$29

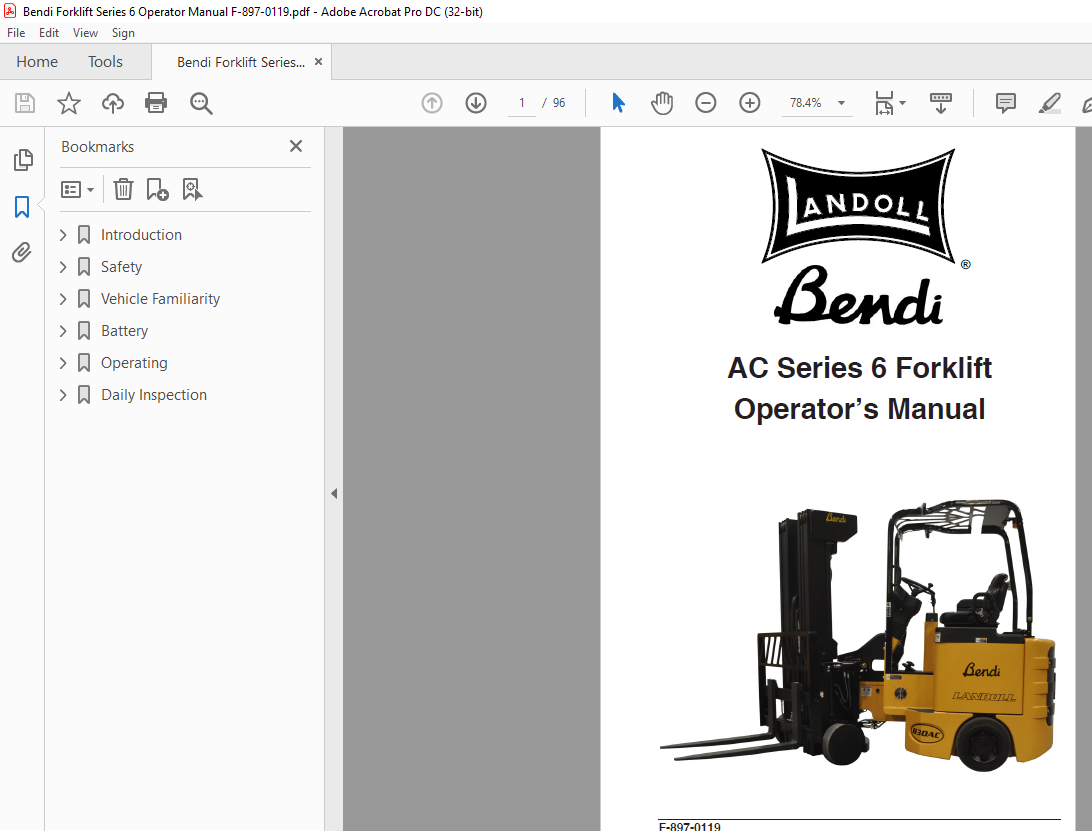

Bendi Landoll AC Series 6 Forklift Operator’s Manual F-897-0119 – PDF DOWNLOAD

Bendi Landoll AC Series 6 Forklift Operator’s Manual F-897-0119 – PDF DOWNLOAD

The Bendi Landoll AC Series 6 Forklift Operator’s Manual F-897-0119, available for PDF download, offers essential guidance for safe and efficient operation of Series 6 forklifts, ensuring user safety and optimal performance.

FILE DETAILS:

Bendi Landoll AC Series 6 Forklift Operator’s Manual F-897-0119 – PDF DOWNLOAD

Language : English

Pages : 96

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

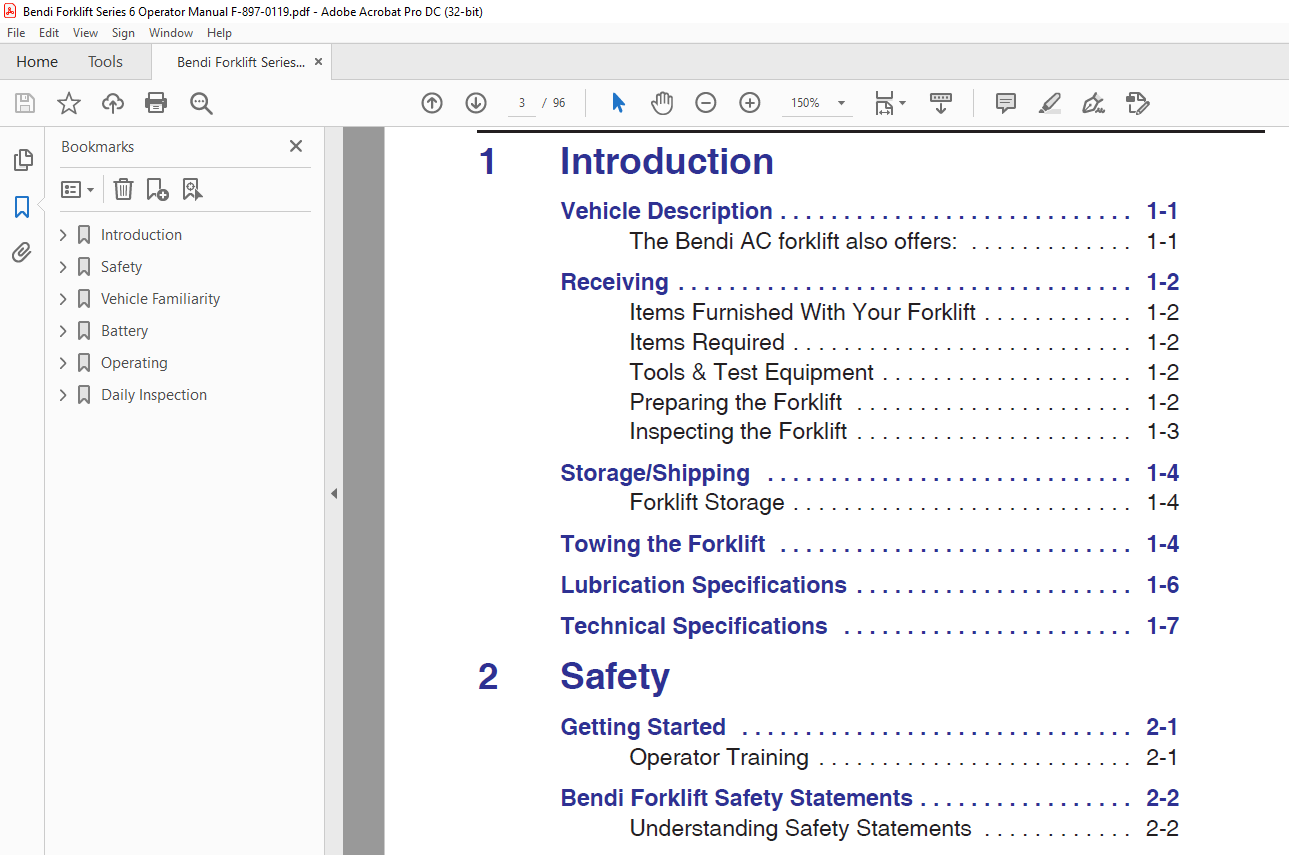

TABLE OF CONTENTS:

Bendi Landoll AC Series 6 Forklift Operator’s Manual F-897-0119 – PDF DOWNLOAD

1 Introduction

Vehicle Description 1-1

The Bendi AC forklift also offers: 1-1

Receiving 1-2

Items Furnished With Your Forklift 1-2

Items Required 1-2

Tools & Test Equipment 1-2

Preparing the Forklift 1-2

Inspecting the Forklift 1-3

Storage/Shipping 1-4

Forklift Storage 1-4

Towing the Forklift 1-4

Lubrication Specifications 1-6

Technical Specifications 1-7

2 Safety

Getting Started 2-1

Operator Training 2-1

Bendi Forklift Safety Statements 2-2

Understanding Safety Statements 2-2

Site Supervision 2-3

Terminology and Illustrations Used 2-3

Decals 2-3

Operator Safety 2-8

Tipping 2-9

Speed 2-10

Battery Safety 2-10

Charging Safety 2-11

Hydraulic System 2-12

Service Repair 2-13

Available Options 2-13

Fork Positioner 2-13

Fire Extinguisher 2-13

In case of a fire! 2-14

ii F-897-0119

Additional Publications 2-14

3 Vehicle Familiarity

Overview 3-1

Forklift Identification 3-1

Data Plate 3-2

Series Serial Number Code 3-3

Forklift Overview 3-4

Frame 3-4

Major Structural Points 3-4

Overhead Guard 3-4

ESD Straps 3-4

Brake System 3-5

Brake Pedal 3-5

Braking by Plugging 3-5

Parking Brake 3-5

Check the Brake Fluid Level 3-6

Electrical System 3-7

Traction 3-7

Steering 3-8

Accelerator Pedal 3-8

Steering Column 3-9

Key Switch 3-9

Steering Wheel and Tilt Clamp 3-9

Dash 3-10

Operator Switches 3-10

Dash Display 3-10

Tires and Wheels 3-12

Inspection 3-12

Chunking (Chipping) or Embedded Objects 3-12

Undercutting and Uneven Wear 3-13

Flat-spotting 3-13

To Extend Tire Life 3-13

Emergency Stop 3-14

Directional Control Switch 3-14

iii

Horn 3-14

Hydraulic System 3-15

Hydraulic Cylinders and Valves 3-15

Hydraulic Hoses, Tubing and Fittings 3-16

Check Hydraulic Oil 3-16

Mast Controls 3-17

Mast Assemblies 3-18

Mast Operation 3-21

Lift Lever 3-21

Tilt Lever 3-22

Side Shift Lever 3-23

Seat 3-24

Seat Adjustments 3-24

Seat Switch 3-25

Seat Belt 3-26

Forks 3-26

Rated Capacity and Load Center 3-26

Fork Inspection 3-27

Fork Marking 3-27

Available Options 3-27

EE Series (Electrical Enclosure) 3-27

Cold Storage (Freezer Package) 3-28

Lights and Alarms 3-28

3-28

4 Battery

Battery Inspection 4-2

Check Fluid Level 4-2

Checking Specific Gravity 4-3

Removing the Battery 4-4

Battery Roll-out and Restraint System 4-5

Roll-out Battery Removal 4-5

Roll-out Battery Installation 4-5

Charging the Battery 4-5

Charging Procedure 4-6

5 Operating

Overview 5-1

iv F-897-0119

Principles of Forklift Operation 5-2

Basic Operating Procedures 5-2

Getting On and Off the Forklift 5-3

Driving Position 5-3

Turning and Intersections 5-4

Stopping 5-5

Parking 5-5

Faults 5-6

Diagnostics 5-6

Understanding Stability 5-7

Basic Principles 5-7

Tilting Considerations 5-9

Knowing the Rated Capacity 5-9

Counterweight 5-9

Determining the Load Weight 5-10

Maximum Fork Lift Height 5-11

Tipping 5-11

Longitudinal Tipping 5-12

Lateral Tipping 5-12

Lateral or Longitudinal Tipping 5-12

Bendi Deep Reach (optional) 5-13

Setting the Forks 5-14

Fork Positioner 5-15

Retrieving a Load 5-15

Transporting a Load 5-18

Traveling on Inclines 5-18

Unloading The Forklift 5-19

Dock Boards and Forklifts 5-23

Attachments 5-23

Workplace Conditions 5-24

Working in Hazardous Environments 5-24

Atmospheric/Electrical 5-25

Chemical Hazards 5-25

6 Daily Inspection

Inspections Overview 6-1

v

Maintenance Schedule 6-1

Daily Checklist 6-1

Operator Daily Pre-Shift Inspection Checklist 6-2