$35.95

Ammann ARS 122 Single Drum Roller Operating Manual 0059-0062 PDF

Ammann ARS 122 Single Drum Roller Cummins BS III Operating Manual SN 0059-0062 – PDF DOWNLOAD

FILE DETAILS:

Ammann ARS 122 Single Drum Roller Cummins BS III Operating Manual SN 0059-0062 – PDF DOWNLOAD

Language : English

Pages : 136

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Ammann ARS 122 Single Drum Roller Cummins BS III Operating Manual SN 0059-0062 – PDF DOWNLOAD

Content 8

1 SPECIFICATION MANUAL 13

1 1 Basic Data 14

1 2 Dimension Chart 16

1 3 Technical Data 17

2 OPERATING INSTRUCTIONS 23

2 1 Dewaxing and Inspection of a Newly Supplied Machine 24

2 2 Safety Instructions 25

2 2 1 Safety measures to operate the Machine 25

2 2 1 1 How to start the compaction work 25

2 2 1 2 Work safety secured by User 25

2 2 2 Driver Qualification Requirements 26

2 2 3 Driver’s Duties 27

2 2 4 Forbidden activities – safety and guarantee 28

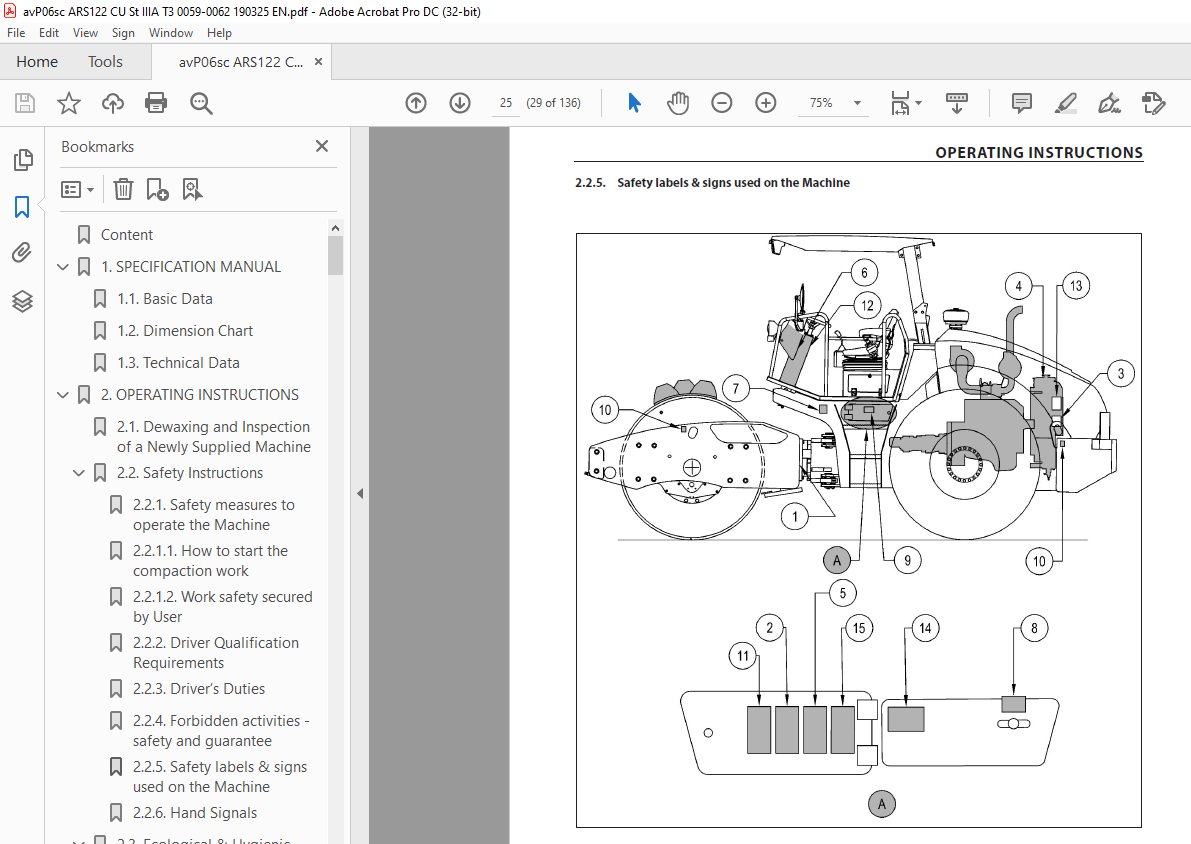

2 2 5 Safety labels & signs used on the Machine 29

2 2 6 Hand Signals 32

2 3 Ecological & Hygienic Principles 35

2 3 1 Hygienic Principles 35

2 3 2 Ecological Principles 35

2 4 Preservation & Storage 36

2 4 1 Short-term preservation & storage for the period of 1 – 2 months 36

2 4 2 Machine preservation & storage for the period over 2 months 36

2 5 Machine disposal upon its life termination 37

2 6 Machine Description 38

2 7 Controlling and operation of the machine 39

2 8 How to Control and Use the Machine 45

2 8 1 Start the Engine 45

2 8 2 Travel & Reversing 47

2 8 3 Travel with vibration 49

2 8 4 Emergency stop of the Machine 50

2 8 5 Stop the Machine & the Engine 51

2 8 6 Machine Shutdown 52

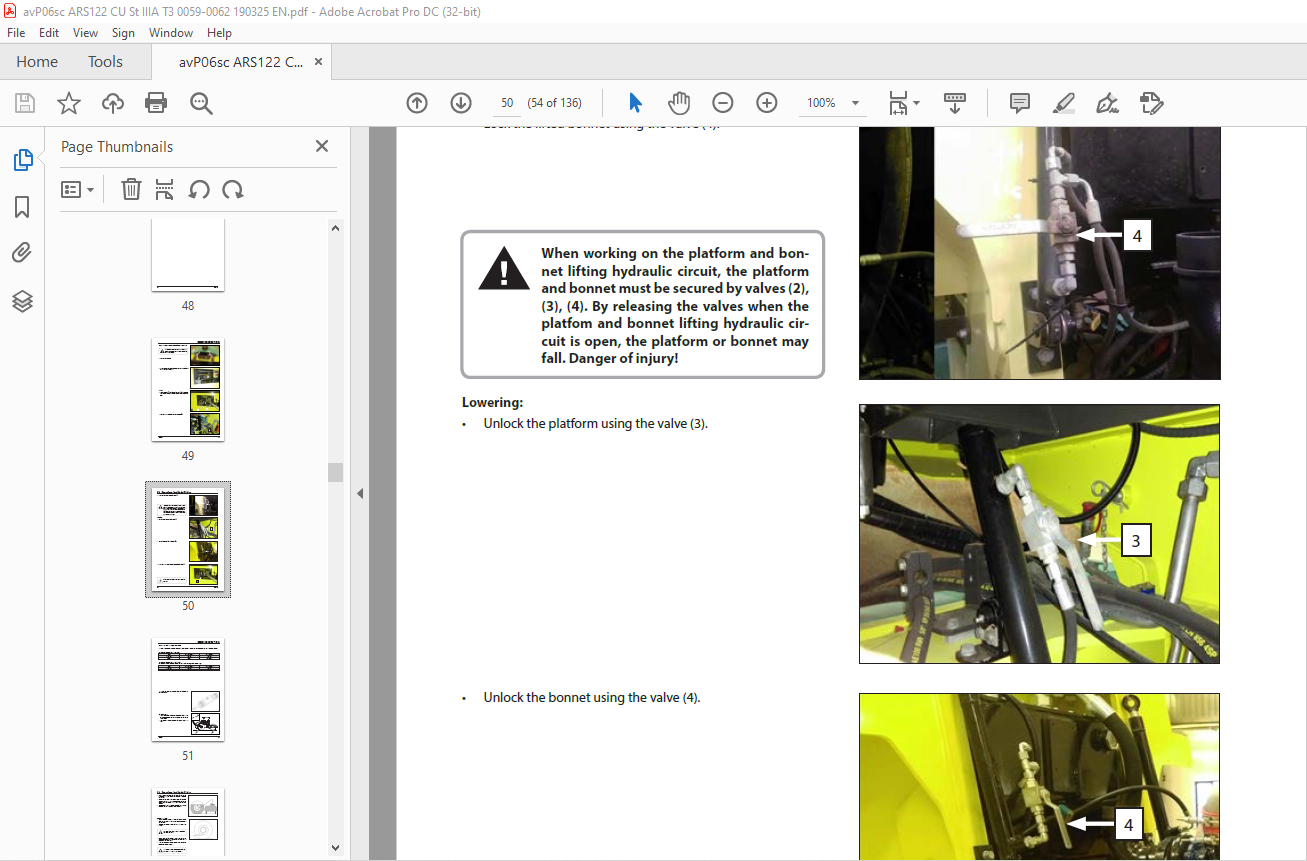

2 8 7 Platform & Bonnet raising and lowering 53

2 8 8 Ballasting of tyres with liquid 55

2 9 Machine Transportation 57

2 9 1 Machine transportation by its own axle 57

2 9 2 Machine transportation by public road 57

2 9 3 How to load the machine 58

2 9 3 1 Loading the machine using a ramp 58

2 9 4 Towing of Machine 60

2 10 Special Conditions for the Machine Application 66

2 10 1 Vibration driving on compacted and hard materials 66

2 10 2 Machine use under heavy climatic conditions 66

2 10 2 1 Machine operation under low temperatures 66

2 10 2 2 Machine operation under high temperatures and humidity 67

2 10 2 3 Operating the Machine at high altitudes 67

2 10 2 4 Machine operation at extremely dusty environment 67

3 MAINTENANCE MANUAL 71

3 1 Special Conditions for the Machine Application 73

3 1 1 Safety during Machine Maintenance 73

3 1 2 Fire precautions when refilling 73

3 1 3 Ecological & Hygienic Principles 74

3 2 Specification of fluids 75

3 2 1 Engine Oil 75

3 2 2 Fuel 76

3 2 3 Cooling Liquid 76

3 2 4 Hydraulic Oil 77

3 2 5 Gearbox Oil 78

3 2 6 Lubricating Grease 78

3 3 Refills 79

3 4 Lubrication & Maintenance Table 80

3 5 Lubrication and service plan 82

3 6 Individual Operations of Maintenance 83

Every 20 Hours of Operation or Daily 84

3 6 1 Check the oil amount in engine 84

3 6 2 Check the amount of cooling liquid in the System 85

3 6 3 Check the amount of oil inside hydraulic tank 86

3 6 4 Crankcase breather 87

3 6 5 Check fan condition 88

3 6 6 Check engine belt 88

3 6 7 Check engine air intake 89

3 6 8 Check the amount of fuel 90

3 6 9 How to clean water separator 91

3 6 10 Check the alarm & control devices 92

Every 100 Hours 93

3 6 11 Check tire pressure 93

Every 250 Hours or Once in 3 Months 94

3 6 12 How to replace oil in the engine 94

3 6 13 Check the fixing of the engine 97

3 6 14 Battery check 98

3 6 15 Check the function of Air Filter Vacuum Switch 99

3 6 16 Machine Lubrication 100

3 6 17 How to check oil inside vibrator 102

3 6 18 How to check oil in gearboxes 103

Every 500 Hours or Once in 6 Months 104

3 6 19 Replacement of fuel filter of the engine 104

3 6 20 Cooling liquid inspection 106

3 6 21 Check of wiring 106

3 6 22 Exchanging cleaner element of air cleaner 107

3 6 23 Check if wheel bolts are tightened 109

3 6 24 Change oil in the gearboxes 109

Every 1000 Hours or Once in Year 111

3 6 25 Check, adjust valve clearance 111

3 6 26 How to check tightening pulley and belt of the engine 111

3 6 27 Inspect the damping system 113

3 6 28 How to clean fuel tank 114

Every 2000 Hours or Every 2 Years 115

3 6 29 How to change oil in the vibrator 115

3 6 30 How to change hydraulic oil and filter 116

3 6 31 How to change engine coolant 120

Maintenance – As Needed 122

3 6 32 How to clean engine cooler and hydraulic oil 122

3 6 33 How to deaerate fuel system 123

3 6 34 How to adjust the scrapers 125

3 6 35 How to clean the Machine 126

3 6 36 Check bolted connections 126

3 7 Defects 129

3 8 Appendixes 130

3 8 1 Wiring Diagram 130

3 8 2 Hydraulic Diagram 132

ARS122_1_2017-04 pdf 0

Content 0

1 SPECIFICATION MANUAL 0

1 1 Basic Data 0

1 2 Dimension Chart 0

1 3 Technical Data 0

2 OPERATING INSTRUCTIONS 0

2 1 Dewaxing and Inspection of a Newly Supplied Machine 1

2 2 Safety Instructions 2

2 2 1 Safety measures to operate the Machine 2

2 2 1 1 How to start the compaction work 2

2 2 1 2 Work safety secured by User 2

2 2 2 Driver Qualification Requirements 3

2 2 3 Driver’s Duties 4

2 2 4 Forbidden activities – safety and guarantee 5

2 2 5 Safety labels & signs used on the Machine 6

2 2 6 Hand Signals 9

2 3 Ecological & Hygienic Principles 12

2 3 1 Hygienic Principles 12

2 3 2 Ecological Principles 12

2 4 Preservation & Storage 13

2 4 1 Short-term preservation & storage for the period of 1 – 2 months 13

2 4 2 Machine preservation & storage for the period over 2 months 13

2 5 Machine disposal upon its life termination 14

2 6 Machine Description 15

2 7 Controlling and operation of the machine 16

2 8 How to Control and Use the Machine 22

2 8 1 Start the Engine 22

2 8 2 Travel & Reversing 24

2 8 3 Travel with vibration 26

2 8 4 Emergency stop of the Machine 27

2 8 5 Stop the Machine & the Engine 28

2 8 6 Machine Shutdown 29

2 8 7 Platform & Bonnet raising and lowering 30

2 8 8 Ballasting of tyres with liquid 32

2 9 Machine Transportation 34

2 9 1 Machine transportation by its own axle 34

2 9 2 Machine transportation by public road 34

2 9 3 How to load the machine 35

2 9 3 1 Loading the machine using a ramp 35

2 9 4 Towing of Machine 37

2 10 Special Conditions for the Machine Application 43

2 10 1 Vibration driving on compacted and hard materials 43

2 10 2 Machine use under heavy climatic conditions 43

2 10 2 1 Machine operation under low temperatures 43

2 10 2 2 Machine operation under high temperatures and humidity 44

2 10 2 3 Operating the Machine at high altitudes 44

2 10 2 4 Machine operation at extremely dusty environment 44

3 MAINTENANCE MANUAL 0

3 1 Special Conditions for the Machine Application 2

3 1 1 Safety during Machine Maintenance 2

3 1 2 Fire precautions when refilling 2

3 1 3 Ecological & Hygienic Principles 3

3 2 Specification of fluids 4

3 2 1 Engine Oil 4

3 2 2 Fuel 5

3 2 3 Cooling Liquid 5

3 2 4 Hydraulic Oil 6

3 2 5 Gearbox Oil 7

3 2 6 Lubricating Grease 7

3 3 Refills 8

3 4 Lubrication & Maintenance Table 9

3 5 Lubrication and service plan 11

3 6 Individual Operations of Maintenance 12

Every 20 Hours of Operation or Daily 13

3 6 1 Check the oil amount in engine 13

3 6 2 Check the amount of cooling liquid in the System 14

3 6 3 Check the amount of oil inside hydraulic tank 15

3 6 4 Crankcase breather 16

3 6 5 Check fan condition 17

3 6 6 Check engine belt 17

3 6 7 Check engine air intake 18

3 6 8 Check the amount of fuel 19

3 6 9 How to clean water separator 20

3 6 10 Check the alarm & control devices 21

Every 100 Hours 22

3 6 11 Check tire pressure 22

Every 250 Hours or Once in 3 Months 23

3 6 12 How to replace oil in the engine 23

3 6 13 Check the fixing of the engine 26

3 6 14 Battery check 27

3 6 15 Check the function of Air Filter Vacuum Switch 28

3 6 16 Machine Lubrication 29

3 6 17 How to check oil inside vibrator 31

3 6 18 How to check oil in gearboxes 32

Every 500 Hours or Once in 6 Months 33

3 6 19 Replacement of fuel filter of the engine 33

3 6 20 Cooling liquid inspection 35

3 6 21 Check of wiring 35

3 6 22 Exchanging cleaner element of air cleaner 36

3 6 23 Check if wheel bolts are tightened 38

3 6 24 Change oil in the gearboxes 38

Every 1000 Hours or Once in Year 40

3 6 25 Check, adjust valve clearance 40

3 6 26 How to check tightening pulley and belt of the engine 40

3 6 27 Inspect the damping system 42

3 6 28 How to clean fuel tank 43

Every 2000 Hours or Every 2 Years 44

3 6 29 How to change oil in the vibrator 44

3 6 30 How to change hydraulic oil and filter 45

3 6 31 How to change engine coolant 49

Maintenance – As Needed 51

3 6 32 How to clean engine cooler and hydraulic oil 51

3 6 33 How to deaerate fuel system 52

3 6 34 How to adjust the scrapers 54

3 6 35 How to clean the Machine 55

3 6 36 Check bolted connections 55

3 7 Defects 58

3 8 Appendixes 59

3 8 1 Wiring Diagram 59

3 8 2 Hydraulic Diagram 61