$33.95

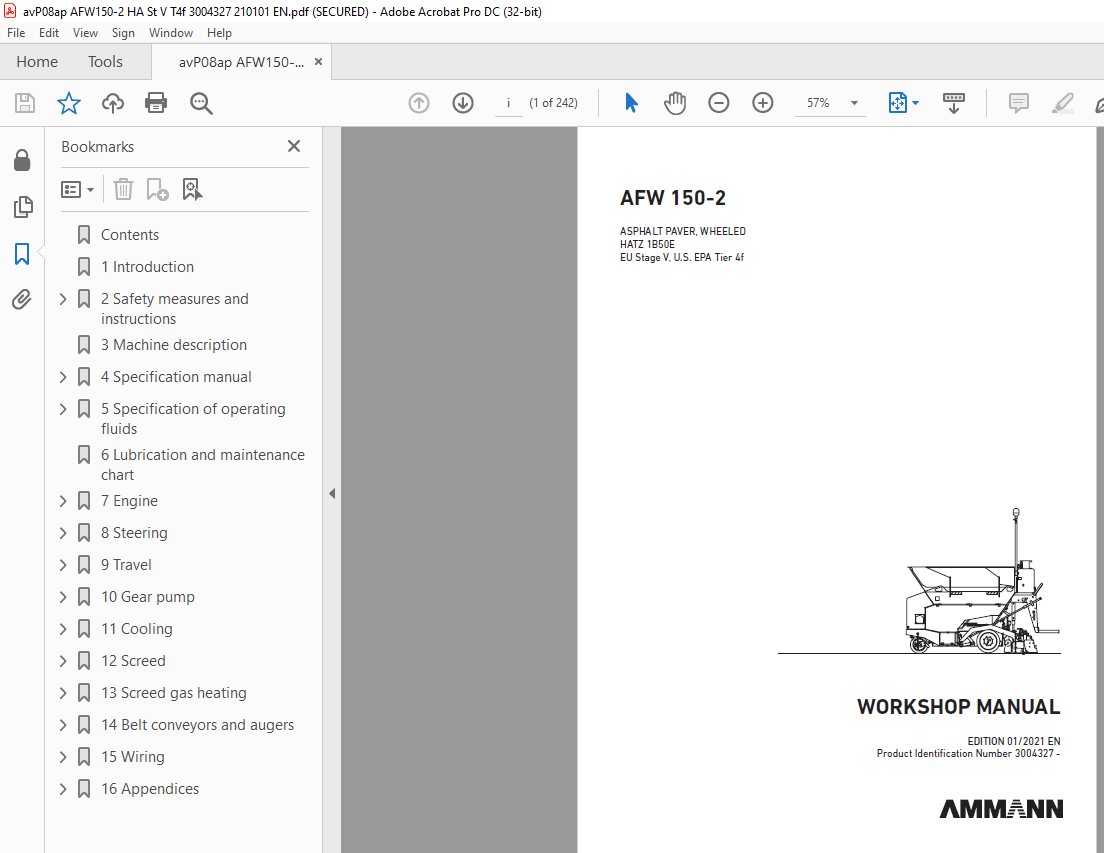

Ammann AFW 150-2 Asphalt Paver, Wheeled Workshop Manual 3004327 PDF

Ammann AFW 150-2 Asphalt Paver, Wheeled Hatz 1B50E EU Stage V, U.S. EPA Tier 4f Workshop Manual SN 3004327 – PDF DOWNLOAD

FILE DETAILS:

Ammann AFW 150-2 Asphalt Paver, Wheeled Hatz 1B50E EU Stage V, U.S. EPA Tier 4f Workshop Manual SN 3004327 – PDF DOWNLOAD

Language : English

Pages : 242

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Ammann AFW 150-2 Asphalt Paver, Wheeled Hatz 1B50E EU Stage V, U.S. EPA Tier 4f Workshop Manual SN 3004327 – PDF DOWNLOAD

Contents 4

1 Introduction 9

2 Safety measures and instructions 13

2 1Safety rules 14

2 2Environmental and hygiene principles 17

2 3Fire prevention 18

3 Machine description 19

4 Specification manual 25

4 1Basic data 26

4 2Dimensional drawing of the machine 28

4 3Technical data 30

4 4Machine gradeability and lateral static stability of the machine 32

5 Specification of operating fluids 35

5 1Engine oil 36

5 2Fuel 37

5 3Hydraulic oil 37

5 4Anti-adherent solution 37

5 5Liquid gas 38

5 6Lubricating grease 38

5 7Fluids 39

6 Lubrication and maintenance chart 41

7 Engine 45

7 1Description of engine basic elements 46

7 2Technical data of the manufacturer 48

7 3Engine diagnostics 49

7 3 1Measuring glow plug resistance 49

7 3 2Measuring glow plug power supply 49

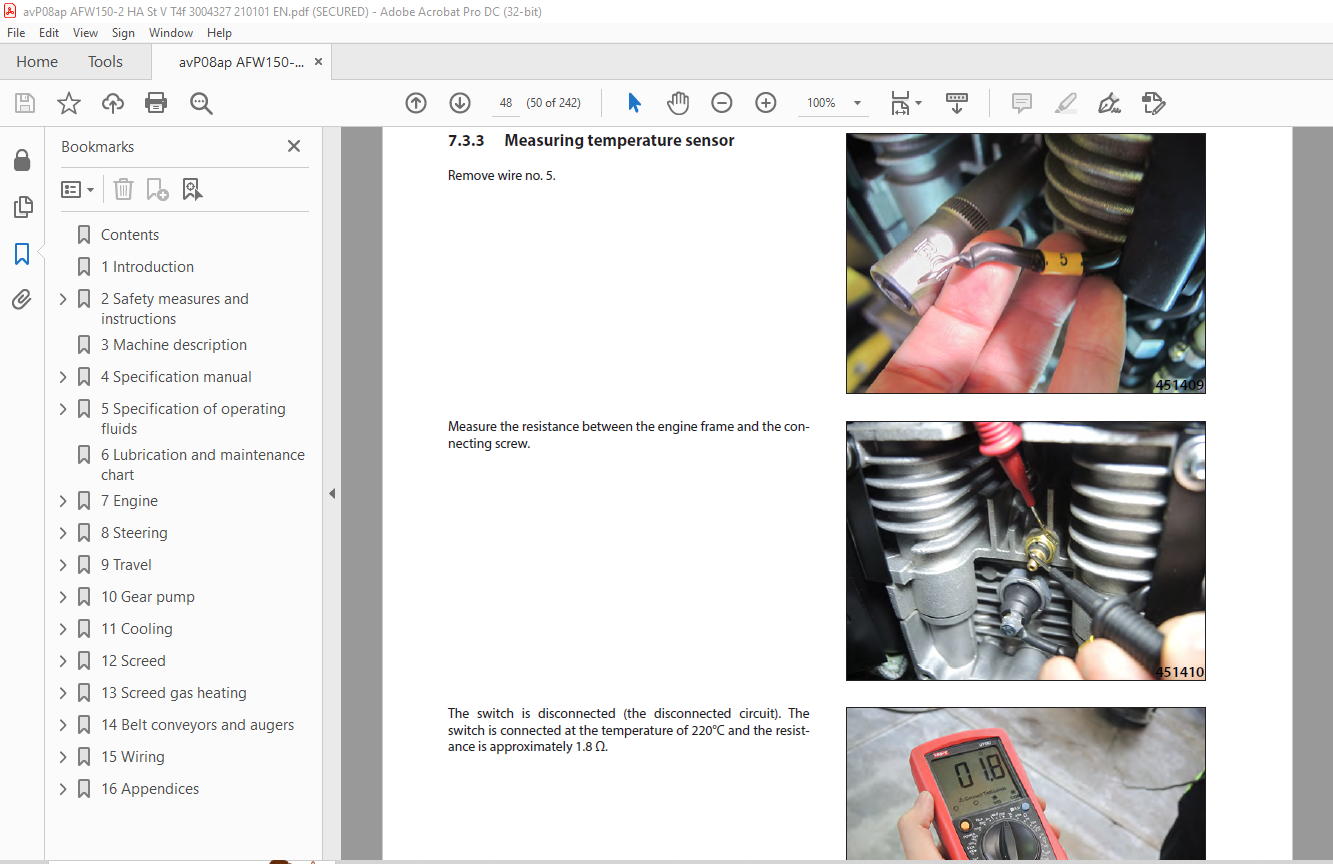

7 3 3Measuring temperature sensor 50

7 3 4Measuring lubricating oil pressure switch 51

7 3 5Measuring engine speed 52

7 4Dismounting the charging controller 53

7 5Mounting the charging controller 54

7 6Dismounting the engine 55

7 7Mounting the engine 60

8 Steering 65

8 1Description of basic elements 66

8 2Technical data of the manufacturer 67

8 3Diagnostics 67

8 4Replacement of the gear pump 68

8 5 Dismounting the steering linear hydraulic motor 70

8 6 Mounting the steering linear hydraulic motor 72

8 7Dismounting the steering unit 73

8 8Removal of the hydraulic tank 74

8 9Mounting the hydraulic tank 76

8 10Adjustment of the front wheel turning angle indicator 77

9 Travel 79

9 1Description of basic elements 80

9 2Diagnostics 83

9 2 1Measuring the brake switch 83

9 2 2Measuring the brake valve electromagnet Y7 84

9 2 3Measuring the refilling pressure 85

9 2 4Measuring the maximum pressure for forward and reverse travel 86

9 2 5Measuring the resistance of the electromagnet coil 88

9 3Removal of the travel pump 88

9 4Dismounting the hydraulic motor and travel gearbox 90

9 5Mounting the hydraulic motor and travel gearbox 92

10 Gear pump 95

10 1Description of basic elements 96

10 2Diagnostics 98

10 2 1Measuring the pressure of the belt conveyor and auger 98

10 2 2Measuring the screed lifting pressure 99

10 2 3Measuring the screed extension pressure 100

10 2 4Measuring the maximum vibrator pressure 101

10 2 5Measuring the vibration frequency 102

10 3 Dismounting the gear pump 103

10 4Dismounting the vibration units 104

10 5Hydraulic system switchboard 106

10 5 1Description of basic elements 106

11 Cooling 109

11 1Description of basic elements 110

11 2Cooling diagnostics 110

11 2 1Fan test 110

11 2 2Temperature sensor 110

11 3Dismounting the cooler 111

11 4Mounting the cooler 113

12 Screed 117

12 1Dismounting the screed lifting cylinder 118

12 2Replacement of linear hydraulic motors for screed extension 120

12 3Basic setting of the screed 122

12 4Replacement of the friction plates 125

12 4 1Front frame 126

12 4 2Rear frames 129

13 Screed gas heating 133

13 1Gas system diagram 134

13 2Ignition process 135

13 3Diagnostics 137

13 3 1Gas equipment tightness check 137

13 4Reducing valve 139

13 5Gas hoses 139

13 6Gas manifold 139

13 6 1Gas manifold replacement 139

13 7Screed heating burner 141

13 7 1Screed heating burner replacement 141

13 7 2Cleaning the gas burner nozzle 142

13 7 3Gas flame adjustment 144

13 7 4Test of burner ignition 145

13 8Gas supply solenoid valves 147

13 8 1Valve cleanliness inspection 147

13 8 2Measuring resistance of the coils of gas supply valve electromagnets 148

13 8 3Measuring power supply of the coils of gas supply valve electromagnets 149

13 9Ignition units 150

13 9 1Measuring resistance on the ignition unit 150

13 9 2Voltage measurement on the cable harness of ignition units 151

13 10High-voltage cables 152

13 11Spark plugs 152

13 11 1Spark plug function test 152

13 11 2Spark plug check procedure 153

13 12Temperature sensor 154

14 Belt conveyors and augers 155

14 1Replacement of the hydraulic motor for driving the augers and the belt conveyor 156

14 2Dismounting the belt conveyor chain 159

14 3Mounting the belt conveyor chain 163

14 4Setting the belt conveyor chain sag 167

14 5Dismounting the belt conveyor chain drive 169

14 6Dismounting the auger chain 172

14 7Replacement of the drive switch of augers and belt conveyor 175

14 7 1Measuring the belt conveyor drive switch S7 176

14 8Dismounting the driving gear wheel of augers 177

14 9Replacement of consumables 178

14 9 1Belt conveyor chain guide plate 178

14 9 2 Cover plates 184

15 Wiring 185

15 1Description of basic components 186

15 1 2Central earthing points X6 and x7 187

15 2Diagnostics 188

15 2 1List of error codes displayed on the display 188

15 2 2Fuse box 191

15 2 3 Diagnostics socket 192

15 2 3 1Measuring of the CAN BUS data bus 193

15 2 3 1 1Measuring voltage of the CAN BUS data bus 193

15 2 3 1 2Measuring resistance of the CAN BUS data bus 193

15 2 4Communication with the control unit A2 by means of Bodas – service 3 5 194

15 2 4 1Connecting the machine to PC 194

15 2 4 2Uploading and deleting errors 197

15 2 4 3Check of parameters 198

15 2 5Display measurement 199

15 2 6Foot switch measurement 200

15 2 7Travel controller measurement 201

15 2 8Paving speed selector measurement 203

15 3Calibration 206

15 3 1Connecting the machine to PC 206

15 3 2Calibration of the travel controller and the paving speed selector 207

15 3 3Travel pump calibration 212

15 4Control unit A2 219

15 4 1Connector of the control unit 220

15 4 2Dismounting the control unit A2 221

15 5Display unit 222

15 5 1Dismounting the display 222

15 6Travel controller 224

15 6 1Dismounting the travel controller A4 224

15 7Paving speed selector 226

15 7 1Dismounting the paving speed selector 226

15 8Battery 228

16 Appendices 229

16 1Machine wiring diagram 230

16 2Machine hydraulic system diagram 236

16 2 1Measuring points of the hydraulic circuit 238

16 3Screed gas heating system diagram 239