Starting from:

$30.95

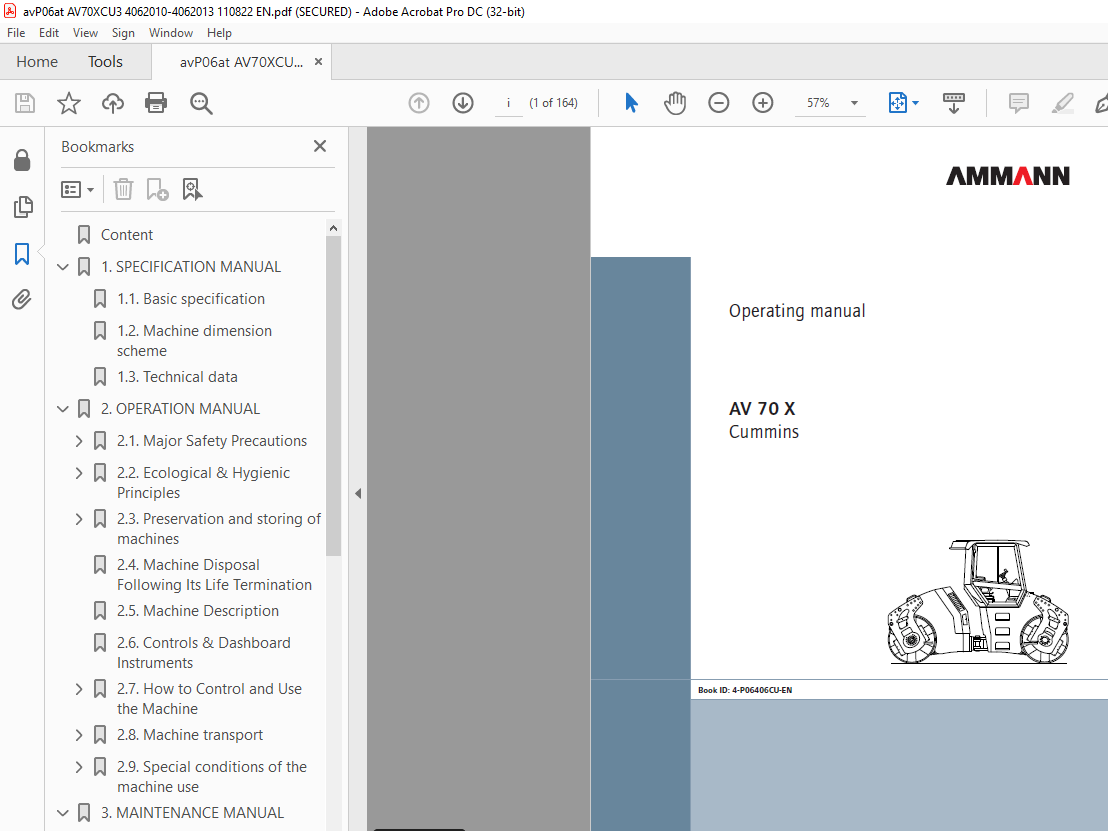

Ammann AV 70 X Tandem Roller Operating Manual SN 4062010 - PDF

Ammann AV 70 X Tandem Roller Cummins Tier 3 Operating Manual SN 4062010 – PDF DOWNLOAD

FILE DETAILS:

Ammann AV 70 X Tandem Roller Cummins Tier 3 Operating Manual SN 4062010 – PDF DOWNLOAD

Language : English

Pages :164

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Ammann AV 70 X Tandem Roller Cummins Tier 3 Operating Manual SN 4062010 – PDF DOWNLOAD

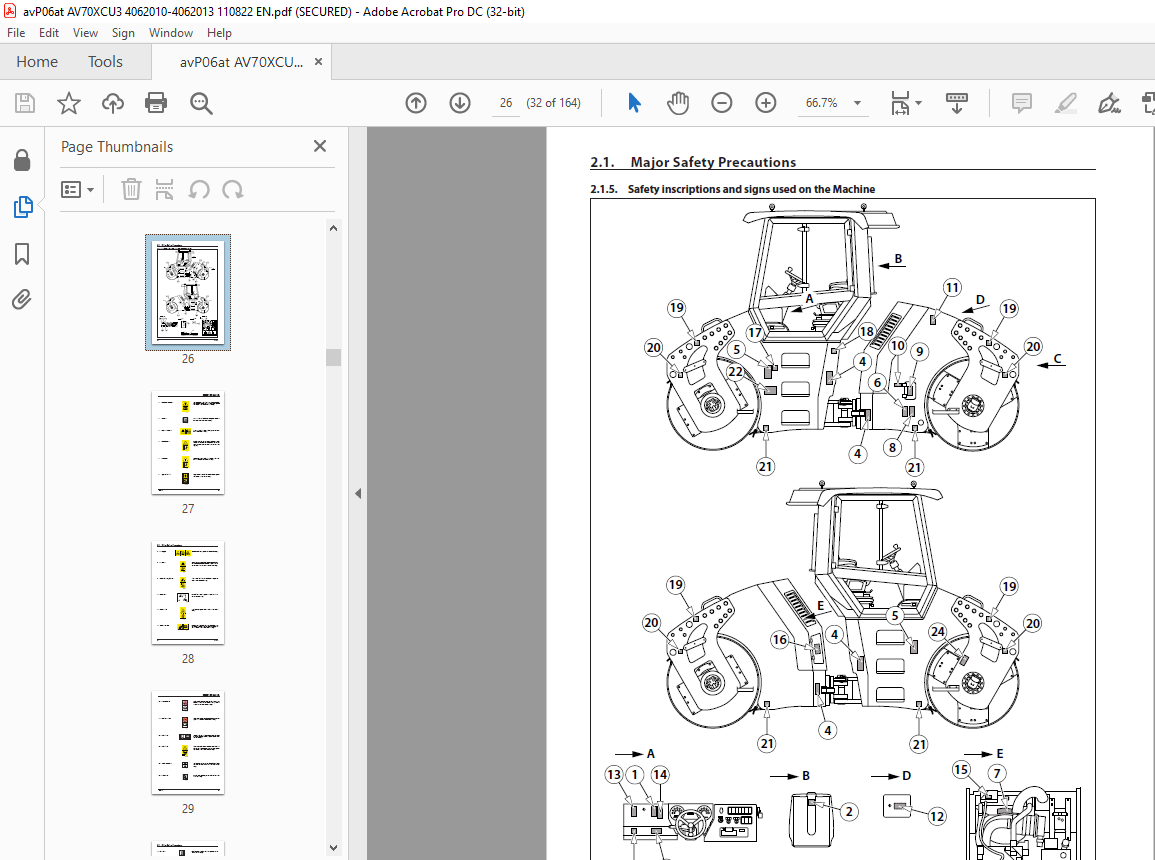

Content............................................................................ 10 1. SPECIFICATION MANUAL............................................................ 15 1.1. Basic specification....................................................... 16 1.2. Machine dimension scheme.................................................. 18 1.3. Technical data............................................................ 20 2. OPERATION MANUAL................................................................ 25 2.1. Major Safety Precautions.................................................. 27 2.1.1. Safety Measures during Machine Operation ........................... 27 2.1.1.1. Compaction Work Commencement ..................................... 27 2.1.1.2. Work Safety Secured by User....................................... 27 2.1.1.3 Ensurance of safety measures by the owner.......................... 28 2.1.1.4. ROPS Cab ......................................................... 28 2.1.2. Reguirements on Driver’s Qualification.............................. 29 2.1.3. Driver’s Liabilities................................................ 29 2.1.4. Banned Operations................................................... 31 2.1.5. Safety inscriptions and signs used on the Machine .................. 32 2.1.6. Hand Signals........................................................ 37 2.2. Ecological & Hygienic Principles.......................................... 41 2.2.1. Hygienic Principles ................................................ 41 2.2.2. Ecological Principles .............................................. 41 2.3. Preservation and storing of machines...................................... 42 2.3.1. Short-term preservation and storage for a period of 1 – 2 months.... 42 2.3.2. Machine Preservation & Storage for the Period Over 2 Months Long.... 42 2.3.3. Dewaxing and inspection of the supplied machine..................... 43 2.4. Machine Disposal Following Its Life Termination........................... 44 2.5. Machine Description....................................................... 45 2.6. Controls & Dashboard Instruments ......................................... 46 2.7. How to Control and Use the Machine........................................ 66 2.7.1. Start-up of the engine.............................................. 67 2.7.2. Travel and reversing................................................ 71 2.7.3. Emergency stop of the Machine....................................... 79 2.7.4. How to stop the Machine and its engine.............................. 79 2.7.5. Machine parking..................................................... 79 2.7.6. Bonnet raising and lowering......................................... 80 2.7.7. Sprinkling.......................................................... 83 2.7.8. Edge cutter and compacter........................................... 85 2.8. Machine transport......................................................... 86 2.8.1. How to load the Machine............................................. 87 2.9. Special conditions of the machine use..................................... 88 2.9.1. Machine towing...................................................... 88 2.9.2. How to operate the Machine during its running-in.................... 92 2.9.3. Operating the Machine at low temperatures........................... 92 2.9.4. Machine operation at high temperatures and humidity................. 92 2.9.5. Machine operation at high altitudes................................. 92 2.9.6. Machine operation within very dusty environment..................... 92 2.9.7. Driving with vibrations on compacted and hard materials............. 92 3. MAINTENANCE MANUAL.............................................................. 95 3.1. Safety and other measures for machine maintenance......................... 97 3.1.1. Safety of machine maintenance....................................... 97 3.1.2. Fire precautions during operation media exchanges................... 97 3.1.3. Ecological and hygienic principles.................................. 98 3.2. Media specification....................................................... 99 3.2.1. Engine oil.......................................................... 99 3.2.2. Fuel................................................................100 3.2.3. Cooling liquid......................................................101 3.2.4. Hydraulic oil ......................................................101 3.2.5. Lube grease ........................................................102 3.2.6. Glass washer fluid .................................................102 3.2.7. Gear oil............................................................102 3.3. Media ....................................................................103 3.4. Lubrication and Maintenance Chart.........................................104 3.5. Lubrication Chart.........................................................106 3.6. Lubrication and Maintenance Operations....................................107 After 20 hours of operation (daily)........................................108 3.6.1. Engine oil level check..........................................108 3.6.2. Engine cooling liquid level check..............................109 3.6.3. Inspect the engine belt ........................................110 3.6.4. Crankcase breather..............................................110 3.6.5. Inspect air filter vacuum valve................................111 3.6.6. Inspect fan condition...........................................111 3.6.7. Fuel level check................................................112 3.6.8. Hydraulic tank oil level check..................................113 3.6.9. Water tank refilling............................................113 3.6.10. Inspect alarm and control devices.............................114 Following 250 hours of operation (3 months)................................116 3.6.11. Engine oil exchange............................................116 3.6.12. Inspect engine induction manifold..............................118 3.6.13. Inspect engine cooling circuit.................................118 3.6.14. Inspect the battery............................................120 3.6.15. Air filter sensor check........................................122 3.6.16. Watering filter cleaning.......................................123 3.6.17. Machine lubrication............................................125 After 500 hours of operation (after 6 months)..............................127 3.6.18. Engine fuel filter exchange....................................127 3.6.19. Engine cooling liquid level check..............................128 After 1,000 hours of operation (after 1 year)..............................129 3.6.20. Inspect engine belt............................................129 3.6.21. Inspect the exhaust system.....................................129 3.6.22. Inspect the silencing system...................................130 3.6.23. Clean the water tank...........................................132 3.6.24. Oil change in the gearboxes....................................133 After 2,000 hours of operation (after 2 years).............................134 3.6.25. Checking and adjusting valve clearance.........................134 3.6.26. Engine coolant exchange........................................134 3.6.27. How to exchange oil in the vibrators...........................138 3.6.28. How to exchange hydraulic oil and filters......................138 Maintenance as required....................................................142 3.6.29. Fuel system breathing..........................................142 3.6.30. How to replace air filter elements.............................143 3.5.31. How to clean water separator of fuel filter....................145 3.6.32. Cleaning of coolers............................................146 3.6.33. How to clean cab ventilation filter............................146 3.6.34. Drain water from sprinkling circuit before winter season.......147 3.6.35. Adjust the scrapers...........................................149 3.6.36. Machine cleaning ..............................................151 3.6.37. Check the tightening of bolted connections.....................151 3.7. Defects...................................................................155 3.8. Attachments...............................................................156 Wiring Diagram.............................................................156 Hydraulic diagram .........................................................160

1 file (14.9MB)