$35.95

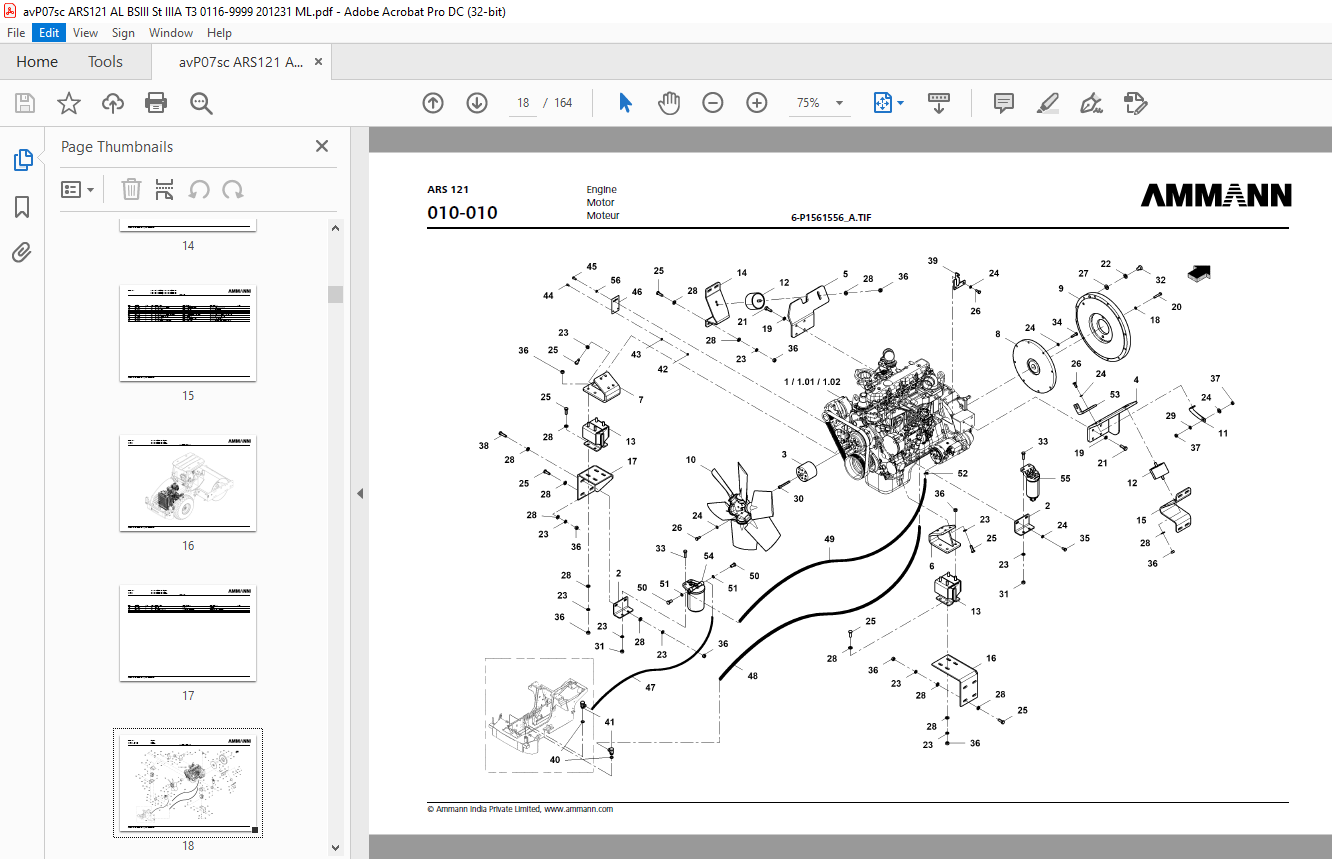

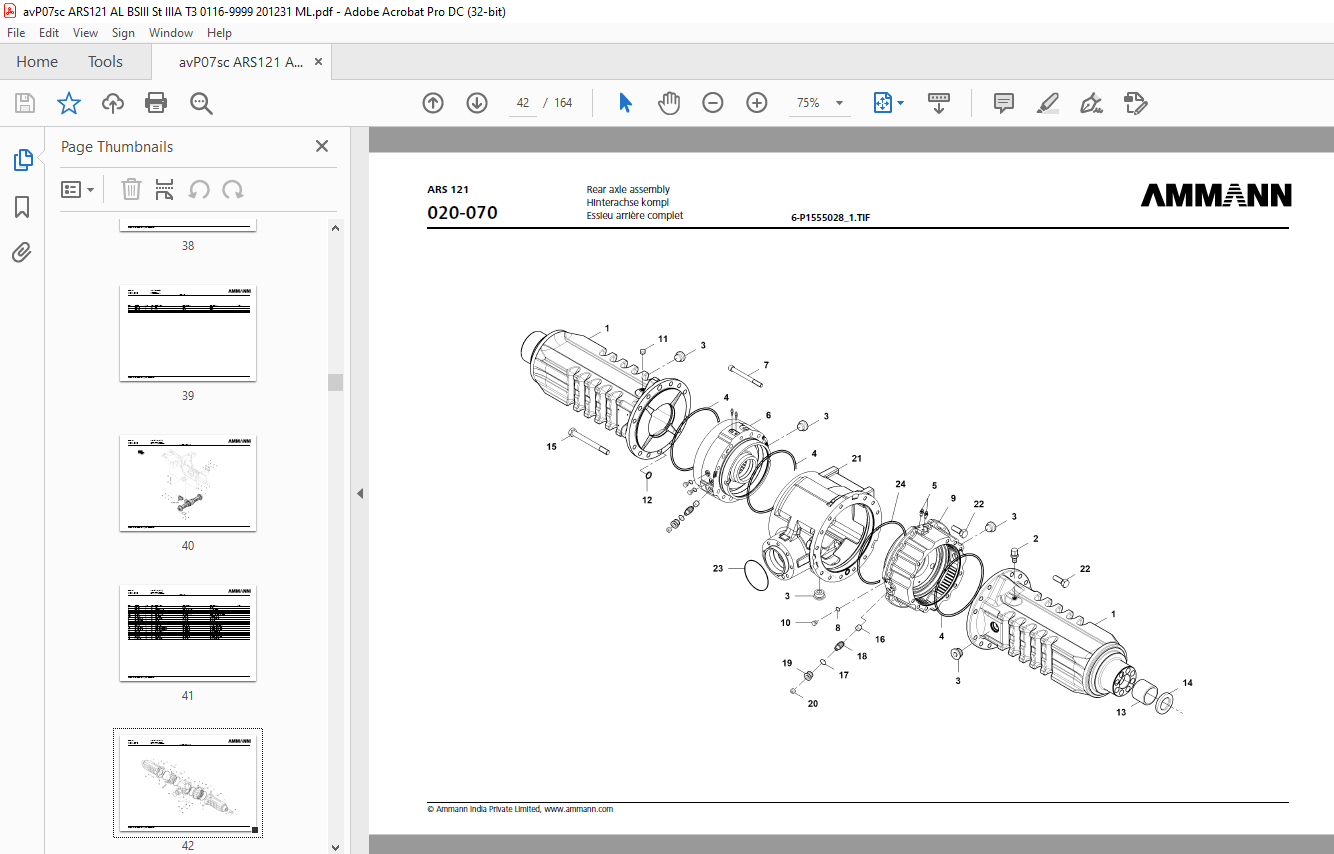

Ammann ARS 121 Single Drum Roller Parts Catalogue Manual 0116 - PDF

Ammann ARS 121 Single Drum Roller Ashok Leyland BSIII / EU STAGE IIIA / US EPA Tier 3 Parts Catalogue Manual SN 0116 – PDF DOWNLOAD

FILE DETAILS:

Ammann ARS 121 Single Drum Roller Ashok Leyland BSIII / EU STAGE IIIA / US EPA Tier 3 Parts Catalogue Manual SN 0116 – PDF DOWNLOAD

Language : English

Pages : 164

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Ammann ARS 121 Single Drum Roller Ashok Leyland BSIII / EU STAGE IIIA / US EPA Tier 3 Parts Catalogue Manual SN 0116 – PDF DOWNLOAD

1 SPECIFICATION MANUAL 13

1 1 Basic Data 14

1 2 Dimension Chart 16

1 3 Technical Data 17

2 OPERATING INSTRUCTIONS 21

2 1 Dewaxing and Inspection of a Newly Supplied Machine 22

2 2 Safety Instructions 23

2 2 1 Safety measures to operate the machine 23

2 2 1 1 How to start the compaction work 23

2 2 1 2 Work safety secured by user 23

2 2 2 Driver qualification requirements 24

2 2 3 Driver’s duties 25

2 2 4 Not permitted activities – safety and guarantee 26

2 2 5 Safety labels and signs used on the machine 27

2 2 6 Hand signals 31

2 3 Ecological and Hygienic Principles 34

2 3 1 Hygienic principles 34

2 3 2 Ecological principles 34

2 4 Preservation and Storage 35

2 4 1 Short-term preservation and storage for the period of 1 – 2 months 35

2 4 2 Machine preservation and storage for the period over 2 months 35

2 5 Machine Disposal upon Its Life Termination 36

2 6 Machine Description 37

2 6 1 Chassis 37

2 6 2 Electrical 38

2 6 2 1 Hydraulic components 40

2 7 Controlling and Operation of the Machine 42

2 7 1 Dashboard 42

2 7 1 1 Instrument cluster indications (17) 45

2 7 2 Driver’s seat 47

2 7 3 Battery cut-off switch 47

2 8 How to Control and Use the Machine 48

2 8 1 Starting the engine 48

2 8 1 1 How to start using jumper cables through different battery 49

2 8 2 Travel and reversing 50

2 8 3 Working / Moving on slopes 51

2 8 4 Travel with vibration 52

2 8 5 Emergency stop of the machine 53

2 8 6 Stopping the machine 54

2 8 7 Shutting down engine and machine 55

2 8 8 Bonnet lifting and lowering 56

2 8 9 Ballasting of tyres with liquid 58

2 9 Machine Transportation 60

2 9 1 Machine transportation by its own 60

2 9 2 Machine transportation by carrier 60

2 9 2 1 Loading the machine by crane 61

2 9 2 2 Loading the machine using a ramp 61

2 9 2 3 How to lock the steering joint 62

2 9 3 Towing of machine 63

2 9 3 1 Bypassing the hydrostatic system 64

2 9 3 2 Deactivating the bypass function 64

2 9 3 3 Parking brake disable, 3 radial screw system 65

2 9 3 4 Parking brakes enable 66

2 10 Special Conditions for the Machine Application 67

2 10 1 Vibration driving on compacted and hard materials 67

2 10 2 Machine use under extreme climatic conditions 67

2 10 2 1 Machine operation at low temperatures 67

2 10 2 2 Machine operation under high temperatures and humidity 68

2 10 2 3 Operating the machine at high altitudes 68

2 10 2 4 Machine operating at extremely dusty environment 68

3 MAINTENANCE MANUAL 73

3 1 Special Conditions for the Machine Application 74

3 1 1 Safety during machine maintenance 74

3 1 2 Fire precautions when refilling 74

3 1 3 Ecological and hygienic principles 75

3 2 Specification of Fluids 76

3 2 1 Engine oil 76

3 2 2 Fuel 77

3 2 3 Cooling liquid 77

3 2 4 Hydraulic oil 78

3 2 5 Lubricating grease 78

3 2 6 Axle – Differential and epicyclic gearbox oil 79

3 2 7 Drum cooling liquid 79

3 3 Refills 80

3 4 Lubrication and Maintenance Table 81

3 5 Lubrication and Service Plan 83

3 6 Individual Operations of Maintenance 0

Every 20 hours of operation 85

3 6 1 Engine oil level check and restoration 85

3 6 2 Coolant level check and restoration 86

3 6 3 Hydraulic oil level check and restoration 87

3 6 4 Crankcase breather inspection 88

3 6 5 Fan condition check 89

3 6 6 Engine fan belt inspection 89

3 6 7 Engine air intake system inspection 90

3 6 8 Fuel level check and refilling 91

3 6 9 Drain fuel filter cum water separator 92

3 6 10 Alarm and control devices check 93

Every 150 hours of operation 94

3 6 11 Tyre pressure check 94

Every 250 hours of operation 95

3 6 12 Engine mounts and fasteners inspection 95

3 6 13 Replacement of fuel filter (mud filter) 96

3 6 14 Battery check 98

3 6 15 Air filter vacuum switch function check 99

3 6 16 Machine lubrication 100

3 6 17 Vibrator assembly oil level check 102

3 6 18 Axle – Epicyclic gearboxes oil level check 103

3 6 19 Axle – Differential gearboxes gearbox oil level check 104

Every 500 hours of operation 105

3 6 20 Engine oil change 105

3 6 20 1 Engine oil filter replacement 105

3 6 21 Fuel filter cum water separator replacement 108

3 6 22 Coolant level check 110

3 6 23 Wiring check 110

3 6 24 Wheel bolts tightening check 111

Every 1000 hours of operation 112

3 6 25 Air filter element replacement 112

3 6 26 Engine valve clearance adjustment 114

3 6 27 Engine fan belt tension check 114

3 6 28 Vibration damping pad condition inspection 116

3 6 29 Fuel tank cleaning 117

Every 1500 hours of operation 118

3 6 30 Axle – Differential oil change 118

3 6 31 Axle – Epicyclic gearbox oil change 119

Every 2000 hours of operation 120

3 6 32 Vibrator casing oil change 120

3 6 33 Hydraulic oil, suction line filter cartridge and strainer replacement 121

3 6 34 Coolant change 125

Maintenance – As needed 127

3 6 35 Drum cooling liquid (optional) 127

3 6 36 Coolant, oil and air cooler cleaning 128

3 6 37 Air purging from fuel system 129

3 6 38 Scraper adjustment 131

3 6 39 Battery charging 132

3 6 40 Machine Cleaning 133

3 6 41 Screwed connections check 133

3 7 Schematics 136

3 7 1 Electrical schematic 136

3 7 2 Hydraulic schematic 137

3 8 General Information 138

3 8 1 Acronyms and abbreviations 138