Starting from:

$30.95

Home

AMMANN

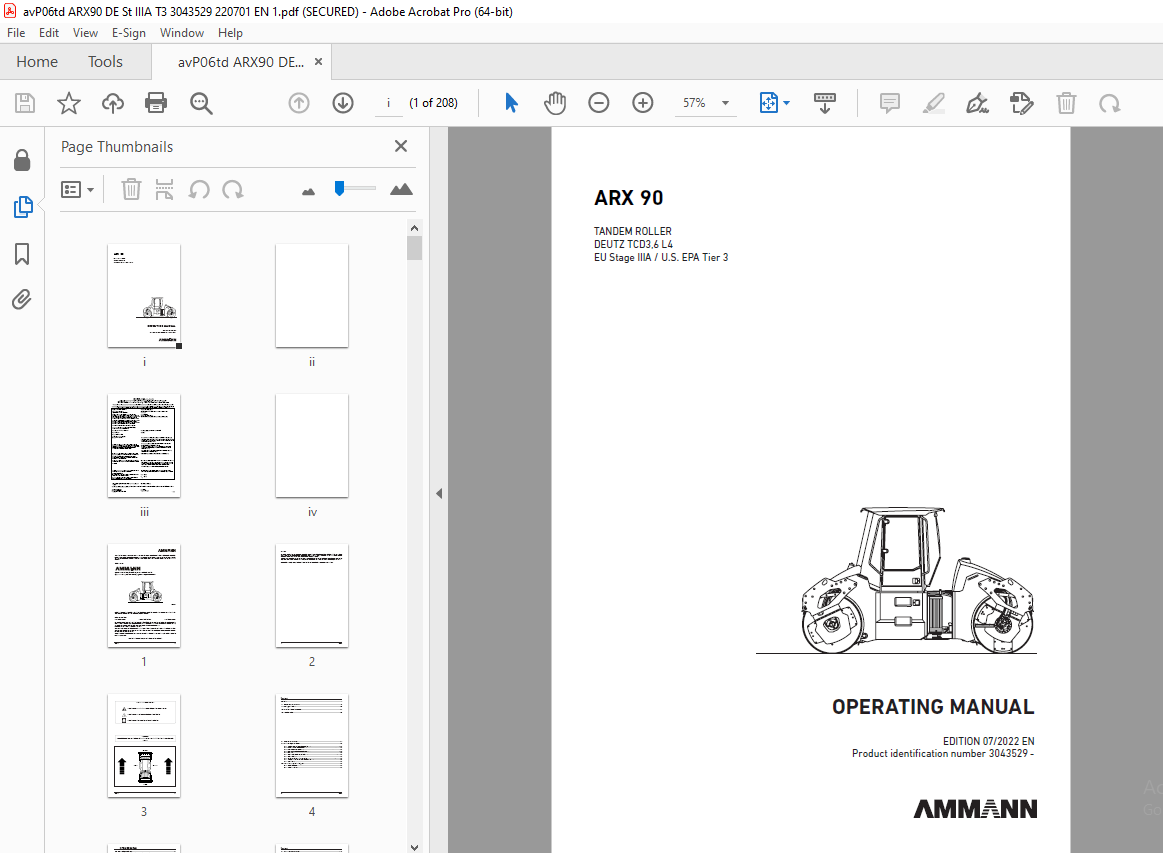

AMMANN ARX 90 TANDEM ROLLER DEUTZ TCD3,6 L4 EU STAGE IIIA / U.S. EPA TIER 3 OPERATING MANUAL - PDF

AMMANN ARX 90 TANDEM ROLLER DEUTZ TCD3,6 L4 EU STAGE IIIA / U.S. EPA TIER 3 OPERATING MANUAL - PDF

AMMANN ARX 90 TANDEM ROLLER DEUTZ TCD3,6 L4 EU STAGE IIIA / U.S. EPA TIER 3 OPERATING MANUAL (3043529) – PDF DOWNLOAD

FILE DETAILS:

AMMANN ARX 90 TANDEM ROLLER DEUTZ TCD3,6 L4 EU STAGE IIIA / U.S. EPA TIER 3 OPERATING MANUAL (3043529) – PDF DOWNLOAD

Language : English

Pages : 208

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

AMMANN ARX 90 TANDEM ROLLER DEUTZ TCD3,6 L4 EU STAGE IIIA / U.S. EPA TIER 3 OPERATING MANUAL (3043529) – PDF DOWNLOAD

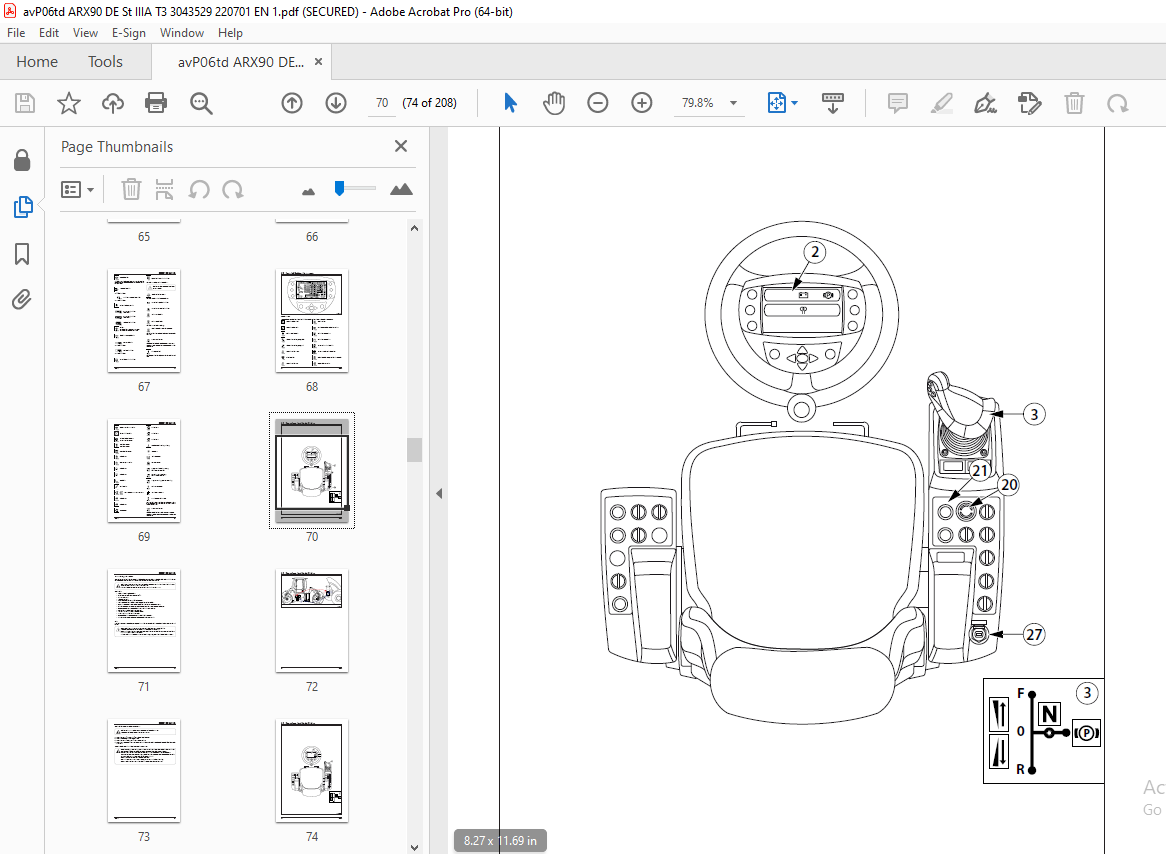

Content..................................................................................... 8 1. SPECIFICATION MANUAL..................................................................... 13 1.1. Basic specification................................................................ 14 1.2. Machine dimension scheme........................................................... 16 1.3. Technical data..................................................................... 20 2. OPERATION MANUAL......................................................................... 25 2.1. Major Safety Precautions........................................................... 27 2.1.1. Safety Measures during Machine Operation .................................... 27 2.1.1.1. Compaction Work Commencement .............................................. 27 2.1.1.2. Work Safety Secured by User................................................ 27 2.1.1.3 Ensurance of safety measures by the owner................................... 28 2.1.1.4. ROPS Cab................................................................... 28 2.1.2. Reguirements on Driver’s Qualification....................................... 29 2.1.3. Driver’s Liabilities......................................................... 29 2.1.4. Forbidden activities - safety and guarantee.................................. 31 2.1.5. Safety inscriptions and signs used on the Machine ........................... 32 2.1.6. Hand Signals................................................................. 37 2.2. Ecological & Hygienic Principles................................................... 40 2.2.1. Hygienic Principles ......................................................... 40 2.2.2. Ecological Principles ....................................................... 40 2.3. Preservation & Storage ............................................................ 41 2.3.1. Short-term preservation and storage for a period of 1 - 2 months............. 41 2.3.2. Machine Preservation & Storage for the Period Over 2 Months Long............. 41 2.3.3. Dewaxing and inspection of the supplied machine.............................. 42 2.4. Machine Disposal Following Its Life Termination.................................... 43 2.5. Machine Description................................................................ 44 2.6. Controls & Dashboard Instruments .................................................. 46 2.6.1. Display control.............................................................. 64 2.7. How to Control and Use the Machine................................................. 74 2.7.1. Start-up of the engine....................................................... 75 2.7.2. Travel and reversing......................................................... 79 2.7.3. How to stop the Machine and its engine....................................... 85 2.7.4. Emergency stop of the Machine................................................ 85 2.7.5. Machine parking.............................................................. 87 2.7.6. Sprinkling................................................................... 87 2.7.6.1. Water sprinkling........................................................... 87 2.7.6.2. Emulsion sprinkling....................................................... 89 2.7.7. Ammann edge cutter (optional)................................................ 91 2.7.8. Infra thermometer (optional)................................................. 93 2.7.9. Ammann spreader (optional) .................................................. 95 2.7.10. Telematics readiness (optional)............................................. 97 2.7.11. ACE FORCE (optional)........................................................ 98 2.7.11.1. Parameters setting screen.................................................100 2.7.11.2. Double (chaotic) drum rebound.............................................101 2.8. Machine transport..................................................................102 2.8.1. How to load the Machine......................................................103 2.8.1.1. Loading the machine using a ramp...........................................103 2.8.1.2. Loading the machine using a crane..........................................104 2.9. Special conditions to use the Machine..............................................105 2.9.1. Machine towing...............................................................105 2.9.2. How to operate the Machine during its running-in.............................110 2.9.3. Operating the Machine at low temperatures....................................110 2.9.4. Machine operation at high temperatures and humidity..........................110 2.9.5. Machine operation at high altitudes..........................................110 2.9.6. Machine operation within very dusty environment..............................110 2.9.7. Driving with vibrations on compacted and hard materials......................110 3. MAINTENANCE MANUAL.......................................................................111 3.1. Safety and other measures for machine maintenance..................................113 3.1.1. Safety of machine maintenance................................................113 3.1.2. Fire precautions during operation media exchanges............................113 3.1.3. Ecological and hygienic principles...........................................114 3.2. Media specification................................................................115 3.2.1. Engine oil...................................................................115 3.2.2. Fuel.........................................................................116 3.2.3. Cooling liquid...............................................................116 3.2.4. Hydraulic oil ...............................................................117 3.2.5. Gearbox oil..................................................................117 3.2.6. Lube grease .................................................................118 3.2.7. Glass washer fluid ..........................................................118 3.2.8. Drum cooling liquid..........................................................118 3.2.9. Air Conditioning filling.....................................................118 3.2.10. Vibratory oil...............................................................118 3.2.11. Emulsion....................................................................118 3.3. Media .............................................................................119 3.4. Lubrication and Maintenance Chart..................................................120 3.5. Lubrication and Service Plan.......................................................122 3.6. Lubrication and Maintenance Operations.............................................124 Every 20 hours of operation (daily).................................................125 3.6.1. Engine oil level check...................................................125 3.6.2. Checking the engine for leaks............................................125 3.6.3. Engine cooling liquid level check........................................126 3.6.4. Air filter dust valve check..............................................127 3.6.5. Inspect fan condition....................................................127 3.6.6. Fuel level check.........................................................128 3.6.7. Hydraulic tank oil level check...........................................129 3.6.8. Water tank refilling.....................................................129 3.6.9. Sprinkling nozzle check.................................................130 3.6.10. Inspect alarm and control devices......................................131 3.6.11. Gearbox oil check.......................................................133 3.6.12. Belt inspection (air-conditioning).....................................133 3.6.13. Checking the exhaust system for leaks...................................133 3.6.14. Brake test..............................................................134 3.6.14.1. Check of the parking brake............................................134 3.6.14.2. Check of the emergency brake..........................................135 3.6.14.3. Check of the service brake............................................136 3.6.15. Check of the tightness of the fuel and hydraulic system.................137 Every 250 hours of operation........................................................138 3.6.16. Watering filter cleaning................................................138 3.6.17. Machine lubrication.....................................................140 3.6.18. Checking pressure in tyres .............................................141 3.6.19. Seat switch check.......................................................141 Every 500 hours of operation, but at least once a year..............................142 3.6.20. Inspect the engine belt ................................................142 3.6.21. Engine oil exchange.....................................................142 3.6.22. Inspect engine induction manifold.......................................145 3.6.23. Air filter sensor check.................................................146 3.6.24. Engine cooling liquid level check.......................................147 3.6.25. Check of wiring.........................................................147 3.6.26. Cleaning the water separator ..........................................148 3.6.27. Checking the coolant level (Air-conditioning)...........................148 3.6.28. Engine fuel filter exchange.............................................149 3.6.29. How to replace air filter elements......................................151 3.6.30. How to clean cab ventilation filter.....................................153 3.6.31. Oscillation drum belt lubrication.......................................153 Every 1000 hours of operation.......................................................154 3.6.32. Inspect engine cooling circuit..........................................154 3.6.33. Inspect the battery.....................................................155 3.6.34. Inspection of the engine belts..........................................157 3.6.35. Exchanging oil in gearboxes.............................................158 3.6.36. Vibrations system oil exchange..........................................160 3.6.37. Inspect the silencing system............................................161 3.6.38. Water tank cleaning.....................................................163 3.6.39. Air cooler cleaning.....................................................164 3.6.40. Engine inspection.......................................................165 3.6.41. Engine and machine diagnostics..........................................165 3.6.42. Checking engine belt (Air-conditioning).................................166 3.6.43. Checking the air conditioning compressor mounting (Air-conditioning)....166 Every 2000 hours of operation.......................................................167 3.6.44. Replace hydraulic oil and filters ......................................167 3.6.45. Oscillation drum belt replacement.......................................170 Every 6000 hours of operation.......................................................171 3.6.46. Engine coolant exchange.................................................171 Maintenance as required.............................................................173 3.6.47. Deaerating (venting) the fuel system....................................173 3.6.48. Cleaning of coolers.....................................................174 3.6.49. Drain water from sprinkling circuit before winter season................175 3.6.50. Adjustment of scrapers.................................................177 3.6.51. Charging of the battery.................................................179 3.6.52. Machine cleaning .......................................................180 3.6.53. Check the tightening of bolted connections..............................180 3.7. Defects............................................................................183 3.8. Attachments........................................................................184 Wiring diagram......................................................................184 Wiring diagram of chip spreader.....................................................190 Hydraulic system diagram ARX 90.....................................................192 Hydraulic system diagram ARX 90 HF..................................................194 Hydraulic system diagram ARX 90 C...................................................196 Hydraulic diagram of chip spreader..................................................198 Table of spare parts................................................................200 Content of the set of filters after 500 and 1000 operating hours. (4-21383).........201 Content of the set of filters after 2000 operating hours. (4-760123)................201 Error codes ........................................................................202

1 file (8.4MB)