$35

1997 Komatsu 95 Series Diesel Engine Shop Manual SEBE61460114 – PDF DOWNLOAD

1997 Komatsu 95 Series Diesel Engine Shop Manual SEBE61460114 – PDF DOWNLOAD

FILE DETAILS:

1997 Komatsu 95 Series Diesel Engine Shop Manual SEBE61460114 – PDF DOWNLOAD

Language : English

Pages : 784

Downloadable : Yes

File Type : PDF

Size: 43.8 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

1997 Komatsu 95 Series Diesel Engine Shop Manual SEBE61460114 – PDF DOWNLOAD

FOREWORD

GENERAL

This shop manual has been prepared as an aid to improve the quality of repairs by g1vmg the

serviceman an accurate understanding of the product and by showing him the correct way to perform

repairs and make judgements. Make sure you understand the contents of this manual and use it to full

effect at every opportunity.

This shop manual mainly contains the necessary technical information for operations performed in a

service workshop. For ease of understanding, the manual is divided into the following chapters; these

chapters are further divided into the each main group of components.

STRUCTURE AND FUNCTION

This section explains the structure and function of each component. It serves not only to give

an understanding of the structure, but also serves as reference material for troubleshooting.

TESTING AND ADJUSTING

This section explains checks to be made before and after performing repairs, as well as

adjustments to be made at completion of the checks and repairs.

Troubleshooting charts correlating “Problems” to “Causes” are also included in this section.

DISASSEMBLY AND ASSEMBLY

This section explains the order to be followed when removing, installing, disassembling or

assembling each component, as well as precautions to be taken for these operations.

MAINTENANCE STANDARD

This section gives the judgement standards when inspecting disassembled parts.

TABLE OF CONTENTS:

1997 Komatsu 95 Series Diesel Engine Shop Manual SEBE61460114 – PDF DOWNLOAD

COVER…………………………………………………………………………………………… 1

CONTENTS………………………………………………………………………………………… 2

01 GENERAL………………………………………………………………………………………. 25

GENERAL VIEW…………………………………………………………………………………. 26

SPECIFICATIONS……………………………………………………………………………….. 28

GENERAL ASSEMBLY DRAWING………………………………………………………………………. 50

ENGINE PERFORMANCE CURVE………………………………………………………………………. 92

WEIGHT TABLE………………………………………………………………………………….147

11 STRUCTURE AND FUNCTION………………………………………………………………………….149

GENERAL STRUCTURE……………………………………………………………………………..150

INTAKE AND EXHAUST SYSTEM………………………………………………………………………160

INTAKE AND EXHAUST SYSTEM…………………………………………………………………..160

FTG AIR CLEANER……………………………………………………………………………175

TURBOCHARGER………………………………………………………………………………178

AFTER-COOLER………………………………………………………………………………185

ENGINE BODY…………………………………………………………………………………..187

CYLINDER HEAD……………………………………………………………………………..187

VALVE SYSTEM………………………………………………………………………………205

CYLINDER BLOCK…………………………………………………………………………….213

CYLINDER LINER (FOR REPAIR ONLY)…………………………………………………………….219

MAIN CIRCULATION SYSTEM…………………………………………………………………….220

TIMING GEAR……………………………………………………………………………….237

FLYWHEEL AND FLYWHEEL HOUSING……………………………………………………………….243

LUBRICATION SYSTEM…………………………………………………………………………….247

LUBRICATION SYSTEM CHART……………………………………………………………………247

OIL PUMP………………………………………………………………………………….251

OIL FILTER………………………………………………………………………………..252

OIL FILTER MOUNT (FOR PC200,220-5)…………………………………………………………..253

OIL COOLER………………………………………………………………………………..254

FUEL SYSTEM…………………………………………………………………………………..256

FUEL SYSTEM CHART………………………………………………………………………….256

FUEL INJECTION PUMP………………………………………………………………………..268

OUTLINE OF ELECTRONIC GOVERNOR SYSTEM………………………………………………………..283

SYSTEM ELECTRICAL CIRCUIT DIAGRAM……………………………………………………………286

LOAD DETECTION SYSTEM (OPTION)………………………………………………………………290

LOAD DETECTOR SYSTEM (OPTION)……………………………………………………………….291

SYSTEM STRUCTURE DIAGRAM (3-PHASE CURRENT)……………………………………………………292

GOVERNOR………………………………………………………………………………….297

FEED PUMP…………………………………………………………………………………301

FUEL INJECTION NOZZLE………………………………………………………………………303

FUEL CUT SOLENOID………………………………………………………………………….306

ENGINE STOP MOTOR………………………………………………………………………….309

FUEL FILTER……………………………………………………………………………….314

WATER SEPARATOR……………………………………………………………………………315

COOLING SYSTEM………………………………………………………………………………..316

COOLING SYSTEM CHART……………………………………………………………………….316

WATER PUMP………………………………………………………………………………..319

CORROSION RESISTOR (OPTION)…………………………………………………………………322

THERMOSTAT AND FAN DRIVE……………………………………………………………………323

EXHAUST BRAKE……………………………………………………………………………..330

SOLENOID VALVE…………………………………………………………………………….331

ELECTRICAL SYSTEM……………………………………………………………………………..333

ALTERNATOR………………………………………………………………………………..333

STARTING MOTOR…………………………………………………………………………….342

ELECTRICAL INTAKE AIR HEATER………………………………………………………………..348

ACCESSORY…………………………………………………………………………………….352

AIR COMPRESSOR…………………………………………………………………………….352

12 TESTING AND ADJUSTING…………………………………………………………………………..354

INTAKE AND EXHAUST SYSTEM………………………………………………………………………355

ADJUSTING VALVE CLEARANCE…………………………………………………………………..355

MEASURING EXHAUST GAS COLOR…………………………………………………………………357

ENGINE BODY…………………………………………………………………………………..358

MEASURING COMPRESSION PRESSURE………………………………………………………………358

MEASURING BLOW-BY PRESSURE………………………………………………………………….359

ADJUSTING ENGINE SPEED SENSOR……………………………………………………………….360

FUEL SYSTEM…………………………………………………………………………………..361

CHECKING AND ADJUSTING FUEL INJECTION TIMING………………………………………………….361

ADJUSTING GOVERNOR (3D95S-W-1)………………………………………………………………370

TESTING AND ADJUSTING FUEL CUT SOLENOID ……………………………………………………..373

PROCEDURE FOR ADJUSTING ENGINE STOP MOTOR CABLE……………………………………………….378

ADJUSTING FUEL INJECTION PRESSURE (CRACKING PRESSURE)………………………………………….380

LUBRICATION SYSTEM…………………………………………………………………………….383

MEASURING OIL PRESSURE……………………………………………………………………..383

MEASURING OIL TEMPERATURE…………………………………………………………………..384

COOLING SYSTEM………………………………………………………………………………..385

MEASURING WATER TEMPERATURE…………………………………………………………………385

TESTING AND ADJUSTING FAN BELT TENSION……………………………………………………….386

FUEL INJECTION PUMP CALIBRATION DATA…………………………………………………………….387

PERFORMANCE TEST………………………………………………………………………………505

RUN-IN STANDARD……………………………………………………………………………505

PERFORMANCE TEST CRITERIA…………………………………………………………………..513

TESTING AND ADJUSTING TOOL LIST……………………………………………………………..533

TESTING AND ADJUSTING DATA………………………………………………………………….534

TROUBLESHOOTING……………………………………………………………………………….556

METHOD OF USING TROUBLESHOOTING CHART………………………………………………………..557

POINTS TO REMEMBER WHEN TROUBLESHOOTING………………………………………………………561

S-1 STARTING PERFORMANCE IS POOR (STARTING ALWAYS TAKES TIME)…………………………………..562

S-2 ENGINE DOES NOT START…………………………………………………………………..563

① ENGINE DOES NOT TURN………………………………………………………………….563

② ENGINE TURNS BUT NO EXHAUST GAS COMES OUT (FUEL IS NOT BEING INJECTED)……………………..564

③ EXHAUST GAS COMES OUT BUT ENGINE DOES NOT START (FUEL IS BEING INJECTED)……………………565

S-3 ENGINE DOES NOT PICK UP SMOOTHLY (FOLLOW-UP IS POOR)……………………………………….566

S-4 ENGINE STOPS DURING OPERATIONS…………………………………………………………..567

S-5 ENGINE DOES NOT ROTATE SMOOTHLY………………………………………………………….568

S-6 ENGINE LACKS OUTPUT (NO POWER)…………………………………………………………..569

S-7 EXHAUST GAS IS BLACK (INCOMPLETE COMBUSTION)………………………………………………570

S-8 OIL CONSUMPTION IS EXCESSIVE (OR EXHAUST GAS IS BLUE)………………………………………571

S-9 OIL BECOMES CONTAMINATED QUICKLY…………………………………………………………572

S-10 FUEL CONSUMPTION IS EXCESSIVE…………………………………………………………..573

S-11 OIL IS IN COOLING WATER,OR WATER SPURTS BACK,OR WATER LEVEL GOES DOWN……………………….574

S-12 OIL PRESSURE LAMP LIGHTS UP (DROP IN OIL PRESSURE)………………………………………..575

S-13 OIL LEVEL RISES……………………………………………………………………….576

S-14 WATER TEMPERATURE BECOMES TOO HIGH (OVERHEATING)………………………………………….577

S-15 ABNORMAL NOISE IS MADE…………………………………………………………………578

S-16 VIBRATION IS EXCESSIVE…………………………………………………………………579

S-17 DIAGNOSIS OF ELECTRONICAL GOVERNOR BY DIAGNOSIS DISPLAY (ELECTRONICAL GOVERNOR MADE BY ZEXEL)….580

13 DISASSEMBLY AND ASSEMBLY………………………………………………………………………..596

GENERAL DISASSEMBLY AND ASSEMBLY (3D95S-W-1)……………………………………………………..597

GENERAL DISASSEMBLY (3D95S-W-1) ……………………………………………………………598

1. FAN,FAN PULLEY………………………………………………………………………598

2. ALTERNATOR………………………………………………………………………….598

3. STARTING MOTOR………………………………………………………………………599

4. WATER PUMP………………………………………………………………………….599

5. FILTER,LEVEL GAUGE…………………………………………………………………..599

6. FUEL FILTER,INJECTION TUBLE…………………………………………………………..599

7. NOZZLE HOLDER……………………………………………………………………….599

8. GLOW PLUG…………………………………………………………………………..599

9. FUEL INJECTION PUMP………………………………………………………………….599

10. CYLINDER HEAD COVER…………………………………………………………………600

11. ROCKER ARM…………………………………………………………………………600

12. PUSH RODS………………………………………………………………………….600

13. CYLINDER HEAD ASSEMBLY………………………………………………………………600

14. FLYWHEEL…………………………………………………………………………..601

15. HOUSING……………………………………………………………………………601

16. CRANKSHAFT PULLEY…………………………………………………………………..601

17. OIL PAN……………………………………………………………………………601

18. OIL SUCTION PIPE……………………………………………………………………601

19. GEAR COVER…………………………………………………………………………602

20. IDLER GEAR…………………………………………………………………………602

21. OIL PUMP…………………………………………………………………………..602

22. CAMSHAFT ASSEMBLY…………………………………………………………………..602

23. PISTON,CONNECTING ROD ASSEMBLY……………………………………………………….602

24. MAIN CAP…………………………………………………………………………..604

25. CRANKSHAFT…………………………………………………………………………604

26. TAPPET…………………………………………………………………………….604

GENERAL ASSEMBLY…………………………………………………………………………..605

1. TAPPET……………………………………………………………………………..605

2. CAMSHAFT ASSEMBLY……………………………………………………………………605

3. CRANKSHAFT………………………………………………………………………….605

4. MAIN CAP……………………………………………………………………………606

5. PISTON,CONNECTING ROD ASSEMBLY………………………………………………………..607

6. OIL PUMP……………………………………………………………………………609

7. IDLER GEAR………………………………………………………………………….609

8. GEAR COVER………………………………………………………………………….610

9. OIL SUCTION PIPE…………………………………………………………………….610

10. OIL PAN……………………………………………………………………………610

11. CRANKSHAFT PULLEY…………………………………………………………………..610

12. HOUSING……………………………………………………………………………611

13. FLYWHEEL…………………………………………………………………………..611

14. CYLINDER HEAD………………………………………………………………………611

15. PUSH RODS………………………………………………………………………….613

16. ROCKER ARM…………………………………………………………………………613

17. ADJUSTING VALVE CLEARANCE……………………………………………………………614

18. CYLINDER HEAD COVER…………………………………………………………………614

19. FUEL INJECTION PUMP…………………………………………………………………614

20. GLOW PLUG………………………………………………………………………….614

21. NOZZLE HOLDER………………………………………………………………………615

22. FUEL FILTER,INJECTION TUBE…………………………………………………………..615

23. OIL FILTER,LEVEL GAUGE………………………………………………………………615

24. WATER PUMP…………………………………………………………………………615

25. STARTING MOTOR……………………………………………………………………..615

26. ALTERNATOR…………………………………………………………………………616

27. FAN,FAN PULLEY……………………………………………………………………..616

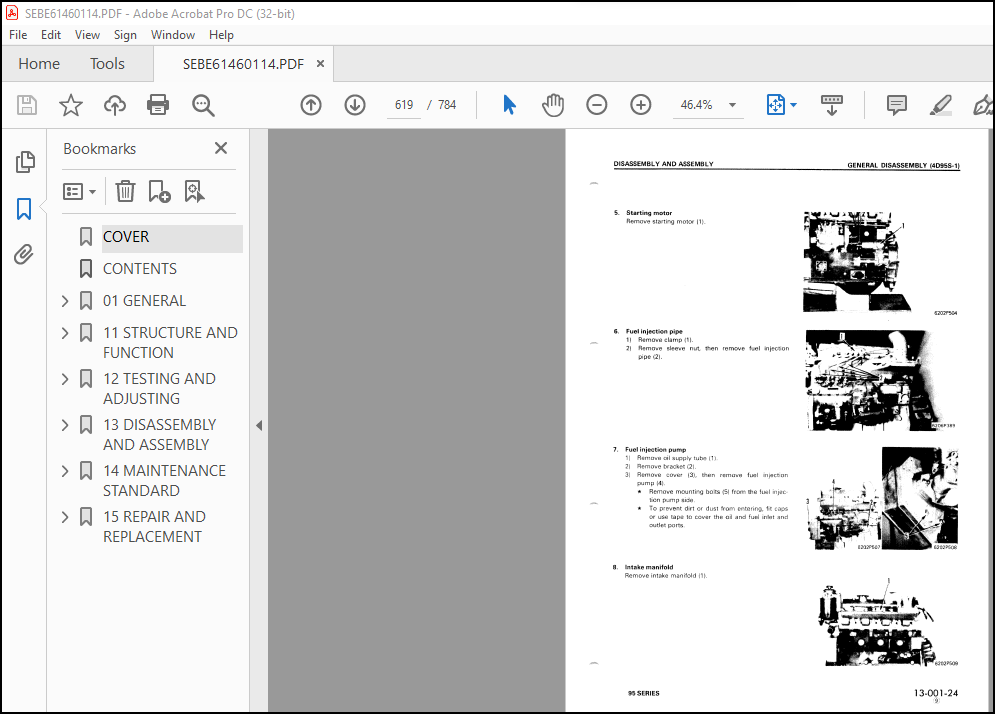

GENERAL DISASSEMBLY AND ASSEMBLY (4D95S-1)……………………………………………………….617

GENERAL DISASSEMBLY (4D95S-1)……………………………………………………………….618

1. SETTING IN UNIT REPAIR STAND………………………………………………………….618

2. FAN………………………………………………………………………………..618

3. ALTERNATOR………………………………………………………………………….618

4. FAN PULLEY………………………………………………………………………….618

5. STARTING MOTOR………………………………………………………………………619

6. FUEL INJECTION PIPE………………………………………………………………….619

7. FUEL INJECTION PUMP………………………………………………………………….619

8. INTAKE MANIFOLD……………………………………………………………………..619

9. WATER PUMP………………………………………………………………………….620

10. GLOW WIRE,GLOW PLUG…………………………………………………………………620

11. NOZZLE HOLDER………………………………………………………………………620

12. CYLINDER HEAD COVER…………………………………………………………………620

13. ROCKER ARM ASSEMBLY…………………………………………………………………620

14. PUSH RODS………………………………………………………………………….621

15. CYLINDER HEAD ASSEMBLY………………………………………………………………621

16. PTO SHAFT………………………………………………………………………….622

17. OIL PAN……………………………………………………………………………622

18. OIL SUCTION PIPE……………………………………………………………………622

19. CRANKSHAFT PULLEY…………………………………………………………………..622

20. GEAR CASE COVER…………………………………………………………………….623

21. OIL PUMP…………………………………………………………………………..623

22. IDLER GEAR…………………………………………………………………………623

23. CAMSHAFT ASSEMBLY…………………………………………………………………..623

24. FLYWHEEL…………………………………………………………………………..624

25. FLYWHEEL HOUSING……………………………………………………………………624

26. PISTON,CONNECTING ROD ASSEMBLY……………………………………………………….624

27. MAIN CAP…………………………………………………………………………..626

28. CRANKSHAFT…………………………………………………………………………627

29. TAPPET…………………………………………………………………………….627

GENERAL ASSEMBLY (4D95S-1)………………………………………………………………….628

1. SETTING IN UNIT REPAIR STAND………………………………………………………….628

2. TAPPET……………………………………………………………………………..628

3. CRANKSHAFT………………………………………………………………………….628

4. MAIN CAP……………………………………………………………………………629

5. PISTON,CONNECTING ROD ASSEMBLY………………………………………………………..630

6. FLYWHEEL HOUSING…………………………………………………………………….633

7. FLYWHEEL……………………………………………………………………………634

8. CAMSHAFT ASSEMBLY……………………………………………………………………634

9. IDLER GEAR………………………………………………………………………….634

10. OIL PUMP…………………………………………………………………………..635

11. GEAR CASE COVER…………………………………………………………………….636

12. CRANKSHAFT PULLEY ………………………………………………………………….636

13. OIL SUCTION PIPE……………………………………………………………………636

14. OIL PAN……………………………………………………………………………637

15. PTO SHAFT………………………………………………………………………….637

16. CYLINDER HEAD ASSEMBLY………………………………………………………………637

17. PUSH RODS………………………………………………………………………….638

18. ROCKER ARM ASSEMBLY…………………………………………………………………639

19. ADJUSTING VALVE CLEARANCE……………………………………………………………639

20. CYLINDER HEAD COVER…………………………………………………………………640

21. NOZZLE HOLDER………………………………………………………………………640

22. GLOW WIRE,GLOW PLUG…………………………………………………………………640

23. WATER PUMP…………………………………………………………………………640

24. INTAKE MANIFOLD…………………………………………………………………….640

25. FUEL INJECTION PUMP…………………………………………………………………641

26. FUEL INJECTION PIPE…………………………………………………………………641

27. STARTING MOTOR……………………………………………………………………..641

28. FAN PULLEY ………………………………………………………………………..642

29. ALTERNATOR…………………………………………………………………………642

30. FAN……………………………………………………………………………….642

31. LOWERING ENGINE…………………………………………………………………….642

GENERAL DISASSEMBLY (4D95L SERIES)………………………………………………………………643

GENERAL ASSEMBLY (4D95L SERIES)…………………………………………………………………657

GENERAL DISASSEMBLY (6D95L SERIES)………………………………………………………………678

GENERAL ASSEMBLY (6D95L SERIES)…………………………………………………………………691

DISASSEMBLY AND ASSEMBLY OF AIR COMPRESSOR……………………………………………………….712

14 MAINTENANCE STANDARD……………………………………………………………………………719

TURBOCHARGER………………………………………………………………………………….720

CYLINDER HEAD…………………………………………………………………………………723

VALVE,VALVE GUIDE……………………………………………………………………………..728

ROCKER ARM SHAFT,PUSH ROD AND TAPPET…………………………………………………………….731

CYLINDER BLOCK………………………………………………………………………………..732

CRANKSHAFT……………………………………………………………………………………734

CAMSHAFT……………………………………………………………………………………..738

TIMING GEAR (HELICAL GEAR)……………………………………………………………………..744

FLYWHEEL AND FLYWHEEL HOUSING…………………………………………………………………..748

PISTON,PISTON RING AND PISTON PIN……………………………………………………………….749

CONNECTING ROD………………………………………………………………………………..758

OIL PUMP……………………………………………………………………………………..759

REGULATOR VALVE……………………………………………………………………………….761

WATER PUMP,THERMOSTAT………………………………………………………………………….762

FUEL SYSTEM…………………………………………………………………………………..765

15 REPAIR AND REPLACEMENT………………………………………………………………………….767

TABLE OF SPECIAL TOOLS…………………………………………………………………………768

GRINDING CYLINDER HEAD MOUNTING SURFACE………………………………………………………….769

REPLACING VALVE SEAT INSERT…………………………………………………………………….770

REPLACING VALVE GUIDE………………………………………………………………………….774

GRINDING VALVE………………………………………………………………………………..775

REPLACING CAM BUSHING………………………………………………………………………….776

REPLACING CRANKSHAFT GEAR………………………………………………………………………778

REPLACING CAM GEAR…………………………………………………………………………….778

REPLACING FLYWHEEL RING GEAR……………………………………………………………………779

PRESSURE TEST…………………………………………………………………………………780

CYLINDER LINER (SPECIAL RESTORATION PART)………………………………………………………..781

MACHINING DRAWING FOR CYLINDER BLOCK BORE………………………………………………………..782

ADDITIONAL MACHINING OF CAM JOURNAL……………………………………………………………..783

GRINDING CRANKSHAFT……………………………………………………………………………784