$35.95

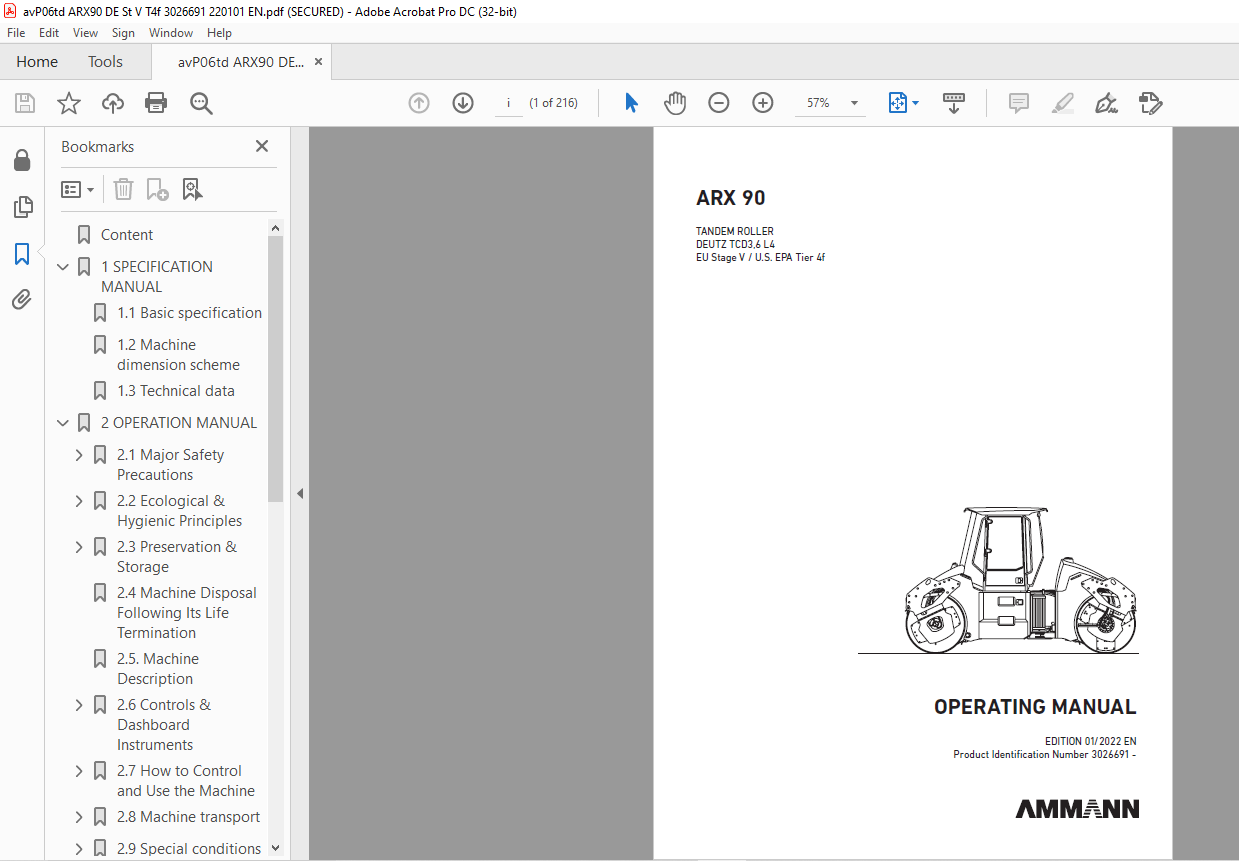

Ammann ARX 90 Tandem Roller Operating Manual 3026691 PDF

Ammann ARX 90 Tandem Roller Deutz TCD3,6 L4 EU Stage V / U.S. EPA Tier 4f Operating Manual 3026691 – PDF DOWNLOAD

FILE DETAILS:

Ammann ARX 90 Tandem Roller Deutz TCD3,6 L4 EU Stage V / U.S. EPA Tier 4f Operating Manual 3026691 – PDF DOWNLOAD

Language : English

Pages : 216

Downloadable : Yes

File Type : PDF

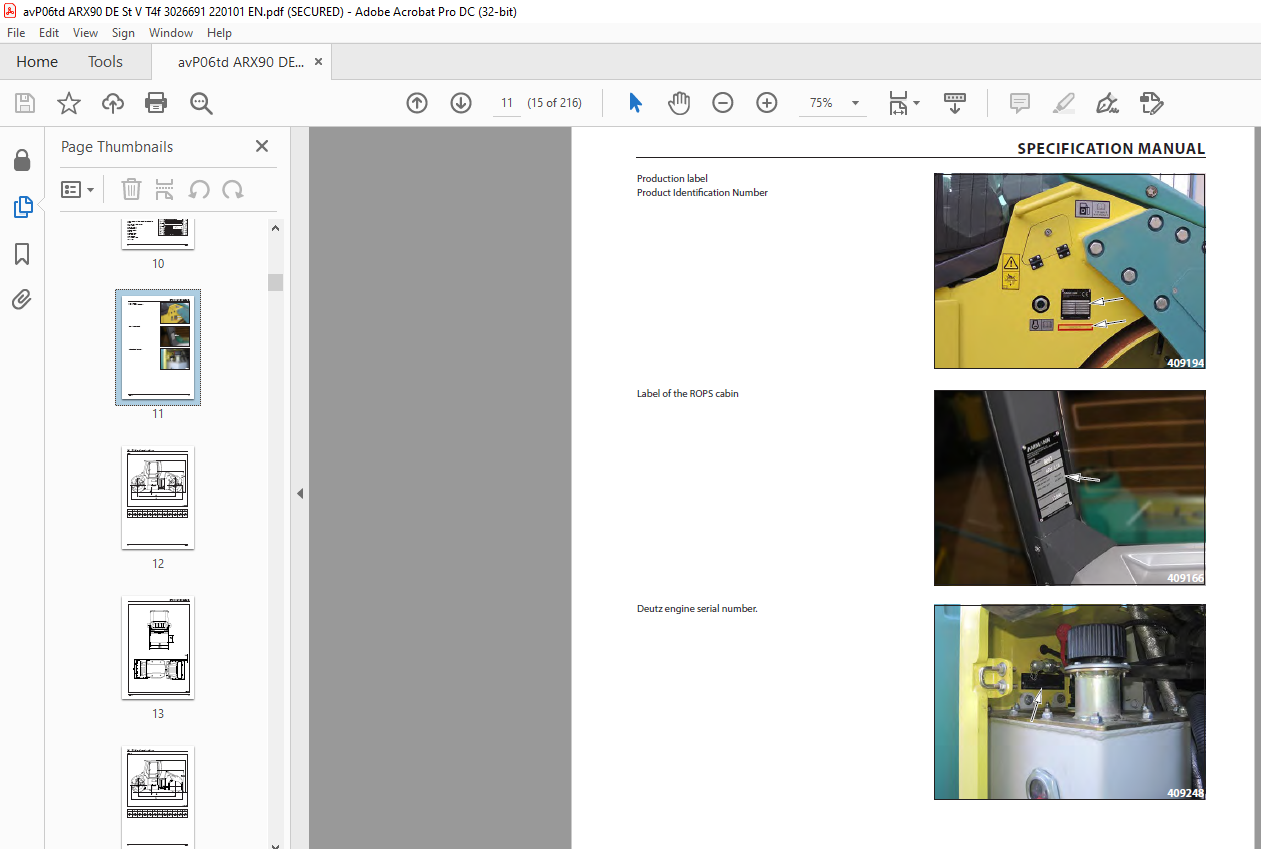

IMAGES PREVIEW OF THE MANUAL:

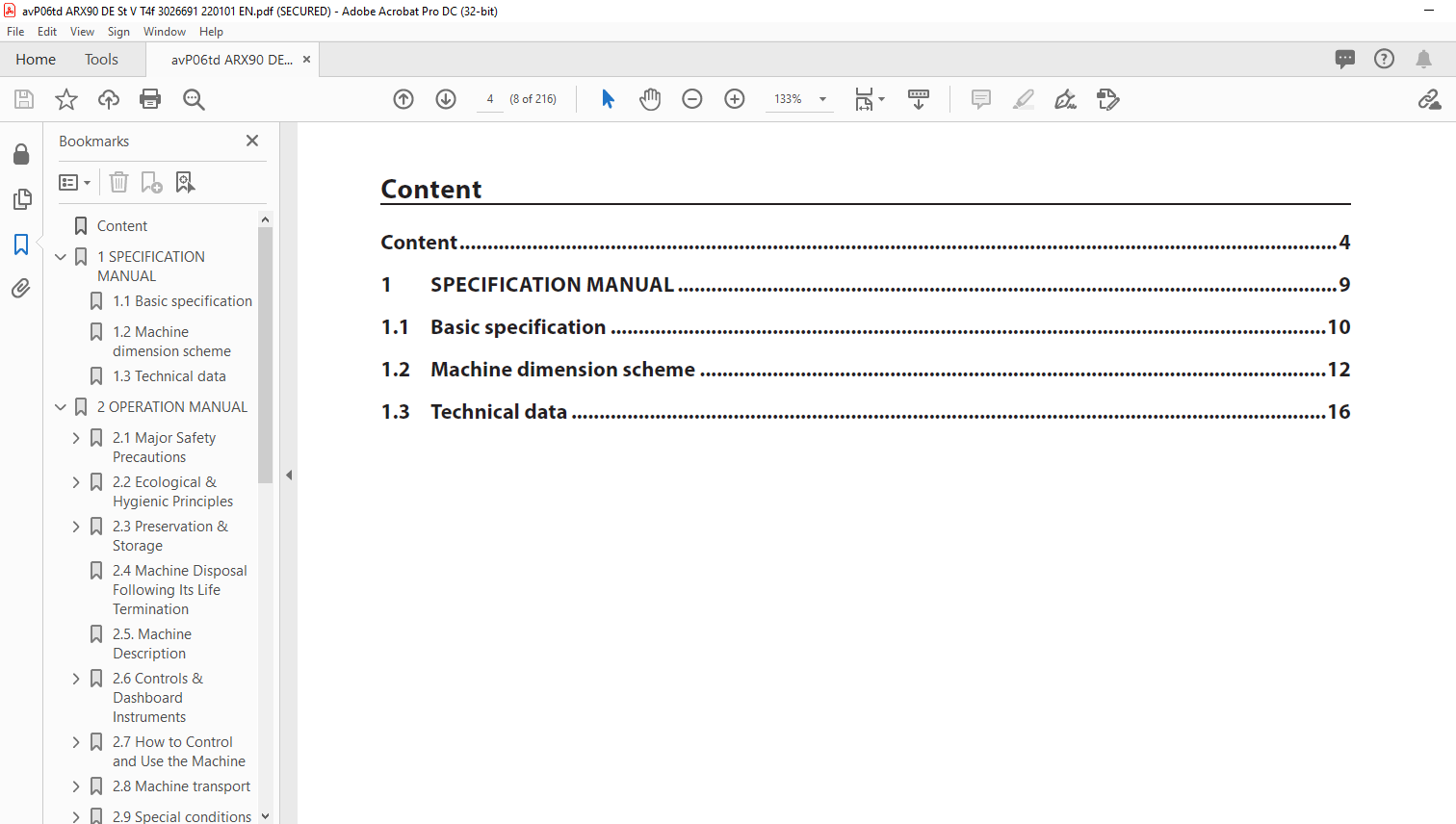

TABLE OF CONTENTS:

Ammann ARX 90 Tandem Roller Deutz TCD3,6 L4 EU Stage V / U.S. EPA Tier 4f Operating Manual 3026691 – PDF DOWNLOAD

Content 81 SPECIFICATION MANUAL 131 1Basic specification 141 2Machine dimension scheme 161 3Technical data 202 OPERATION MANUAL 252 1Major Safety Precautions 272 1 1Safety Measures during Machine Operation 272 1 1 1Compaction Work Commencement 272 1 1 2Work Safety Secured by User 272 1 1 3Ensurance of safety measures by the owner 282 1 1 4ROPS Cab 282 1 2Reguirements on Driver’s Qualification 292 1 3Driver’s Liabilities 292 1 4Forbidden activities – safety and guarantee 312 1 5Safety inscriptions and signs used on the Machine 322 1 6Hand Signals 372 2Ecological & Hygienic Principles 402 2 1Hygienic Principles 402 2 2Ecological Principles 402 3Preservation & Storage 412 3 1Short-term preservation and storage for a period of 1 – 2 months 412 3 2Machine Preservation & Storage for the Period Over 2 Months Long 412 3 3Dewaxing and inspection of the supplied machine 422 4Machine Disposal Following Its Life Termination 432 5 Machine Description 442 6Controls & Dashboard Instruments 462 6 1Display control 632 7How to Control and Use the Machine 742 7 1Start-up of the engine 752 7 2Travel and reversing 792 7 3How to stop the Machine and its engine 852 7 4Emergency stop of the Machine 852 7 5Machine parking 872 7 6Sprinkling 872 7 6 1Water sprinkling 872 7 6 2Emulsion sprinkling 892 7 7Ammann edge cutter (optional) 912 7 8Infra thermometer (optional) 932 7 9Ammann spreader (optional) 952 7 10Telematics readiness (optional) 972 7 11ACE FORCE (optional) 982 7 11 1Parameters setting screen 1002 7 11 2Double (chaotic) drum rebound 1012 8Machine transport 1022 8 1How to load the Machine 1032 8 1 1Loading the machine using a ramp 1032 8 1 2Loading the machine using a crane 1042 9Special conditions to use the Machine 1052 9 1Machine towing 1052 9 2How to operate the Machine during its running-in 1092 9 3Operating the Machine at low temperatures 1092 9 4Machine operation at high temperatures and humidity 1092 9 5Machine operation at high altitudes 1092 9 6Machine operation within very dusty environment 1092 9 7Driving with vibrations on compacted and hard materials 1093 MAINTENANCE MANUAL 1113 1Safety and other measures for machine maintenance 1133 1 1Safety of machine maintenance 1133 1 2Fire precautions during operation media exchanges 1133 1 3Ecological and hygienic principles 1143 2Media specification 1153 2 1Engine oil 1153 2 2Fuel 1163 2 3Cooling liquid 1163 2 4Hydraulic oil 1173 2 5Gearbox oil 1173 2 6DEF (AdBlue) 1173 2 7Lube grease 1183 2 8Glass washer fluid 1183 2 9Drum cooling liquid 1183 2 10Air Conditioning filling 1183 2 11Vibratory oil 1183 2 12Emulsion 1183 3Media 1193 4Lubrication and Maintenance Chart 1203 5Lubrication and Service Plan 1233 6Lubrication and Maintenance Operations 125After 20 hours of operation (daily) 1263 6 1Engine oil level check 1263 6 2Checking the engine for leaks 1263 6 3Engine cooling liquid level check 1273 6 4Air filter dust valve check 1283 6 5Inspect fan condition 1283 6 6Fuel level check 1293 6 7Check of DEF (AdBlue)volume 1303 6 8Hydraulic tank oil level check 1333 6 9Water tank refilling 1333 6 10 Sprinkling nozzle check 1343 6 11 Inspect alarm and control devices 1353 6 12Gearbox oil check 1373 6 13Belt inspection (air-conditioning) 1373 6 14Checking the exhaust system for leaks 1373 6 15Brake test 1383 6 15 1Check of the parking brake 1383 6 15 2Check of the emergency brake 1393 6 15 3Check of the service brake 1403 6 16Check of the tightness of the fuel and hydraulic system 141Every 250 hours of operation 1423 6 17Watering filter cleaning 1423 6 18Machine lubrication 1443 6 19Checking pressure in tyres 1463 6 20Seat switch check 146Every 500 hours of operation, but at least once a year 1473 6 21Inspect the engine belt 1473 6 22Engine oil exchange 1473 6 23Inspect engine induction manifold 1503 6 24Air filter sensor check 1513 6 25Engine cooling liquid level check 1523 6 26Check of wiring 1523 6 27Cleaning the water separator 1533 6 28Checking the coolant level (Air-conditioning) 1533 6 29Engine fuel filter exchange 1543 6 30Replace air filter elements 1563 6 31Clean cab ventilation filter 1583 6 32Oscillation drum belt lubrication 158Every 1000 hours of operation 1593 6 33Replacement of DEF (AdBlue) filter 1593 6 34Inspect engine cooling circuit 1613 6 35Inspect the battery 1623 6 36Inspection of the engine belts 1643 6 37Exchanging oil in gearboxes 1653 6 38Vibrations system oil exchange 1673 6 39Inspect the silencing system 1683 6 40Water tank cleaning 1703 6 41Air cooler cleaning 1713 6 42Engine inspection 1723 6 43Engine and machine diagnostics 1723 6 44Checking engine belt (Air-conditioning) 1733 6 45Checking the air conditioning compressor mounting (Air-conditioning) 173Every 2000 hours of operation 1743 6 46Replace hydraulic oil and filters 1743 6 47Vent plug replacement 1783 6 48Oscillation drum belt replacement 178Every 6000 hours of operation 1793 6 49Engine coolant exchange 179Maintenance as required 1813 6 50Deaerating (venting) the fuel system 1813 6 51DPF (Diesel Particulate Filter) regeneration 1823 6 52Cleaning of coolers 1833 6 53Drain water from sprinkling circuit before winter season 1843 6 54 Adjustment of scrapers 1863 6 55Charging of the battery 1883 6 56Machine cleaning 1893 6 57Check the tightening of bolted connections 1893 7Defects 192Error codes 1933 8Attachments 198Wiring diagram 198Wiring diagram of chip spreader 202Hydraulic system diagram ARX 90, ARX90 HF 204Oscillation hydraulic system diagram 206Hydraulic system diagram ARX 90 C 208Hydraulic diagram of chip spreader 210Spare parts table for regular maintenance 212Content of the filter set 500 h (4-760169) 213Content of the filter set 1000 h (4-760277) 213Content of the filter set 2000 h (4-760170) 213