………………. 33

Balancer – Installation …………………………………. 77

Balancer – Removal ……………………………………… 53

Locking the Balancer…………………………………. 54

Measuring Backlash…………………………………… 53

Measuring the End Play……………………………….. 54

Removing the Balancer………………………………… 55

Belt Tensioner – Installation ……………………………118

Belt Tensioner – Removal…………………………………. 32

Camshaft – Installation …………………………………. 72

Camshaft End Play – Measuring…………………………. 74

Camshaft Gear Backlash – Measuring…………………….. 74

Camshaft – Removal ……………………………………… 49

Measuring Gear Lash………………………………….. 49

Crankshaft End Play – Measuring ………………………….. 83

Crankshaft – Installation ……………………………….. 61

Crankshaft – Removal ……………………………………. 58

Cylinder Block – Prepare for Assembly ……………………. 60

Cylinder Block – Removing From the Rollover Stand ………….. 60

Cylinder Head – Installation ……………………………..102

Cylinder Head – Removal …………………………………. 42

Cylinder Head – Tightening………………………………..104

Dipstick – Removal………………………………………. 39

Drive Belt – Installation ………………………………..120

Drive Belt – Removal ……………………………………. 31

Engine Assembly ………………………………………… 60

Engine Disassembly ……………………………………… 30

Engine Disassembly and Assembly ………………………….. 26

Assembly……………………………………………. 26

Disassembly…………………………………………. 26

General Information………………………………….. 26

Engine Disassembly and Assembly – Service Tools ……………. 27

Engine Disassembly Check List ……………………………. 29

Engine Weight ………………………………………….. 30

Exhaust Manifold – Installation …………………………..113

Exhaust Manifold – Removal ………………………………. 36

Fan Hub – Installation …………………………………..118

Fan Hub – Removal……………………………………….. 33

Fan Pulley – Removal ……………………………………. 32

Flywheel Housing – Installation ………………………….. 98

Flywheel Housing – Removal ………………………………. 44

Flywheel – Installation …………………………………. 98

Flywheel – Removal ……………………………………… 44

Front Cover – Installation ……………………………….100

Front Cover – Removal …………………………………… 43

Fuel Filter Head – Installation……………………………112

Fuel Filter Head – Removal ………………………………. 36

Fuel Filter – Removal …………………………………… 36

Fuel Lines – Installation ………………………………..110

Fuel Drain Manifold – Installation……………………..111

High Pressure Fuel Lines – Installation…………………111

Injection Pump Supply Line – Installation……………….110

Injection Pump Vent Line – Installation…………………111

Fuel Lines – Removal ……………………………………. 37

Fuel Drain Manifold – Removal…………………………. 38

High Pressure Fuel Line – Removal……………………… 37

Low Pressure Fuel Lines – Removal……………………… 38

Fuel Transfer Pump – Installation ………………………… 86

Fuel Transfer Pump – Removal……………………………… 47

Gear Housing – Installation ……………………………… 69

Gear Housing – Removal ………………………………….. 53

Injection Pump – Installation …………………………… 87

Injection Pumps – Unlocking…………………………… 90

Locked Timed Injection Pump – installation……………… 89

Unlocked Bosch VE Injection Pump Installation…………… 93

Unlocked CAV Injection Pump – Installation……………… 92

Injection Pump – Removal (Rotary Type Pumps) ……………… 44

Drive Gear – Removal…………………………………. 46

Gear Lash – Check……………………………………. 45

Locking the Pump…………………………………….. 45

Injector Nozzles – Installation …………………………..108

Injector Nozzles – Removal……………………………….. 40

Lifting Bracket Removal – Rear …………………………… 31

Lube Pump – Installation ………………………………… 70

Lube Pump – Removal …………………………………….. 51

Measuring Backlash…………………………………… 51

Manifold Cover – Installation …………………………….110

Manifold Cover – Removal ………………………………… 39

Aftercooler – Removal………………………………… 40

Oil Cooler – Installation ……………………………….. 85

Oil Cooler – Removal ……………………………………. 48

Oil – Draining …………………………………………. 31

Oil Filter – Installation ………………………………..121

Oil Pan – Installation ………………………………….. 85

Oil Pan Sealing Surfaces – Sealants……………………. 85

Oil Pan – Removal ………………………………………. 48

Piston and Rod Assemblies – Installation ………………….. 65

Piston and Rod Assemblies – Removal ……………………… 55

Push Rods – Installation………………………………….102

Push Rods – Removal …………………………………….. 42

Rear Seal Housing – Removal ……………………………… 49

Rear Seal – Installation…………………………………. 83

Rocker Levers – Installation ……………………………..103

Rocker Levers – Removal …………………………………. 41

Rollover Stand – Engine Mounting …………………………. 30

Rollover Stand – Engine Removal …………………………..121

Side Oil Fill – Installation …………………………….. 86

Side Oil Fill – Removal …………………………………. 47

Starter – Installation …………………………………..121

Starter – Removal ………………………………………. 30

Steam Cleaning The Engine ……………………………….. 30

Suction Tube – Installation ……………………………… 84

Suction Tube – Removal ………………………………….. 49

Tappet Cover – Installation ……………………………… 86

Tappet Cover – Removal…………………………………… 47

Thermostat – Installation ………………………………..117

Thermostat – Removal ……………………………………. 34

Timing Pin Housing – Removal …………………………….. 52

Timing Pin – Installation………………………………… 74

Turbocharger Drain Tube – Removal ……………………….. 59

Turbocharger – Installation ………………………………114

Turbocharger – Removal ………………………………….. 34

Valve Clearance – Adjustment ……………………………..106

Valve Covers – Installation ………………………………109

Valve Covers – Removal…………………………………… 40

Valve Tappets – Installation …………………………….. 60

Valve Tappets – Removal …………………………………. 51

Vibration Damper/Crankshaft Pulley – Removal………………. 32

Vibration Damper – Installation …………………………..118

Water Inlet Connection – Installation ……………………..119

Water Inlet Connection – Removal …………………………. 48

Water Pump – Installation ………………………………. 99

Water Pump – Removal ……………………………………. 43

Section 1 – Cylinder Block – Group 1…………………………..123

Balancer – Assembly ……………………………………..171

Balancer – Disassembly……………………………………169

Camshaft and Gear – Inspection ……………………………151

Camshaft Lobe Edge Deterioration (Breakdown)Criteria …….153

Camshaft Lobe Pitting Reuse Criteria …………………..152

Camshaft Bushing – Installation …………………………..145

Camshaft – Cleaning ……………………………………..151

Camshaft Expansion Plug – Installation …………………….144

Camshaft Gear – Replacement ………………………………156

Camshaft Gear – Installation (Heated Gear Method) ………156

Camshaft Gear – Installation (With Special Tool 3823589)….158

Camshaft Gear – Removal ………………………………156

Connecting Rod – Inspection ………………………………164

Crankshaft – Cleaning…………………………………….147

Crankshaft Gear – Replacement……………………………..149

Crankshaft – Inspection ………………………………….148

Cylinder Block – Cleaning…………………………………134

Cylinder Block – De-Glazing……………………………….139

Cylinder Block – Disassembly………………………………132

Cylinder Block – Exploded View…………………………….126

Cylinder Block – General Information……………………….129

Camshaft…………………………………………….129

Crankshaft…………………………………………..129

Cylinder Block……………………………………….129

Oil Seals……………………………………………129

Pistons……………………………………………..129

Vibration Damper……………………………………..129

Cylinder Block Group Inspection Checklist…………………..131

Cylinder Block – Inspection……………………………….137

Cylinder Block – Precheck Before Disassembly………………..132

Cylinder Block – Service Tools…………………………….130

Cylinder Block – Storing………………………………….147

Data Plate – Replacement………………………………….179

Dipstick Tube – Replacement……………………………….146

Expansion and Pipe Plug – Installation …………………….142

Fuel Pump Stud – Replacement ……………………………..179

Gear Housing and Timing Pin Assembly – Inspection ………….178

Gear Housing – Disassembly ……………………………….178

Piston and Connecting Rod – Assembly ………………………165

Piston and Connecting Rod – Disassembly …………………..161

Piston Inspection ……………………………………….163

Piston, Pin and Connecting Rod – Cleaning …………………162

Piston Pin – Inspection…………………………………..164

Piston Ring Gap – Checking ……………………………….167

Piston Rings – Installation ………………………………167

Rod Bearing Clearance – Checking ………………………….165

Vibration Damper – Cleaning and Inspection ………………..161

Section 2 – Cylinder Head – Group 2……………………………181

Cup Plug Replacement …………………………………….193

Cylinder Head – Assembly………………………………….201

Cylinder Head – Cleaning …………………………………187

Cylinder Head Combustion Face Inspection ………………….191

Cylinder Head Cracks – Reuse Guidelines ……………………192

Cylinder Head – Disassembly………………………………186

Cylinder Head – Precheck Before Disassembly ………………186

Cylinder Head – Service Tools …………………………….182

Exploded View …………………………………………..184

General Information ……………………………………..185

Valve Guide Inspection …………………………………..191

Valve – Inspection ………………………………………189

Valve Seat Inspection ……………………………………191

Valve Seats – Grinding …………………………………..196

Calculating the Grinding Depth ………………………..196

Measuring the Valve Depth …………………………….196

Valve Spring Inspection…………………………………..192

Valves – Grinding ……………………………………….195

Section 3 – Rocker Levers – Group 3……………………………203

Rocker Lever Assembly – Exploded View ……………………..204

Rocker Lever Assembly – General Information ………………..206

Rocker Lever – Inspection ………………………………..208

Rocker Lever Pedestals – Inspection ……………………….209

Rocker Levers and Pedestals – Cleaning ……………………208

Rocker Levers – Assembly …………………………………209

Rocker Levers – Disassembly ……………………………..207

Section 4 – Tappets and Push – Group 04………………………..211

Push Rods – Inspection……………………………………214

Tappets and Push Rods – Exploded View ……………………..212

Tappets and Push Rods – General Information ……………….213

Valve Tappets – Inspection ……………………………….214

Section 5 – Fuel System – Group 05…………………………….217

Exploded View – Fuel System ………………………………220

Injection Pump – General Information ………………………221

Injection Pump – Identification …………………………..221

Injection Pump Repairs – Bosch VE …………………………221

Delivery Valve Holder/Sealing Washer – Replacement……….222

Fuel Inlet Adapter/Seal – Replacement…………………..226

Overflow Adapter/Sealing Ring – Replacement……………..225

Shaft Seal – Replacement ……………………………..221

Shutdown Lever/Spring – Replacement…………………….224

Shutdown Solenoid – Replacement ……………………….223

Injection Pump Repairs – Lucas CAV DPA ……………………231

Automatic Timing Advance – Disassembly …………………239

Back Leakage Valve – Replacement/Inspection……………..232

Bleed Screws/Sealing Washers – Replacement………………234

Control Lever – Replacement …………………………..237

Fuel Inlet Fitting/Sealing Washer – Replacement………….236

Locking Screw/O-Ring – Replacement …………………….231

Shutdown Lever/Spring – Replacement ……………………238

Shutdown Solenoid – Replacement ……………………….233

Timing Advance – Assembly …………………………….241

Timing Advance Components – Inspection …………………241

Vent Fitting/Sealing Washer – Inspection/Replacement……..235

Injection Pump – Service Tools ……………………………218

Injection Pump Timing – Bosch VE…………………………..227

Section 6 – Injectors – Group 06………………………………247

Exploded View – Fuel System ………………………………249

Fuel Lines – Clean and Inspect ……………………………262

Fuel Drain Manifold ………………………………….263

High Pressure Fuel Lines ……………………………..262

Low Pressure Fuel Lines ………………………………264

Fuel Transfer Pump – Cleaning and Inspecting ………………259

Fuel Transfer Pump – General Information …………………..251

Fuel Transfer Pump – Identification ……………………251

Fuel Transfer Pump – Piston Style Rebuild …………………260

Assembly ……………………………………………261

Cleaning ……………………………………………261

General Information – Injectors …………………………..250

Injector – Assembly ……………………………………..256

Injector – Clean and Inspect ……………………………..254

Injector – Disassembly …………………………………..253

Injector Pump – Service Tools …………………………….248

Injector – Testing ………………………………………258

Chatter Test…………………………………………259

Section 7 – Lubrication Oil System – Group 7……………………267

Filter Bypass Valve – Replace …………………………….274

General Information – Lubrication System …………………..272

Oil Cooler Core ……………………………………..272

Lubricating Oil Cooler – Exploded View …………………….271

Lubricating Oil Pump – Exploded View ………………………276

Lubrication Oil Pump – General Information …………………277

Oil Cooler – Cleaning ……………………………………274

Oil Cooler – Inspection ………………………………….275

Oil Pan and Suction Tube – Cleaning and Inspection …………270

Oil Pan and Suction Tube – Exploded View …………………..268

Oil Pan and Suction Tube – General Information ……………..269

Oil Pump – Inspection ……………………………………278

Pressure Regulator Valve – Assembly ……………………….274

Pressure Regulator Valve – Disassembly …………………….273

Pressure Regulator Valve – Inspection …………………….273

Section 8 – Cooling System – Group 8…………………………..281

Belt Tensioner and Fan Hub – Exploded View ………………..285

Belt Tensioner and Fan Hub – General Information ……………286

Belt Tensioner ………………………………………286

Belt Tensioner – Inspection ………………………………290

Fan Hub Assembly ………………………………………..288

Fan Hub – Disassembly ……………………………………287

Fan Hub – Inspection……………………………………..287

Thermostat Housing Assembly – Exploded View ………………..291

Thermostat Housing Assembly – General Information …………..292

Thermostat – Inspection ………………………………….292

Water Pump – Exploded View ………………………………282

Water Pump – General Information ………………………….283

Water Pump – Inspection …………………………………284

Section 9 – Drive Units – Group 9……………………………..293

Accessory Drive Adapter – Exploded View ……………………294

Accessory Drive Adaptor – Assembly ………………………..297

Accessory Drive Adaptor – Disassembly ……………………..296

Accessory Drive – Cleaning ……………………………….296

Accessory Drive – Inspection ……………………………..296

Drive Units – General Information …………………………295

Accessory Drive Adapter……………………………….295

Section 10 – Air Intake System – Group 10………………………299

Aftercooler – Inspection …………………………………304

Air Intake System – Exploded View …………………………300

Air Intake System – General Information ……………………302

Turbocharger – Cleaning and Inspection for Reuse ……………303

Inspection ………………………………………….303

Section 11 – Exhaust System – Group 11…………………………305

Exhaust Manifold – Exploded View ………………………….306

Exhaust Manifold Inspection……………………………….308

General Information ……………………………………..307

Exhaust Manifold …………………………………….307

Turbocharger Mounting Stud Replacement…………………….308

Section 12 – Air Equipment – Group 12………………………….309

Section 13 – Electrical Equipment – Group 13……………………311

Section 14 – Engine Testing – Group 14…………………………313

Blowby Measurement ………………………………………319

Blowby Conversion Chart (5.613 mm [0.221 in] Orifice) ……319

Engine Dynamometer Test – Engine Run-In …………………..326

Engine Dynamometer Test – Installation of the Engine ……….320

Engine Dynamometer Test – Performance Checking ……………..330

Engine – Painting ……………………………………….334

Engine Run-In Procedure “In Chassis” ……………………..333

Engine Storage – Long Term………………………………..338

Removing the Engine from Long-Term Storage ……………..340

Engine Storage – Short Term……………………………….335

Removing the Engine from Short-Term Storage …………….337

Engine Testing – Engine Side Views ………………………..316

Engine Testing – General Information ………………………318

General Engine Test Specifications …………………….318

Engine Testing – Service Tools ……………………………314

Section 16 Mounting Adaptions – Group 16……………………….345

Flywheel and Ring Gear Inspection ……………………….347

Flywheel Housing Assembly ………………………………..348

Flywheel Housing Inspection ………………………………348

Front Support – Cleaning and Inspection…………………….350

General Information ……………………………………..346

Flywheel and Ring Gear ……………………………….346

Flywheel Housing …………………………………….346

Front Support ……………………………………….346

Ring Gear Replacement ……………………………………347

Wet Clutch Application …………………………………..349

Section V – Engine Component Specifications – Group 18…………..351

Capscrew Markings and Torque Values ……………………….390

Component Specifications and Torque Values …………………356

Air Intake System ……………………………………….382

Combustion Air System ………………………………..381

Compressed Air System Torque Values ……………………382

Cylinder Block – Rebuild Specifications ………………..366

Cylinder Block – Torque Values ………………………..372

Cylinder Head – Rebuild Specifications …………………373

Cylinder Head – Torque Values …………………………375

Electrical System ……………………………………383

Engine Assembly – Capscrew Torque Values ……………….360

Engine Assembly – Specifications……………………….356

Engine Testing – Test Specifications …………………..384

Fan Hub – Specifications ……………………………..380

Fuel System …………………………………………376

Lubricating Oil System – Specifications ………………..378

Rocker Levers and Pedestals …………………………..375

Tappet and Push Rods …………………………………376

Thermostat, Coolant Operating Temperature ………………380

Drive Belt Tension ………………………………………385

Engine Component Torque Values ……………………………353

Newton-Meter to Foot-Pound Conversion Chart ………………..388

Capscrew Markings and Torque Values – U.S. Customary …….389

Pipe Plug Torque Values ………………………………….391

Specifications – General Information ………………………352

Tap-Drill – U.S. Customary & Metric ……………………….392

Weight and Measures – Conversion Factors …………………..387

Section L – Service Literature………………………………..393

Index………………………………………………………399