Starting from:

$34.95

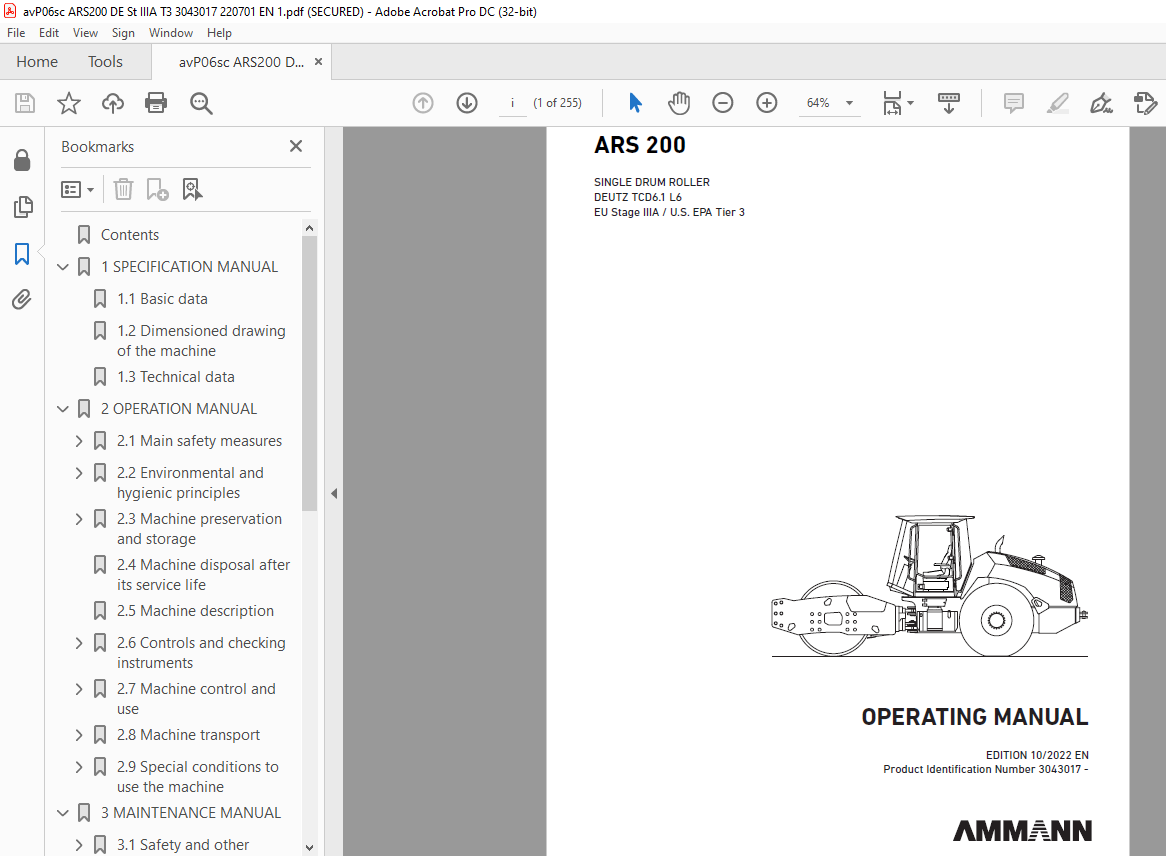

Ammann ARS 200 Single Drum Roller Operating Manual 3043017 - PDF

Ammann ARS 200 Single Drum Roller Deutz TCD6.1 L6 EU Stage IIIA / U.S. EPA Tier 3 Operating Manual 3043017 – PDF DOWNLOAD

FILE DETAILS:

Ammann ARS 200 Single Drum Roller Deutz TCD6.1 L6 EU Stage IIIA / U.S. EPA Tier 3 Operating Manual 3043017 – PDF DOWNLOAD

Language : English

Pages :255

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Ammann ARS 200 Single Drum Roller Deutz TCD6.1 L6 EU Stage IIIA / U.S. EPA Tier 3 Operating Manual 3043017 – PDF DOWNLOAD

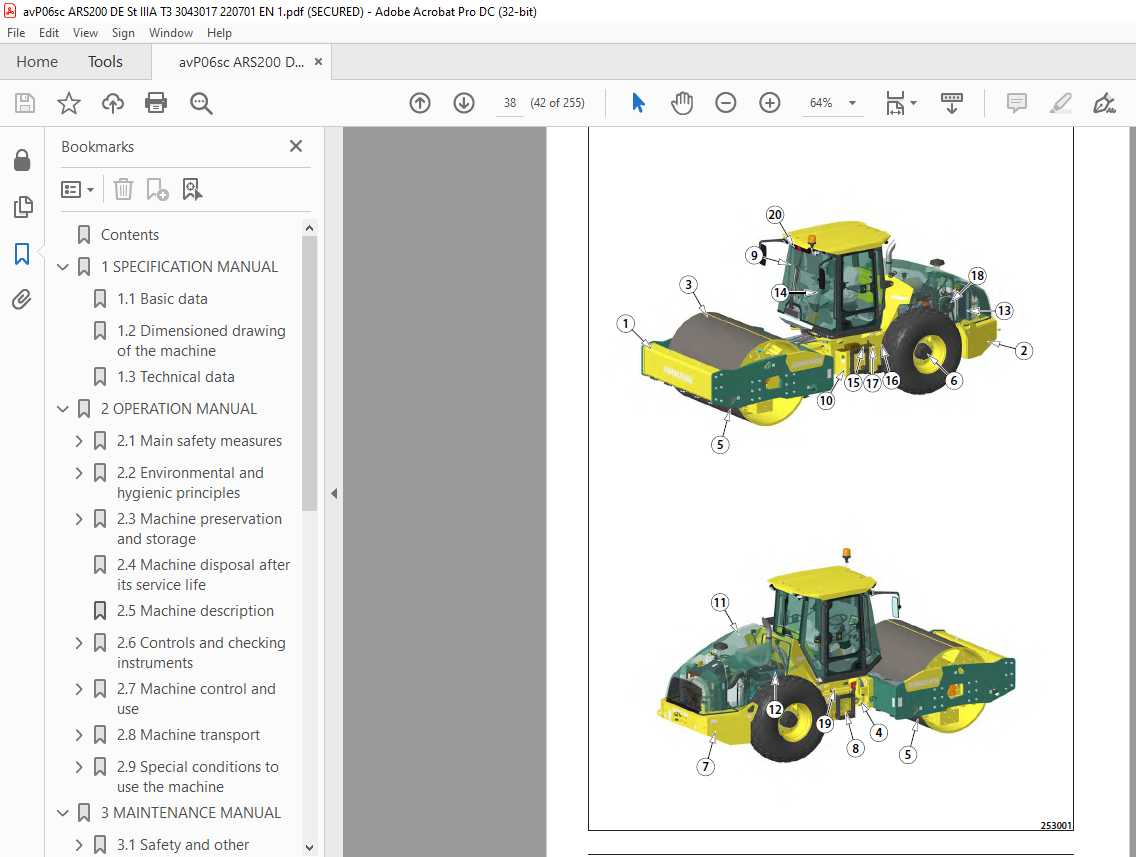

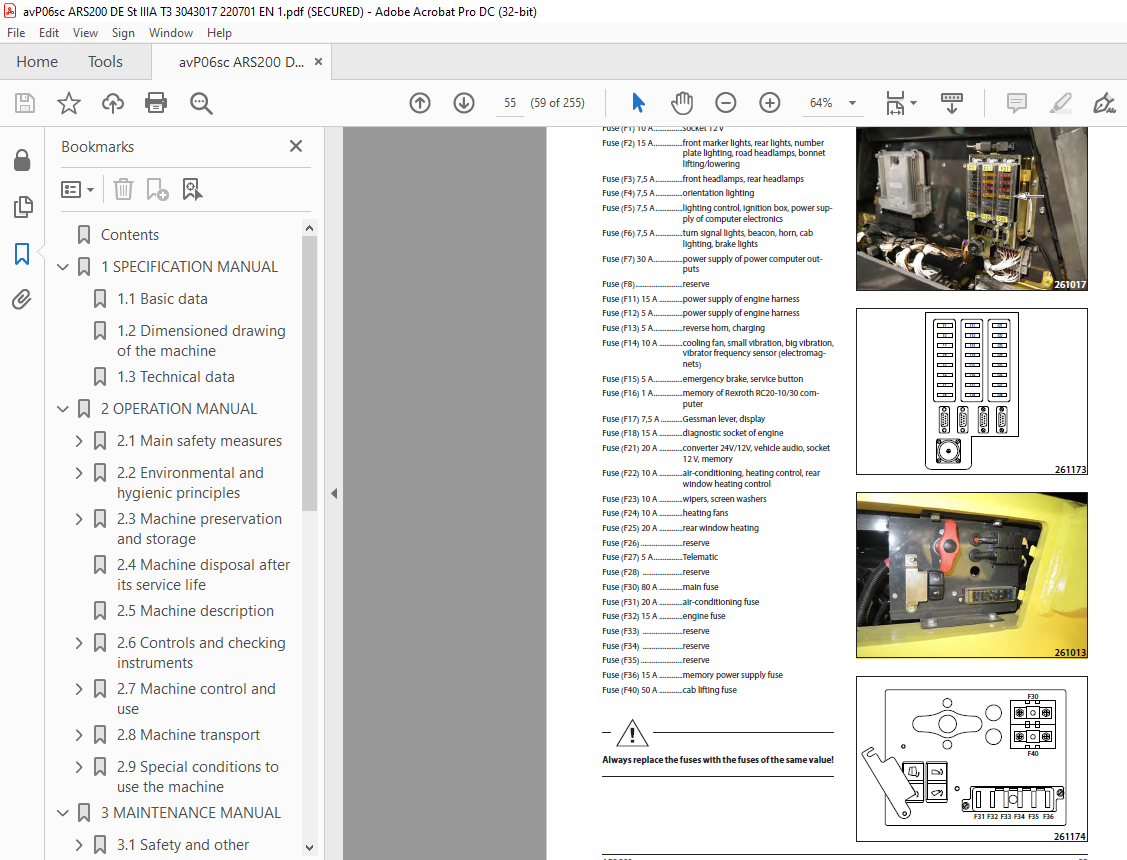

Contents.......................................................................................... 8 1 SPECIFICATION MANUAL............................................................................ 13 1.1 Basic data................................................................................ 14 1.2 Dimensioned drawing of the machine........................................................ 16 1.3 Technical data............................................................................ 18 2 OPERATION MANUAL................................................................................ 23 2.1 Main safety measures...................................................................... 25 2.1.1 Safety measures during machine operation............................................ 25 2.1.1.1 Before compacting works are started............................................... 25 2.1.1.2 Work in the dangerous area........................................................ 25 2.1.1.3 Ensurance of safety measures by the owner......................................... 26 2.1.1.4 Cab with integrated ROPS.......................................................... 26 2.1.2 Requirements for the driver´s qualification......................................... 27 2.1.3 Driver’s obligations................................................................ 28 2.1.4 Forbidden activities – safety and guarantee......................................... 29 2.1.5 Safety notices and signs applied on the machine..................................... 31 2.1.6 Hand signals........................................................................ 35 2.2 Environmental and hygienic principles..................................................... 38 2.2.1 Hygienic principles................................................................. 38 2.2.2 Ecological principles............................................................... 38 2.3 Machine preservation and storage.......................................................... 39 2.3.1 Short-term preservation and storage for 1–2 months.................................. 39 2.3.2 Preservation and storage for more than 2 months..................................... 39 2.3.3 Removal of preservation and inspection of the delivered machine..................... 40 2.4 Machine disposal after its service life................................................... 41 2.5 Machine description....................................................................... 42 2.6 Controls and checking instruments......................................................... 44 2.6.1 Display control – operation screen.................................................. 66 2.6.2 Display control – Information screen................................................ 72 2.6.3 Display control – service screen.................................................... 76 2.6.4 Display disconnected................................................................ 79 2.7 Machine control and use................................................................... 80 2.7.1 Start-up of the engine.............................................................. 81 2.7.2 Travel and reversing................................................................ 87 2.7.3 Stopping the machine and engine..................................................... 93 2.7.4 Machine emergency stop.............................................................. 93 2.7.5 Machine parking..................................................................... 95 2.7.6 Cab and ROPS lifting and lowering................................................... 96 2.7.7 Ballasting of tyres with liquid..................................................... 98 2.7.8 Telematic Readiness................................................................. 99 2.7.9 ACE Force...........................................................................100 2.7.9.1 Entering the ACE Force screen.....................................................100 2.7.9.2 Operation screen..................................................................101 2.7.9.3 Speed selection...................................................................103 2.7.9.4 Frequency setup...................................................................104 2.7.9.5 Kb measurement....................................................................105 2.7.9.6 Speed range visualization.........................................................106 2.7.9.7 Double jump warning and operator guidance ........................................107 2.7.9.8 ACE parameter screen..............................................................108 2.7.9.9 Recognition of compaction value achievement and the status against the target.....109 2.7.9.10 Evaluation of compaction by means of Kb value....................................109 2.7.9.11 Evaluation of compaction by means of a drum jump.................................110 2.7.9.12 Periodic (single) jump...........................................................110 2.7.9.13 Double (chaotic) jump............................................................111 2.7.9.14 General fault....................................................................112 2.7.8 Scraper adjustment..................................................................113 2.8 Machine transport.........................................................................114 2.8.1 Loading the machine.................................................................115 2.8.1.1 Loading the machine using a ramp..................................................115 2.8.1.2 Loading the machine with a crane..................................................116 2.9 Special conditions to use the machine.....................................................117 2.9.1 Safety function and emergency mode of the machine (limp mode).......................117 2.9.1.1 Symbols shown on the display......................................................118 2.9.1.2 Switching to the emergency (limp) mode............................................119 2.9.1.3 Deactivation of the emergency (limp) mode.........................................120 2.9.2 Towing the machine..................................................................121 2.9.3 Operating the machine during initial run period.....................................126 2.9.4 Operating the machine at low temperatures...........................................126 2.9.5 Machine operation under high temperatures and humidity..............................126 2.9.6 Machine operation at high altitudes.................................................127 2.9.7 Machine operation in a very dusty environment.......................................127 2.9.8 Driving with vibration on compacted and hard materials..............................127 3 MAINTENANCE MANUAL..............................................................................129 3.1 Safety and other measures during maintenance of the machine...............................131 3.1.1 Safety during maintenance of the machine............................................131 3.1.2 Fire protection when operating fluids are changed...................................131 3.1.3 Environmental and hygienic principles...............................................132 3.2 Specification of operating fluids.........................................................133 3.2.1 Engine oil..........................................................................133 3.2.2 Fuel................................................................................134 3.2.3 Coolant ............................................................................134 3.2.4 Hydraulic oil.......................................................................135 3.2.5 Gear oil............................................................................136 3.2.6 Lubricating grease..................................................................136 3.2.7 Drum coolant........................................................................136 3.2.8 Windscreen washer fluid.............................................................136 3.2.9 Air-conditioning fluids.............................................................136 3.2.10 Vibrator oil.......................................................................136 3.3 Fluids....................................................................................137 3.4. Lubrication and Maintenance Chart........................................................138 3.5 Lubrication and service plan..............................................................140 3.6 Lubrication and maintenance operations....................................................141 Every 20 hours of operation (daily).......................................................142 3.6.1 Engine oil level check..........................................................142 3.6.2 Engine coolant level check......................................................143 3.6.3 Hydraulic oil level check.......................................................144 3.6.4 Crankcase ventilation...........................................................145 3.6.5 Fan inspection..................................................................145 3.6.6 Inspection of dust valve of the air filter......................................146 3.6.7 Fuel level check................................................................147 3.6.8 Cleaning the water separator of fuel filter.....................................148 3.6.9 Check of warning and checking devices...........................................149 3.6.10 Engine leakage inspection......................................................151 3.6.11 Exhaust system leakage inspection..............................................151 3.6.12 Brake test.....................................................................152 3.6.12.1 Check of the parking brake...................................................152 3.6.12.2 Check of the emergency brake.................................................153 3.6.12.3 Check of the service brake...................................................154 Every 100 hours of operation..............................................................155 3.6.13 Checking pressure in tyres.....................................................155 Every 250 hours of operation..............................................................156 3.6.14 Engine cooling circuit inspection..............................................156 3.6.15 Air filter sensor check........................................................158 3.6.16 Machine lubrication............................................................160 3.6.17 Vibrator oil check.............................................................164 3.6.18 Travel gearbox oil check.......................................................164 3.6.19 Checking pad-foot segments.....................................................166 3.6.20 Seat switch check..............................................................166 Every 500 hours of operation, but at least once a year....................................167 3.6.21 Engine oil change..............................................................167 3.6.22 Engine coolant level check.....................................................170 3.6.23 (Air-conditioning) belt check..................................................171 3.6.24 Fuel filter replacement........................................................172 3.6.25 Air filter element replacement.................................................174 3.6.26 Checking wheel screws for tightening...........................................177 3.6.27 Cleaning the cab ventilation filter............................................177 3.6.28 Wiring inspection..............................................................177 Every 1000 hours of operation.............................................................178 3.6.29 Intake manifold inspection.....................................................178 3.6.30 Battery inspection.............................................................179 3.6.31 Engine belt inspection.........................................................181 3.6.32 Engine belt tensioner check....................................................182 3.6.33 Travel gearbox oil change......................................................183 3.6.34 Shock-absorbing system inspection..............................................185 3.6.35 Engine inspection..............................................................187 3.6.36 Engine and machine diagnostics.................................................187 Every 2000 hours of operation.............................................................188 3.6.37 Vibrator oil change............................................................188 3.6.38 Cleaning and checking the air conditioning system..............................189 3.6.39 Hydraulic oil change and filter replacement....................................190 3.6.40 Cleaning the suction filter of the cab and bonnet lifting and lowering unit....196 3.6.41 Valve clearance check, adjustment..............................................196 Every 6000 hours of operation.............................................................197 3.6.42 Engine coolant change..........................................................197 Maintenance - As Needed...................................................................200 3.6.43 Cooler cleaning................................................................200 3.6.44 Fuel system venting............................................................201 3.6.45 Machine cleaning...............................................................202 3.6.46 Scraper adjustment.............................................................202 3.6.47 Charging of the battery........................................................203 3.6.48 Checking screw connections for tightening......................................204 3.7 Defects...................................................................................206 3.7.1 Machine errors......................................................................207 3.7.2 Errors due to safety functions......................................................209 3.7.3 Errors at the inputs................................................................210 3.7.4 Errors at the outputs...............................................................211 3.7.5 ACE errors..........................................................................212 3.7.6 System errors.......................................................................213 3.7.7 Engine errors.......................................................................214 3.8 Annexes...................................................................................239 Wiring diagram............................................................................239 Hydraulic system diagram – RTM............................................................247 Table of spare parts......................................................................249

1 file (13.4MB)