$35

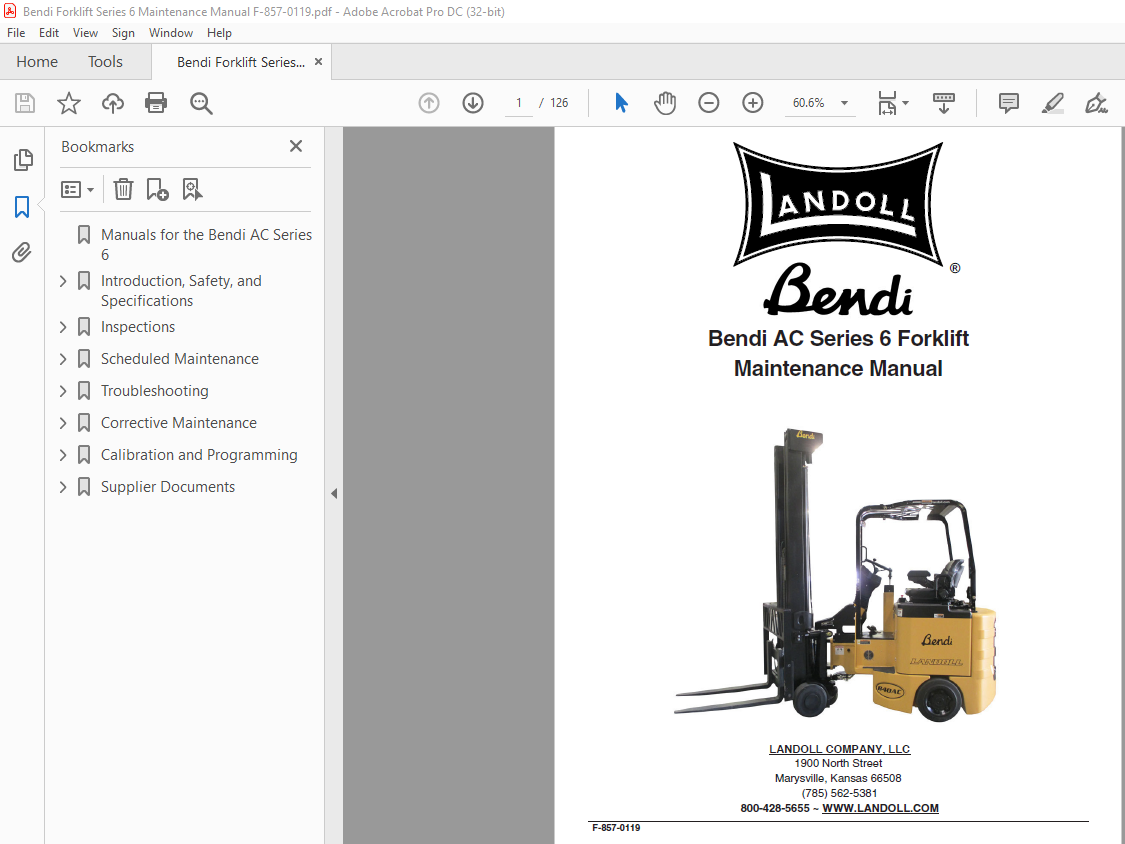

Bendi Landoll AC Series 6 Forklift Maintenance Manual F-857-0119 – PDF DOWNLOAD

Bendi Landoll AC Series 6 Forklift Maintenance Manual F-857-0119 – PDF DOWNLOAD

The Bendi Landoll AC Series 6 Forklift Maintenance Manual F-857-0119, available in PDF format, provides comprehensive guidance for servicing Series 6 forklifts, ensuring optimal performance and longevity through detailed maintenance procedures.

FILE DETAILS:

Bendi Landoll AC Series 6 Forklift Maintenance Manual F-857-0119 – PDF DOWNLOAD

Language : English

Pages : 126

Downloadable : Yes

File Type : PDF

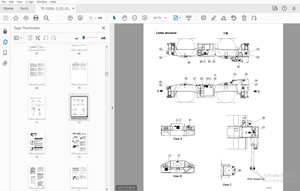

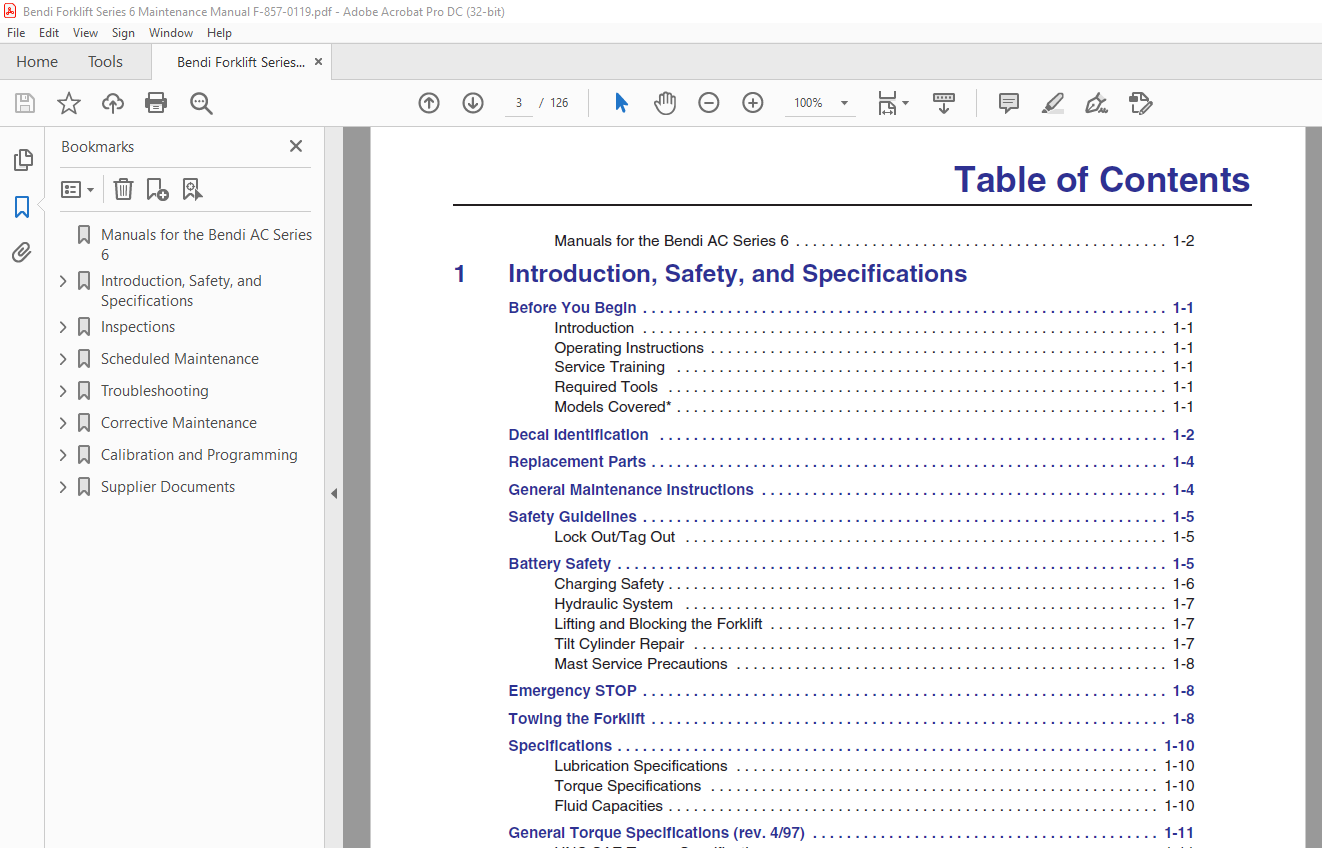

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Bendi Landoll AC Series 6 Forklift Maintenance Manual F-857-0119 – PDF DOWNLOAD

Introduction, Safety, and Specifications

Before You Begin 1-1

Introduction 1-1

Operating Instructions 1-1

Service Training 1-1

Required Tools 1-1

Models Covered* 1-1

Decal Identification 1-2

Replacement Parts 1-4

General Maintenance Instructions 1-4

Safety Guidelines 1-5

Lock Out/Tag Out 1-5

Battery Safety 1-5

Charging Safety 1-6

Hydraulic System 1-7

Lifting and Blocking the Forklift 1-7

Tilt Cylinder Repair 1-7

Mast Service Precautions 1-8

Emergency STOP 1-8

Towing the Forklift 1-8

Specifications 1-10

Lubrication Specifications 1-10

Torque Specifications 1-10

Fluid Capacities 1-10

General Torque Specifications (rev 4/97) 1-11

UNC SAE Torque Specifications 1-11

UNF SAE Torque Specifications 1-11

Metric Torque Specifications 1-12

Metric Torque Specifications 1-12

Hydraulic Fitting Torque Specifications (REV 10/97) 1-12

Parker® Brand Fittings 1-12

Aeroquip® Brand Fittings 1-13

Gates® Brand Fittings 1-13

2 Inspections

Inspection Introduction 2-1

Initial Inspection 2-1

Items Furnished with the Forklift 2-1

Items Required 2-1

Tools and Test Equipment 2-1

To Prepare the Forklift 2-2

ii F-857-0119

Daily Inspection Checklist 2-2

Operator Daily Pre-Shift Inspection Checklist – Bendi Series 6 2-3

Daily Inspections 2-4

Safety Warnings and Manual 2-4

Data Plate 2-4

Wheels and Tires 2-4

ESD Straps 2-4

Parking Brake 2-5

Service Brakes 2-5

Check the Brake Fluid Level 2-5

Forks 2-5

Mast Racking 2-5

Hydraulic Oil 2-5

Hydraulic Cylinders, Hoses, and Fittings 2-5

Battery 2-5

Specific Gravity Correction 2-6

Battery Restraint System 2-6

Operator Controls 2-6

Seat 2-8

3 Scheduled Maintenance

Scheduled Inspections and Maintenance Requirements 3-1

Tools and Equipment Required 3-1

Cleaning and Inspecting the Forklift 3-2

Inspection and/or Maintenance 3-2

Performance Testing 3-2

1st 100 Hours or 2 Week Checklist 3-3

Mast Chains 3-3

Measuring Chain Stretch 3-3

Check Primary Lift Chain 3-3

Check Lift Operation 3-3

Load Backrest 3-3

Wheels and Tires 3-4

Hydraulic Oil Check 3-4

Steering Actuator 3-4

Front Plate 3-4

Planetary Gear Box 3-4

500 Hour or Monthly Inspections 3-5

Hydraulic Maintenance 3-5

Battery 3-6

Controllers and Wire Connections 3-6

Steering 3-7

Brakes 3-7

Wheels and Tires 3-7

Motors and Gearboxes 3-7

General Mast Inspection 3-7

Forks 3-8

Major Structural Points 3-8

Rust Or Corrosion 3-8

Overhead Guard 3-8

iii

Forklift Lubrication 3-9

Tilt Cylinder Fixed End Bearing 3-10

Fork Positioner Lubrication (Option) 3-10

2000 Hour or Yearly Inspections 3-10

Brake Fluid Change 3-10

Change Planetary Gear Box Oil 3-10

4500 Hour Inspection 3-10

Hydraulic Oil Change 3-10

1st 100 Hour Technicians Inspection Checklist – Bendi Series 6 3-11

500 Hour Technicians Inspection Checklist – Bendi Series 6 3-12

2000 Hour Technician Inspection Checklist – Bendi Series 6 3-14

4500 Hour Technician Inspection Checklist – Bendi Series 6 3-14

4 Troubleshooting

Preliminary Procedures 4-1

Troubleshooting Charts 4-1

5 Corrective Maintenance

Corrective Maintenance 5-1

Battery 5-1

Replacing the Battery 5-1

Charging a Wet Cell Battery 5-3

Battery Restraint System and Roll-out Option 5-3

Mast and Front End 5-3

Removing the Forks 5-3

Repairing Forks 5-4

Load Testing Forks 5-4

Mast Removal 5-4

Removing Front Plate Assembly 5-5

Removing the Tilt Cylinder 5-5

Floor Plate Removal 5-6

Tires 5-7

Tire Inspection 5-7

Extending Tire Life 5-8

Brakes 5-8

General Information 5-8

Check Service Disc Brakes 5-9

Required Tools 5-9

Disc Brake Rotors 5-10

Parking Brake System 5-14

Parking Brake Assembly 5-14

Parking Brake Lever 5-14

Checking the Parking Brake Switch 5-15

Replacing Parking Brake Switch 5-15

Replacing the Parking Brake Cable 5-16

Parking Brake Caliper Assembly 5-16

iv F-857-0119

Changing Parking Brake Pads or Replacing Parking Brake Caliper 5-16

Brake Pedal 5-17

Replacing the Rotary Pot 5-18

Brake Hydraulics 5-19

Replacing Master Cylinder 5-19

Bench Bleed the Master Cylinder 5-20

Check Master Cylinder Fluid Level 5-20

Bleeding Brakes 5-21

Replacing Any Other Hydraulic Brake Component 5-22

Electrical 5-22

Electrical Static Discharge 5-22

ESD Strap 5-22

Direction Control Switch 5-22

Check the Return-to-Neutral 5-23

High Current Connections Definition 5-23

Hydraulics 5-24

Check Hydraulic Functions 5-24

Hydraulic Oil 5-24

Hydraulic System Components 5-27

Replacing the Hydraulic Pump and Motor 5-27

Hydraulic Control Valve Assembly 5-27

Hydraulic Control Valve and Switches Removal 5-28

Hydraulic Lift Spool Sensor 5-29

Hydraulic Fittings and Hoses 5-30

Side Shift Circuit 5-30

Steering 5-31

Steering Wheel Removal 5-31

Steering Column (Console) Removal 5-31

Steering Orbital Control Unit 5-32

Front Rotation Assembly 5-32

Removing the Steering Actuator 5-32

Steer (Front Rotation) Sensor 5-34

Steering Column and Dash Display Assembly 5-34

Powertrain 5-36

Inspecting the Drive System 5-36

Rear Wheel Assembly 5-36

Replacing the Gear Box 5-36

Replacing the Traction Drive Motor 5-37

Load Axle 5-38

Accelerator Pedal Assembly 5-39

Safety Features 5-40

Horn Service 5-40

Replacing the Seat Switch and Cable 5-40

Seat Switch 5-40

Overhead Guard, Lighting and Alarms 5-40

Fuses 5-41

6 Calibration and Programming

Controller Theory of Operation 6-1

v

Dash Display Key Legend 6-1

Dash Display Parameters 6-1

Forklift Calibration 6-2

1314 Software Program Installation and Operation 6-2

Software Installation Procedure 6-4

1314 Software Features and Functionality 6-5

Main Features 6-5

Communicating with Bendi Series 6 Controllers 6-6

Programming the Bendi Series 6 Controllers 6-6

Programming the Bendi Series 6 Master, Pump and Slave Controllers 6-7

Truck Type Setup 6-8

Programming Bendi Series 6 6-9

Front and Valve I/O Modules 6-9

Master Controller 6-12

Program 6-12

Truck Selection 1-B30, 2-B40, 3-B40VNA, 4-B5X 6-12

Landoll Traction 6-12

Hour Meter 6-13

Maintenance Due 6-13

1- Speed Mode 6-13

Response 6-13

6-13

Fine Tuning 6-15

Current Limits 6-15

Battery 6-16

Monitor 6-17

Landoll 6-17

Inputs 6-18

Outputs 6-18

Battery 6-19

Motor 6-19

Controller 6-19

Vehicle 6-20

CAN Status 6-20

7 Supplier Documents

Lift Technologies Mast Service Manual 7-1