Starting from:

$35.95

Home

AMMANN

Ammann ARP 95 Tandem Roller Deutz Tier 4 Final Operating Manual SN 4232004 – PDF DOWNLOAD

Ammann ARP 95 Tandem Roller Deutz Tier 4 Final Operating Manual SN 4232004 – PDF DOWNLOAD

Ammann ARP 95 Tandem Roller Deutz Tier 4 Final Operating Manual SN 4232004 – PDF DOWNLOAD

FILE DETAILS:

Ammann ARP 95 Tandem Roller Deutz Tier 4 Final Operating Manual SN 4232004 – PDF DOWNLOAD

Language : English

Pages : 220

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

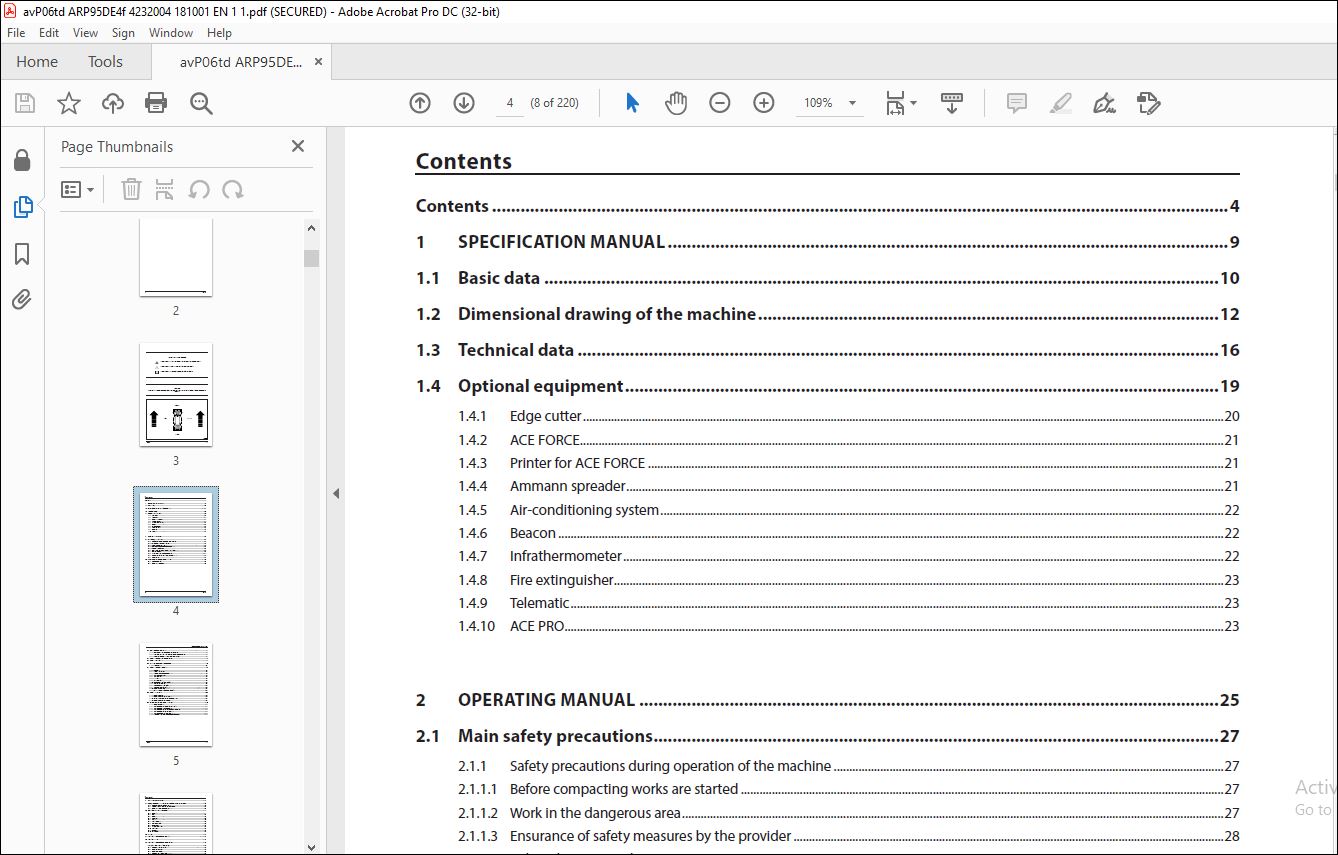

TABLE OF CONTENTS:

Ammann ARP 95 Tandem Roller Deutz Tier 4 Final Operating Manual SN 4232004 – PDF DOWNLOAD

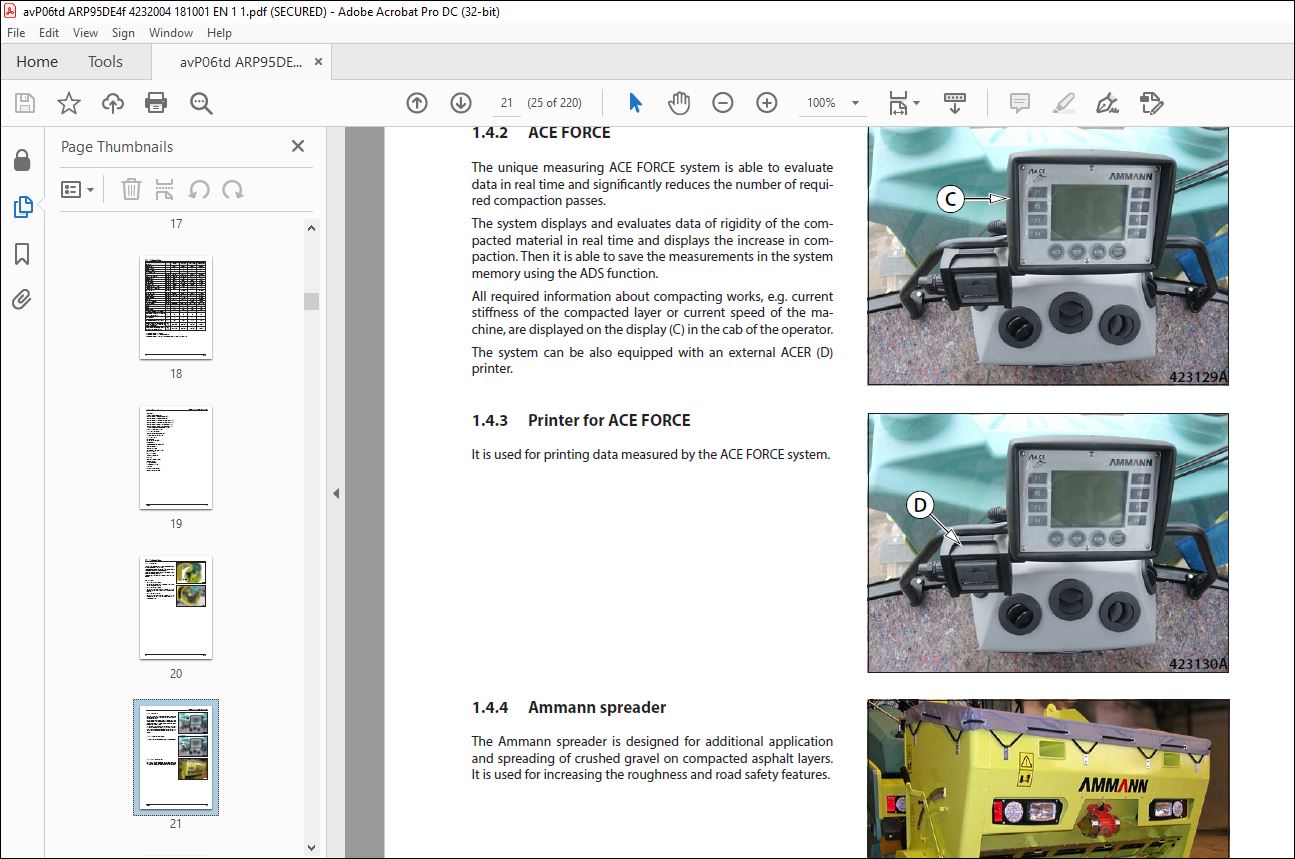

Contents....................................................................................... 8 1 SPECIFICATION MANUAL......................................................................... 13 1.1 Basic data............................................................................. 14 1.2 Dimensional drawing of the machine..................................................... 16 1.3 Technical data......................................................................... 20 1.4 Optional equipment..................................................................... 23 1.4.1 Edge cutter...................................................................... 24 1.4.2 ACE FORCE........................................................................ 25 1.4.3 Printer for ACE FORCE............................................................ 25 1.4.4 Ammann spreader.................................................................. 25 1.4.5 Air-conditioning system.......................................................... 26 1.4.6 Beacon........................................................................... 26 1.4.7 Infrathermometer................................................................. 26 1.4.8 Fire extinguisher................................................................ 27 1.4.9 Telematic........................................................................ 27 1.4.10 ACE PRO......................................................................... 27 2 OPERATING MANUAL............................................................................. 29 2.1 Main safety precautions................................................................ 31 2.1.1 Safety precautions during operation of the machine............................... 31 2.1.1.1 Before compacting works are started............................................ 31 2.1.1.2 Work in the dangerous area..................................................... 31 2.1.1.3 Ensurance of safety measures by the provider................................... 32 2.1.1.4 Cab with integrated ROPS...................................................... 32 2.1.2 Requirements for the machine driver’s qualification.............................. 33 2.1.3 Driver's obligations............................................................. 34 2.1.4 Forbidden activities – safety and guarantee...................................... 35 2.1.5 Safety notices and signs applied on the machine ................................. 36 2.1.6 Manual signals................................................................... 41 2.2 Environmental and hygiene principles................................................... 44 2.2.1 Hygiene principles .............................................................. 44 2.2.2 Environmental principles ........................................................ 44 2.3 Preservation and storage............................................................... 45 2.3.1 Short-term preservation and storage for 1–2 months............................... 45 2.3.2 Preservation and storage of the machine for a period over 2 months............... 45 2.3.3 Depreservation and inspection of the delivered machine........................... 46 2.4 Machine disposal after its service life................................................ 47 2.5 Machine description.................................................................... 48 2.6 Controls and checking instruments...................................................... 50 2.6.1 Display control.................................................................. 70 2.7 Machine operation and use.............................................................. 82 2.7.1 Engine start..................................................................... 83 2.7.2 Drive and reverse drive.......................................................... 87 2.7.3 Stopping the machine and engine.................................................. 95 2.7.4 Machine emergency stop........................................................... 95 2.7.5 Machine parking.................................................................. 97 2.7.6 Sprinkling....................................................................... 97 2.7.6.1 Water sprinkling............................................................... 97 2.7.6.2 Emulsion sprinkling (Combi version)............................................ 99 2.7.7 Cab lifting and lowering.........................................................100 2.7.8 Ammann edge cutter (optional)....................................................107 2.7.9 Ammann spreader (optional) ......................................................108 2.7.10 Infrathermometer (optional).....................................................109 2.7.11 Printer for ACE FORCE (optional equipment)......................................109 2.8. Machine transport.....................................................................110 2.8.1 Loading the machine .............................................................111 2.8.1.1 Loading the machine using a ramp...............................................111 2.8.1.2 Change of the driving direction – turned workplace.............................112 2.8.1.3 Loading the machine using a crane..............................................113 2.9 Special conditions to use the machine..................................................114 2.9.1 Towing the machine...............................................................114 2.9.2 Machine operation during the initial run-in period..............................118 2.9.3 Machine operation at low temperatures...........................................118 2.9.4 Machine operation at higher temperatures and humidity............................118 2.9.5 Machine operation at higher altitudes............................................118 2.9.6 Machine operation in dusty environment...........................................119 2.9.7 Driving with vibration on compacted and hard materials...........................119 3 MAINTENANCE MANUAL...........................................................................121 3.1 Safety and other measures during maintenance of the machine............................123 3.1.1 Safety during machine maintenance................................................123 3.1.2 Fire protection when operating fluids are changed................................123 3.1.3 Environmental and hygiene principles.............................................124 3.2 Specification of operating fluids......................................................125 3.2.1 Engine oil ......................................................................125 3.2.2 Fuel.............................................................................126 3.2.3 Coolant..........................................................................127 3.2.4 Hydraulic oil....................................................................128 3.2.5 Gear oil.........................................................................128 3.2.6 Lubricating grease...............................................................128 3.2.7 Screen washer fluid..............................................................128 3.2.8 Drum coolant.....................................................................129 3.2.9 Air-conditioning filling.........................................................129 3.2.10 Vibrator oil....................................................................129 3.2.11 Emulsion........................................................................129 3.2.12 DEF (AdBlue) ...................................................................130 3.3 Fluids.................................................................................131 3.4 Lubrication and maintenance chart......................................................132 3.5 Lubrication plan.......................................................................134 3.6 Lubrication and maintenance operations.................................................136 Every 20 hours of operation (daily)....................................................137 3.6.1 Checking the oil in the engine...............................................137 3.6.2 Engine tightness check ......................................................137 3.6.3 Engine coolant check.........................................................138 3.6.4 Checking the dust valve of the air filter....................................139 3.6.5 Fan inspection ..............................................................139 3.6.6 Fuel check...................................................................140 3.6.7 Checking the oil in the hydraulic tank.......................................141 3.6.8 Sprinkling tank refilling....................................................141 3.6.9 Check of the sprinkling nozzles..............................................142 3.6.10 Check of warning and checking devices ......................................143 3.6.11 Checking the exhaust system for tightness...................................146 3.6.12 (Air-conditioning) belt check...............................................146 3.6.13 DEF (AdBlue) level check....................................................147 Every 100 hours of operation (weekly)..................................................150 3.6.14 Tyre pressure check ARP 95C, ARP 95C ACE....................................150 3.6.15 Sprinkling filter cleaning..................................................151 Every 250 hours of operation (every 3 months)..........................................153 3.6.16 Machine lubrication.........................................................153 Every 500 hours of operation (every 6 months)..........................................155 3.6.17 Inspection of the engine cooling circuit ...................................155 3.6.18 Checking the engine belt....................................................156 3.6.19 Engine oil change...........................................................156 3.6.20 Checking the intake pipe of the engine......................................159 3.6.21 Engine coolant concentration check..........................................159 3.6.22 Electrical installation check...............................................159 3.6.23 Fuel filter replacement.....................................................160 3.6.24 Replacement of air filter cartridges .......................................162 3.6.25 Cab ventilation filter cleaning.............................................164 3.6.26 Coolant level check (air-conditioning)......................................164 3.6.27 Checking the sensor of the air filter.......................................165 3.6.28 Cleaning the water separator on the fuel filter.............................166 3.6.29 DEF (AdBlue) filter replacement.............................................167 Every 1000 hours of operation (yearly).................................................169 3.6.30 Checking the engine belt....................................................169 3.6.31 Damping system check .......................................................170 3.6.32 Cleaning the water tank.....................................................171 3.6.33 Air cooler cleaning.........................................................172 3.6.34 Checking the engine.........................................................173 3.6.35 Engine and machine diagnostics..............................................173 3.6.36 Oil change in gearboxes.....................................................174 3.6.37 Oil change in vibrators.....................................................175 3.6.38 (Air-conditioning) belt check...............................................176 3.6.39 Checking the compressor for mounting (air-conditioning).....................177 3.6.40 Battery check...............................................................178 Every 2000 hours of operation (every 2 years)..........................................180 3.6.41 Hydraulic oil change........................................................180 3.6.42 Vent plug replacement.......................................................185 3.6.43 Remplacement du filtre ACE pro..............................................185 Every 6000 hours of operation (every 4 years)..........................................186 3.6.44 Engine coolant change ......................................................186 Maintenance as required................................................................188 3.6.45 Fuel system venting ........................................................188 3.6.46 Cooler cleaning.............................................................189 3.6.47 Draining water from the sprinkling circuit before the winter season ........190 3.6.48 Scraper adjustment.........................................................192 3.6.49 Cleaning the machine........................................................194 3.6.50 Checking the screw connections for tightening...............................194 3.6.51 Regeneration of the clogged SCR catalyst (Selective Catalytic Reduction)....197 3.6.52 DPF (Diesel Particulate Filter) regeneration................................198 3.7 Troubleshooting........................................................................199 3.8 Appendices.............................................................................200 Wiring diagram ARP 95..................................................................200 Wiring diagram ARP 95 ACE..............................................................206 Hydraulic system diagram ARP 95........................................................208 Hydraulic system diagram ARP 95C.......................................................210 Hydraulic system diagram ARP 95 ACE....................................................212 Hydraulic system diagram ARP 95C ACE...................................................214 Table of spare parts for regular maintenance...........................................216 Content of the filter set after 500 hours (4-37967)....................................217 Content of the filter set after 2000 hours (4-37968)...................................217

1 file (13.0MB)