$32.95

Ammann ARX 91 Tandem Roller Operating Manual 0016-0119 PDF

Ammann ARX 91 Articulated Tandem Roller Cummins BS III Operating Manual 0016-0119 – PDF DOWNLOAD

FILE DETAILS:

Ammann ARX 91 Articulated Tandem Roller Cummins BS III Operating Manual 0016-0119 – PDF DOWNLOAD

Language : English

Pages : 150

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

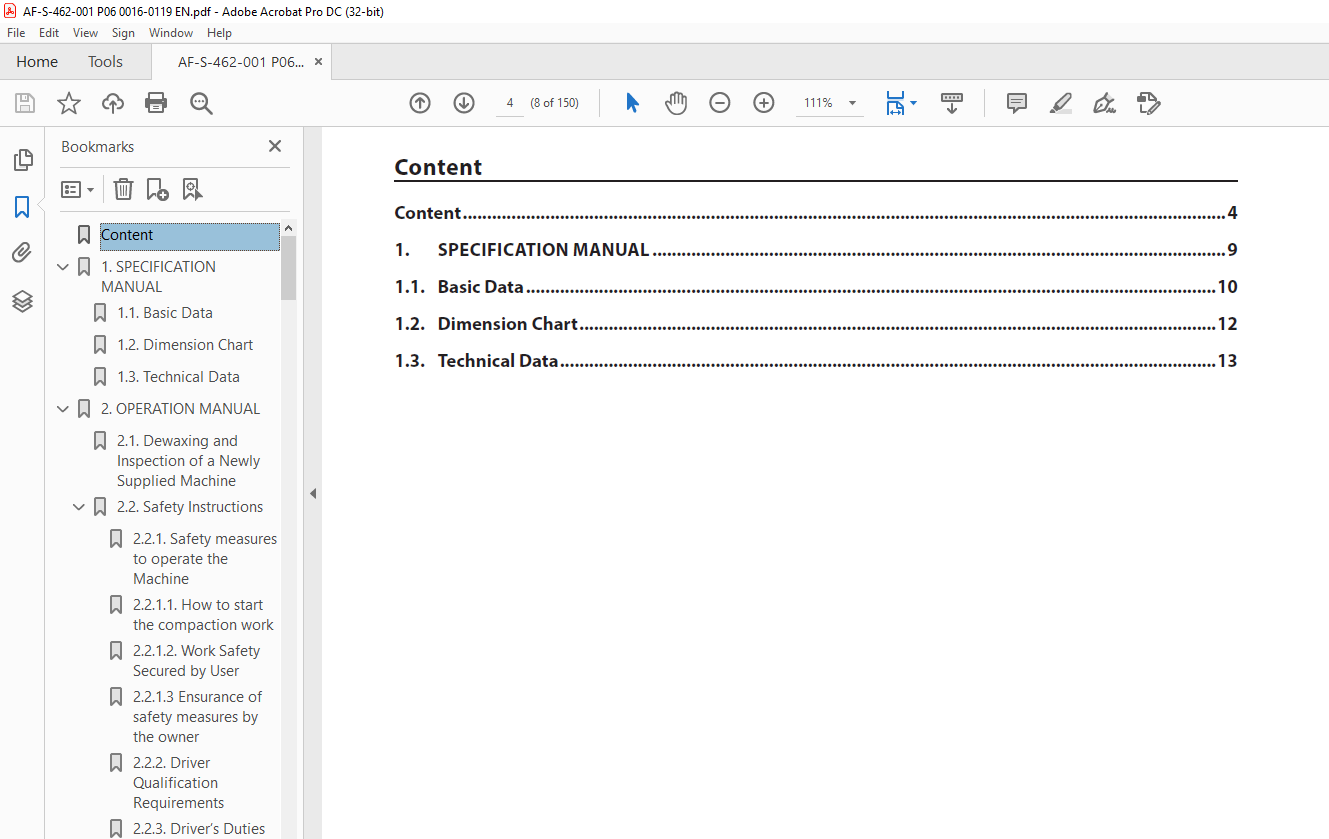

TABLE OF CONTENTS:

Ammann ARX 91 Articulated Tandem Roller Cummins BS III Operating Manual 0016-0119 – PDF DOWNLOAD

Content 8

1 SPECIFICATION MANUAL 13

1 1 Basic Data 14

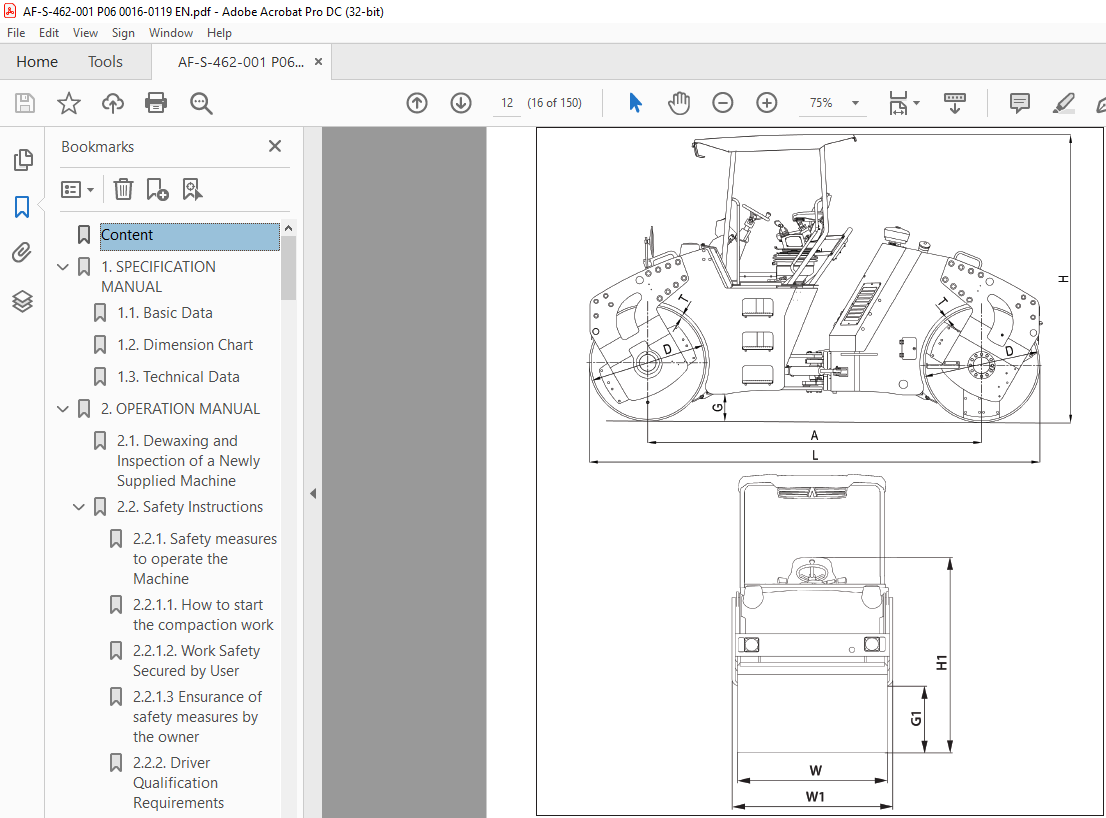

1 2 Dimension Chart 16

1 3 Technical Data 17

2 OPERATION MANUAL 21

2 1 Dewaxing and Inspection of a Newly Supplied Machine 22

2 2 Safety Instructions 23

2 2 1 Safety measures to operate the Machine 23

2 2 1 1 How to start the compaction work 23

2 2 1 2 Work Safety Secured by User 23

2 2 1 3Ensurance of safety measures by the owner 23

2 2 2 Driver Qualification Requirements 24

2 2 3 Driver’s Duties 25

2 2 4 Forbidden activites – safety and gaurantee 26

2 2 5 Safety labels & signs used on the Machine 27

2 2 6 Hand Signals 32

2 3 Ecological & Hygienic Principles 35

2 3 1 Hygienic Principles 35

2 3 2 Ecological Principles 35

2 4 Preservation & Storage 36

2 4 1 Short-term preservation and storage for the period of 1 – 2 months 36

2 4 2 Machine Preservation & Storage for the Period Over 2 Months 37

2 5 Machine Disposal Following Its Life Termination 38

2 6 Machine Description 39

2 7 Controlling and operation of the machine 40

2 8 How to Control and Use the Machine 54

2 8 1 Start the Engine 55

2 8 2 Travel and Reversing 59

2 8 3 Emergency stop of the Machine 63

2 8 4 Stop the Machine and the Engine 63

2 8 5 Machine parking 64

2 8 6 Bonnet raising and lowering 65

2 8 7 Sprinkling 67

2 8 8 Ammann edgecutter (Optional) 68

2 8 9 Infra thermometer (Optional) 69

2 9 Machine transportation 70

2 9 1 Machine transportation by its own axle 70

2 9 2 Machine transportation by public road 70

2 9 3 How to load the Machine 71

2 10 Special conditions to use the Machine 73

2 10 1 Machine towing 73

2 10 2 How to operate the Machine during its running 78

2 10 3 Machine operation under low temperatures 78

2 10 4 Machine operation under High temperaturess and humidity 78

2 10 5 Machine operation under high altitudes 78

2 10 6 Machine operation at extremely dusty environment 78

2 10 7 Driving with vibrations on compacted and hard materials 78

3 MAINTENANCE MANUAL 81

3 1 Safety and other measures for machine maintenance 83

3 1 1 Safety during Machine Maintenance 83

3 1 2 Fire precautions when refilling 83

3 1 3 Ecological and hygienic principles 84

3 2 Specification of fluids 85

3 2 1 Engine oil 85

3 2 2 Fuel 86

3 2 3 Cooling liquid 87

3 2 4 Hydraulic oil 87

3 2 5 Gearbox oil 87

3 2 6 Lubrication grease 87

3 2 7 Drum cooling liquid 87

3 3 Refills 88

3 4 Lubrication and Maintenance Chart 89

3 5 Lubrication and Service plan 91

3 6 Lubrication and Maintenance Operations 92

Every 20 hours of operation or daily 93

3 6 1 Engine oil level check 93

3 6 2 Engine cooling liquid level check 94

3 6 3 Inspect the engine belt 95

3 6 4 Crankcase breather 95

3 6 5 Air filter dust valve check 96

3 6 6 Inspect fan condition 96

3 6 7 Fuel level check 97

3 6 8 Hydraulic tank oil level check 98

3 6 9 Water tank refilling 98

3 6 10 Inspect alarm and control devices 99

Every 250 hours of operation or 3 months 101

3 6 11 Engine oil exchange 101

3 6 12 Inspect engine induction manifold 104

3 6 13 Inspect engine cooling circuit 105

3 6 14 Checking oil in gearboxes 106

3 6 15 Inspect the battery 106

3 6 16 Air filter sensor check 108

3 6 17 Watering filter cleaning 108

3 6 18 Machine lubrication 110

Every 500 hours of operation or 6 months 112

3 6 19 Engine fuel filter and water seperator exchange 112

3 6 20 Engine cooling liquid level check 114

3 6 21 Replace air filter elements 114

3 6 22 Check of wiring 116

Every 1000 hours of operation or 1 year 117

3 6 23 Inspect engine belt 117

3 6 24 Vibrations system oil exchange 118

3 6 25 Inspect the Vibration damper system 119

3 6 26 Fuel tank cleaning 121

3 6 27 Water tank cleaning 122

Every 1500 hours of operation or 1 5 years 123

3 6 28 Exchanging oil in gearboxes 123

Every 2000 hours of operation or 2 years 124

3 6 29 Checking and adjusting valve clearance 124

3 6 30 Engine coolant exchange 124

3 6 31 Replace hydraulic oil and filters 128

Maintenance as required 132

3 6 32 Deaerating (venting) the fuel system 132

3 6 33 Cleaning the water separator 133

3 6 34 Cleaning of coolers 134

3 6 35 Drain water from sprinkling circuit before winter season 135

3 6 36 Adjustment of scrapers 136

3 6 37 Machine cleaning 138

3 6 38 Check the tightening of bolted connections 138

3 7 Defects 141

3 8 Attachments 142

Wiring diagram ARX 91 142

Hydraulic system diagram ARX 91 146

Regular maintenance spare parts chart 148