$35

Bendi Landoll B3-30 ACDS Series 5 Articulated Counterbalance Forklift Maintenance Manual-

Bendi Landoll B3-30 ACDS Series 5 Articulated Counterbalance Forklift Maintenance Manual- PDF DOWNLOAD

FILE DETAILS:

Bendi Landoll B3-30 ACDS Series 5 Articulated Counterbalance Forklift Maintenance Manual- PDF DOWNLOAD

Language : English

Pages :128

Downloadable : Yes

File Type : PDF

TABLE OF CONTENTS:

Bendi Landoll B3-30 ACDS Series 5 Articulated Counterbalance Forklift Maintenance Manual- PDF DOWNLOAD

1 Introduction, Safety, and Specifications

Getting Started 1-1

Introduction 1-1

Operating Instructions 1-1

Service Training 1-1

Required Tools 1-1

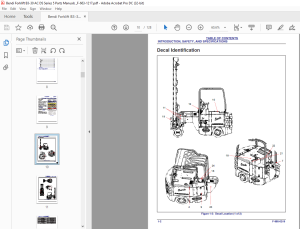

Decal Identification 1-2

Replacement Parts 1-6

General Maintenance Instructions 1-6

Lock Out / Tag Out 1-7

Battery Safety 1-7

Charging Safety 1-8

Hydraulic System 1-8

Tilt Cylinder 1-8

Mast Service Safety 1-9

Lifting and Blocking the Forklift 1-9

Emergency STOP 1-9

Towing the Forklift 1-9

Specifications 1-11

Lubrication Specifications 1-11

Torque Specifications 1-11

Fluid Capacities 1-11

General Torque Specifications (rev 4/97) 1-12

UNC SAE Torque Specifications 1-12

UNF SAE Torque Specifications 1-12

Metric Torque Specifications: 1-13

Metric Torque Specifications 1-13

Hydraulic Fitting Torque Specifications 1-14

Parker® Brand Fittings 1-14

Aeroquip® Brand Fittings 1-14

Gates® Brand Fittings 1-15

2 Planned Inspection and Maintenance

Overview 2-1

Cleaning and Inspecting the Forklift 2-1

Tools and Equipment Required 2-2

Safety Equipment Required 2-2

Inspection Program 2-2

Maintenance Program 2-2

Inspection and Maintenance Responsibilities 2-3

ii F-985-1218

Operators Daily Checklists 2-3

Inspection Practices 2-3

Inspection and Maintenance Practices for Authorized Facilities ONLY 2-3

Preparing for Inspection or Maintenance 2-4

Performance Testing 2-4

Completing Performance Testing 2-4

Operator Daily Pre-Shift Inspection Checklist - Bendi B3-30 AC/DS Series 5 2-5

1st 100 Hour Technicians Inspection Checklist - Bendi B3-30 AC/DS Series 5 2-6

500 Hour Technicians Inspection Checklist - Bendi B3-30 AC/DS Series 5 2-7

2000 Hour Technician Inspection Checklist - Bendi B3-30 AC/DS Series 5 2-9

4500 Hour Technician Inspection Checklist - Bendi B3-30 AC/DS Series 5 2-9

Tires and Wheels 2-10

Chunking (Chipping) or Embedded Objects 2-10

Undercutting and Uneven Wear 2-10

Flat-spotting 2-11

To Extend Tire Life 2-11

ESD Strap 2-11

Fork Inspection 2-11

Rated Capacity and Load Center 2-11

Cracks 2-12

Positioning Lock 2-12

Wear 2-12

Fork Marking 2-12

Overhead Guard 2-12

Hydraulic Cylinders and Valves 2-12

Hydraulic Hoses, Tubing and Fittings 2-12

Check Hydraulic Oil Level 2-12

Battery 2-13

Checking the Battery 2-13

Battery Restraint System and Roll-out (Optional) 2-15

Check the Brake Fluid Level 2-15

Identification Plate and Safety Warning Decals 2-15

Seat Adjustments 2-15

Seat Belt 2-16

Electrical Connections 2-16

Key Switch 2-16

Dash Display 2-16

Parking Brake 2-16

Accelerator Pedal, Directional Switch & Backup Alarm 2-17

Service Brakes 2-17

Seat Switch 2-17

Horn 2-18

Mast Controls 2-18

Lift 2-18

iii

Tilt Control 2-18

Side Shift 2-18

Mast Racking 2-18

Lights 2-19

Speed Switch 2-19

Steering - Check Operation 2-19

Emergency STOP 2-19

Return to Neutral 2-19

General Mast Inspection 2-19

Mast Chains 2-20

Chain Inspection 2-20

Chain Lubrication 2-20

Chain Adjustment 2-20

Check Primary Lift Chain 2-20

Measuring Chain Stretch 2-21

Check Lift Operation 2-21

Load Backrest 2-21

Front Plate 2-22

Check Tilt Cylinder 2-22

Side Shift Cylinder 2-22

Forklift Lubrication 2-23

Tilt Cylinder Clevis 2-24

Fork Positioner Lubrication (Option) 2-24

Steering Knob Lubrication 2-24

Hydraulics 2-24

Change the Pressure Filter 2-24

Change Hydraulic Oil 2-25

Service Disc Brakes 2-25

Wheel Bearings 2-25

Major Structural Points 2-25

Rust Or Corrosion 2-25

Gear Box 2-25

Check Planetary Gear Box 2-25

Nuts, Bolts and Screws 2-26

Stop Block 2-26

3 Troubleshooting

General Bendi B3-30 AC/DS Troubleshooting Charts 3-1

AUDIBLE PROBLEMS 3-1

PERFORMANCE PROBLEMS 3-2

PUMP PROBLEMS 3-7

4 Corrective Maintenance

Corrective Maintenance 4-1

Battery 4-1

Battery Storage 4-1

iv F-985-1218

Battery Roll-out Option and Restraint System 4-2

Replacing the Battery 4-2

Cleaning the Battery 4-4

Charging a Wet Battery 4-4

Mast And Front End 4-5

Removing the Forks 4-5

Repairing Forks 4-5

Load Testing Forks 4-5

Straightness of Blade and Shank 4-5

Fork Angle 4-5

Difference in Height Between Fork Tips 4-5

Measuring Fork Thickness and Distortion 4-5

Adjusting Degree of Tilt 4-6

Mast Removal 4-7

Removing Front Plate Assembly 4-8

Removing the Tilt Cylinder 4-8

Floor Plate 4-9

Floor Plate Removal and Assembly 4-9

Tires and Wheels 4-10

Removing/Replacing the Drive Wheel 4-10

Replacing the Braking Tires 4-10

Brake System 4-11

Brake System Service 4-12

Check Service Drum Brakes 4-12

Checking/Changing Brake Shoes 4-12

Repairing Brake Wheel Cylinders 4-14

Hydraulic Brake Drums 4-14

Parking Brake 4-15

Parking Brake Assembly 4-15

Parking Brake Lever 4-15

Replacing Parking Brake Lever Assembly 4-15

Checking Parking Brake Adjustment 4-15

Adjusting Parking Brake Cable 4-16

Replacing the Parking Brake Cable 4-16

Parking Brake Switch 4-16

Checking Parking Brake Switch 4-16

Replacing Parking Brake Switch 4-16

Service Brakes 4-17

Brake Pedal Assembly 4-17

Master Cylinder 4-18

Replacing Master Cylinder 4-18

Bench Bleed the Master Cylinder 4-19

Check Master Cylinder Fluid Level 4-19

Bleeding Brakes 4-19

Service Brake Pedal Assembly 4-20

Replacing Any Other Hydraulic Brake Component 4-20

Drivetrain 4-21

Traction Motor, and Gear Box 4-21

Service the Gear Box 4-21

v

Gearbox Replacement 4-22

Traction Drive Motor Service 4-23

Accelerator Pedal 4-23

Replacing Accelerator Module 4-23

Electrical 4-23

Fuses 4-23

Electrical Static Discharge 4-23

Electrical Controls and Levers 4-23

Replacing a Complete Control Panel 4-25

Hydraulic Components 4-26

Hydraulic System Maintenance 4-26

Changing Hydraulic Oil 4-26

Change the Hydraulic Oil Filters 4-27

Checking and Adjusting Hydraulic Pressure 4-28

Steering Motor Service 4-29

Hydraulic Pump Service 4-29

Front Rotation Assembly 4-30

Hydraulic Control Valve Assembly 4-31

Steering Column/Dash Assembly 4-34

Remove the Display Panel 4-34

Key Switch 4-35

Rocker (On/Off) Switches 4-35

Steering Wheel Removal 4-36

Steering Column (Console) Removal 4-36

Steering Orbital Control Unit 4-37

Horn Service 4-37

Truck Lighting 4-37

Back Up Alarms 4-37

Overhead Guard, Lighting and Alarms 4-38

Seat Switch Replacement 4-38

5 Bendi B3/30 AC Calibration and Programming

Controller Theory of Operation 5-1

1314 Bendi B3/30 Controller Software Program Installation and Operation 5-3

Software Installation Procedure 5-4

1314 Software Features and Functionality 5-5

Menu 5-5

Tool Bar 5-6

Views Navigation Bar 5-6

Working Area 5-7

Status Bar 5-7

Communicating with the Bendi B3-30 Series 5 Controllers 5-8

Bendi B3-30 Series 5 Parameters 5-8

Programming Bendi B3-30 Series 5 Controllers 5-8

Programming Bendi B3-30 Series 5 Traction and Pump Controllers 5-9

Programming Bendi B3-30 Series 5 Front I/O Modules 5-10

Curtis Controller Troubleshooting 5-13

vi F-985-1218

Program Troubleshooting Chart 5-14

Master Controller 5-20

Program 5-20

Landoll Traction 5-20

Hour Meter 5-21

Maintenance Due 5-21

1- Speed Mode 5-21

Response 5-21

Fine Tuning 5-23

Current Limits 5-23

Battery 5-24

Monitor 5-25

Landoll 5-25

Inputs 5-26

Outputs 5-26

Battery 5-27

Motor 5-27

Controller 5-27

Vehicle 5-28

CAN Status 5-28

Controller Maintenance 5-28

Controller Cleaning 5-28

6 Supplier Provided Documentation

Lift Technologies Mast Service Manual 6-1

IMAGES PREVIEW OF THE MANUAL:

S.M 07/24