$37

Bendi Forklift IV Series B25-442-180D Electric Narrow Aisle Forklift Service Manual – PDF DOWNLOAD

Bendi Forklift IV Series B25-442-180D Electric Narrow Aisle Forklift Service Manual – PDF DOWNLOAD

FILE DETAILS:

Bendi Forklift IV Series B25-442-180D Electric Narrow Aisle Forklift Service Manual – PDF DOWNLOAD

Language : English

Pages :286

Downloadable : Yes

File Type : PDF

B25-4/42-180D B35-4/48-180D

B30-4/42-180D B40-4/48-180D

B45-4/48-180D

TABLE OF CONTENTS:

Bendi Forklift IV Series B25-442-180D Electric Narrow Aisle Forklift Service Manual – PDF DOWNLOAD

Table of Contents 1-i

Using This Manual 2-1

Safety 2-1

Warranty and Parts 2-1

Truck Overview 2-1

Receiving and Inspection 2-1

Operation 2-2

Preventive Maintenance 2-2

Troubleshooting 2-2

Corrective Maintenance 2-2

Mast IPB (illustrated parts breakdown) 2-3

Base IPB (illustrated parts breakdown) 2-3

Appendix, A through Z 2-3

Safety

Precautions 0-1

Safety 0-2

Site Supervision 0-2

Operator 0-3

Seat Belt 0-4

Seat Safety Switch 0-5

Emergency STOP Button0-5

Parking Brake 0-5

Tipping Hazards 0-6

Longitudinal Tipping Can Occur When: 0-6

Lateral Tipping Can Occur When: 0-7

Traveling and Load Handling 0-7

Speed 0-9

Visibility 0-9

ii

Battery Care 0-9

Features0-9

Care0-10

Service Repair 0-11

Side Shifting 0-12

Safety Labels 0-13

General 0-13

Available Options 0-17

Fork Positioner, Non-Side Shifting0-17

Fire Extinguisher 0-18

Rollout Battery Tray 0-18

Additional Publications 0-19

Truck Overview 1-1

Introduction 1-1

Truck Layout 1-3

Overview 1-5

Frame 1-5

Traction Drive 1-5

Brake System1-5

Parking Brake 1-5

Safety Interlock1-5

Electrical System 1-6

Traction 1-6

Main Pump Motor (Lift) 1-6

Power Steering 1-6

Battery 1-6

Hydraulic System 1-7

Steering 1-7

Mast Controls 1-7

Side Shift 1-7

Operator’s Cab 1-8

Driver Controls 1-8

Battery Compartment Access Cover /Latch1-10

Dash Display Panel 1-12

Mast Assemblies 1-13

Technical Specifications 1-16

Bendi Series IV Narrow Aisle Forklift 1-16

Appendix 1-16

Models 1-16

EE Series (Electrical Enclosure)1-16

Cold Storage (Freezer Package)1-16

Available Options 1-16

Fire Extinguisher 1-16

Fork Positioner, Non-Side Shifting1-17

Light and Alarms 1-18

Rollout Battery Tray1-19

Receiving and Inspection 2-1

Receiving Your Truck 2-1

Items Furnished With Your Truck 2-1

Items Required 2-1

Tools and Test Equipment 2-1

To Prepare the Truck 2-2

Charging a Wet Battery 2-2

Using the Hydrometer2-4

To Charge the Battery:2-4

Charging a Dry Battery 2-6

To Charge a Dry-Cell Battery: 2-7

Inspection Check List 2-8

Visual Checks 2-8

Routine Checks 2-9

Replacing the Battery 2-12

To Replace a Battery 2-12

Rollout Battery Tray Option 2-14

Storage, Towing or Shipping 2-14

Truck Storage 2-14

Battery Storage 2-15

Towing the Truck 2-15

To Ship the Truck 2-16

Using Lifting Equipment2-17

Operation 3-1

To Begin Operating 3-2

Understanding Stability 3-2

Capacity3-4

Serial Number Code3-6

Load Center 3-7

Counterweight 3-7

Maximum Fork Height3-8

Determining Weight of the Load3-8

Working in Hazardous Environments 3-9

Atmospheric/Electrical 3-9

Chemical Hazards 3-9

Pre-Operation Checklist 3-9

Adjusting the Driver’s Seat 3-10

Seat Belt 3-11

Bendi Series IV Forklift Operator’s Manual

iii

Tilt Steering Column 3-12

Fork Adjustment 3-12

Manual Fork Adjust 3-13

Fork Positioner Option – Automatic 3-13

Driving the Truck 3-14

Practice Session 3-15

The Mast 3-16

Handling the Load 3-18

To Pick Up the Load 3-19

To Deliver a Load 3-22

Fire Extinguisher Option 3-27

In Case of a Fire ! 3-27

Fork Positioner Option 3-28

Hydraulic System 3-29

Power Steering System 3-29

Mast Systems 3-30

Tilt and Shift3-32

Lift and Lower3-32

Electrical Control System 3-33

General 3-33

Dash Displays 3-34

Preventative

Maintenance 4-1

Tables 4-2

Preventative Maintenance Schedule 4-2

Recommended Lubricants 4-3

Overview 4-7

Tools or Equipment Required 4-8

Special Tools Required4-8

Safety Equipment Required 4-8

Floor Access Panel – Removal 4-9

Daily Inspection 4-10

Check Batteries 4-10

To Check the Battery: 4-11

Check Power Steering 4-12

Check Hydraulic Functions 4-12

Check the Return-to-Neutral 4-13

Check Primary Lift Chain 4-13

Inspect Tires 4-14

Chunking (Chipping) or Embedded Objects 4-15

Undercutting and Uneven Wear4-15

Flat-spotting4-16

Bendi Series IV Forklift Operator’s Manual

iv

To Expand Tire Life 4-16

Check Driver’s Seat Switch 4-17

Weekly Inspection 4-18

Check Hydraulic Oil Level 4-18

Check Master Cylinder Fluid Level 4-19

Check Tilt Cylinder Racking 4-20

Tilt Cylinder Racking and Tilt Degree Setting 4-20

Lubricating the Truck 4-23

Front Column Rotation Bearings/Gears 4-24

Tilt Cylinder Clevises4-25

Mast Mounting Pins 4-25

Forks and Side Shifter 4-26

Check Planetary Gear Box 4-26

Check Lift Operation 4-29

Drive Wheel Lug Nuts 4-30

Cooling Fans 4-30

Three Month Inspection 4-31

Check Nuts, Bolts, and Screws 4-31

Change Hydraulic Oil Filter 4-32

Check Service Disc Brakes 4-33

To Check the Brakes4-33

Semi-Annual 4-34

General 4-34

Inspection Check List 4-36

Inspect Electrical Connections 4-36

Fork Inspection 4-36

Replacing Motor Brushes 4-39

Exposing the Motors4-39

Traction Motor Brushes4-41

Pump and Power Steering Motor Brushes 4-42

Annual Inspection 4-43

Change Hydraulic Oil 4-43

Lubricate Front Steer Wheel Bearings 4-45

Inspecting the Bearings, Race and Inner Seal 4-46

Lubricate Steer Wheel Knob 4-47

SRE Controller 4-48

General Practice 4-48

Options 4-49

Fork Positioner Lubrication, Non-Side Shifting 4-49

Rollout Battery Tray 4-50

Troubleshooting 5-1

Preliminary Procedures 5-1

Bendi Series IV Forklift Operator’s Manual

v

Visible Problems 5-2

Spills and Waste Management 5-8

Spills of Sulfuric Acid 5-8

Handling and Storage 5-9

Waste Generation and Disposal 5-9

Recycling locations 5-10

Audible Problems 5-11

Performance Problems 5-14

Pump Problems 5-26

SRE Controller Problems 5-28

Overview 5-28

Corrective Maintenance 6-1

Introduction 6-1

Tools Needed 6-1

Before You Begin 6-2

Lifting the Truck 6-3

Electrical Static Discharge 6-4

Hydraulic Fittings and Hoses 6-4

Cleaning and Inspection 6-5

Brake System 6-6

Disc Brakes 6-6

Brake Pedal 6-6

Service Brake Linkage6-6

Brake Cut-off and Light Switch 6-8

Parking Brake Handle 6-8

Adjust the Parking Brake Handle 6-9

Adjust Parking Brake Caliper6-10

Mast Lift Chains 6-10

Inspect Lift Chains 6-10

Chain and Roller Adjustment 6-10

Main Pump Relief Valve 6-11

General 6-11

To Check and/or Adjust Pressure 6-11

Steer Pump Relief Valve 6-14

General 6-14

To Check and/or Adjust Pressure 6-15

Front Rotation Pot 6-16

General 6-16

To Adjust and/or Replace6-17

SRE Control Adjust 6-17

General 6-17

Set up 6-18

Bendi Series IV Forklift Operator’s Manual

vi

Brake System – Repair 6-19

Changing Brakes 6-20

To Change Brake Pads 6-20

Replace the Brake Caliper Assembly 6-23

Caliper Pistons 6-24

Disc Brake Rotors 6-25

Measure Thickness 6-25

Check Lateral Run-Out (Warping) 6-25

Replace Brake Rotor Assemblies6-26

Master Cylinder 6-27

To Remove the Old Cylinder 6-27

Bench Bleed the Master Cylinder6-29

To Install the New Cylinder 6-30

Rigid Brake Line 6-30

To Replace a Damaged Line 6-31

Bleeding Brakes 6-32

Parking Brake Assembly 6-34

Continuity test6-34

Replace Micro Switch 6-35

Replacing the Brake Cable6-35

Service Brake Pedal Assembly 6-37

Brake Warning Switch 6-37

Brake Pedal6-37

Removing Forks 6-38

Steer (Load) Wheels 6-39

To Check 6-39

Wheel Bearings, Seals and Race 6-39

Replacing Tires/Wheels 6-41

Drive Wheels 6-41

Steer (Load) Wheels 6-42

Console Assembly 6-42

Remove Left Side Cover 6-43

Display or Cable 6-44

Key Switch 6-45

Option Rocker (On/Off) Switches 6-45

Circuit Breaker Panel 6-46

Steering Assembly 6-46

Steering Wheel 6-47

Steering Column (Console) 6-47

Orbital Steer Unit 6-49

To Service the Orbital Control Unit 6-49

Steering Motor or Support Bearing 6-50

Bendi Series IV Forklift Operator’s Manual

vii

Hints6-51

To Service the Motor6-51

Steer Pump and Motor 6-52

To Replace the Pump and/or Motor6-53

To Service the Steer Pump6-55

Lift Circuit 6-56

To Replace the Pump and/or Motor6-56

To Service the Lift Pump6-59

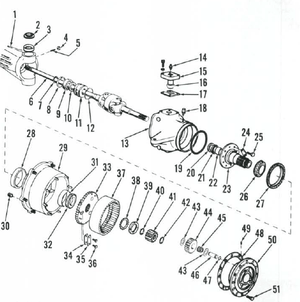

Traction Drive – Rear 6-60

To Begin… 6-60

To Replace Gear Unit / Motor 6-60

Hydraulic Valve Assemblies 6-63

Steer Control Valve 6-63

Hydraulic Control Valve and Switches 6-64

Hydraulic Lift Pot 6-66

General 6-66

To Adjust and/or Replace6-66

Linear Accelerator Module 6-67

Module and Cable Assembly 6-67

Pedal Spring 6-69

Seat Switch 6-69

Replace the Switch and Cable 6-70

Front End Assembly 6-70

To Begin… 6-72

Rotation Seals, Bearings or Spur Gear 6-72

To Remove Spur Gear Only6-73

Rotation Seals and Bearings 6-75

Hints for reassembly6-76

The Mast 6-76

Removing the Mast From the Truck 6-77

Tilt Cylinders 6-80

Sideshifter 6-82

Articulation Bearing and Seal 6-83

Stop Block 6-84

Horn and Direction Control 6-85

Horn/Horn Pushbutton 6-85

Direction Control Switch 6-86

Fans 6-87

To Replace a Fan 6-87

Options 6-88

Lights 6-89

Back Up Alarms 6-89

Appendix A – H 7-91

Appendix I – P 8-93

Appendix Q – Z 9-95

IMAGES PREVIEW OF THE MANUAL: