Starting from:

$30.95

Ammann eARX 26-2 Tandem Roller Operating Manual 3000000 - PDF

Ammann eARX 26-2 Tandem Roller Operating Manual 3000000 – PDF DOWNLOAD

FILE DETAILS:

Ammann eARX 26-2 Tandem Roller Operating Manual 3000000 – PDF DOWNLOAD

Language : English

Pages : 152

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Ammann eARX 26-2 Tandem Roller Operating Manual 3000000 – PDF DOWNLOAD

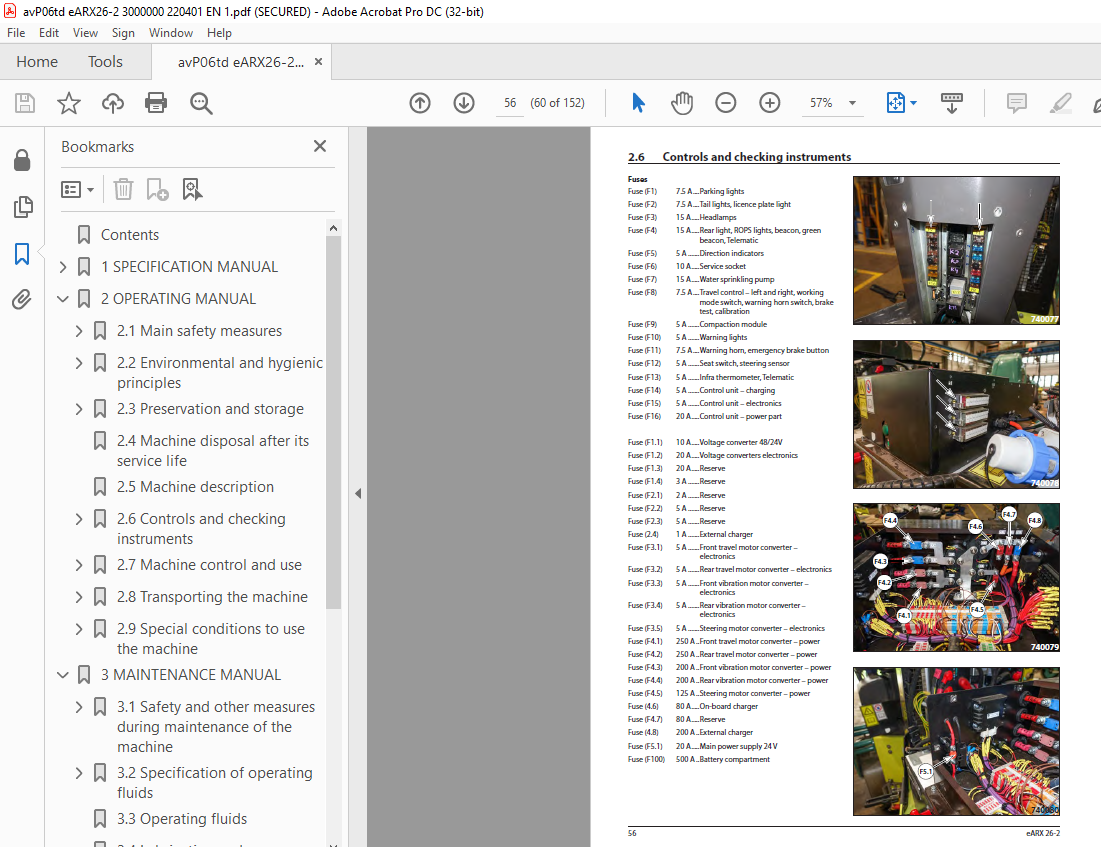

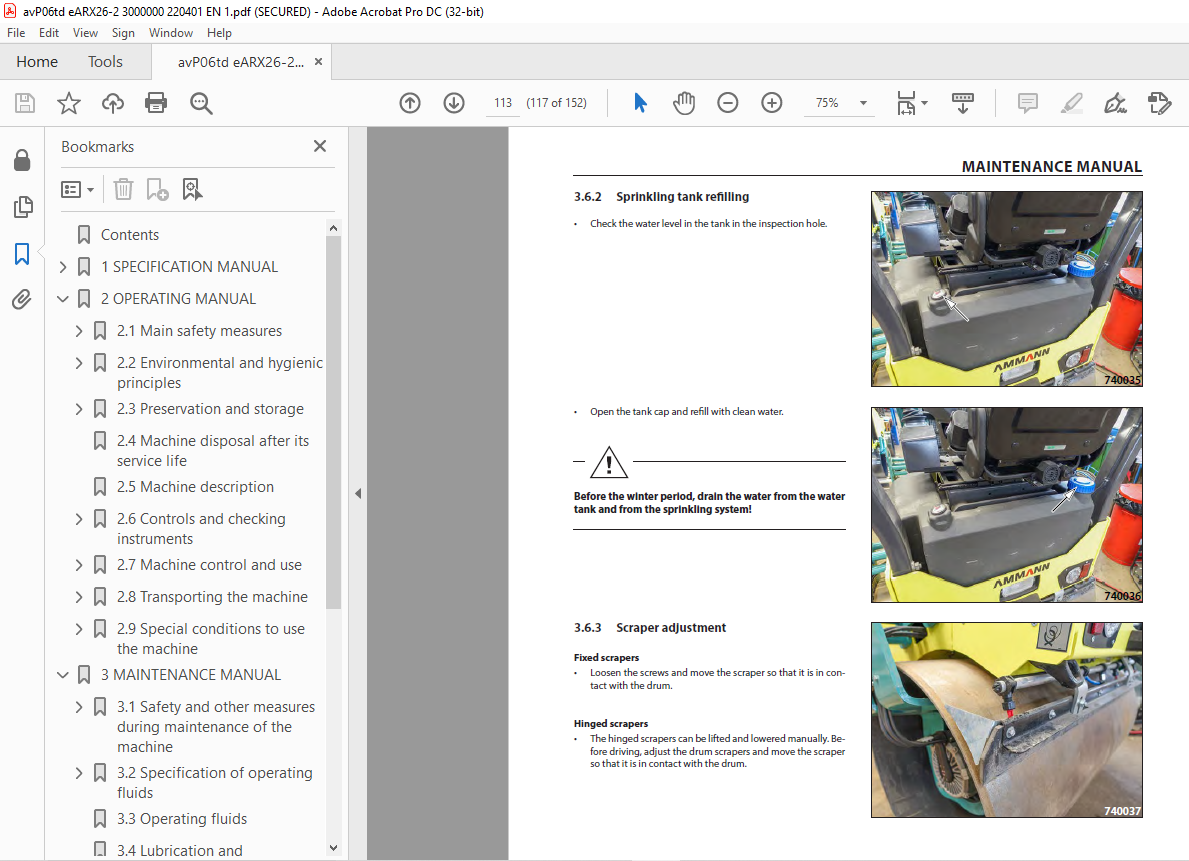

Contents.................................................................................. 8 1 SPECIFICATION MANUAL.................................................................... 13 1.1 Basic data........................................................................ 14 1.2 Dimensional drawing of the machine................................................ 16 1.3 Technical data.................................................................... 18 2 OPERATING MANUAL........................................................................ 21 2.1 Main safety measures.............................................................. 23 2.1.1 Safety measures during machine operation.................................... 23 2.1.1.1 Before compaction works are started....................................... 23 2.1.1.2 Work in the dangerous area................................................ 23 2.1.1.3 Dangerous area and safe distance.......................................... 24 2.1.1.4 Ensuring safety measures on the part of the owner......................... 26 2.1.1.5 Protective ROPS frame..................................................... 26 2.1.2 Requirements for the qualification of machine operators..................... 26 2.1.3 Driver’s obligations........................................................ 27 2.1.4 Forbidden activities – safety and guarantee................................. 28 2.1.5 Power circuit of travel, vibration and steering............................. 29 2.1.6 Safety notices and signs applied on the machine ............................ 31 2.1.7 Hand signals................................................................ 34 2.2 Environmental and hygienic principles............................................. 37 2.2.1 Hygiene principles ......................................................... 37 2.2.2 Environmental principles.................................................... 37 2.3 Preservation and storage.......................................................... 39 2.3.1 Short-term preservation and storage for 1 – 2 months........................ 39 2.3.2 Preservation and storage of the machine for more than 2 months.............. 39 2.3.3 Removal of preservation of the machine...................................... 41 2.4 Machine disposal after its service life........................................... 43 2.5 Machine description............................................................... 44 2.6 Controls and checking instruments................................................. 46 2.6.1 Dashboard and control panels................................................ 47 2.7 Machine control and use........................................................... 64 2.7.1 Starting the machine........................................................ 65 2.7.2 Travel and reversing........................................................ 67 2.7.3 Stopping and switching off the machine...................................... 71 2.7.4 Machine emergency stop...................................................... 71 2.7.5 Panic response.............................................................. 73 2.7.6 Machine parking............................................................. 74 2.7.7 Battery charging............................................................ 75 2.7.8 Battery Management System (BMS)............................................. 80 2.7.9 Sprinkling.................................................................. 81 2.7.10 ACE Force (optional equipment)............................................. 81 2.7.11 Infra thermometer (optional equipment)..................................... 82 2.7.12 Telematics readiness....................................................... 88 2.7.13 ROPS lifting and lowering.................................................. 89 2.7.14 Lowering and lifting of the ROPS frame with a plastic canopy............... 91 2.7.15 Lowering and raising of the plastic canopy ................................ 97 2.7.16 Calibration mode........................................................... 99 2.8 Transporting the machine..........................................................102 2.8.1 Loading the machine.........................................................103 2.8.1.1 Loading the machine using a ramp..........................................103 2.8.1.2 Loading the machine with a crane..........................................104 2.9 Special conditions to use the machine.............................................105 2.9.1 Drum offset.................................................................105 2.9.2 Operating the machine at low temperatures...................................106 2.9.3 Machine operation under high temperatures and humidity......................106 2.9.4 Machine operation in a very dusty environment...............................106 2.9.5 Driving with vibration on compacted and hard materials .....................106 3 MAINTENANCE MANUAL......................................................................107 3.1 Safety and other measures during maintenance of the machine.......................109 3.1.1 Safety during maintenance of the machine....................................109 3.1.2 Fire protection when operating fluids are changed...........................109 3.1.3 Environmental and hygienic principles.......................................110 3.2 Specification of operating fluids.................................................111 3.2.1 Hydraulic oil...............................................................111 3.2.2 Lubricating grease..........................................................111 3.3 Operating fluids..................................................................112 3.4 Lubrication and maintenance chart.................................................113 3.5 Lubrication and service plan......................................................114 3.6 Lubrication and maintenance operations............................................115 Every 20 hours of operation (daily)...............................................116 3.6.1 Check of the traction battery charge condition..........................116 3.6.2 Sprinkling tank refilling...............................................117 3.6.3 Scraper adjustment......................................................117 3.6.4 Inspection of warning and checking devices..............................118 3.6.5 Brake test..............................................................120 3.6.5.1 Check of the parking brake............................................120 3.6.5.2 Check of the emergency brake..........................................121 3.6.5.3 Check of the service brake............................................122 3.6.6 Checking the hydraulic system for leaks.................................123 3.6.7 Electrical installation inspection......................................123 Every 100 hours of operation......................................................124 3.6.8 Machine lubrication.....................................................124 Every 250 hours of operation......................................................125 3.6.9 Sprinkling filter cleaning..............................................125 Every 1000 hours of operation.....................................................126 3.6.10 Hydraulic oil and filter replacement...................................126 3.6.11 Inspection of the shock-absorbing system...............................128 3.6.12 Swinging support check.................................................128 3.6.13 Articulation joint check...............................................128 Maintenance as required...........................................................129 3.6.14 Traction battery charging..............................................129 3.6.15 Gas strut replacement..................................................129 3.6.16 Cleaning the water tank................................................130 3.6.17 Cleaning the machine...................................................130 3.6.18 Draining water from the sprinkling circuit before the winter season....131 3.6.19 Checking the screw connections for tightening..........................132 3.7 Defects...........................................................................134 3.7.1 Converter errors............................................................135 3.8 Annexes...........................................................................136 3.8.1 Wiring diagram..............................................................136 3.8.2 Hydraulic system diagram....................................................148

1 file (8.7MB)