$33.95

Ammann ARR 1575 Trench Roller Operating Manual 3001980 PDF

Ammann ARR 1575 Trench Roller YANMAR 3TNV80F-SPAMM U.S. EPA Tier 4f Operating Manual 3001980 – PDF DOWNLOAD

FILE DETAILS:

Ammann ARR 1575 Trench Roller YANMAR 3TNV80F-SPAMM U.S. EPA Tier 4f Operating Manual 3001980 – PDF DOWNLOAD

Language : English

Pages : 140

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Ammann ARR 1575 Trench Roller YANMAR 3TNV80F-SPAMM U.S. EPA Tier 4f Operating Manual 3001980 – PDF DOWNLOAD

Content 4

1 SPECIFICATION MANUAL 9

1 1 Basic Data 10

1 2 Dimension Chart 12

1 3 Technical Data 13

2 OPERATION MANUAL 17

2 1 Major Safety Precautions 19

2 1 1 Safety Measures during Machine Operation 19

2 1 1 1 Compaction Work Commencement 19

2 1 1 2 Work Safety Secured by User 19

2 1 1 3 Assurance of safety measures by the operator 20

2 1 2 Requirements on qualification of operating personnel 20

2 1 3 Driver’s obligations 21

2 1 4 Forbidden activities – safety and guarantee 22

2 1 5 Safety notices and signs applied on the machine 23

2 1 6 Safety notices and signs applied on the infrared remote control 28

2 1 7 Hand signals 29

2 2 Environmental and hygienic principles 32

2 2 1 Hygienic principles 32

2 2 2 Ecological principles 32

2 3 Machine preservation and storage 33

2 3 1 Short-term preservation and storage for a period of 1–2 months 33

2 3 2 Preservation and storage for a period longer than 2 months 33

2 3 3 Putting the machine into operation after storage 34

ARR 1575 5

OPERATING MANUAL

2 4 Disposal of the machine at the end of its service life 35

2 5 Machine description 36

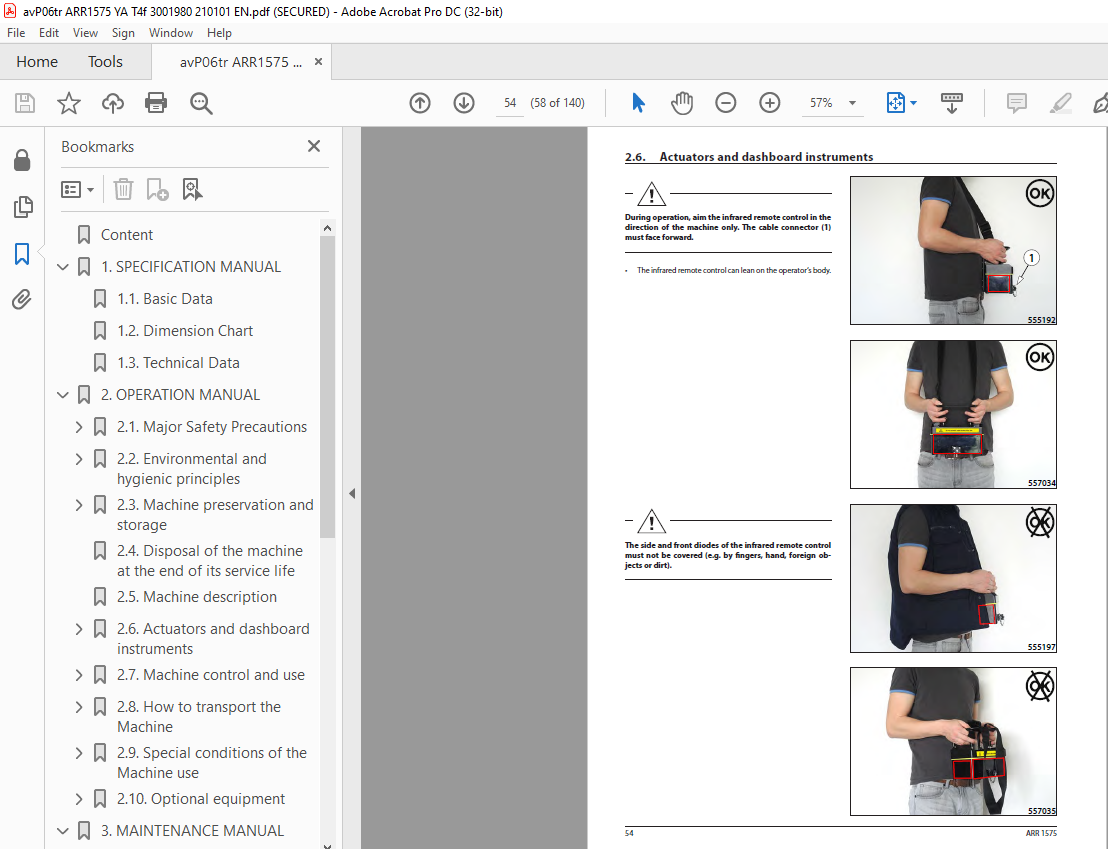

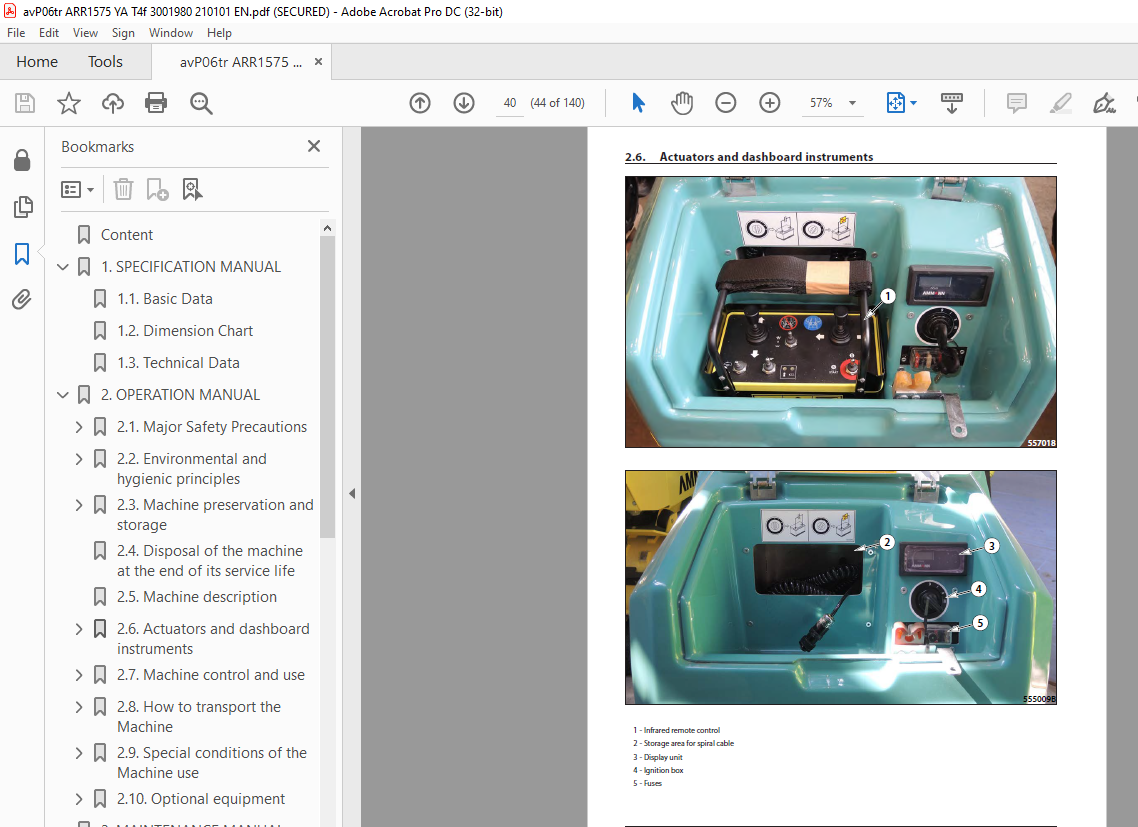

2 6 Actuators and dashboard instruments 40

2 6 1 Display unit 41

2 6 2 Infrared remote control 45

2 6 3 Light indication 58

2 7 Machine control and use 59

2 7 1 Commissioning 59

2 7 2 Protective cover 60

2 7 3 Start-up of the engine 61

2 7 4 Driving and braking 63

2 7 5 Turning off the engine 66

2 7 6 Machine parking 66

2 7 7 Opening the front and rear bonnets 67

2 7 8 ACEecon system 68

2 7 9 Telematic Readiness 68

2 7 10 Roller overturning 69

2 8 How to transport the Machine 71

2 8 1 Machine loading 72

2 8 1 1 Loading the machine using a ramp 72

2 8 1 2 Loading the machine using a crane 73

2 9 Special conditions of the Machine use 75

2 9 1 Machine operation during running-in 75

2 9 2 Machine operation at low temperatures 75

2 9 3 Machine operation under high temperatures and humidity 76

2 9 4 Machine operation at higher altitudes 76

2 9 5 Machine operation in very dusty environment 76

2 9 6 Driving with vibrations on compacted and hard materials 76

2 10 Optional equipment 77

2 10 1 Shutdown bar 77

2 10 2 Drum extension set 77

2 10 3 Filter set 500 operating hours 78

2 10 4 Cover tarpaulin 78

6 ARR 1575

Content

3 MAINTENANCE MANUAL 81

3 1 Safety and other measures for machine maintenance 83

3 1 1 Safety of machine maintenance 83

3 1 2 Fire protection measures during exchanges of operating fluids 83

3 1 3 Ecological and hygienic principles 84

3 2 Specification of fluids 85

3 2 1 Engine oil 85

3 2 2 Fuel 86

3 2 3 Coolant 87

3 2 4 Hydraulic oil 88

3 2 5 Lubricating grease 88

3 3 Fills 89

3 4 Lubrication and Maintenance Chart 90

3 5 Lubrication and service plan 92

3 6 Individual Operations of Maintenance 93

Every 10 hours of operation (daily) 94

3 6 1 Checking fuel level 94

3 6 2 Engine oil level check 95

3 6 3 Engine cooling liquid level check 96

3 6 4 Hydraulic tank oil level check 97

3 6 5 Cleaning the hydraulic oil cooler 98

3 6 6 Air filter check 99

3 6 7 Cleaning of the water separator 100

3 6 8 Scrapers 100

3 6 9 Check of the near and remote halt function 101

3 6 10 Check of the safety bar function (optional equipment) 102

3 6 11 Check of drum extension tightening screws 102

Every 50 hours of operation 103

3 6 12 Inspection of brakes 103

3 6 13 Battery check 104

Every 100 hours of operation (weekly) 105

3 6 14 Lubricating steering cylinder, bearing 105

Every 250 operating hours (3 months) 106

3 6 15 Check of the fan and engine belt condition 106

3 6 16 Replacement of engine oil and filter 107

ARR 1575 7

OPERATING MANUAL

Every 500 hours of operation (6 months) 109

3 6 17 Replacement of fuel filters 109

3 6 18 Air filter cartridge replacement 111

Every 1000 hours of operation (1 year) 113

3 6 19 Exchanging hydraulic oil and filter 113

3 6 20 Engine cooling liquid change 115

3 6 21 Cleaning the fuel tank 116

3 6 22 Valve clearance adjustment 117

3 6 23 Check of swing support 117

3 6 24 Check of articulation joint 118

3 6 25 Checking the damping system 118

Maintenance – As Needed 119

3 6 26 Replacement of engine cover gas struts 119

3 6 27 Cleaning the machine 120

3 6 28 Charging of the battery 121

3 6 29 Check of the screw connection tightening 122

3 7 Defects 125

3 8 Annexes 126

3 8 1 Wiring diagram 126

3 8 2 Hydraulic system diagram 128

3 8 3 Table of spare parts 130