Starting from:

$35.95

Home

AMMANN

Ammann ARP 95 Tandem Roller Deutz TCD3,6 L4 EU Stage V / U.S. EPA Tier 4f Workshop Manual SN 3026131

Ammann ARP 95 Tandem Roller Deutz TCD3,6 L4 EU Stage V / U.S. EPA Tier 4f Workshop Manual SN 3026131

Ammann ARP 95 Tandem Roller Deutz TCD3,6 L4 EU Stage V / U.S. EPA Tier 4f Workshop Manual SN 3026131 – PDF DOWNLOAD

FILE DETAILS:

Ammann ARP 95 Tandem Roller Deutz TCD3,6 L4 EU Stage V / U.S. EPA Tier 4f Workshop Manual SN 3026131 – PDF DOWNLOAD

Language : English

Pages : 610

Downloadable : Yes

File Type : PDF

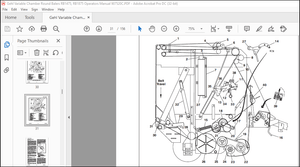

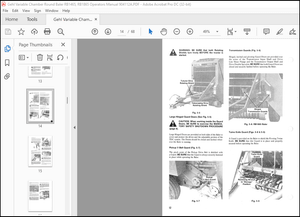

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Ammann ARP 95 Tandem Roller Deutz TCD3,6 L4 EU Stage V / U.S. EPA Tier 4f Workshop Manual SN 3026131 – PDF DOWNLOAD Contents 5 1 Introduction 9 1 1About this workshop manual 12 2 Safety measures and instructions 13 2 1Safety rules 14 2 2Environmental and hygiene principles 17 2 3Fire prevention 18 2 4Claim conditions and disclaimer of liability 18 3 Machine description 19 4 Specification manual 23 4 1Basic specification 24 4 2Machine dimension scheme 26 4 3Technical data 30 4 4Optional equipment 33 5 Media specification 35 5 1Engine oil 36 5 2Fuel 37 5 3Cooling liquid 37 5 4Hydraulic oil 38 5 5Gearbox oil 38 5 6Lube grease 38 5 7Glass washer fluid 38 5 8Drum cooling liquid 39 5 9Air Conditioning filling 39 5 10Vibratory oil 39 5 11Emulsion 39 5 12DEF (AdBlue) 39 5 13Media 40 6 Lubrication and Maintenance Chart 41 7 Ammann display 47 7 1Display control 48 8 Engine 59 8 1Description of the engine and basic components 61 8 2Technical data of the manufacturer 62 8 3Troubleshooting 63 8 4Engine removal 68 8 4 1Removal of the frame with the engine from the machine 69 8 4 2Removal of the engine from the frame 74 8 4 3Engine installation 80 9 Steering 81 9 1Description of basic elements 83 9 4Removal of the linear hydraulic motor of steering 85 9 4 1Replacement of the linear hydraulic motor of steering 85 9 4 2Replacement of the linear hydraulic motor of cab lifting 87 9 4 3Replacement of seals of the linear hydraulic motor 91 9 5Removal of the steering wheel 96 9 6Removal of the steering pump 99 9 6 1Installation of the steering pump 102 9 7Removal of the hydraulic tank 105 9 7 1Installation of the hydraulic tank 109 9 8Removal of the oscillation plate bearings (003-051-1) 112 9 8 1Installation of the oscillation plate bearings (003-051-1) 117 9 9Steering block replacement 126 9 10Setting the stops and setting the planeness 132 9 10 1Adjustment of the stops 132 9 10 2Adjustment of the planeness 133 10 Travel 135 10 1Description of the basic elements 137 10 4Removal of the travel hydraulic motor 138 10 4 1Installation of the travel hydraulic motor 152 10 5Removal of the ACE travel hydraulic motor 164 10 5 1Installation of the ACE travel hydraulic motor 171 10 6Removal of the travel gearbox and hydraulic motor of ARP95 K 178 10 6 1Installation of the travel gearbox and hydraulic motor of ARP95 K 183 10 7Removal of the travel pump 185 10 7 1Installation of the travel pump 191 10 8Removal of the travel pump coupling 194 10 8 1Installation of the travel pump coupling 197 11 Vibration 199 11 1Description of the basic elements 201 11 4Removal of the vibration hydraulic motor 203 11 4 1Installation of the vibration hydraulic motor 207 11 5Removal of the vibration pump – rear drum 210 11 5 1Installation of the vibration pump – rear drum 214 11 6Removal of the vibration pump – front drum 216 11 6 1Installation of the vibration pump – front drum 220 11 7Removal of the drum from the machine 223 11 7 1Installation of the drum in the machine 234 11 7 2Installation of the damper plate – classic drum 243 11 8Removal of vibrator bearings 247 11 8 1Covers – removal of bearings 247 11 8 2Vibrator – removal of inner rings 259 11 9Installation of vibrator bearings 263 11 9 1Covers – installation of bearings 263 11 9 2Vibrator – installation of inner rings 266 11 10Replacement of drum rubber-metals 269 11 11Removal of the ACE vibrator 273 11 11 1Remove of the ACE gearbox hydraulic motor 273 11 11 2Removal of the vibrator from an ACE drum 279 11 11 3Removal of inner bearing rings 284 11 11 4Removal of bearings 291 11 11 5Removal of the outer eccentric 295 11 11 6Removal of the inner eccentric 298 11 12Installation of the ACE vibrator 300 11 12 1Installation of the inner eccentric 300 11 12 2Installation of the outer eccentric 305 11 12 3Installation of bearings 310 11 12 4Installation of inner bearing rings 315 11 12 5Installation of the vibrator in the drum 320 11 12 6Mechanical setting of ACE system shaft and eccentric masses 328 11 12 7Installation of the ACE gearbox hydraulic cylinder 330 11 12 7 1 Linear sensor setting 336 11 12 8Installation of the damper plate – ACE drum 338 11 13Replacement of ACE drum rubber-metals 342 11 14Adjustment of the vibration frequency 346 11 15ACE PRO autocalibration 350 11 16Removal of the bearing of the standard drum and ACE drum 354 11 16 1Installation of the bearing of the standard drum and ACE drum 360 12 Cooling 367 12 1Description of basic components of the cooling hydraulics 369 12 4Removal of the cooling hydraulic motor and propeller 370 12 4 1Installation of the cooling hydraulic motor and propeller 375 12 5Removal of the cooling pump 378 12 5 1Installation of the cooling pump 381 12 6Removal of the combined cooler 383 13 Cab and platform 389 13 1Replacement of the heater ball valve 391 13 2Replacement of the heater 395 13 3Replacement of the heater fan 398 13 4Removal of the cab 403 13 4 1Installation of the cab 415 13 5Removal of the platform 427 13 5 1Installation of the platform 435 13 6Removal of the platform rubber-metals 440 14 Fuel tank 447 14 1Removal of the fuel tank 449 14 1 1Installation of the fuel tank 451 15 Sprinkling 453 15 2Removal of the sprinkling pumps 455 15 3Removal of the front water tank 458 15 3 1Installation of the sprinkling pump 463 15 3 2Installation of the front water tank 464 15 4Removal of the rear water tank 467 15 4 1Installation of the rear water tank 471 16 Electrical installation 473 16 2Measurement technique 475 16 3Safety and instructions 476 16 4Fitting of fuses 477 16 5Removal of the seat switch 478 16 6Removal of the travel lever and switches 482 16 7Adjustment of the induction sensor 486 16 8Batteries 489 16 9Alternator 491 16 9 1Removal of the alternator 494 17 Troubleshooting 497 17 1Machine error codes 498 17 2Engine error codes 501 18 Appendices 537 18 1Measuring points 539 18 1 1Conditions to measure the refilling pressure 542 18 1 2Conditions to measure the cutter pressure 543 18 1 3Conditions to measure the pressure in the steering circuit 544 18 1 4Conditions to measure the travel pressure 545 18 1 5Conditions to measure the vibration pressure 546 18 1 6Conditions to measure the pressure in the cooling circuit 549 18 2Wiring diagram ARP 95 550 18 3Wiring diagram ARP 95 ACE 556 18 4Electric installations cable harnesses 559 18 5Hydraulic system diagram ARP 95 598 18 6Hydraulic system diagram ARP 95 C 600 18 7Hydraulic system diagram ARP 95 ACE 602 18 8Hydraulic system diagram ARP 95C ACE 604 18 9Check the tightening of bolted connections 606

1 file (44.0MB)