Starting from:

$33.95

Ammann ASC 170 Single Drum Roller Operating Manual 3001339 PDF

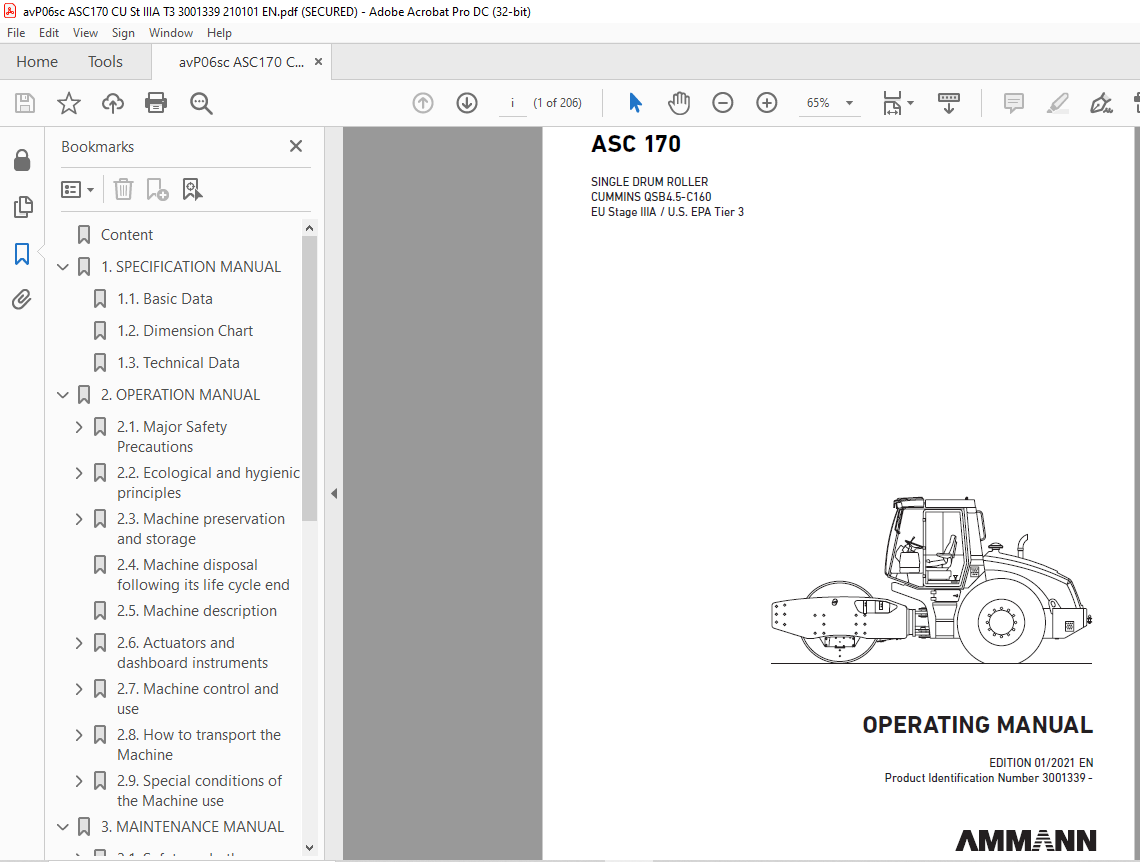

Ammann ASC 170 Single Drum Roller Cummins QSB4.5-C160 EU Stage IIIA/U.S EPA Tier 3 Operating Manual 3001339 – PDF DOWNLOAD

FILE DETAILS:

Ammann ASC 170 Single Drum Roller Cummins QSB4.5-C160 EU Stage IIIA/U.S EPA Tier 3 Operating Manual 3001339 – PDF DOWNLOAD

Language : English

Pages : 206

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Ammann ASC 170 Single Drum Roller Cummins QSB4.5-C160 EU Stage IIIA/U.S EPA Tier 3 Operating Manual 3001339 – PDF DOWNLOAD

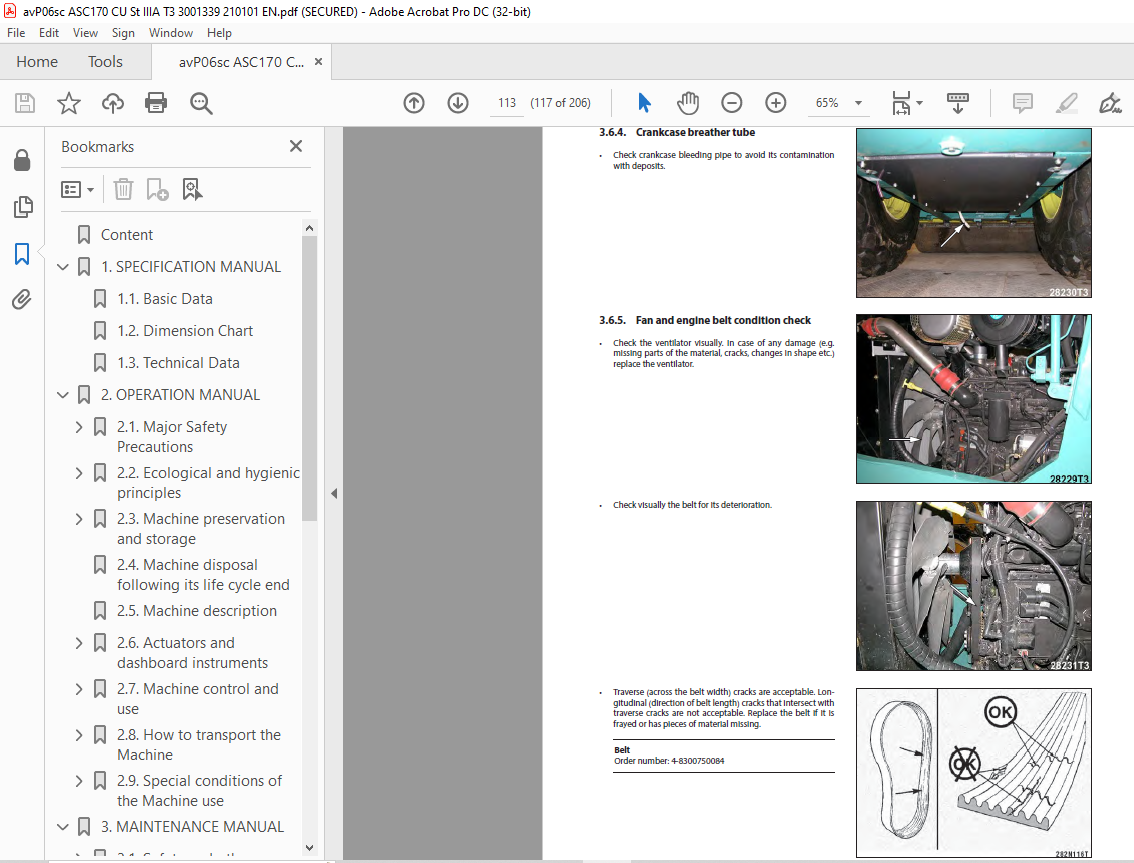

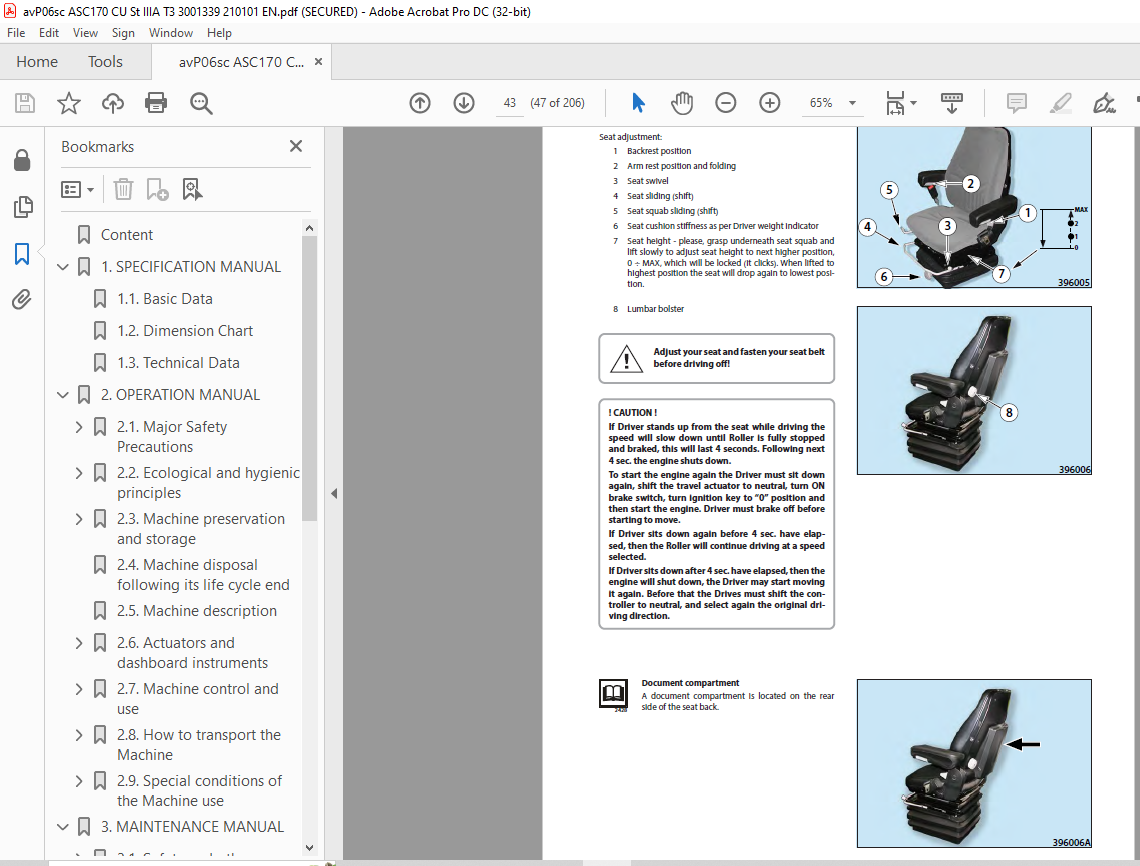

Content................................................................................................. 8 1. SPECIFICATION MANUAL................................................................................. 13 1.1. Basic Data..................................................................................... 14 1.2. Dimension Chart................................................................................ 16 1.3. Technical Data................................................................................. 18 2. OPERATION MANUAL..................................................................................... 25 2.1. Major Safety Precautions....................................................................... 27 2.1.1. Safety Measures during Machine Operation ................................................ 27 2.1.1.1. Compaction Work Commencement .......................................................... 27 2.1.1.2. Work Safety Secured by User............................................................ 27 2.1.1.3 Ensurance of safety measures by the owner............................................... 28 2.1.1.4. ROPS................................................................................... 28 2.1.2. Reguirements on Driver’s Qualification................................................... 29 2.1.3. Driver’s Liabilities..................................................................... 30 2.1.4. Forbidden activities – safety and guarantee.............................................. 31 2.1.5. Safety inscriptions and signs used on the Machine........................................ 32 2.1.6. Hand signals............................................................................. 37 2.2. Ecological and hygienic principles............................................................. 40 2.2.1. Hygienic principles...................................................................... 40 2.2.2. Ecological principles ................................................................... 40 2.3. Machine preservation and storage............................................................... 41 2.3.1. Short-term preservation and storage for a period of 1 – 2 months......................... 41 2.3.2. Preservation and storage for the period over 2 months long............................... 41 2.3.3. Dewaxing and inspection of a supplied machine............................................ 42 2.4. Machine disposal following its life cycle end.................................................. 43 2.5. Machine description............................................................................ 44 2.6. Actuators and dashboard instruments............................................................ 45 2.6.1. Power View control ...................................................................... 60 2.7. Machine control and use........................................................................ 70 2.7.1. Starting the engine...................................................................... 70 2.7.2. Travel and reversing..................................................................... 73 2.7.3. Emergency stop of the Machine............................................................ 76 2.7.4. How to stop the Machine and its engine................................................... 77 2.7.5. Machine parking.......................................................................... 78 2.7.6. Compactometer (optional equipment)....................................................... 78 2.7.7. Cab and bonnet raising and lowering...................................................... 79 2.7.8. Ballasting of tyres with liquid.......................................................... 83 2.8. How to transport the Machine................................................................... 85 2.8.1. Loading the machine...................................................................... 86 2.8.1.1. Loading the machine using a ramp....................................................... 86 2.8.1.2. Loading the machine using a crane...................................................... 87 2.9. Special conditions of the Machine use.......................................................... 88 2.9.1. Machine towing........................................................................... 88 2.9.2. Machine operation during running-in...................................................... 94 2.9.3. Machine operation at low temperatures.................................................... 94 2.9.4. Operating the Machine at high temperatures and humidity.................................. 95 2.9.5. Operating the Machine at high altitudes.................................................. 96 2.9.6. Work of the machine in the dusty environment............................................. 96 2.9.7. Driving with vibrations on compacted and hard materials.................................. 96 3. MAINTENANCE MANUAL................................................................................... 99 3.1. Safety and other measures for machine maintenance..............................................101 3.1.1. Safety of machine maintenance............................................................101 3.1.2. Fire precautions during operation media exchanges........................................101 3.1.3. Ecological and hygienic principles.......................................................102 3.2. Specification of fluids........................................................................103 3.2.1. Engine oil...............................................................................103 3.2.2. Fuel.....................................................................................105 3.2.3. Coolant .................................................................................106 3.2.4. Hydraulic oil............................................................................107 3.2.5. Gearbox oil..............................................................................107 3.2.6. Lubricating grease.......................................................................107 3.2.7. Drum cooling liquid......................................................................107 3.2.8. Windshield washer liquid.................................................................107 3.2.9. Air-conditioning filling.................................................................107 3.3. Fills..........................................................................................108 3.4. Lubrication and Maintenance Chart..............................................................109 3.5. Lubrication and service plan...................................................................112 3.6. Individual Operations of Maintenance...........................................................113 Every 20 hours of operation (daily).............................................................114 3.6.1. Engine oil level check...............................................................114 3.6.2. Engine cooling liquid level check....................................................115 3.6.3. Hydraulic oil level check............................................................116 3.6.4. Crankcase breather tube..............................................................117 3.6.5. Fan and engine belt condition check..................................................117 3.6.6. Air filter dust valve check..........................................................118 3.6.7. Warning and control devices check....................................................119 Every 100 hours of operation (weekly)...........................................................120 3.6.8. Tyre pressure check..................................................................120 Every 250 hours of operation (3 months).........................................................121 3.6.9. Engine inlet piping check............................................................121 3.6.10. Check of the fan and engine belt condition..........................................122 3.6.11. Coolers check.......................................................................123 3.6.12. Battery check.......................................................................124 3.6.13. Air filter sensor check.............................................................125 3.6.14. Machine lubrication.................................................................126 3.6.15. Oil in the vibrator check...........................................................129 3.6.16. Oil in the travel gearboxes check...................................................130 3.6.17. Pad foot segments inspection........................................................132 Every 500 hours of operation (6 months).........................................................133 3.6.18. Engine oil change...................................................................133 3.6.19. Fuel filters replacement............................................................136 3.6.20. Air filter elements replacement.....................................................138 3.6.21. Filters of the cab ventilation and heating replacement..............................140 3.6.22. Engine cooling liquid check.........................................................141 3.6.23. Wiring check........................................................................141 3.6.24. Air filter of the air conditioning system replacement...............................142 3.6.25. Wheel bolts tightening check........................................................142 Every 1000 hours of operation (1 year)..........................................................143 3.6.26. Engine belt check...................................................................143 3.6.27. Oil in the travel gearboxes change..................................................145 3.6.28. Air conditioning compressor mounting check..........................................146 3.6.29. Damping system check................................................................147 Every 2000 hours of operation (2 years).........................................................149 3.6.30. Oil in the vibrator change..........................................................149 3.6.31. Air conditioning system cleaning....................................................150 3.6.32. Hydraulic oil and filter change.....................................................151 3.6.33. Cleaning of the suction strainer unit of the cab and bonnet raising and lowering....155 3.6.34. Engine cooling liquid change........................................................156 Every 5000 hours of operation (4 years).........................................................158 3.6.35. Valve clearance adjustment..........................................................158 Maintenance - As Needed.........................................................................159 3.6.36. Water separator cleaning............................................................159 3.6.37. Coolers cleaning....................................................................160 3.6.38. Machine cleaning....................................................................161 3.6.39. Scrapers adjustment.................................................................162 3.6.40. Drum cooling mixture................................................................163 3.6.41. Charging of the battery.............................................................164 3.6.42. Screw connection tightening check...................................................165 3.7. Defects........................................................................................167 3.8. Annexes........................................................................................168 Wiring diagram..................................................................................168 Wiring diagram - road lighting..................................................................176 Wiring diagram – RTM............................................................................182 Wiring diagram – wheel lock.....................................................................188 Hydraulic system diagram - INTER - Wheel differential lock......................................194 Hydraulic system diagram - Interaxle differential lock ATC......................................196 Hydraulic system diagram - electro-hydraulic cab and bonnet lifting.............................198 Hydraulic system diagram - manual cab and bonnet lifting........................................199 Table of spare parts............................................................................200

1 file (11.0MB)