$32.95

Ammann AV 130 X Tandem Roller Operating Manual 00024 - PDF

Ammann AV 130 X Articulated Tandem Roller Cummins Tier 3 Operating Manual SN 00024 – PDF DOWNLOAD

FILE DETAILS:

Ammann AV 130 X Articulated Tandem Roller Cummins Tier 3 Operating Manual SN 00024 – PDF DOWNLOAD

Language : English

Pages : 168

Downloadable : Yes

File Type : PDF

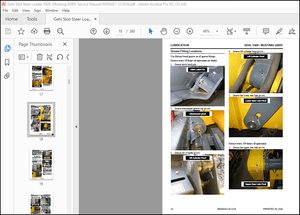

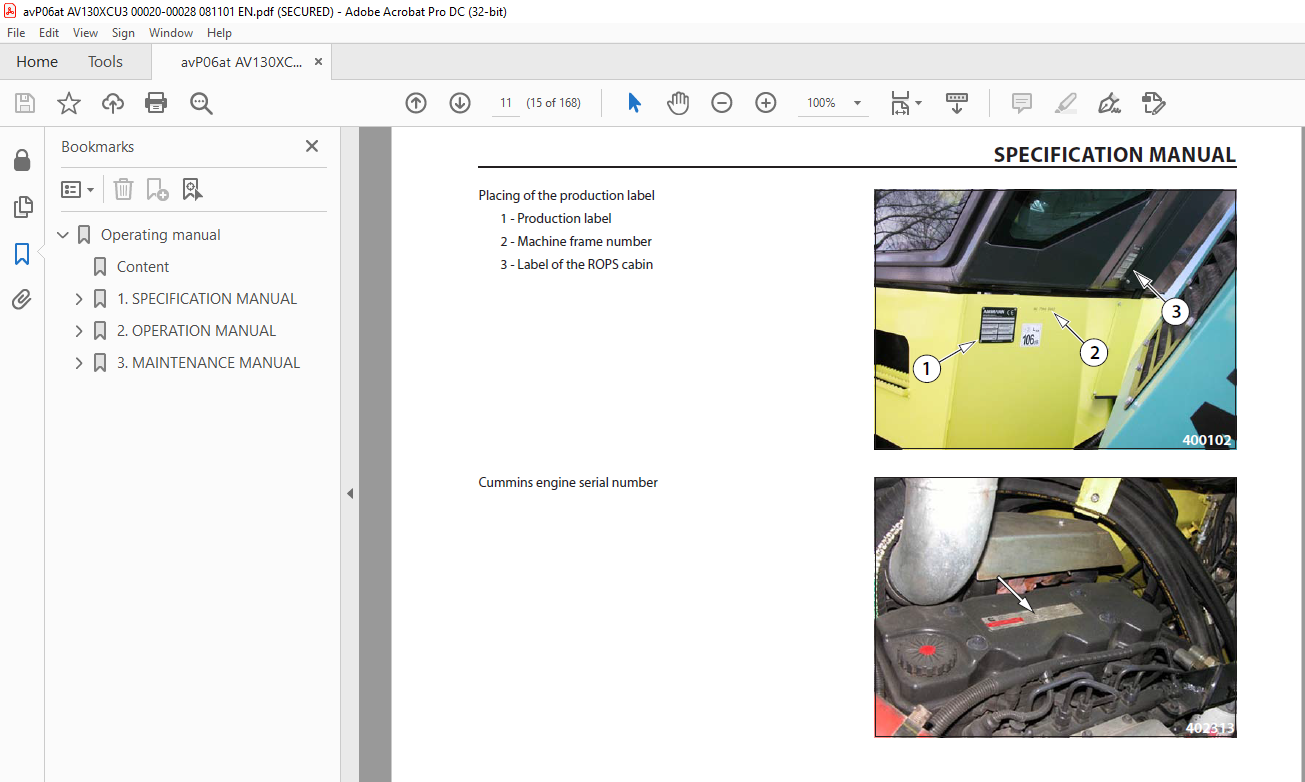

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Ammann AV 130 X Articulated Tandem Roller Cummins Tier 3 Operating Manual SN 00024 – PDF DOWNLOAD

Operating manual 1

Content 8

1 SPECIFICATION MANUAL 13

1 1 Basic specification 14

1 1 1 Area of use 14

1 1 2 Machine design 14

1 2 Machine dimension scheme 16

1 3 Technical data 18

1 3 1 Weights 18

1 3 2 Drive of travel – driving properties 18

1 3 3 The vibrations 18

1 3 4 Engine 18

1 3 5 The Brakes 19

1 3 6 Drive 19

1 3 7 Fills 19

1 3 8 Sprinkling 19

1 3 9 Electrical installation 19

1 3 10 Hygienic parameters 20

2 OPERATION MANUAL 23

2 1 Major Safety Precautions 25

2 1 1 Safety Measures during Machine Operation 25

2 1 1 1 Compaction Work Commencement 25

2 1 1 2 Work Safety Secured by User 25

2 1 1 3Ensurance of safety measures by the owner 26

2 1 1 4 ROPS Cab 26

2 1 2 Reguirements on Driver’s Qualification 27

2 1 3 Driver’s Liabilities 27

2 1 4 Banned Operations 29

2 1 5 Safety inscriptions and signs used on the Machine 30

2 1 6 Hand Signals 34

2 2 Ecological & Hygienic Principles 37

2 2 1 Hygienic Principles 37

2 2 2 Ecological Principles 37

2 3 Preservation & Storage 38

2 3 1 Short-Term Preservation & Storate for the Period of 1 ÷ 2 Months 38

2 3 2 Machine Preservation & Storage for the Period Over 2 Months Long 38

2 3 3 De-conservation and inspection of brand new machines 39

2 4 Machine Disposal Following Its Life Termination 40

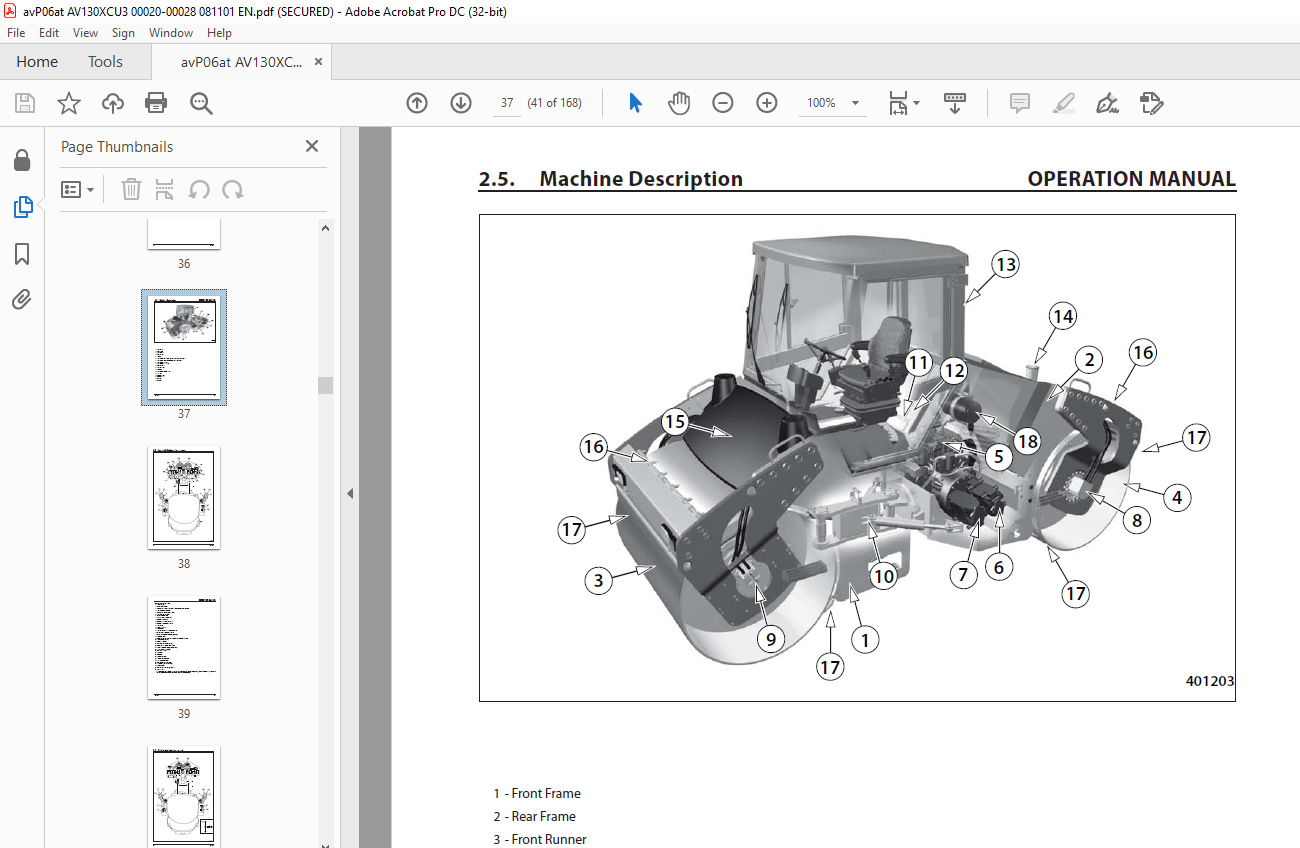

2 5 Machine Description 41

2 6 Controls & Dashboard Instruments 42

2 7 Machine basic functions control 64

2 7 1 Engine starting 65

2 7 2 Machine travel and reversing with no vibration 69

2 7 3 Machine travel and reversation incl vibrations 75

2 7 4 Driving with vibrations on compacted and hard materials 75

2 7 5 Compacting near constructed facilities 75

2 7 6 How to stop the Machine and its engine 77

2 7 7 Safe stopping of the Machine 77

2 7 8 Emergency stop of the Machine 79

2 7 9 Machine shutdown 79

2 7 10 Sprinkling 79

2 7 11 How to lift and let down the engine bonnet 80

2 7 12Edge cutter and compacter 81

2 7 13 Infra thermometer 82

2 8 Machine transport 83

2 8 1 Machine towing 83

2 8 2 How to load the Machine 86

2 8 3 Transporting by the road 87

2 9 Special conditions to use the Machine 88

2 9 1 How to operate the Machine during its running-in 88

2 9 2 Operating the Machine at low temperatures 88

2 9 3 Machine operation at high temperatures and humidity 88

2 9 4 Machine operation at high altitudes 88

2 9 5 Machine operation within very dusty environment 88

3 MAINTENANCE MANUAL 91

3 1 Safety Standards at Lubrication and Maintenance 93

3 1 1 Safety of machine maintenance 93

3 1 2 Fire precautions during operation media exchanges 93

3 1 3 Ecological and hygienic principles 94

3 1 3 1 Hygienic principles 94

3 1 3 2 Ecological principles 94

3 2 Specification of fluids 95

3 2 1 Engine oil 95

3 2 2 Fuel 96

3 2 3 Coolant 96

3 2 4 Hydraulic oil 97

3 2 5 Gearbox oil 98

3 2 6 Lubricating grease 98

3 2 7 Windshield washer liquid 98

3 3 Fills 99

3 4 Lubrication and Maintenance Chart 100

3 5 Lubrication Chart 102

3 6 Individual Operations of Maintenance 103

Every 20 Hours or Daily 104

3 6 1 Checking the amount of oil in the engine 104

3 6 2 Checking cooling liquid of the engine 105

3 6 3 Hydraulic tank oil level checking 106

3 6 4 Crankcase breather tube 106

3 6 5 Checking the condition of the ventilator and belt 107

3 6 6 Checking the vacuum valve of the air cleaner 108

3 6 7 Fuel level checking 109

3 6 8 Watering tank filling 110

3 6 9 Cleaning the water separator 111

3 6 10 Warning and control devices checking 112

Every 250 Hours or Once in 3 Months 114

3 6 11 Air intake cooler, intake piping 114

3 6 12 Checking the cooling circuit of the engine 115

3 6 13 Checking the engine belt 116

3 6 14 Checking battery 117

3 6 15 Air filter vacuum switch function checking 119

3 6 16 Joint bearings, pins 120

3 6 17 Checking oil in gearboxes 122

3 6 18 Watering filter and sprinkler screens 123

Every 500 Hours or Once in 6 Month 124

3 6 19 Engine oil exchange 124

3 6 20 Engine fuel filter exchange 127

3 6 21 Checking cooling liquid 128

Every 1000 Hours or Once a Year 129

3 6 22 How to check tightening pulley and belt of the engine 129

3 6 23 Exchanging oil in gearboxes 131

3 6 24 Damping system checking – drum and cabin 133

3 6 25 Fuel tank cleaning 134

3 6 26 Water tank cleaning 136

Every 2000 Hours or Every 2 Years 137

3 6 27 Vibrations system oil exchange 137

3 6 28 How to replace hydraulic oil and filters 138

3 6 29 Exchanging the engine cooling liquid 142

3 6 30 Exchanging cleaner elements of air cleaner 144

Maintenance – As Needed 146

3 6 31 Cleaning the engine radiator and hydraulic oil 146

3 6 32 Water discharge from watering circuit before winter season 147

3 6 33 Cleaning the air cleaner of cabin ventilation 149

3 6 34 Cleaning the machine 150

3 6 35 Adjustment of scrapers 151

3 6 36 Checking and tightening bolted joints 153

3 7 Defects 155

3 8 Appendixes 156

Wiring scheme 156

Hydraulic Diagram 160

Air conditioner 162