$34.95

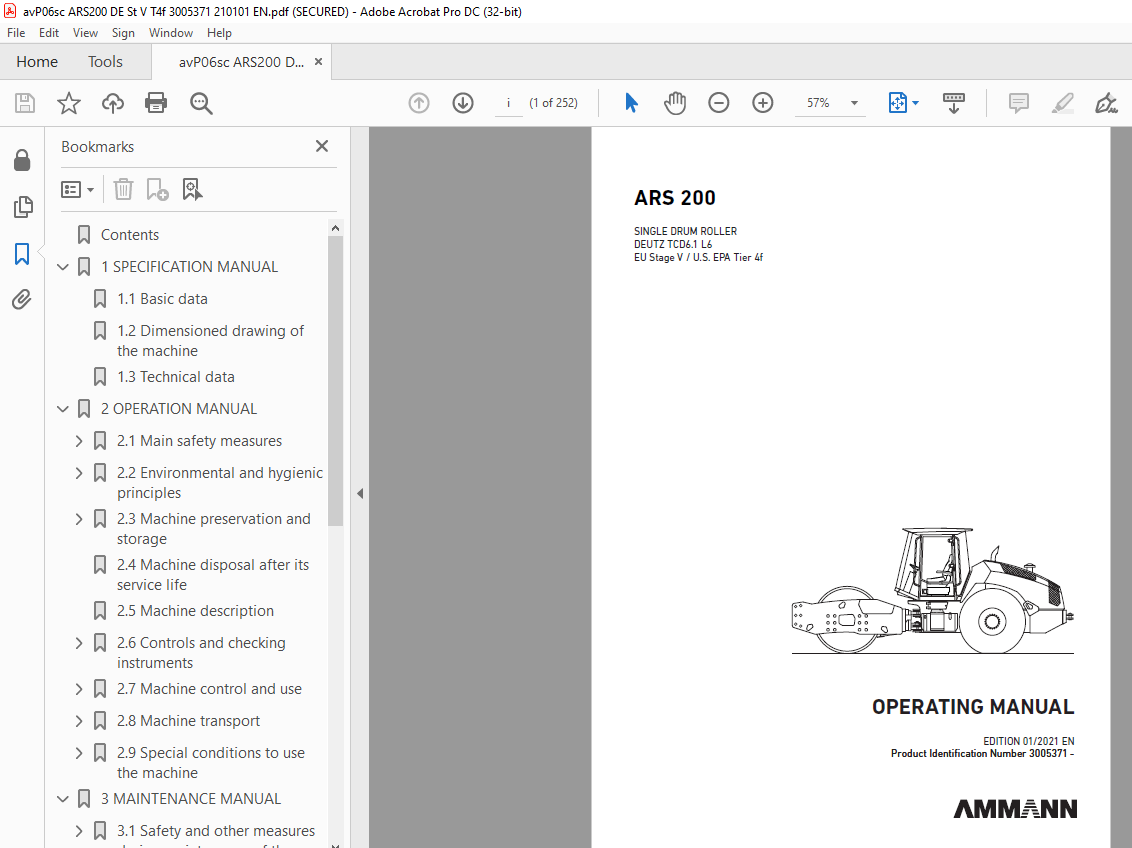

Ammann ARS 200 Single Drum Roller Operating Manual 3005371 PDF

Ammann ARS 200 Single Drum Roller Deutz TCD6.1 L6 EU Stage V / U.S. EPA Tier 4f Operating Manual 3005371 – PDF DOWNLOAD

FILE DETAILS:

Ammann ARS 200 Single Drum Roller Deutz TCD6.1 L6 EU Stage V / U.S. EPA Tier 4f Operating Manual 3005371 – PDF DOWNLOAD

Language : English

Pages : 252

Downloadable : Yes

File Type : PDF

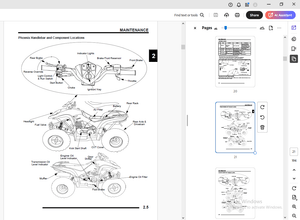

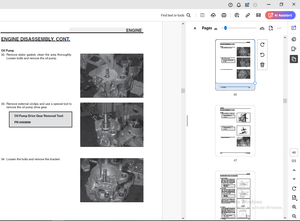

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Ammann ARS 200 Single Drum Roller Deutz TCD6.1 L6 EU Stage V / U.S. EPA Tier 4f Operating Manual 3005371 – PDF DOWNLOAD

Contents 8

1 SPECIFICATION MANUAL 13

1 1Basic data 14

1 2Dimensioned drawing of the machine 16

1 3Technical data 18

2 OPERATION MANUAL 23

2 1Main safety measures 25

2 1 1Safety measures during machine operation 25

2 1 1 1Before compacting works are started 25

2 1 1 2Work in the dangerous area 25

2 1 1 3Ensurance of safety measures by the owner 26

2 1 1 4Cab with integrated ROPS 26

2 1 2Requirements for the driver´s qualification 27

2 1 3Driver’s obligations 28

2 1 4Forbidden activities – safety and guarantee 29

2 1 5Safety notices and signs applied on the machine 31

2 1 6Hand signals 35

2 2Environmental and hygienic principles 38

2 2 1Hygienic principles 38

2 2 2Ecological principles 38

2 3Machine preservation and storage 39

2 3 1Short-term preservation and storage for 1–2 months 39

2 3 2Preservation and storage for more than 2 months 39

2 3 3Removal of preservation and inspection of the delivered machine 40

2 4Machine disposal after its service life 41

2 5Machine description 42

2 6Controls and checking instruments 44

2 6 1Display control – operation screen 64

2 6 2Display control – Information screen 70

2 6 3Display control – service screen 74

2 6 4Display disconnected 77

2 7Machine control and use 78

2 7 1Start-up of the engine 79

2 7 2Travel and reversing 83

2 7 3Stopping the machine and engine 89

2 7 4Machine emergency stop 89

2 7 5Machine parking 91

2 7 6Cab and ROPS lifting and lowering 92

2 7 7Ballasting of tyres with liquid 94

2 7 8Telematic Readiness 95

2 7 7ACE Force 96

2 7 7 1Parameters setting screen 98

2 7 7 2Double drum rebound 99

2 8Machine transport 100

2 8 1Loading the machine 101

2 8 1 1Loading the machine using a ramp 101

2 8 1 2Loading the machine with a crane 102

2 9Special conditions to use the machine 103

2 9 1Safety function and emergency mode of the machine (limp mode) 103

2 9 1 1Symbols shown on the display 104

2 9 1 2Switching to the emergency (limp) mode 105

2 9 1 3Deactivation of the emergency (limp) mode 106

2 9 2Towing the machine 107

2 9 3Operating the machine during initial run period 112

2 9 4Operating the machine at low temperatures 112

2 9 5Machine operation under high temperatures and humidity 112

2 9 6Machine operation at high altitudes 112

2 9 7Machine operation in a very dusty environment 112

2 9 8Driving with vibration on compacted and hard materials 112

3 MAINTENANCE MANUAL 115

3 1Safety and other measures during maintenance of the machine 117

3 1 1Safety during maintenance of the machine 117

3 1 2Fire protection when operating fluids are changed 117

3 1 3Environmental and hygienic principles 118

3 2Specification of operating fluids 119

3 2 1Engine oil 119

3 2 2Fuel 120

3 2 3Coolant 120

3 2 4Hydraulic oil 121

3 2 5Gear oil 121

3 2 6DEF (AdBlue) 122

3 2 7Lubricating grease 122

3 2 8Drum coolant 122

3 2 9Windscreen washer fluid 122

3 2 10Air-conditioning fluids 122

3 2 11Vibrator oil 122

3 3Fluids 123

3 4 Lubrication and Maintenance Chart 124

3 5Lubrication and service plan 127

3 6Lubrication and maintenance operations 128

Every 20 hours of operation (daily) 129

3 6 1Engine oil level check 129

3 6 2Engine coolant level check 130

3 6 3Hydraulic oil level check 131

3 6 4Crankcase ventilation 132

3 6 5Fan inspection 132

3 6 6Inspection of dust valve of the air filter 133

3 6 7Fuel level check 134

3 6 8Cleaning the water separator of fuel filter 135

3 6 9Check of warning and checking devices 136

3 6 10Engine leakage inspection 138

3 6 11Exhaust system leakage inspection 138

3 6 12DEF (AdBlue) level check 139

3 6 13Brake test 142

3 6 13 1Check of the parking brake 142

3 6 13 2Check of the emergency brake 143

3 6 13 3Check of the service brake 144

Every 100 hours of operation (weekly) 145

3 6 14Checking pressure in tyres 145

Every 250 hours of operation (3 months) 146

3 6 15Engine cooling circuit inspection 146

3 6 16Air filter sensor check 148

3 6 17Machine lubrication 150

3 6 18Vibrator oil check 154

3 6 19Travel gearbox oil check 155

3 6 20Checking pad-foot segments 157

3 6 21Seat switch check 157

Every 500 hours of operation (6 months) 158

3 6 22Engine oil change 158

3 6 23Engine coolant level check 161

3 6 24(Air-conditioning) belt check 162

3 6 25DEF (AdBlue) filter replacement 163

3 6 26Fuel filter replacement 165

3 6 27Air filter element replacement 167

3 6 28Checking wheel screws for tightening 170

3 6 29Cleaning the cab ventilation filter 170

3 6 30Wiring inspection 170

Every 1000 hours of operation (1 year) 171

3 6 31Intake manifold inspection 171

3 6 32Battery inspection 172

3 6 33Engine belt inspection 174

3 6 34Engine belt tensioner check 175

3 6 35Travel gearbox oil change 175

3 6 36Shock-absorbing system inspection 177

3 6 37Cleaning the fuel tank 179

3 6 38Engine inspection 180

3 6 39Engine and machine diagnostics 180

Every 2000 hours of operation (2 years) 181

3 6 40Vibrator oil change 181

3 6 41Cleaning and checking the air conditioning system 182

3 6 42Hydraulic oil change and filter replacement 183

3 6 43Cleaning the suction filter of the cab and bonnet lifting and lowering unit 189

3 6 44Valve clearance check, adjustment 190

3 6 45Vent plug replacement 190

Every 6000 hours of operation (4 years) 191

3 6 46Engine coolant change 191

Maintenance – As Needed 194

3 6 47Cooler cleaning 194

3 6 48Fuel system venting 195

3 6 49Machine cleaning 196

3 6 50Scraper adjustment 197

3 6 51DPF clogging regeneration (Diesel Particulate Filter) 198

3 6 52Charging of the battery 199

3 6 53Checking screw connections for tightening 200

3 7Defects 203

3 7 1Machine errors 204

3 7 2Errors due to safety functions 206

3 7 3Errors at the inputs 207

3 7 4Errors at the outputs 208

3 7 5ACE errors 209

3 7 6System errors 210

3 7 7Engine errors 211

3 8Annexes 236

Wiring diagram 236

Hydraulic system diagram – RTM 244

Table of spare parts 246