$45

AGCO® DTb series tractors Workshop Service Manual – PDF DOWNLOAD

AGCO® DTb series tractors Workshop Service Manual – PDF DOWNLOAD

FILE DETAILS:

AGCO® DTb series tractors Workshop Service Manual – PDF DOWNLOAD

Language : English

Pages :2630

Downloadable : Yes

File Type : PDF

Size:428 MB

DESCRIPTION:

AGCO® DTb series tractors Workshop Service Manual – PDF DOWNLOAD

1 Using the manual

General The purpose of this manual is to assist Dealers and Agents in the efficient installation, servicing and repair of AGCO equipment. If the procedures are carried out as detailed and specialised tools are used where appropriate, the operations should be completed within the times stated in the repair time schedule.

Service tools

Where the use of a service tool is necessary to carry out an operation, the tool reference is mentioned with

the relevant instruction.

Tool drawings for makeshift tools are given at the end of the relevant sections.

Repairs and parts replacement

When parts have to be replaced, it is essential that only genuine AGCO parts are used.

The following points are of particular importance when carrying out repairs and fitting replacement parts and

accessories. Tractor safety may be compromised if non-genuine parts are fitted.

Legislation in certain countries prohibits the fitting of parts that do not comply with the tractor manufacturer’s

specifications. Torque wrench setting figures given in the workshop manual must be strictly adhered to.

Locking devices must be fitted where specified. If the efficiency of a locking device is impaired during disassembly,

it must be replaced.

The tractor warranty may be invalidated if non-genuine AGCO parts are fitted. All AGCO parts are guaranteed

by the manufacturer. AGCO Dealers and Agents are required to supply genuine parts only.

TABLE OF CONTENTS:

AGCO® DTb series tractors Workshop Service Manual – PDF DOWNLOAD

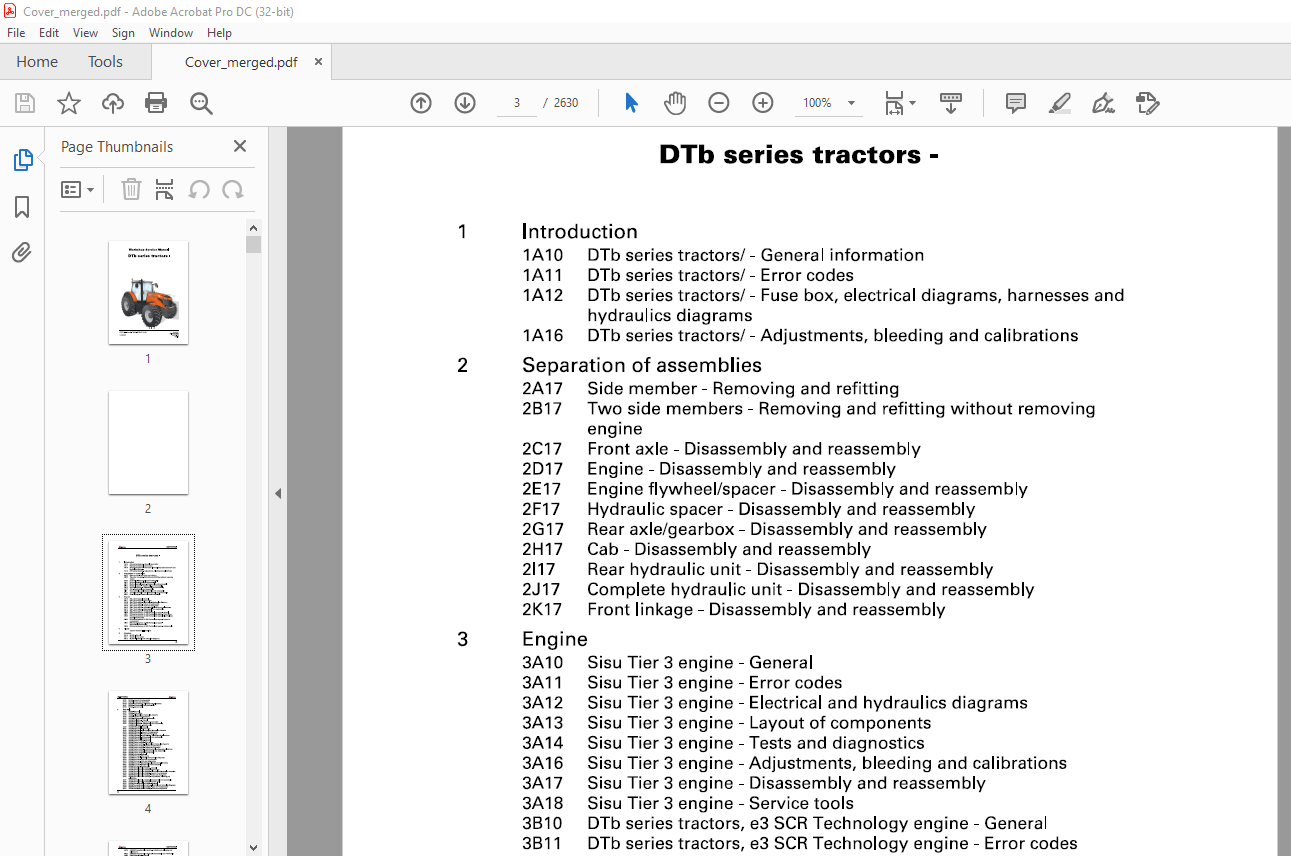

1 Introduction

1A10 DTb series tractors/ – General information

1A11 DTb series tractors/ – Error codes

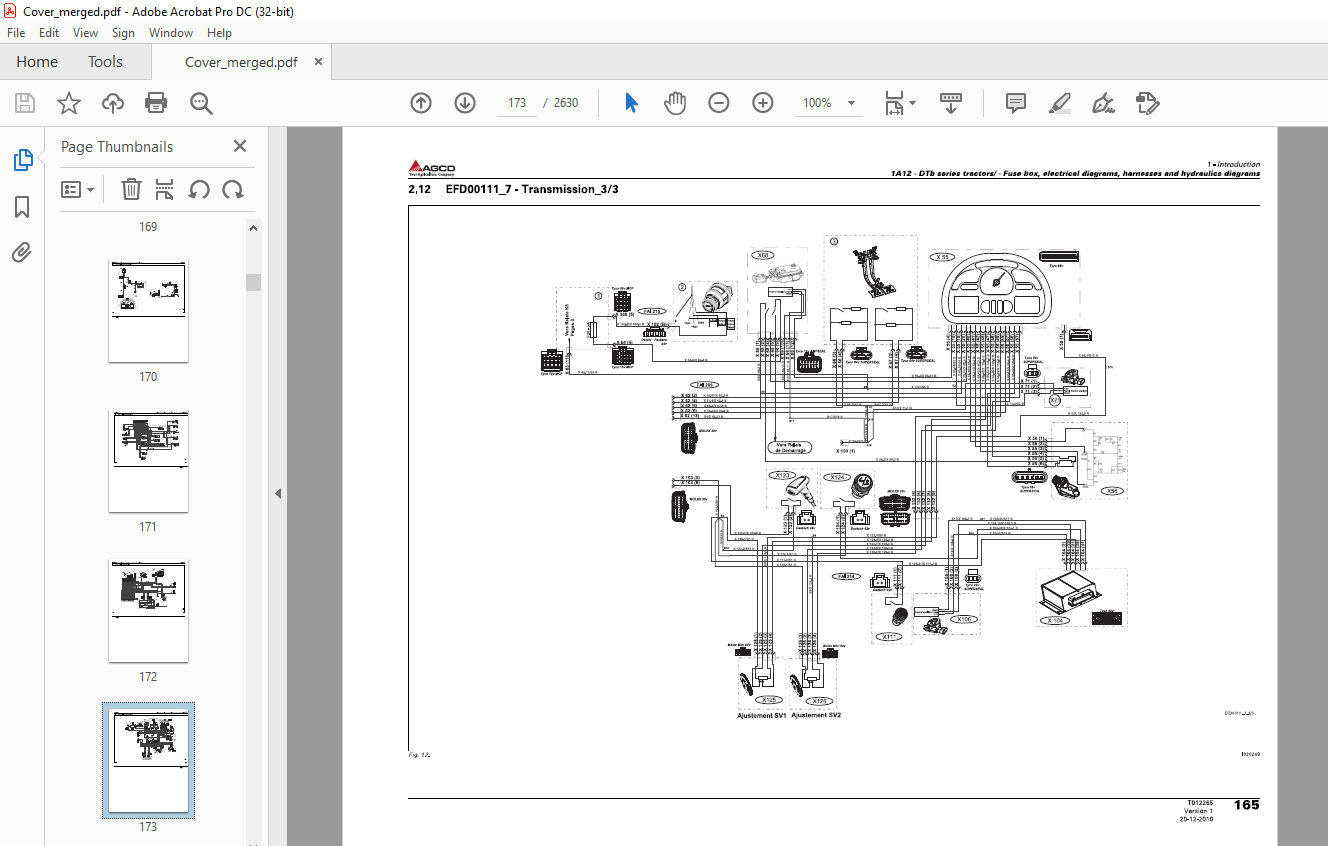

1A12 DTb series tractors/ – Fuse box, electrical diagrams, harnesses and

hydraulics diagrams

1 A 16 DTb series tractors/ – Adjustments, bleeding and calibrations

2 Separation of assemblies

2A 17 Side member – Removing and refitting

2B17 Two side members – Removing and refitting without removing

engine

2C17 Front axle – Disassembly and reassembly

2D17 Engine – Disassembly and reassembly

2E17 Engine flywheel/spacer – Disassembly and reassembly

2F17 Hydraulic spacer – Disassembly and reassembly

2G17 Rear axle/gearbox – Disassembly and reassembly

2H17 Cab – Disassembly and reassembly

2117 Rear hydraulic unit – Disassembly and reassembly

2J17 Complete hydraulic unit – Disassembly and reassembly

2K17 Front linkage – Disassembly and reassembly

3 Engine

3A 10 Sisu Tier 3 engine – General

3A11 Sisu Tier 3 engine – Error codes

3A12 Sisu Tier 3 engine – Electrical and hydraulics diagrams

3A13 Sisu Tier 3 engine – Layout of components

3A14 Sisu Tier 3 engine – Tests and diagnostics

3A16 Sisu Tier 3 engine -Adjustments, bleeding and calibrations

3A17 Sisu Tier 3 engine – Disassembly and reassembly

3A18 Sisu Tier 3 engine – Service tools

3B10 DTb series tractors, e3 SCR Technology engine – General

3B11 DTb series tractors, e3 SCR Technology engine – Error codes

3B12 DTb series tractors, e3 SCR Technology engine – Electrical and

hydraulics diagrams

3B13 DTb series tractors, e3 SCR Technology engine – Layout of

components

3B17 DTb series tractors, e3 SCR Technology engine –

Disassembly/reassembly

3B18 DTb series tractors, e3 SCR Technology engine – Service tools

4 Clutch

Chapter intentionally left blank

5 Gearbox

5A10 ML260 – General

5A11 ML260 – Error codes

5A12 ML260 – Electrical and hydraulics diagrams

3

DTb series tractors –

Table of contents

~,a.AGCO

Your Agriculture Company

ML260 – Layout of components

ML260 – Tests and diagnostics

ML260 – Adjustments, bleeding and calibrations

ML260 – Disassembly and reassembly

ML260 – Service tools

Rear axle

6A10 HA260 – General

6A11 HA260 – Error codes

6A12 HA260 – Electrical and hydraulics diagrams

6A 13 HA260 – Layout of components

6A17 HA260 – Disassembly and reassembly

6A20 HA260/Final drives – General

6A23 HA260/Final drives – Layout of components

6A27 HA260/Final drives – Disassembly and reassembly

HA260/Final drives – Service tools

HA260/Differential – General

HA260/Differential – Error codes

HA260/Differential – Electrical and hydraulics diagrams

HA260/Differential – Layout of components

HA260/Differential – Tests and diagnostics

HA260/Differential – Adjustments, bleeding and calibrations

HA260/Differential – Disassembly and reassembly

HA260/Differential – Service tools

HA260/Tractor braking – General

HA260/Tractor braking – Error codes

HA260/Tractor braking – Electrical and hydraulics diagrams

HA260/Tractor braking – Layout of components

HA260/Tractor braking – Tests and diagnostics

HA260/Tractor braking – Adjustments, bleeding and calibrations

HA260/Tractor braking – Disassembly and reassembly

HA260/Tractor braking – Service tools

HA260/ParkLock – General

HA260/ParkLock – Error codes

HA260/ParkLock – Electrical and hydraulics diagrams

HA260/ParkLock – Layout of components

HA260/ParkLock – Tests and diagnostics

HA260/ParkLock – Adjustments, bleeding and calibrations

HA260/ParkLock – Disassembly and reassembly

HA260/ParkLock – Service tools

HA260/Hydraulic trailer braking – General

HA260/Hydraulic trailer braking – Error codes

HA260/Hydraulic trailer braking – Electrical and hydraulics diagrams

HA260/Hydraulic trailer braking – Layout of components

HA260/Hydraulic trailer braking – Tests and diagnostics

HA260/Hydraulic trailer braking – Adjustments, bleeding and

calibrations

HA260/Hydraulic trailer braking – Disassembly and reassembly

HA260/Hydraulic trailer braking – Service tools

HA260/Pneumatic trailer braking – General

HA260/Pneumatic trailer braking – Electrical and hydraulics diagrams

HA260/Pneumatic trailer braking – Layout of components

HA260/Pneumatic trailer braking – Tests and diagnostics

~.. .A GCO

Your Agriculture Company

DTb series tractors –

Table of contents

6A76 HA260/Pneumatic trailer braking – Adjustments, bleeding and

calibrations

6A77 HA260/Pneumatic trailer braking – Disassembly and reassembly

6A80 HA260/Auto-hitch – General

6A82 HA260/Auto-hitch – Electrical and hydraulics diagrams

6A83 HA260/Auto-hitch – Layout of components

6A86 HA260/Auto-hitch – Adjustments, bleeding and calibrations

6A90 HA260/Wheels and hub – General

6A93 HA260/Wheels and hub – Layout of components

6A96 HA260/Wheels and hub – Adjustments, bleeding and calibrations

7 Power take-off

7 A 10 HA260/Power take-off – General

7 A 11 HA260/Power take-off – Error codes

7A12 HA260/Power take-off- Electrical and hydraulics diagrams

7 A 13 HA260/Power take-off – Layout of components

7A14 HA260/Power take-off – Tests and diagnostics

7 A 16 HA260/Power take-off – Adjustments, bleeding and calibrations

7A17 HA260/Power take-off- Disassembly and reassembly

7 A 18 HA260/Power take-off – Service tools

7810 Zuidberg front power take-off – General

7812 Zuidberg front power take-off – Electrical and hydraulics diagrams

7813 Zuidberg front power take-off – Layout of components

7814 Zuidberg front power take-off – Tests and diagnostics

7816 Zuidberg front power take-off – Adjustments, bleeding and

calibrations

7817 Zuidberg front power take-off – Disassembly and reassembly

8 Front axle

8A 10 DANA770 – General

8A 11 DANA770 – Error codes

8A12 DANA770 – Electrical and hydraulics diagrams

8A 13 DANA770 – Location of components – Front axle

8A14 DANA770 – Tests and diagnostics

8A 16 DANA770 – Adjustments, bleeding and calibrations

8A17 DANA770 – Disassembly and reassembly

8A 18 DANA770 – Service tools

8817 Bearings and transmission shaft – Disassembly and reassembly

8C10 4WD clutch – General

8C11 4WD clutch – Error codes

8C12 4WD clutch – Electrical and hydraulics diagrams

8C13 4WD clutch – Layout of components

8C14 4WD clutch – Tests and diagnostics

8C16 4WD clutch – Adjustments, bleeding and calibrations

8C17 4WD clutch – Disassembly and reassembly

8D10 Steering unit – General

8D12 Steering unit – Electrical and hydraulics diagrams

8D13 Steering unit – Layout of components

8D14 Steering unit – Tests and diagnostics

8D17 Steering unit – Disassembly and reassembly

9 Hydraulics

9A 10 LS hydraulic system – General

9A12 LS hydraulic system – Electrical and hydraulics diagrams

LS hydraulic system – Layout of components

LS hydraulic system – Tests and diagnostics

LS hydraulic system – Service tools

LS hydraulic system/Hydraulic pumps – General

LS hydraulic system/Hydraulic pumps – Electrical and hydraulics

diagrams

LS hydraulic system/Hydraulic pumps – Layout of components

LS hydraulic system/Hydraulic pumps – Tests and diagnostics

LS hydraulic system/Hydraulic pumps – Disassembly and reassembly

LS hydraulic system/Hydraulic pumps – Service tools

LS hydraulic system/Auxiliary spool valves – General

LS hydraulic system/Auxiliary spool valves – Error codes

LS hydraulic system/Auxiliary spool valves- Electrical and hydraulics

diagrams

LS hydraulic system/Auxiliary spool valves – Layout of components

LS hydraulic system/Auxiliary spool valves – Tests and diagnostics

LS hydraulic system/Auxiliary spool valves – Disassembly and

reassembly

LS hydraulic system/Auxiliary spool valves – Service tools

LS hydraulic system/Rear linkage – General

LS hydraulic system/Rear linkage – Error codes

LS hydraulic system/Rear linkage – Electrical and hydraulics

diagrams

LS hydraulic system/Rear linkage – Layout of components

LS hydraulic system/Rear linkage – Tests and diagnostics

LS hydraulic system/Rear linkage – Adjustments, bleeding and

calibrations

LS hydraulic system/Rear linkage – Disassembly and reassembly

LS hydraulic system/Rear linkage – Service tools

LS hydraulic system/Front linkage – General

LS hydraulic system/Front linkage – Electrical and hydraulics

diagrams

LS hydraulic system/Front linkage – Layout of components

LS hydraulic system/Front linkage – Tests and diagnostics

LS hydraulic system/Front linkage – Adjustments, bleeding and

calibrations

9A57 LS hydraulic system/Front linkage – Disassembly and reassembly

9A58 LS hydraulic system/Front linkage – Service tools

Electricity

10A10 Electricity – General

1 0A 12 Electricity – Electrical and hydraulics diagrams

1 0A 13 Electricity – Layout of components

10B10 Fuse box – General

10B12 Fuse box – Diagrams and plans

10B13 Fuse box – Layout of components

10B17 Fuse box – Disassembly and reassembly

10C12 Alternator – Electrical and hydraulics diagrams

1OC13 Alternator – Layout of components

10C14 Alternator – Tests and diagnostics

1OC17 Alternator – Disassembly and reassembly

1OC18 Alternator – Service tools

10D12 Batteries – Electrical and hydraulics diagrams

~.. .A GCO

Your Agriculture Company

DTb series tractors –

Table of contents

10E10 Starter – General

10E12 Starter – Electrical and hydraulics diagrams

10E13 Starter – Layout of components

1 0E14 Starter – Tests and diagnostics

10E17 Starter – Disassembly and reassembly

1OF10 Battery isolator – – General

11 Electronics

11A10 Automatic air conditioning function – General

11B10 Power take-off function – General

11 C10 Engine function – General

11D10 Transmission function – General

11E10 ParkLock function – General

11F10 4WD function – General

11 G10 Differential lock function – General

11H10 Headlights module function – General

11110 Suspended front axle function – General

11J10 Suspended cab function – General

11K10 Auxiliary hydraulics function – General

11L10 Linkage function – General

11 M10 Vistronic function – General

11N10 SpeedSteer function – General

11012 I so bus – Electrical and hydraulics diagrams

11 P11 Auto-Guide – Error codes

11P12 Auto-Guide – Electrical and hydraulics diagrams

11010 Telemetry – General

11011 Telemetry – Error codes

11012 Telemetry – Electrical and hydraulics diagrams

11013 Telemetry – Layout of components

11015 Telemetry – Programming and setting parameters

11017 Telemetry – Disassembly and reassembly

12 Cab

12A10 Standard air conditioning – General

12A 12 Standard air conditioning – Electrical and hydraulics diagrams

12A13 Standard air conditioning – Layout of components

12A14 Standard air conditioning – Tests and diagnostics

12A 16 Standard air conditioning – Adjustments, bleeding and calibrations

12A17 Standard air conditioning – Disassembly and reassembly

12A 18 Standard air conditioning – Service tools

12B10 Self-regulating air conditioning – General

12B11 Self-regulating air conditioning – Error codes

12B12 Self-regulating air conditioning – Electrical and hydraulics diagrams

12B13 Self-regulating air conditioning – Layout of components

12B14 Self-regulating air conditioning – Tests and diagnostics

12B16 Self-regulating air conditioning – Adjustments, bleeding and

calibrations

12B17 Self-regulating air conditioning – Disassembly and reassembly

12B18 Self-regulating air conditioning – Service tools

12C10 Passive hydraulic suspension – General

12C11 Passive hydraulic suspension – Error codes

12C12 Passive hydraulic suspension – Electrical and hydraulics diagrams

12C13 Passive hydraulic suspension – Layout of components

7

DTb series tractors – ~.. .A GCO

Table of contents YourAgrlcuitu,eCompany

13

14

8

12C14 Passive hydraulic suspension – Tests and diagnostics

12C16 Passive hydraulic suspension – Adjustments, bleeding and

calibrations

12C17 Passive hydraulic suspension – Disassembly and reassembly

12D10 Semi-active hydraulic suspension – General

12D11 Semi-active hydraulic suspension – Error codes

12D12 Semi-active hydraulic suspension – Electrical and hydraulics

diagrams

12D13 Semi-active hydraulic suspension – Layout of components

12D14 Semi-active hydraulic suspension – Tests and diagnostics

12D16 Semi-active hydraulic suspension -Adjustments, bleeding and

calibrations

12D17 Semi-active hydraulic suspension – Disassembly and reassembly

12E10 Passive pneumatic suspension – General

12E11 Passive pneumatic suspension – Error codes

12E12 Passive pneumatic suspension – Electrical and hydraulics diagrams

12E13 Passive pneumatic suspension – Layout of components

12E14 Passive pneumatic suspension – Tests and diagnostics

12E16 Passive pneumatic suspension – Adjustments, bleeding and

calibrations

Passive pneumatic suspension – Disassembly and reassembly

Semi-active pneumatic suspension – General

Semi-active pneumatic suspension – Error codes

Semi-active pneumatic suspension – Layout of components

Semi-active pneumatic suspension – Tests and diagnostics

Semi-active pneumatic suspension – Adjustments, bleeding and

calibrations

12F17 Semi-active pneumatic suspension – Disassembly and reassembly

12G 10 Reverse station – General

12G11 Reverse station – Error codes

12G12 Reverse station – Electrical and hydraulics diagrams

12G13 Reverse station – Layout of components

12G14 Reverse station – Tests and diagnostics

12G16 Reverse station – Adjustments, bleeding and calibrations

12G17 Reverse station – Disassembly and reassembly

Accessories

13A12 Front-end loader – Electrical and hydraulics diagrams

Service tools

14A01 General

14A03 Engine

14A05 Gearbox

14A06 Rear axle

14A07 Power take-off

14A08 Front axle

14A09 Hydraulics

14A10 Electricity

14A12 Cab

IMAGES PREVIEW OF THE MANUAL: