$35.95

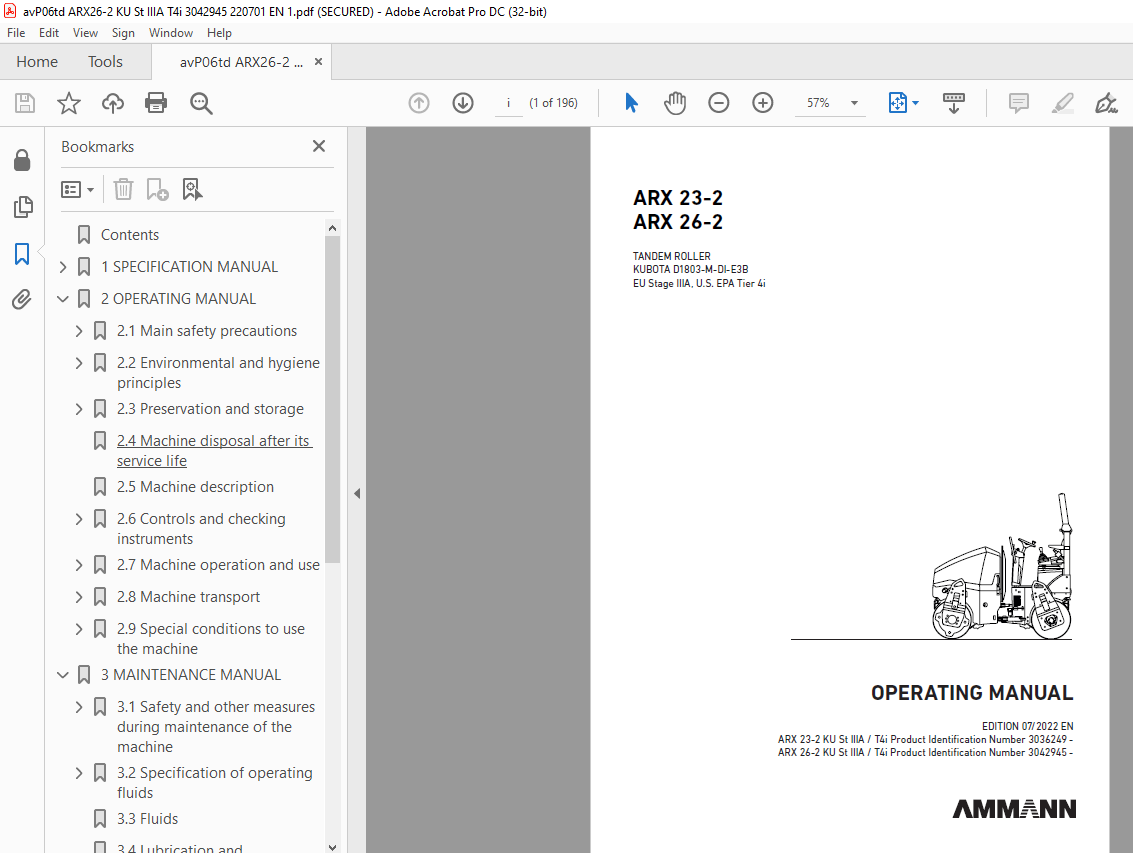

Ammann ARX 23-2 ARX 26-2 Tandem Roller Operating Manual - PDF

Ammann ARX 23-2 ARX 26-2 Tandem Roller Kubota D1803-M-DI-E3B EU Stage IIIA, U.S. EPA Tier 4i Operating Manual – PDF DOWNLOAD

FILE DETAILS:

Ammann ARX 23-2 ARX 26-2 Tandem Roller Kubota D1803-M-DI-E3B EU Stage IIIA, U.S. EPA Tier 4i Operating Manual – PDF DOWNLOAD

Language : English

Pages : 196

Downloadable : Yes

File Type : PDF

ARX 23-2 KU St IIIA / T4i Product Identification Number 3036249-

ARX 26-2 KU St IIIA / T4i Product Identification Number 3042945-

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Ammann ARX 23-2 ARX 26-2 Tandem Roller Kubota D1803-M-DI-E3B EU Stage IIIA, U.S. EPA Tier 4i Operating Manual – PDF DOWNLOAD

Contents 8

1 SPECIFICATION MANUAL 13

1 1Basic data 14

1 2Dimensional drawing of the machine 16

1 3Technical data 18

2 OPERATING MANUAL 23

2 1Main safety precautions 25

2 1 1Safety precautions during operation of the machine 25

2 1 1 1Before compacting works are started 25

2 1 1 2Work in the dangerous area 25

2 1 1 3Ensurance of safety measures by the provider 26

2 1 1 4Protective ROPS frame 26

2 1 2Requirements for the qualification of machine operators 27

2 1 3Driver’s obligations 28

2 1 4Forbidden activities – safety and guarantee 29

2 1 5Safety notices and signs applied on the machine 31

2 1 6Hand signals 35

2 2Environmental and hygiene principles 38

2 2 1Hygiene principles 38

2 2 2Environmental principles 38

2 3Preservation and storage 39

2 3 1Short-term preservation and storage for 1–2 months 39

2 3 2Preservation and storage of the machine for a period over 2 months 39

2 3 3Machine depreservation 41

2 4Machine disposal after its service life 43

2 5Machine description 44

2 6Controls and checking instruments 46

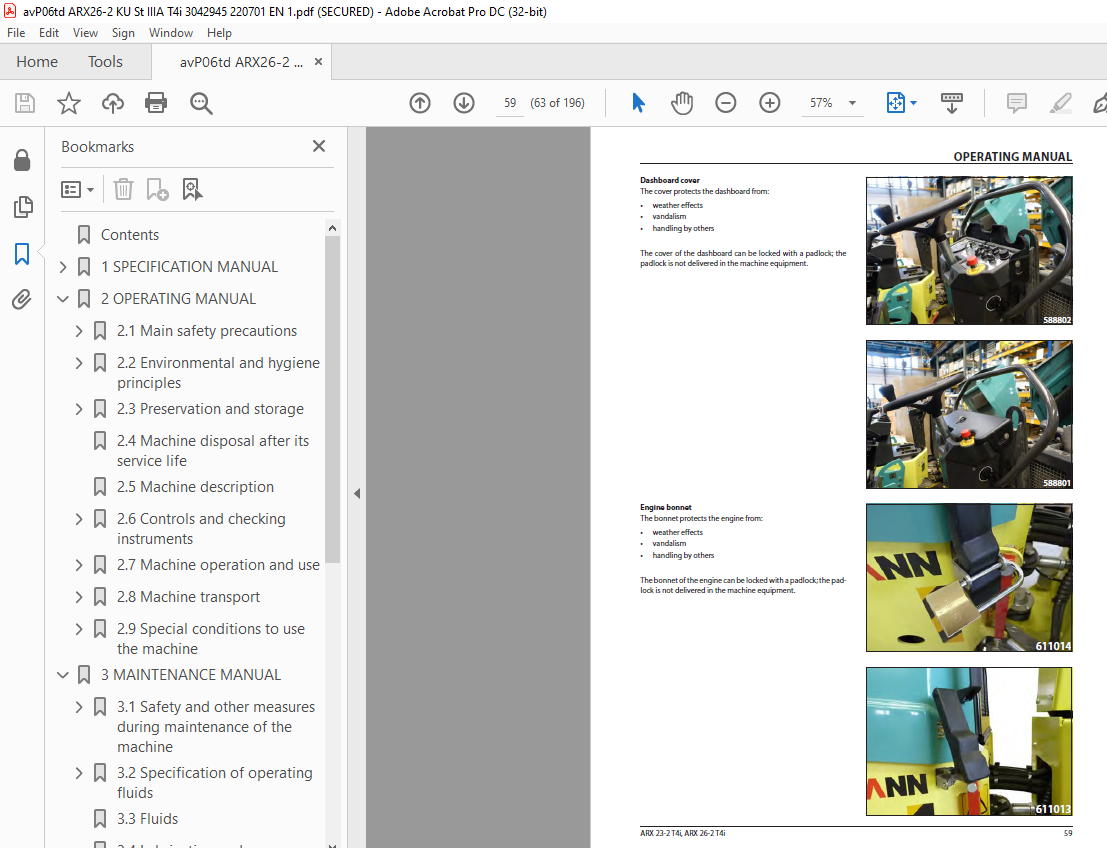

2 6 1Dashboard and control panels 47

2 7Machine operation and use 64

2 7 1Starting the engine 65

2 7 2Drive and reverse drive 69

2 7 3Stopping the machine and turning off the engine 77

2 7 4Machine emergency stop 77

2 7 5Machine parking 79

2 7 6Panic response 79

2 7 7Sprinkling 81

2 7 8ACE Force (optional equipment) 81

2 7 9Infrathermometer (optional equipment) 82

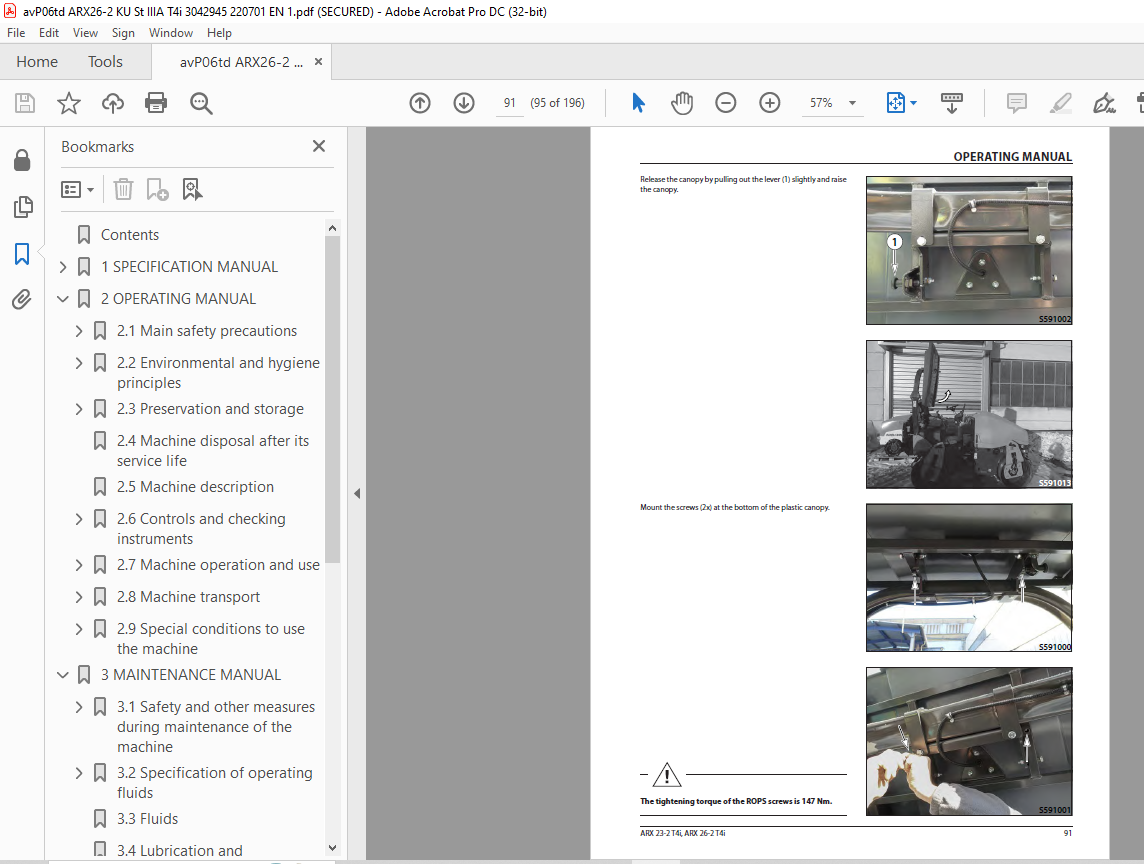

2 7 10ROPS lifting and lowering 88

2 7 10 1Lowering and raising of the ROPS frame with a plastic canopy 90

2 7 11Telematics readiness 96

2 7 12Edge cutter (optional equipment) 97

2 7 13Calibration mode 98

2 7 14Lowering and raising of the plastic canopy 101

2 8Machine transport 103

2 8 1Loading the machine 104

2 8 1 1Loading the machine using a ramp 104

2 8 1 2Loading the machine using a crane 105

2 9Special conditions to use the machine 106

2 9 1Towing the machine 106

2 9 2Drum offset 108

2 9 3Machine operation during initial run period 109

2 9 4Machine operation at low temperatures 109

2 9 5Machine operation at higher temperatures and humidity 109

2 9 6Machine operation at higher altitudes 109

2 9 7Machine operation in dusty environment 110

2 9 8Driving with vibration on compacted and hard materials 110

3 MAINTENANCE MANUAL 111

3 1Safety and other measures during maintenance of the machine 113

3 1 1Safety during machine maintenance 113

3 1 2Fire protection when operating fluids are changed 113

3 1 3Environmental and hygiene principles 114

3 2Specification of operating fluids 115

3 2 1Engine oil 115

3 2 2Fuel 116

3 2 3Coolant 117

3 2 4Hydraulic oil 118

3 2 5Lubricating grease 118

3 2 6Emulsion 118

3 3Fluids 119

3 4Lubrication and maintenance chart 120

3 5Lubrication and service plan 122

3 6Lubrication and maintenance operations 123

Every 20 hours of operation (daily) 124

3 6 1Fuel check 124

3 6 2Engine oil check 125

3 6 3Engine coolant check 126

3 6 4Checking the oil in the hydraulic tank 127

3 6 5Cleaning the hydraulic oil cooler 128

3 6 6Air filter check 129

3 6 7Sprinkling emulsion level check 130

3 6 8Sprinkling tank refilling 131

3 6 9Scraper adjustment 131

3 6 10Inspection of warning and checking devices 132

3 6 11Engine leakage check 134

3 6 12Check of the fan and engine belt for condition 134

3 6 13Brake test 135

3 6 13 1Check of the parking brake 135

3 6 13 2Check of the emergency brake 136

3 6 13 3Check of the service brake 137

3 6 14Check of the tightness of the fuel and hydraulic system 138

Every 50 hours of operation 139

3 6 15Check of hoses and clips 139

3 6 16Battery inspection 140

Every 100 hours of operation 141

3 6 17Air filter cleaning 141

3 6 18Cleaning the water separator on the fuel filter 142

3 6 19Machine lubrication 143

3 6 20Tyre pressure check 144

Every 250 hours of operation 145

3 6 21Fuel filter replacement 145

3 6 22Engine oil change 146

3 6 23Checking the hoses of the engine cooler for wear and mounting 148

3 6 24Checking the hoses and clips for mounting 148

3 6 25Sprinkling filter cleaning 149

3 6 26Engine intake pipe inspection 150

Every 500 hours of operation, but at least once a year 151

3 6 27Fuel tank cleaning 151

3 6 28Electrical installation inspection 152

3 6 29Replacement of the fuel separator filter cartridge 152

3 6 30Valve clearance check and adjustment 153

3 6 31Engine cooler cleaning 153

3 6 32Check of rubber-metal elements of the engine cooler 154

Every 1000 hours of operation 155

3 6 33Hydraulic oil change and filter replacement 155

3 6 34Replacement of air filter cartridges 157

3 6 35Damping system check 159

3 6 36Swinging support check 160

3 6 37Articulation joint check 160

Every 2000 hours of operation 161

3 6 38Engine belt replacement 161

3 6 39Engine coolant change 161

3 6 40Replacement of hoses of the cooling system 163

3 6 41Replacement of rubber-metal elements of the engine cooler 163

3 6 42Replacement of hoses of the fuel system 164

3 6 43Replacement of suction hoses 164

Maintenance as required 165

3 6 44Gas strut replacement 165

3 6 45Cleaning the water separator 166

3 6 46Cleaning the water tank 166

3 6 47Cleaning the machine 167

3 6 48Draining water from the sprinkling circuit before the winter season 168

3 6 49Fuel system venting 168

3 6 50Charging of the battery 170

3 6 51Checking the screw connections for tightening 171

3 7Troubleshooting 173

3 7 1List of error codes displayed on the display 174

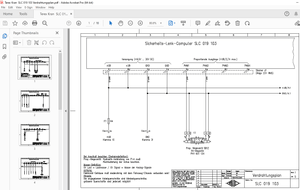

3 8Appendices 182

Wiring diagram 182

Hydraulic diagram ARX 23-2 T4i, ARX 26-2 T4i 188

Hydraulic diagram ARX 23-2C, ARX 26-2C 190

Table of spare parts for regular maintenance 192

Content of the filter set after 250 hours (4-760243) 193

Content of the filter set after 500 hours (4-760244) 193

Content of the filter set after 1000 hours (4-760245) 193