Starting from:

$30.95

Ammann AP 240 Pneu Tyred Roller Operating Manual 3001576 - PDF

AMMANN AP 240 PNEU TYRED ROLLER CUMMINS QSB3.3-C99 EU STAGE IIIA / U.S. EPA Tier 3 OPERATING MANUAL 3001576 – PDF DOWNLOAD

FILE DETAILS:

AMMANN AP 240 PNEU TYRED ROLLER CUMMINS QSB3.3-C99 EU STAGE IIIA / U.S. EPA Tier 3 OPERATING MANUAL 3001576 – PDF DOWNLOAD

Language : English

Pages :182

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

AMMANN AP 240 PNEU TYRED ROLLER CUMMINS QSB3.3-C99 EU STAGE IIIA / U.S. EPA Tier 3 OPERATING MANUAL 3001576 – PDF DOWNLOAD

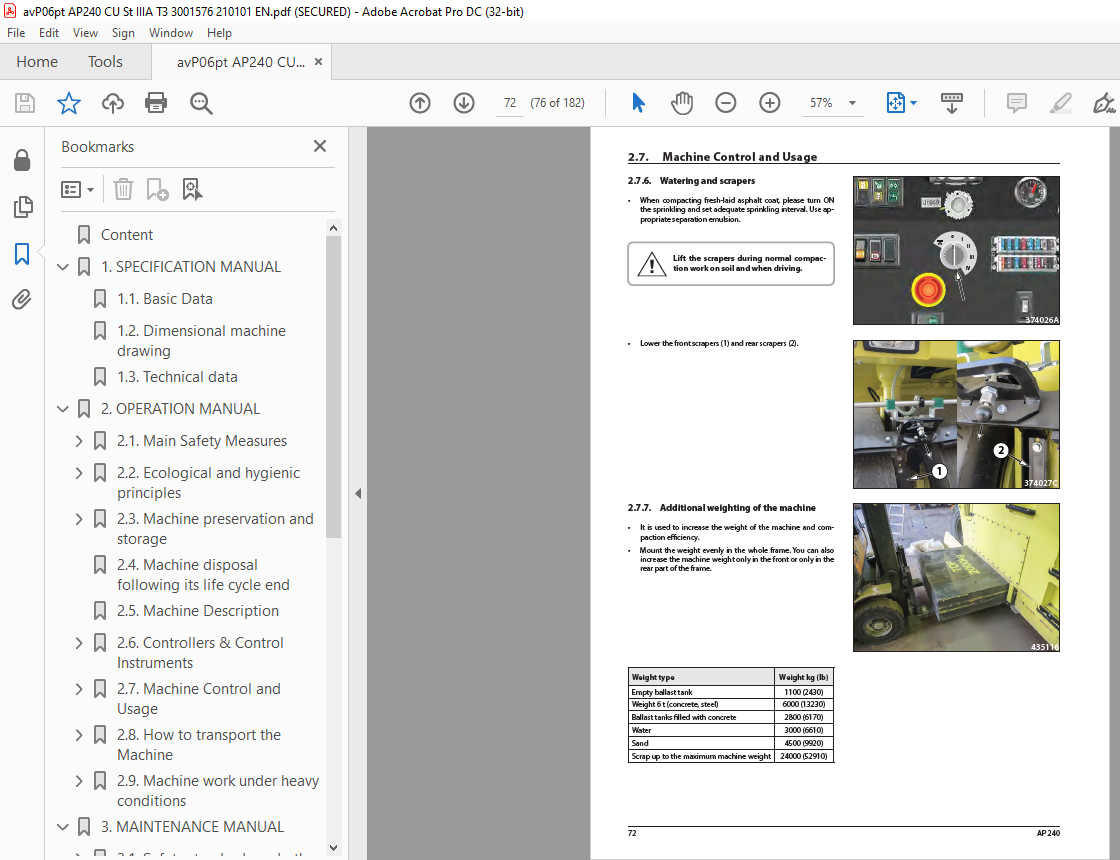

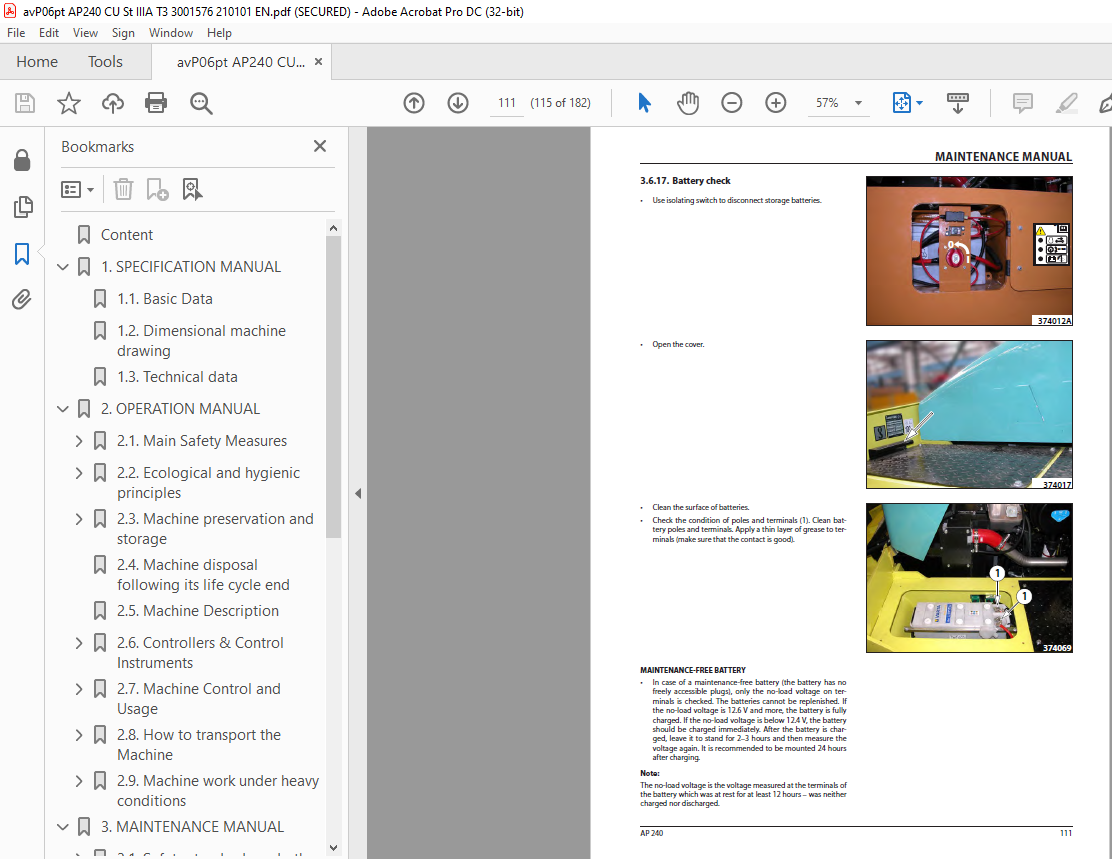

Content........................................................................................ 8 1. SPECIFICATION MANUAL........................................................................ 13 1.1. Basic Data............................................................................ 14 1.2. Dimensional machine drawing........................................................... 16 1.3. Technical data........................................................................ 19 2. OPERATION MANUAL............................................................................ 25 2.1. Main Safety Measures.................................................................. 27 2.1.1. Safety measures during Machine operation........................................ 27 2.1.1.1. Compaction Work Commencement.................................................. 27 2.1.1.2. Work in the dangerous area.................................................... 27 2.1.1.3 Ensurance of safety measures by the owner...................................... 28 2.1.1.4. ROPS.......................................................................... 28 2.1.2. Requirements for qualification of driver........................................ 29 2.1.3. Duties of the driver............................................................ 30 2.1.4. Forbidden activities – safety and guarantee..................................... 31 2.1.5. Safety inscriptions and symbols used on the Machine............................. 32 2.1.6. Hand signals.................................................................... 36 2.2. Ecological and hygienic principles.................................................... 39 2.2.1. Hygienic principles............................................................. 39 2.2.2. Ecological principles........................................................... 39 2.3. Machine preservation and storage...................................................... 40 2.3.1. Short-term preservation and storage for a period of 1 – 2 months................ 40 2.3.2. Preservation and storage for the period over 2 months long...................... 40 2.3.3. Dewaxing and inspection of a supplied machine................................... 41 2.4. Machine disposal following its life cycle end......................................... 42 2.5. Machine Description................................................................... 43 2.6. Controllers & Control Instruments..................................................... 44 2.6.1. Power View control ............................................................. 57 2.7. Machine Control and Usage............................................................. 67 2.7.1. Engine starting................................................................. 68 2.7.2. Travel & Reversation............................................................ 70 2.7.3. Emergency stop of the Machine................................................... 73 2.7.4. How to stop the Machine and the engine.......................................... 74 2.7.5. Machine parking................................................................. 75 2.7.6. Watering and scrapers........................................................... 76 2.7.7. Additional weighting of the machine............................................. 76 2.7.8. Edge Cutter..................................................................... 77 2.8. How to transport the Machine.......................................................... 78 2.8.1. Loading the machine............................................................. 79 2.8.1.1. Loading the machine using a ramp.............................................. 79 2.8.1.2. Loading the machine using a crane............................................. 79 2.9. Machine work under heavy conditions................................................... 80 2.9.1. Machine towing.................................................................. 80 2.9.2. Machine operation during its running-in period.................................. 82 2.9.3. Machine operation at low temperatures........................................... 82 2.9.4. Machine work under high temperatures and humidity............................... 82 2.9.5. Machine work in high altitudes.................................................. 82 2.9.6. Work of the machine in the dusty environment.................................... 82 3. MAINTENANCE MANUAL.......................................................................... 85 3.1. Safety standards and other maintenance regulations ................................... 87 3.1.1. Safety of machine maintenance................................................... 87 3.1.2. Fire precautions during operation media exchanges............................... 87 3.1.3. Ecological and hygienic standards............................................... 88 3.2. Media Specification................................................................... 89 3.2.1. Engine Oil...................................................................... 89 3.2.2. Fuel............................................................................ 90 3.2.3. Coolant ........................................................................ 91 3.2.4. Hydraulic Oil .................................................................. 91 3.2.5. Oil – epicyclic transmission incl. torque converter............................. 92 3.2.6. Gear Oil ....................................................................... 92 3.2.7. Brake Fluid..................................................................... 92 3.2.8. Lube Grease..................................................................... 92 3.2.9. Windscreen Sprayer Liquid....................................................... 92 3.2.10. Air-conditioning filling....................................................... 92 3.3. Media................................................................................. 93 3.4. Lubrication and Maintenance Chart..................................................... 94 3.5. Lubrication and Service Plan ......................................................... 97 3.6. Lubrication and Maintenance Operations................................................ 98 Every 20 hours of operation (daily).................................................... 99 3.6.1. Engine oil level check...................................................... 99 3.6.2. Engine cooling liquid level check...........................................100 3.6.3. Crankcase breather tube.....................................................100 3.6.4. Fan condition check and engine belt check...................................101 3.6.5. Air filter dust valve check.................................................102 3.6.6. Hydraulic oil level check...................................................102 3.6.7. Brake fluid check...........................................................103 3.6.8. Water tank refill...........................................................104 3.6.9. Water separator cleaning....................................................104 3.6.10. Oil in the gearbox check...................................................105 3.6.11. Warning and control devices check..........................................106 3.6.12. Check of the front axle....................................................108 Every 100 hours of operation (weekly)..................................................109 3.6.13. Tyre pressure check........................................................109 3.6.14. Check of the oil level in the front axle hydraulic cylinders...............110 Every 250 hours of operation (3 months)................................................111 3.6.15. Engine oil change..........................................................111 3.6.16. Engine induction manifold and air filter sensor check......................113 3.6.17. Battery check..............................................................115 3.6.18. Machine lubrication........................................................117 Every 500 hours of operation (6 months)................................................119 3.6.19. Fuel filters replacement...................................................119 3.6.20. Engine cooling liquid check................................................121 3.6.21. Gearbox oil filter replacement.............................................122 3.6.22. Oil in differential and oil in rear axle check.............................123 3.6.23. Wiring check...............................................................123 3.6.24. Checking the air-conditioning coolant level................................124 3.6.25. Air filter elements replacement............................................125 3.6.26. Filter of the cab ventilation replacement.................................127 3.6.27. Air filter of the air conditioning system replacement......................128 Every 1000 hours of operation (1 year).................................................129 3.6.28. Brake shoes adjustment.....................................................129 3.6.29. KM nuts tightening check and front wheels lubrication......................132 3.6.30. Hydraulic accumulator check................................................133 3.6.31. Engine belt check..........................................................134 3.6.32. Inspection of the air-conditioning compressor and air-conditioning belt....135 3.6.33. Gearbox oil change.........................................................136 3.6.34. Oil in differential change.................................................137 3.6.35. Air drier replacement......................................................138 Every 2000 hours of operation (2 years)................................................139 3.6.36. Valve clearance adjustment.................................................139 3.6.37. Oil in rear axle change....................................................139 3.6.38. Hydraulic oil and filter change............................................141 3.6.39. Oil in front axle hydraulic cylinders change...............................145 3.6.40. Brake fluid change.........................................................146 3.6.41. Engine cooling liquid change...............................................148 3.6.42. Compressor check...........................................................150 3.6.43. Air conditioning system check..............................................151 Maintenance if required................................................................152 3.6.44. Water from separator draining..............................................152 3.6.45. Fuel system venting........................................................153 3.6.46. Coolers cleaning...........................................................154 3.6.47. Refilling the oil level in the front axle hydraulic cylinders..............155 3.6.48. Sprinkling filter cleaning.................................................157 3.6.49. Brush scrapers cleaning....................................................157 3.6.50. Machine cleaning...........................................................158 3.6.51. Check of wheel nuts for tightening.........................................159 3.6.52. Air collector inspection...................................................159 3.6.53. Charging of the battery....................................................160 3.6.54. Screw connection tightening check..........................................161 3.7. Defects...............................................................................163 3.8. Annexes...............................................................................164 3.8.1. Wiring Diagram..................................................................164 3.8.2. Hydraulics Diagram..............................................................170 3.8.3. Air Distribution................................................................172 3.8.4. Table of spare parts............................................................174

1 file (9.0MB)