$31

Bendi Landoll B330 Very Narrow Aisle Forklift Planned Maintenance Manual – PDF DOWNLOAD

Bendi Landoll B330 Very Narrow Aisle Forklift Planned Maintenance Manual – PDF DOWNLOAD

The Bendi Landoll B330 Very Narrow Aisle Forklift Planned Maintenance Manual offers detailed instructions for scheduled maintenance tasks. Download for comprehensive guidance on keeping your forklift in optimal condition.

FILE DETAILS:

Bendi Landoll B330 Very Narrow Aisle Forklift Planned Maintenance Manual – PDF DOWNLOAD

Language : English

Pages : 88

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

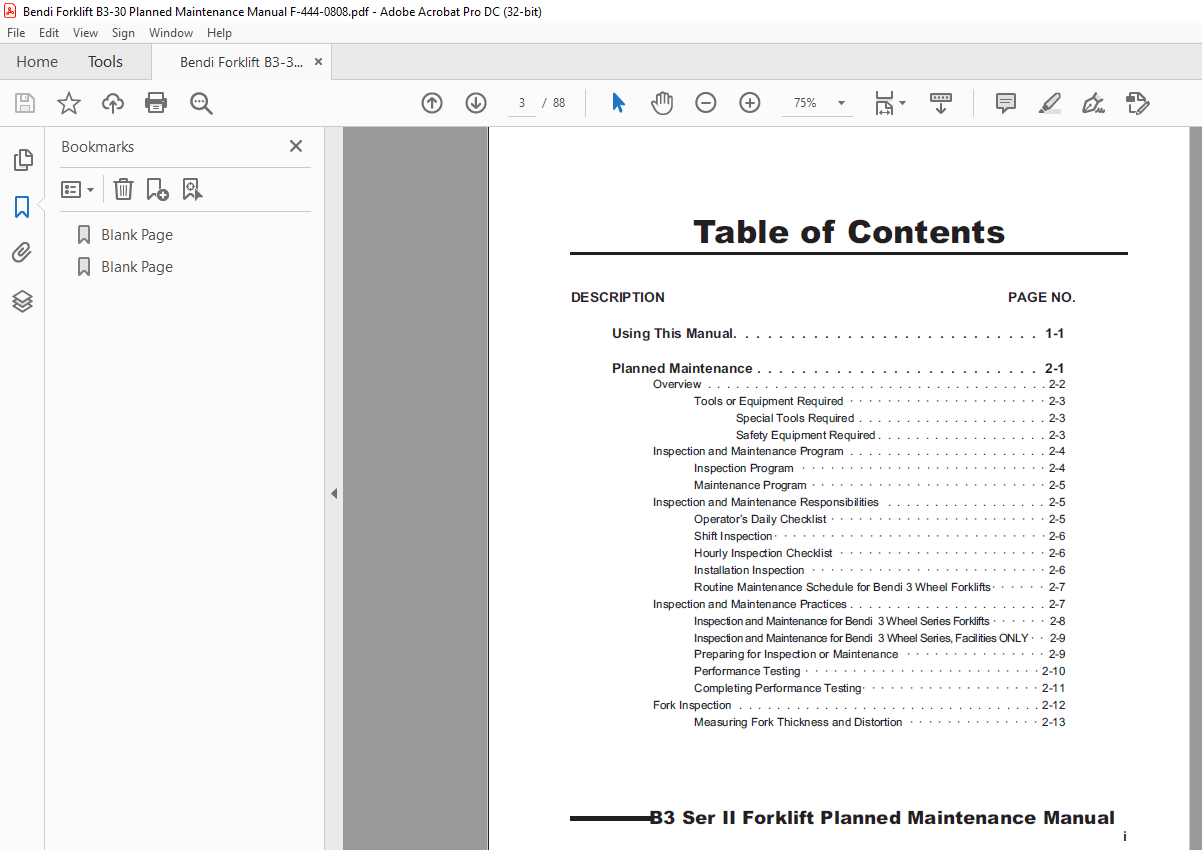

TABLE OF CONTENTS:

Bendi Landoll B330 Very Narrow Aisle Forklift Planned Maintenance Manual – PDF DOWNLOAD

DESCRIPTION PAGE NO

Using This Manual 1-1

Planned Maintenance 2-1

Overview 2-2

Tools or Equipment Required · 2-3

Special Tools Required 2-3

Safety Equipment Required 2-3

Inspection and Maintenance Program 2-4

Inspection Program 2-4

Maintenance Program · 2-5

Inspection and Maintenance Responsibilities 2-5

Operator’s Daily Checklist · 2-5

Shift Inspection· 2-6

Hourly Inspection Checklist 2-6

Installation Inspection · 2-6

Routine Maintenance Schedule for Bendi 3 Wheel Forklifts· · 2-7

Inspection and Maintenance Practices 2-7

Inspection and Maintenance for Bendi 3Wheel Series Forklifts 2-8

Inspection and Maintenance for Bendi 3Wheel Series, Facilities ONLY 2-9

Preparing for Inspection or Maintenance · 2-9

Performance Testing · 2-10

Completing Performance Testing· 2-11

Fork Inspection 2-12

Measuring Fork Thickness and Distortion 2-13

Mast Maintenance 2-15

Inspection Check List· 2-16

Load Roller Maintenance · 2-16

Chain Maintenance 2-17

Chain Inspection 2-17

Chain Lubrication 2-17

Chain Adjustment 2-18

Measuring Chain Stretch 2-18

Check Lift Operation · 2-19

Check Primary Lift Chain · 2-20

Checking and Adjusting Degree of Tilt 2-21

Side Shift Circuit Maintenance 2-23

Checking for Leaks 2-23

Identification Plate and Safety Warnings 2-24

Lubricating the Truck 2-25

Tilt Cylinder Clevis 2-26

Main Rotation Bearings/Gears 2-27

Battery Rollout Tray· · 2-28

Fork Positioner Lubrication, Non-Side Shifting (Option) · 2-29

Inspect Tires 2-30

Chunking (Chipping) or Embedded Objects · 2-31

Undercutting and Uneven Wear · 2-31

Flat-spotting· · 2-32

To Extend Tire Life 2-32

Drive Wheel Lug Nuts 2-33

Check Planetary Gear Box 2-33

Replacing Motor Brushes 2-36

Exposing the Motors · 2-36

Traction Drive Motor Brushes 2-37

Lift Pump and Power Steering Motor Brushes 2-39

Check Service Drum Brakes 2-41

To Check the Brakes · 2-41

Power Steering System Maintenance 2-42

Check Power Steering 2-43

Filling and Air Bleeding the Power Steering System · 2-44

Lubricate Steer Wheel Knob 2-44

Check Hydraulic Functions 2-45

Check the Return-to-Neutral 2-46

Check Driver’s Seat Switch 2-47

Floor Plate Removal 2-48

Check Master Cylinder Fluid Level 2-49

Hydraulic System Maintenance 2-50

B3 Ser II Forklift Planned Maintenance Manual

ii

Check Hydraulic Oil Level 2-51

Change Hydraulic Oil Filter 2-53

Change Hydraulic Oil · 2-54

Battery Care and Maintenance 2-56

Electrical Static Discharge 2-57

Check Batteries· · 2-58

To Check the Battery · 2-59

Battery Charging · 2-60

Inspecting the Bearings, Race and Inner Seal 2-61

Check Nuts, Bolts, and Screws 2-63

Inspect Electrical Connections 2-64

Curtis Controller · 2-65

General Practice · 2-66

B3 Ser II Forklift Planned Maintenance Manual

iii