$36

AGCO® NA 5200 Draper Header SERVICE MANUAL – PDF DOWNLOAD

AGCO® NA 5200 Draper Header SERVICE MANUAL – PDF DOWNLOAD

FILE DETAILS:

AGCO® NA 5200 Draper Header SERVICE MANUAL – PDF DOWNLOAD

Language : English

Pages :220

Downloadable : Yes

File Type : PDF

Size:35.2 MB

DESCRIPTION:

AGCO® NA 5200 Draper Header SERVICE MANUAL – PDF DOWNLOAD

GENERAL INFORMATION

The operating and maintenance instructions included in this manual are assembled from field testing and other data. The information is written for general conditions. Make adjustments as necessary for specific conditions.

UNITS OF MEASUREMENT

Measurements are given in metric units followed by the equivalent in U.S. units. Hardware sizes are given in millimeters for metric hardware and inches for U.S. hardware.

REPLACEMENT PARTS

To receive efficient service, always give the dealer the following information:

• Correct part description or part number.

• Model number of the machine.

• Serial number of the machine.

DESCRIPTION

- A draper header is used to put the crop into a windrow without conditioning the crop. The crop is moved onto the cutterbar by the reel. The knife cuts the crop and the reel moves the cut crop onto the drapers. The drapers move the crop to the draper opening where the crop falls to the ground in a windrow.

- The draper opening size determines the size of the windrow. On a double swath header, the draper position determines the direction of draper operation and windrow position. See the Operation section of this manual for more information on the following items.

TABLE OF CONTENTS:

AGCO® NA 5200 Draper Header SERVICE MANUAL – PDF DOWNLOAD

SAFETY

AGCO®

5200

Draper Header

SERVICE MANUAL

79035581 A Rev

SIN: XXXXXXXXXCHDW1999 AND PRIOR

CONTENTS

Safety Alert Symbol 1

Safety Messages 1

Informational Messages 1

Safety Signs 2

A Word To The Operator 2

Operator Manual 3

Prepare For Operation 4

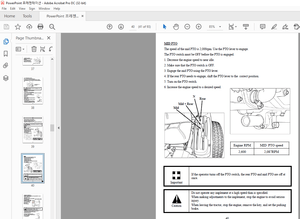

Operation 5

General Information 5

PPE (Personal Protection Equipment) 6

Seat Instructions 6

Shield and Guards 6

Exhaust Warning 7

Flying Debris 7

Handrails 8

Agricultural Chemicals 8

Travel On Public Roads 9

Maintenance 10

General Information 10

Fire Prevention and First Aid 12

Checking for High Pressure Leaks 13

Tire Safety 13

Cylinder Stops – If Equipped 14

Late Production Tractors 14

Early Production Tractors 14

GENERAL INFORMATION

Introduction 15

Units of Measurement 15

Replacement Parts 15

Machine Identification 15

Serial Number Description (2009 and prior) 16

Serial Number Description (2010 and up) 16

Description 17

Header 17

Reel 17

Drapers 17

Component Location 18

Component Access 19

End Shield 19

Reel Drive Shield 19

79035581 A Rev

Rear Shields 19

General Maintenance Information 20

Bolt Torque Values 20

Bearing Replacement 21

DRAPER

General Draper Maintenance 23

Draper Removal and Installation 23

Draper Removal 23

Draper Installation 24

Draper Tension 25

Roller Alignment 25

Drive Roller 25

Idler Roller 26

Draper Tracking 27

Idler Roller – Early Production 28

Disassembly 28

Assembly 29

Idler Roller – Late Production 30

Disassembly 30

Assembly 30

Drive Roller – Early Production 32

Disassembly 32

Assembly 33

Drive Roller – Late Production 34

Disassembly 34

Assembly 35

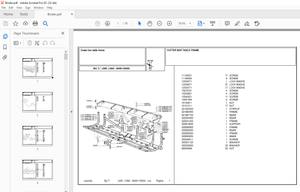

CUTTING COMPONENTS

General Sickle Maintenance 37

Sickle Removal and Replacement 37

Standard Sickle and Guards 38

Sickle to Holddown Adjustment 38

Sickle Guard Replacement 39

Sickle Section Replacement 39

SCH Sickle and Guards (Schumacher Manufacturing Co ) 39

Sickle Guard Replacement 40

Sickle Section Replacement 40

Sickle Drive Gearbox 41

Gearbox Alignment 41

Removal 44

Installation 46

Components 48

Disassembly 50

Assembly 54

Head Assembly 61

ELECTRICAL

ii

Tools 63

Electrical Schematic 64

General Testing Information 66

Multimeter 66

Basic Checks 66

Continuity and Resistance Check 66

Voltage Check 67

Connectors 68

Checking A Connector 68

Terminal Numbers 68

Dielectric Grease 68

Pin and Socket Replacement 69

Lighting 72

Header Speed Sensor Adjustments 73

Adjustment 73

79035581 A Rev

Testing 74

HYDRAULICS

Hydraulic Schematic 75

Serial Number HU and Prior 75

Serial Number xxxxxxxxxAHDW1101 and up 77

Sickle Drive Motor 81

Removal 81

Installation 84

Disassembly 89

Assembly 93

Reel Drive Motor (SN HT10296 and Prior) 98

Removal 98

Installation 101

Disassembly 106

Assembly 109

Reel Drive Motor (SN HT10297 and Up) 113

Removal 113

Installation 116

Disassembly 121

Inspection of Motor Components 126

Assembly 129

Conveyor Drive Motor (Eaton) 138

Removal 138

Installation 140

Disassembly 143

Assembly 146

Conveyor Drive Motor (Parker) 150

Removal 150

Installation 152

Disassembly 155

Inspection of Motor Components 160

Assembly 163

Relief Valve manifolds (HU and Prior) 172

Removal 172

Installation 173

Disassembly 173

Inspection 174

Assembly 174

Relief Valve manifold (xxxxxxxxxAHDW1101 and up) 175

Removal 175

Installation 175

Disassembly 176

Inspection 176

Assembly 176

Flow Control Valve 177

Removal 177

Installation 177

Disassembly 178

Inspection 178

Assembly 179

Draper Control Valve – Double Swath Headers Only 180

Removal 180

Installation 180

Valve Adjustment 181

Disassembly 182

Inspection 182

Assembly 182

Reel Lift Master Cylinder 183

Removal 183

Installation 183

Components 184

Disassembly 185

79035581 A Rev iii

Inspection 185

Assembly 185

Reel Lift Slave Cylinder 186

Removal 186

Installation 186

Components 187

Disassembly 187

Inspection 187

Assembly 188

Reel Lift Cylinder Phase 189

Reel Leveling 189

Deck Shift Cylinder – Double Swath Headers Only 190

Removal 190

Installation 190

Components 191

Disassembly 192

Inspection 192

Assembly 192

REEL

Reel Drive Chain 193

Shield 193

Reel Drive Chain Replacement 193

Reel Drive Chain Alignment and Tension 194

Reel Drive 195

Disassembly 195

Assembly 195

UHC Reel 196

General Information 196

Maintenance 196

Roller Adjustment 196

Tine Pitch 197

Inspection 197

Reel Tine Replacement 198

Reel Bats 198

Control Arms, Reel Arms, and Control Plate Components 202

TROUBLESHOOTING

Cutterbar 205

Reel 207

Draper 208

SPECIFICATIONS

Dimensions and Weights 209

Header 209

Sickle 210

Reel 210

Gauge Wheel Tires 210

Draper 210

Lubrication 210

INDEX 211

IMAGES PREVIEW OF THE MANUAL: