$34.95

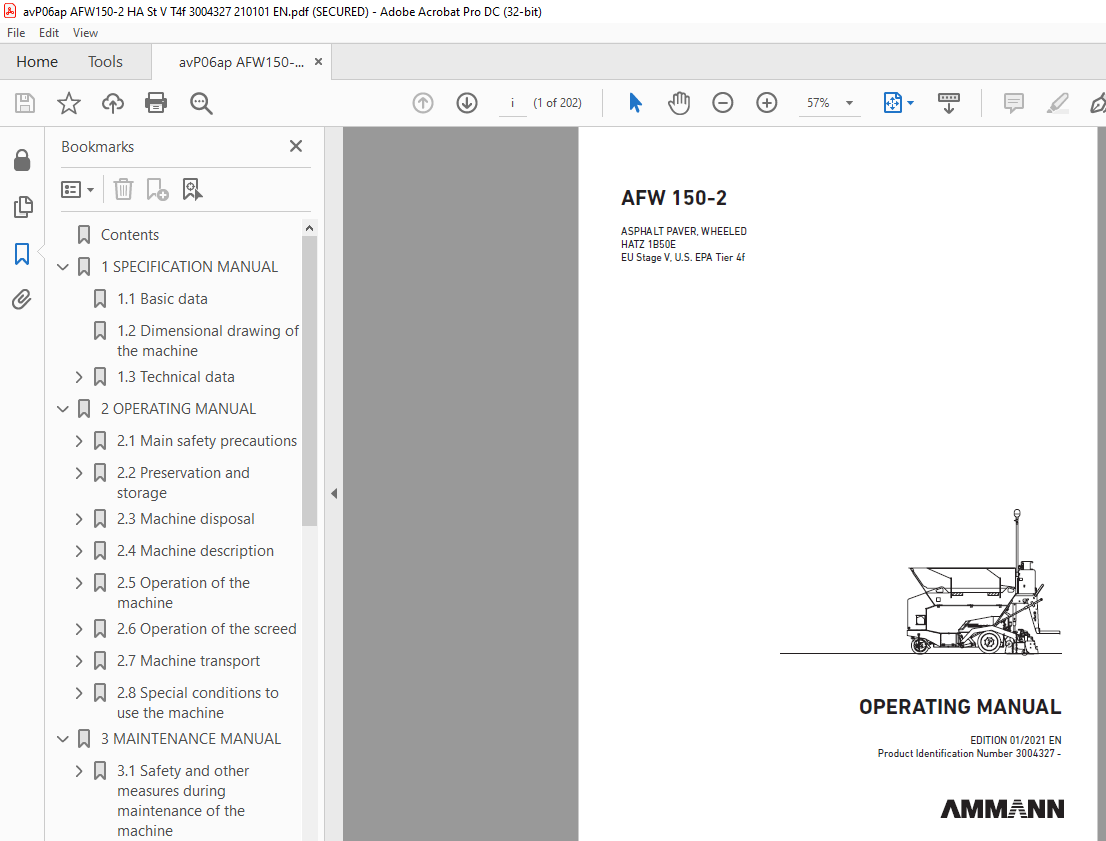

Ammann AFW 150-2 Asphalt Paver, Wheeled Operating Manual 3004327 PDF

Ammann AFW 150-2 Asphalt Paver, Wheeled Hatz 1B50E EU Stage V, U.S. EPA Tier 4f Operating Manual SN 3004327 – PDF DOWNLOAD

FILE DETAILS:

Ammann AFW 150-2 Asphalt Paver, Wheeled Hatz 1B50E EU Stage V, U.S. EPA Tier 4f Operating Manual SN 3004327 – PDF DOWNLOAD

Language : English

Pages : 202

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

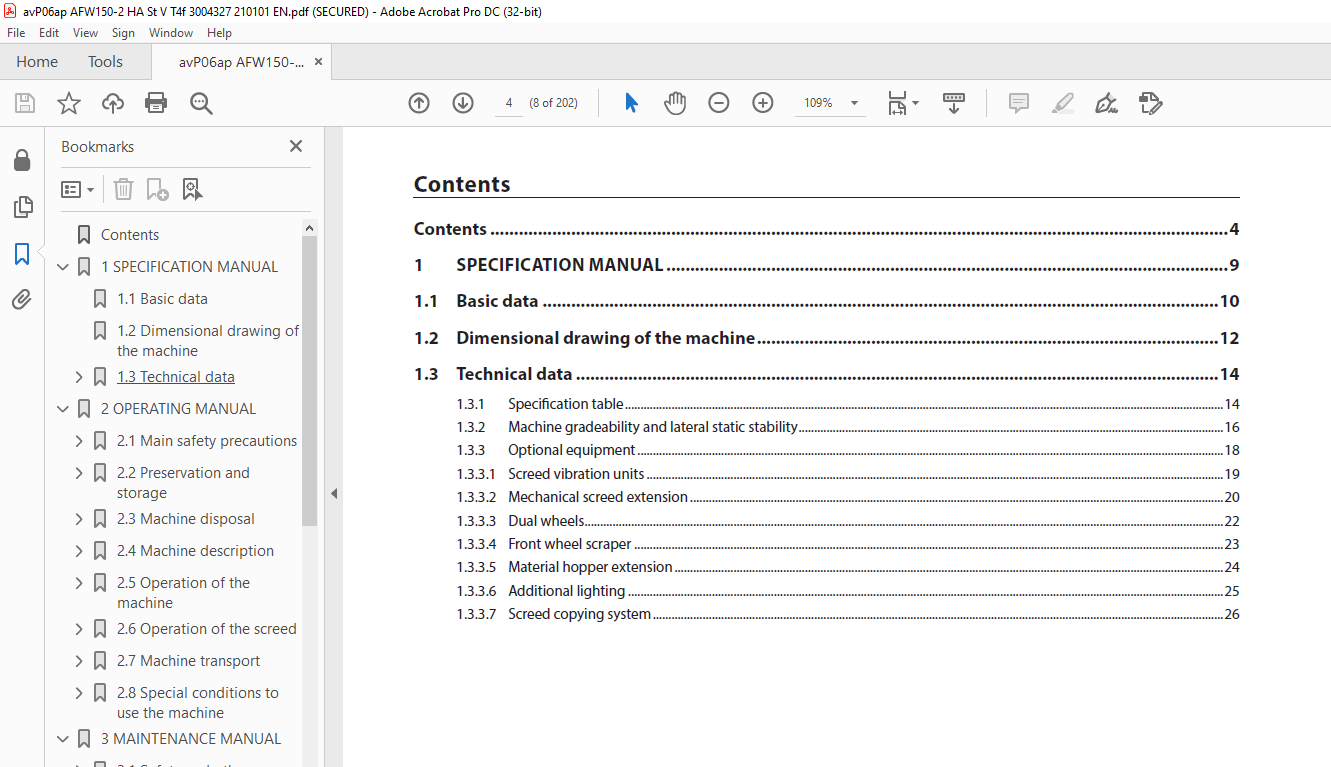

TABLE OF CONTENTS:

Ammann AFW 150-2 Asphalt Paver, Wheeled Hatz 1B50E EU Stage V, U.S. EPA Tier 4f Operating Manual SN 3004327 – PDF DOWNLOAD

Contents 8

1 SPECIFICATION MANUAL 13

1 1Basic data 14

1 2Dimensional drawing of the machine 16

1 3Technical data 18

1 3 1Specification table 18

1 3 2Machine gradeability and lateral static stability 20

1 3 3Optional equipment 22

1 3 3 1Screed vibration units 23

1 3 3 2Mechanical screed extension 24

1 3 3 3Dual wheels 26

1 3 3 4Front wheel scraper 27

1 3 3 5Material hopper extension 28

1 3 3 6Additional lighting 29

1 3 3 7Screed copying system 30

2 OPERATING MANUAL 33

2 1Main safety precautions 34

2 1 1Obligations before putting into operation 34

2 1 2Assurance of safety precautions by the owner 34

2 1 3Requirements for qualified personnel 35

2 1 4Machine operator’s obligations 36

2 1 5Screed operators’ obligations 37

2 1 6Driver’s stand and screed operator stand during machine operation 38

2 1 7Dangerous zone and safe distance 39

2 1 8Machine operation at unclear working areas 42

2 1 9Manual signals 42

2 1 10Safety notices and symbols used on the machine 46

2 1 11Personal protective equipment 50

2 1 12General safety precautions 51

2 1 13Safety precautions during machine operation 51

2 1 14Safety and fire precautions during the use of gas bottles 52

2 1 15Safety precautions for the use of portable fire extinguisher 53

2 1 16Safety and fire precautions during welding on the machine 53

2 1 17Safety precautions for electrical and electronic equipment of the machine 54

2 1 18Prohibited activities 55

2 2Preservation and storage 57

2 2 1Storage places and storage conditions 57

2 2 2Preservation and storage of the machine for 1–2 months 58

2 2 3Preservation and storage of the machine for a period over 2 months 59

2 2 4Removing chemical preservatives and putting the machine into operation 60

2 3Machine disposal 61

2 3 1Machine disposal after its service life 61

2 4Machine description 62

2 4 1Description of main parts of the machine and screed 63

2 4 2Main dashboard 67

2 4 3Display 71

2 4 4 Foot switch 73

2 5Operation of the machine 75

2 5 1Turning ON/OFF the battery disconnecter 75

2 5 2Basic equipment of the machine 76

2 5 3Machine footboard 79

2 5 4Deposition boxes and safety covers on the machine 80

2 5 5Mounting of screed reduction plates 82

2 5 6Beacon 84

2 5 7Driver’s stand 85

2 5 8Starting the engine 86

2 5 9Starting the engine using starting leads from external power supply 87

2 5 10Travel and reversing of the machine 88

2 5 11Stopping the machine and engine 90

2 5 12Machine parking 91

2 5 13Front wheel 92

2 5 14Using and setting the paving direction indicator 93

2 5 15Hopper 94

2 5 16Material outlet 95

2 5 17Conveyor 96

2 5 18Conveyor limit switch 97

2 5 19Augers 98

2 6Operation of the screed 99

2 6 1Lifting and lowering the screed 99

2 6 2Screed lock 100

2 6 3Setting the paving width 102

2 6 4Setting the paving thickness 104

2 6 5Setting the roadway profile 105

2 6 6Setting the end gates 106

2 6 7Screed vibration (optional equipment) 107

2 6 8Screed gas heating 108

2 6 9Loading material to the machine 115

2 6 10Start of paving 116

2 6 11End of paving 117

2 7Machine transport 118

2 7 1Preparation of the machine for transport 118

2 7 2Loading the machine using a ramp 119

2 7 3Loading the machine with a crane 120

2 7 4Machine transport 121

2 7 5Preparation of the machine for operation after transportation 121

2 8Special conditions to use the machine 122

2 8 1Towing the machine 122

2 8 2Climatic conditions 123

2 8 3Operation of the machine in dusty environment 123

3 MAINTENANCE MANUAL 125

3 1Safety and other measures during maintenance of the machine 127

3 1 1Safety precautions during machine maintenance 127

3 1 2Safety and fire precautions during replacement of operating fluids 128

3 1 3Environmental and hygienic principles 129

3 1 3 1Hygienic principles 129

3 1 3 2Environmental principles 129

3 2Specification of operating fluids 130

3 2 1Engine oil 130

3 2 2Fuel 131

3 2 3Hydraulic oil 131

3 2 4Anti-adherent solution 131

3 2 5Liquid gas 132

3 2 6Lubricating grease 132

3 3Table of fluid quantities 133

3 3 1Overview of fluids quantities and overview of symbols specified in maintenance plans 133

3 4Lubrication and maintenance chart 134

3 5Lubrication and service plan 136

3 5 1Maintenance plan 136

3 6Lubrication and maintenance operations 137

Every 10 hours at the beginning of work (daily) 138

3 6 1Fuel level check 138

3 6 2Engine oil check 139

3 6 3Hydraulic oil check in the hydraulic tank 140

3 6 4Driver’s stand cleaning 141

3 6 5Cleaning the hopper, outlets and conveyor 142

3 6 6Auger cleaning 143

3 6 7Test of burner ignition, flame position adjustment and spark plug maintenance 144

3 6 8Gas equipment tightness check 148

3 6 9Brake test 149

3 6 9 1Check of the parking brake 149

3 6 9 2Check of the emergency brake 150

3 6 9 3Check of the service brake 151

3 6 10Check of the tightness of the fuel and hydraulic system 152

Every 10 hours at the end of work (daily) 153

3 6 11Fuel level check 153

3 6 12Cleaning the hopper, outlets and conveyor 154

3 6 13Auger cleaning 155

Every 50 hours (week) 156

3 6 14Cleaning the water separator 156

3 6 15Machine lubrication 157

Every 100 hours of operation (monthly) 160

3 6 16Fuel system tightness check 160

3 6 17Rear wheel fastening check 161

3 6 18Conveyor chain tensioning 162

Every 250 hours of operation (every 3 months) 163

3 6 19Engine oil replacement 163

3 6 20Engine air intake check 164

3 6 21Hydraulic oil cooler cleaning 165

3 6 22Hydraulic circuit tightness check 166

3 6 23Battery check 167

3 6 24Checking the conveyor drive chain tension 169

Every 500 hours of operation (every 6 months) but at least once a year 170

3 6 25Replacement of fuel filters 170

3 6 26Air filter replacement 172

3 6 27Front and rear wheel condition check 173

Every 1000 hours (yearly) 174

3 6 28Engine oil filter cleaning 174

3 6 29Hydraulic oil and hydraulic oil filter replacement 176

3 6 30Gas line hose replacement 178

Maintenance as required 179

3 6 31Battery replacement 179

3 6 32Charging of the battery 180

3 6 33Screw connections tightness check 181

3 7Troubleshooting 183

3 7 1Troubleshooting 183

3 7 2Troubleshooting engine faults when indicator lamps are lit on the display 183

3 7 3Troubleshooting the hydraulic system 183

3 7 4Troubleshooting the electrical system 184

3 7 5Troubleshooting of screed heating when active error indicator lamp is lit and an error code is shown on the display 184

3 7 6List of error codes displayed on the display 185

3 8Appendices 188

3 8 1Machine wiring diagram 188

3 8 2Machine hydraulic system diagram 194

3 8 2 1Measuring points of the hydraulic circuit 196

3 8 3Screed gas heating system diagram 197

3 8 4Table of spare parts for regular maintenance 198

3 8 5Content of the filter set after 500 hours (4-760224) 198

3 8 6Content of the filter set after 1000 hours (4-760225) 198