$35

AGCO® NA ST30X ST32 Hydro Tractor SERVICE MANUAL 79023898 A – PDF DOWNLOAD

AGCO® NA ST30X ST32 Hydro Tractor SERVICE MANUAL 79023898 A – PDF DOWNLOAD

FILE DETAILS:

AGCO® NA ST30X ST32 Hydro Tractor SERVICE MANUAL 79023898 A – PDF DOWNLOAD

Language : English

Pages :186

Downloadable : Yes

File Type : PDF

Size:96.5 MB

DESCRIPTION:

AGCO® NA ST30X ST32 Hydro Tractor SERVICE MANUAL 79023898 A – PDF DOWNLOAD

GENERAL PRECAUTIONS FOR

SEPARATION AND RE-INSTALLATION

Before Operation

- Always be safety-conscious in selecting clothes to wear and suitable tools to use. Before disassembly, be sure that you familiarize yourself with the assembled condition for subsequent reference in reassembly. Keep parts and tools in proper order during operations. When servicing electrically live parts, be sure to disconnect the negative battery terminal.

- To prevent oil or water leaks, use the liquid gasket as required. When reassembling disassembled parts, discard used gaskets, O-rings, or oil seals and install new ones. When lifting up only the front or rear part of the tractor, be sure to wedge the grounded wheels.

- When the tractor is jacked up, be sure to support the entire tractor with something like a stand. Lifting it up with a jack only is a dangerously unstable procedure. When replacing parts, use authorized, genuine AGCO parts only. AGCO assumes no responsibility for accidents, operating problems or damage caused by the use of imitation parts. Also, the use of unauthorized parts will result in relatively poor machine performance.

Precautions to be Followed When Installing Common Parts

- Roller or Ball Bearings When a bearing is fitted in by the outer race, use an installer, which is specially designed to push only the outer race and vice versa. The installer must be designed to install the bearing on the shaft in a parallel position. When installing a bearing, which appears the same on both sides, install it so that the face, which has the identification number faces in a direction for easy visual identification.

- All the bearings, which are to be installed in the transmission case should be placed so that their identification number faces outward. If a shaft or a hole where a bearing is to be installed has a stopper, the bearing should be pushed in completely until it is seated against the stopper. Installed bearings should turn smoothly. Oil Seals Oil seal installer should be designed so as not to deform the oil seals.

- During installation, be careful not to damage the lips, and assure that it is pushed in parallel to the shaft or hole. When oil seals are installed, there should be neither turnover of the lips nor dislocation of the springs. When a multi-lip seal is installed, the grooves between lips should be filled with grease, not adhesive.

- a lithium-based grease. There should be no oil or water leaks through the installed oil seals. 0-Rings O-rings should be coated with grease before installing. Installed O-rings should have no slack or twist. Installed O-rings should maintain proper air tightness. 1A-

TABLE OF CONTENTS:

AGCO® NA ST30X ST32 Hydro Tractor SERVICE MANUAL 79023898 A – PDF DOWNLOAD

GENERAL INFORMATION 1A

SPLITTING THE TRACTOR 2A

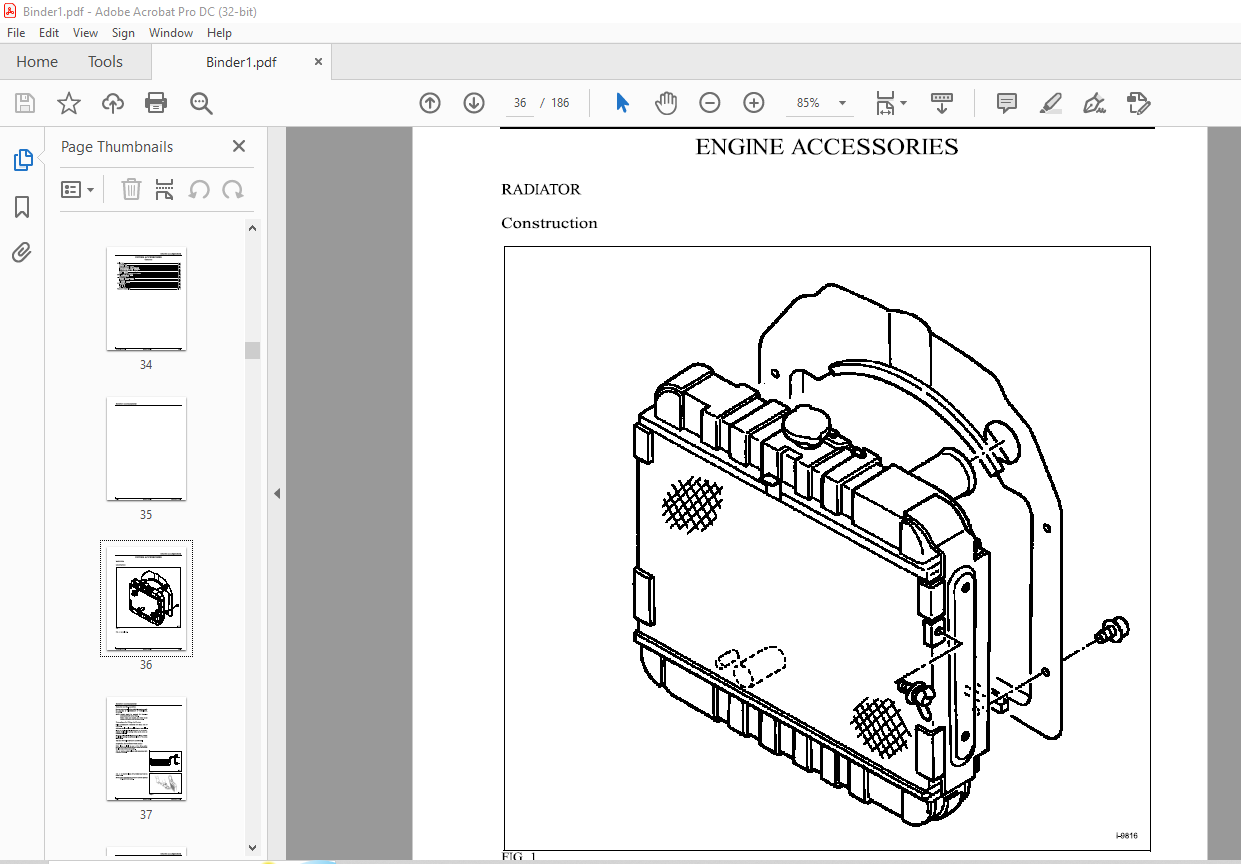

ENGINE ACCESSORIES 3A

ENGINE 38

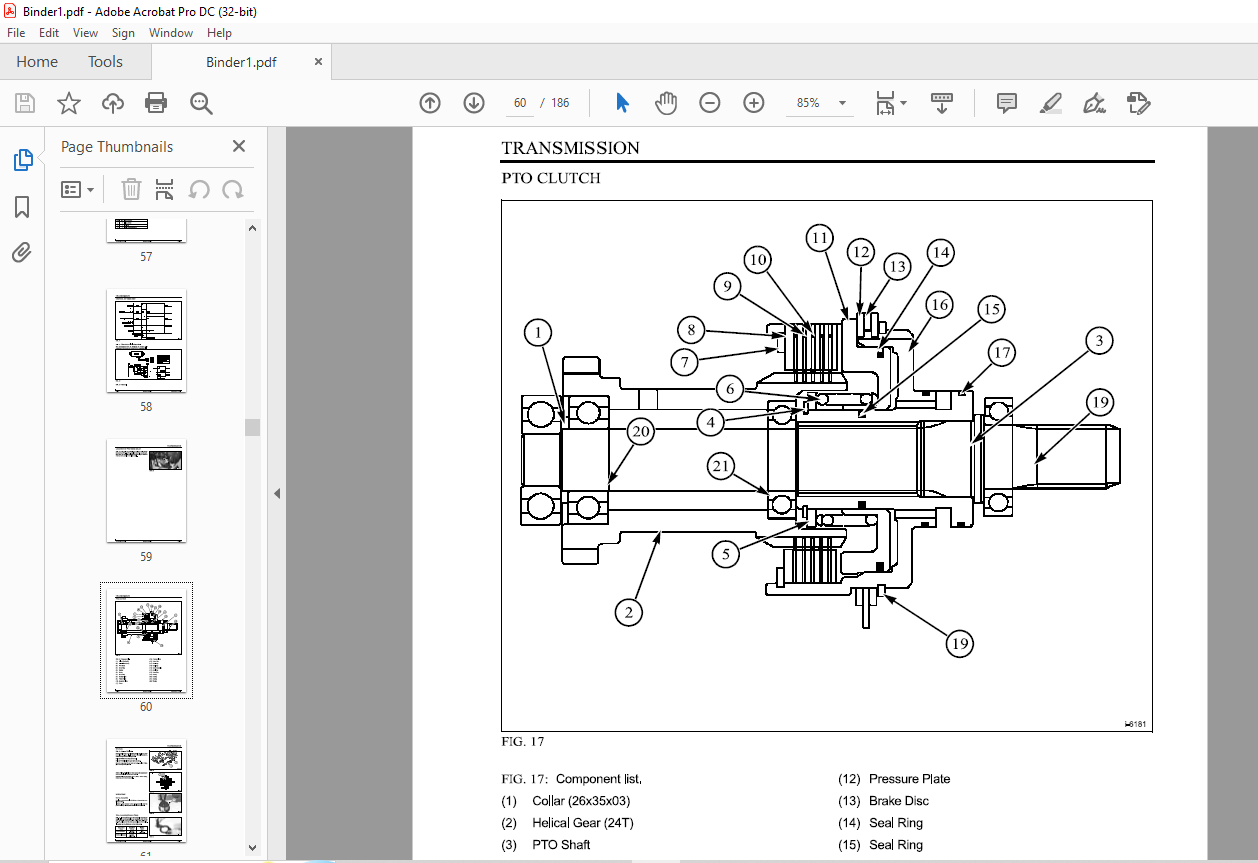

TRANSMISSION 4A

HYDROSTATIC TRANSMISSION SA

FRONT AXLE 6A

STEERING 7A

HYDRAULIC SYSTEM BA

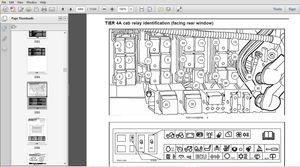

ELECTRICAL SYSTEM 9A

© AGCO Corporation, 2005 All rights reserved

Part Number 79023898 (English)

Printed in USA

August, 2005

GENERAL INFORMATION

GENERAL INFORMATION

Contents

TRACTOR TYPES AND PUNCHED IDENTIFICATION MARKS 1A-3

Name Plate 1 A-4

Specifications 1 A-5

1428V/ST30X

4WD 1A-5

Traveling Speeds 1A-9

SHIFT

POSITIONS 1A-9

1428V /ST30X

Hydrostatic

(Engine 2500 rpm) 1A-9

1431

Hydrostatic

(Engine 2600 rpm) 1A-9

KPH 1A-9

MPH 1A-9

KPH 1A-9

Tire 1A-9

Agri 1A-9

Agri 1A-9

Forward 1 A-9

Forward 1 A-9

GENERAL PRECAUTIONS FOR SEPARATION AND RE-INSTALLATION 1A-10

Before Operation 1A-10

Precautions to be Followed When Installing Common Parts 1A-10

Roller or Ball Bearings 1A-10

Oil Seals 1A-10

O-Rings 1A-10

Snap Rings 1A-11

Spring (Roll) Pins 1A-11

Cotter Pins 1A-11

Bolts and Nuts 1A-12

Grease Fittings 1A-12

Other Precautions 1A-12

IMAGES PREVIEW OF THE MANUAL: