$32.95

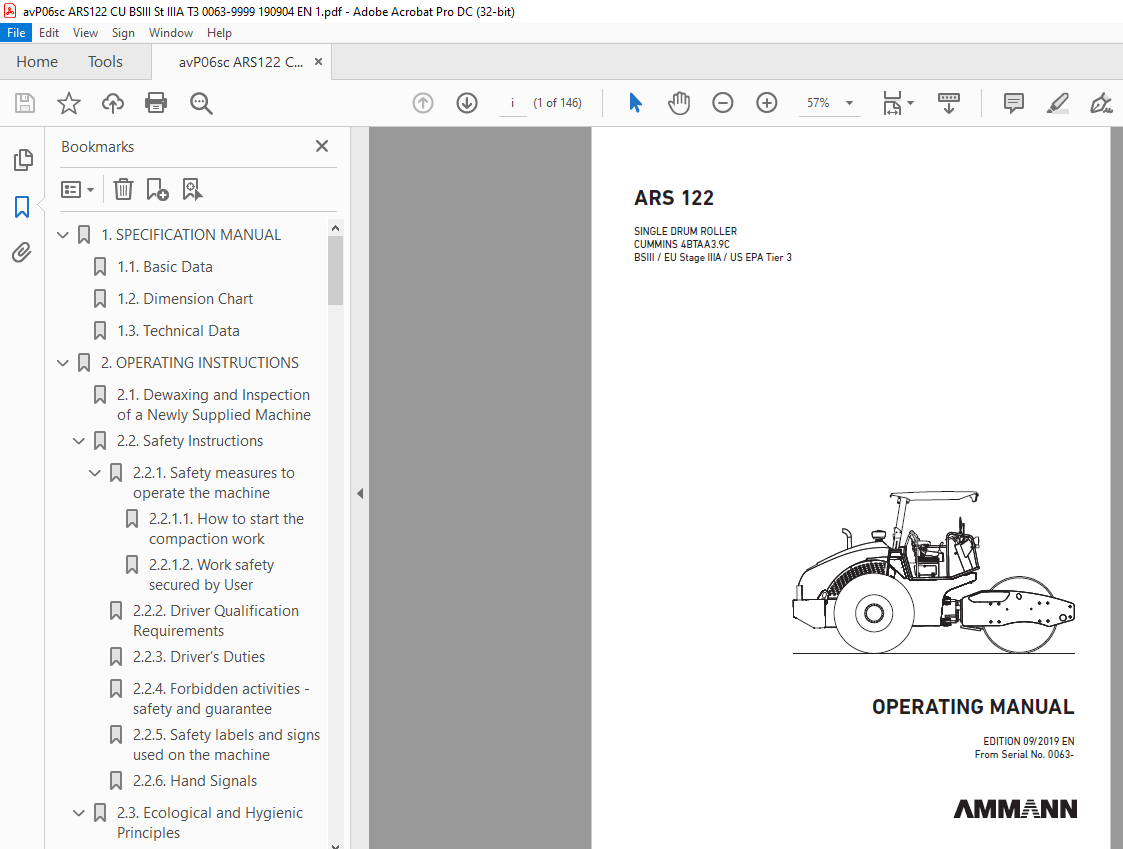

Ammann ARS 122 Single Drum Roller Operating Manual 0063 - PDF

Ammann ARS 122 Single Drum Roller Cummins BS III Operating Manual SN 0063 – PDF DOWNLOAD

FILE DETAILS:

Ammann ARS 122 Single Drum Roller Cummins BS III Operating Manual SN 0063 – PDF DOWNLOAD

Language : English

Pages : 146

Downloadable : Yes

File Type : PDF

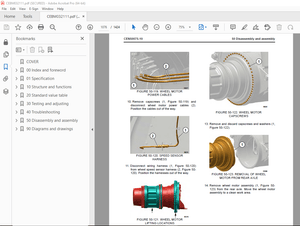

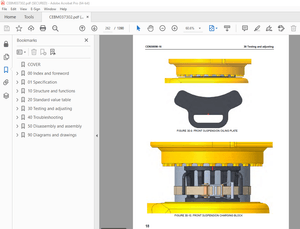

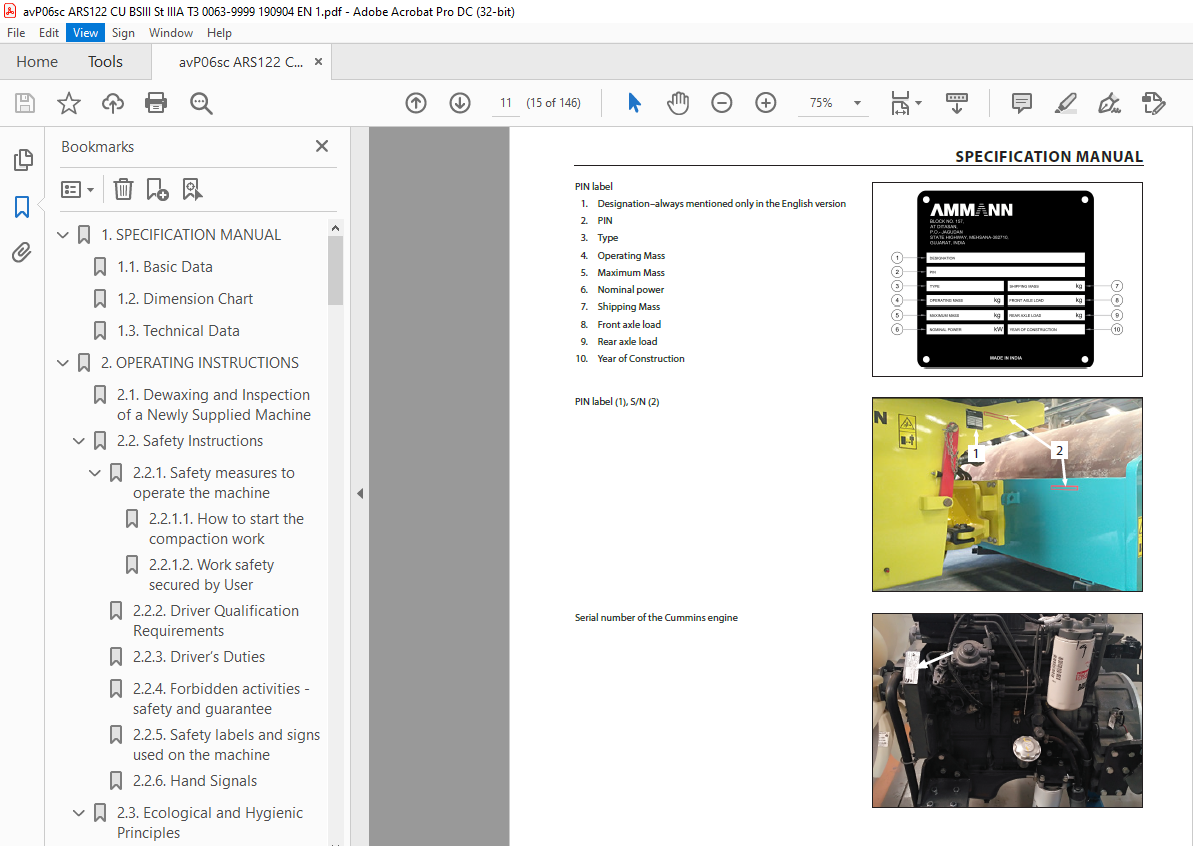

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Ammann ARS 122 Single Drum Roller Cummins BS III Operating Manual SN 0063 – PDF DOWNLOAD

1 SPECIFICATION MANUAL 13

1 1 Basic Data 14

1 2 Dimension Chart 16

1 3 Technical Data 17

2 OPERATING INSTRUCTIONS 23

2 1 Dewaxing and Inspection of a Newly Supplied Machine 24

2 2 Safety Instructions 25

2 2 1 Safety measures to operate the machine 25

2 2 1 1 How to start the compaction work 25

2 2 1 2 Work safety secured by User 25

2 2 2 Driver Qualification Requirements 26

2 2 3 Driver’s Duties 27

2 2 4 Forbidden activities – safety and guarantee 28

2 2 5 Safety labels and signs used on the machine 29

2 2 6 Hand Signals 33

2 3 Ecological and Hygienic Principles 36

2 3 1 Hygienic Principles 36

2 3 2 Ecological Principles 36

2 4 Preservation and Storage 37

2 4 1 Short-term preservation and storage for the period of 1 – 2 months 37

2 4 2 Machine preservation and storage for the period over 2 months 37

2 5 Machine Disposal upon its Life Termination 38

2 6 Machine Description 39

2 6 1 Chassis 39

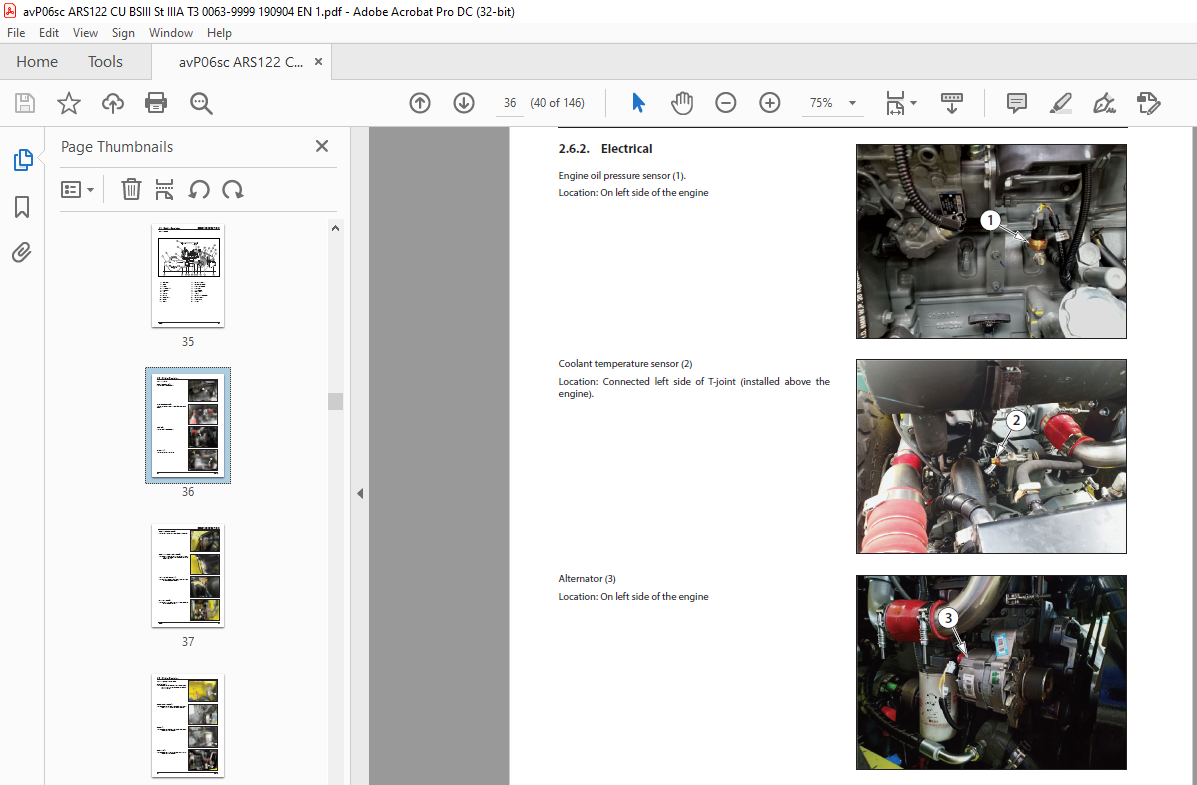

2 6 2 Electrical 40

2 6 2 1 Hydraulic components 42

2 7 Controlling and Operation of the Machine 44

2 7 1 Dashboard and Control Panel 44

2 7 1 1 Instrument cluster indications (17) 47

2 7 2 Driver’s seat 49

2 7 3 Battery cut-off switch 49

2 8 How to Control and Use the Machine 50

2 8 1 Starting the engine 50

2 8 1 1 Normal Starting 50

2 8 1 2 Starting engine with jumper cables through different battery 51

2 8 1 3 Starting engine at low temperature 51

2 8 2 Travel and reversing 52

2 8 3 Working / Moving on slopes 53

2 8 4 Travel with vibration 54

2 8 5 Emergency stop of the machine 55

2 8 6 Stopping the machine 56

2 8 7 Machine Shutdown 57

2 8 8 Cab control’s and accessories (Optional) 58

2 8 9 Platform/Bonnet raising and lowering 62

2 8 10 Ballasting of tyres with liquid 64

2 9 Machine Transportation 66

2 9 1 Machine transportation by its own axle 66

2 9 2 Machine transportation by public road 66

2 9 3 Loading the machine by crane 67

2 9 3 1 Loading the machine using a ramp 67

2 9 4 Towing of machine 69

2 10 Special Conditions for the Machine Application 75

2 10 1 Vibration driving on compacted and hard surface 75

2 10 2 Machine use under extreme climatic conditions 75

2 10 2 1 Machine operation under low temperatures 75

2 10 2 2 Machine operation under high temperatures and humidity 76

2 10 2 3 Operating the machine at high altitudes 76

2 10 2 4 Machine operation at extremely dusty environment 76

3 MAINTENANCE MANUAL 79

3 1 Special Conditions for the Machine Application 80

3 1 1 Safety during machine maintenance 80

3 1 2 Fire precautions when refilling 80

3 1 3 Ecological and hygienic principles 81

3 2 Specification of Fluids 82

3 2 1 Engine oil 82

3 2 2 Fuel 83

3 2 3 Cooling liquid 83

3 2 4 Hydraulic oil 84

3 2 5 Gearbox oil 85

3 2 6 Lubricating grease 85

3 2 7 Screen washer liquid 85

3 2 8 Air-conditioning filling 85

3 2 9 Drum cooling liquid 85

3 3 Refills 86

3 4 Lubrication and Maintenance Table 87

3 5 Lubrication and service plan 89

3 6 Individual Operations of Maintenance 90

Every 20 Hours of Operation 91

3 6 1 Engine oil level check and restoration 91

3 6 2 Coolant level check and restoration 92

3 6 3 Hydraulic oil level check and restoration 93

3 6 4 Crankcase breather tube 94

3 6 5 Fan condition check 95

3 6 6 Engine fan belt inspection 95

3 6 7 Engine air intake system inspection 96

3 6 8 Fuel level check and refilling 97

3 6 9 Drain water from water in fuel separator 98

3 6 10 Alarm and control devices check 99

3 6 11 Tyre pressure check 100

Every 150 hours of operation 101

3 6 12 Oil level check in drive gearboxes 101

Every 250 hours of operation 102

3 6 13 Replacement of fuel filters (mud strainer and water separator) 102

3 6 14 Engine oil and oil filter replacement 104

3 6 15 Engine mounts and fasteners inspection 107

3 6 16 Battery check 108

3 6 17 Air filter vacuum switch function check 109

3 6 18 Machine lubrication 110

3 6 19 Vibrator assembly oil level check 113

Every 500 hours of operation 114

3 6 20 Hydraulic oil filter replacement 114

3 6 21 Wiring check 115

3 6 22 Air filter of the air conditioning system replacement 115

3 6 23 Wheel bolts tightening check 116

3 6 24 Cab ventilation and heating filters replacement 117

Every 1000 hours of operation 118

3 6 25 Air filter element replacement 118

3 6 26 Engine valve clearance adjustment 120

3 6 27 Engine pulley and belt tension check 120

3 6 28 Air conditioner compressor mounting check 122

3 6 29 Drive gearboxes oil change 122

3 6 30 Vibration damping pad condition inspection 124

3 6 31 Fuel tank cleaning 125

Every 2000 hours of operation 126

3 6 32 Vibrator casing oil change 126

3 6 33 Hydraulic oil, suction line filter cartridge and strainer replacement 127

3 6 34 Coolant change 131

3 6 35 Air conditioning system cleaning 133

Maintenance – As Needed 134

3 6 36 Coolant, oil and air cooler cleaning 134

3 6 37 Bleeding air from fuel system 135

3 6 38 Scraper adjustment 137

3 6 39 Drum cooling mixture (Optional) 138

3 6 40 Machine Cleaning 139

3 6 41 Screwed connections check 139

3 7 Schematics 142

3 7 1 Electrical schematic 142

3 7 2 Hydraulic schematic 143

3 8 General Information 144

3 8 1 Acronyms and Abbreviations 144