$39

Bendi Landoll B40i3 Forklift Maintenance Manual F-503-1010 – PDF DOWNLOAD

Bendi Landoll B40i3 Forklift Maintenance Manual F-503-1010 – PDF DOWNLOAD

The Bendi Landoll B40i3 Forklift Maintenance Manual F-503-1010 is a comprehensive guide for technicians. It includes maintenance procedures, troubleshooting tips, and repair information to ensure optimal performance of the B40i3 model.

FILE DETAILS:

Bendi Landoll B40i3 Forklift Maintenance Manual F-503-1010 – PDF DOWNLOAD

Language : English

Pages : 250

Downloadable : Yes

File Type : PDF

DESCRIPTION

Bendi Landoll B40i3 Forklift Maintenance Manual F-503-1010 – PDF DOWNLOAD

Introduction, Safety and Inspection

- Before You Begin (Please Read): This manual is for service technicians seeking maintenance and parts info. It includes planned maintenance, troubleshooting tips, and repair guidance to resolve issues.

- Introduction: For service techs, this manual provides maintenance, parts, and troubleshooting info for the Bendi B40i3.

- Operating Instructions: Not included. Contact Landoll Corporation if missing.

- Service Training: Landoll Corporation offers training on operation, repair, maintenance, hydraulics, electrics, and wire guidance. Visit for details

- IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Bendi Landoll B40i3 Forklift Maintenance Manual F-503-1010 – PDF DOWNLOAD

1 Introduction, Safety and Inspection

Before You Begin (Please Read) 1-1

Introduction 1-1

Operating Instructions 1-1

Service Training 1-1

Tools Needed 1-1

Replacement Parts 1-1

General Maintenance Instructions 1-2

For your Safety 1-3

Battery Safety Rules: 1-3

Hydraulic System 1-3

Towing the Truck 1-3

Towing Vehicle Requirements 1-4

Towing a Truck in the Reverse Direction 1-4

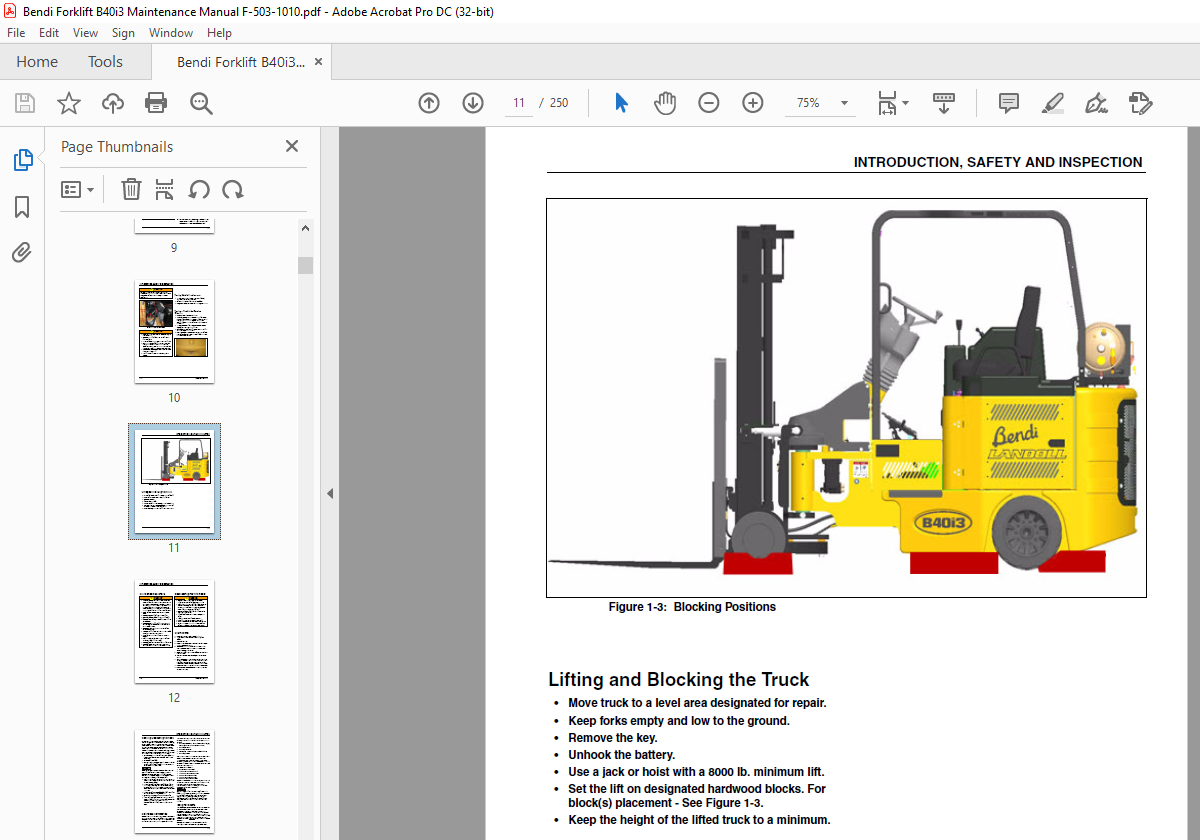

Lifting and Blocking the Truck 1-5

Mast Service Precautions 1-6

Disconnecting the Tilt Cylinder 1-6

Mast Removal 1-6

Cleaning & Inspecting the Truck 1-7

Maintenance Introduction 1-7

Inspection Sheets 1-7

Lubrication Specifications 1-15

Torque Specifications 1-15

Fluid Capacities 1-15

2 Planned Maintenance

Planned Maintenance Requirements 2-1

Tools or Equipment Required 2-1

Preparing for Inspection or Maintenance 2-2

Performance Testing 2-2

Completing Performance Testing 2-3

Daily Inspection 2-3

Fuel System Check 2-3

Power Steering Check 2-3

Checking the Battery 2-4

Check Hydraulic Functions 2-4

Check Driver’s Seat Switch 2-4

Check Hydraulic Oil Level 2-4

Check Engine Oil Level 2-5

Check Primary Lift Chain 2-6

Inspect Tires 2-6

Flat-spotting 2-7

To Extend Tire Life 2-7

F-503-0610 Edition

300 Hours Inspection 2-8

Check Nuts, Bolts, and Screws 2-8

Check Lift Operation 2-8

Drive Wheel Lug Nuts 2-8

Hydraulic System Maintenance 2-9

Side Shift Circuit Maintenance 2-9

Identification Plate and Safety Warnings 2-9

Check Tilt Cylinder Racking 2-10

Tilt Cylinder Racking and Tilt Degree Settings 2-10

Lubricating the Truck 2-12

Cooling System 2-16

Air Filter 2-16

Change Engine Oil and Filter 2-16

600 Hour Inspection 2-17

Change Hydraulic Oil and Tank Filter 2-17

Floor Plate Removal 2-18

Mast Maintenance 2-19

Load Roller Maintenance 2-19

Chain Maintenance 2-20

Lubricate Steer Wheel Knob 2-21

Fork Inspection 2-21

2000 Hours Inspection 2-23

Change Hydraulic Oil 2-23

3 Troubleshooting and Corrective Maintenance

Troubleshooting 3-1

ENGINE PROBLEMS 3-1

ELECTRICAL PROBLEMS 3-7

AUDIBLE PROBLEMS 3-7

VISIBLE PROBLEMS 3-9

Corrective Maintenance 3-13

Before You Begin 3-14

Lifting the Truck 3-14

Floor Plate(s) Removal 3-15

Removing Forks 3-16

Repairing Forks 3-16

Load Testing Forks 3-16

Side Shifter 3-17

Mast 3-18

Removing the Mast From the Truck 3-18

Tilt Cylinders, from S/N # 5913 on 3-20

Front Axle Assembly 3-21

To Check Load Wheels 3-21

Wheel Bearings, Seals and Race 3-22

Removing the Front Axle 3-23

Articulation Bearing and Seal 3-23

Front Rotation Assembly 3-24

Removing the Bull Gear 3-24

Rotation Seals and Bearings 3-24

Stop Block 3-26

Steer (Front Rotation) Pot 3-26

Steering Motor and Support Bearing 3-27

Auxiliary Pump – Steer and Lift Circuit 3-28

Accelerator and Brakes 3-29

Replacing the Throttle (Accelerator) Pedal Assembly 3-29

Stop Pedal/Park Brake Assembly 3-30

Checking the Park Brake efficiency 3-30

Steering Column and Console Assembly 3-30

Remove Right Side Cover 3-31

Display 3-31

Key Switch 3-32

Option Rocker (On/Off) Switches 3-32

Steering Wheel 3-32

Steering Column (Console) 3-33

Orbital Steer Unit 3-34

Load Sense Steering System 3-34

Steering Counterbalance Valve 3-35

Hydraulic Control Valve Assembly 3-35

General 3-35

Hydraulic Control Valve 3-37

Steer System Relief Valve 3-37

Hydrostatic Pump 3-38

Charge Pressure Check 3-38

To Remove and Replace the Hydrostatic Pump 3-39

To Prime the Hydrostatic Pump 3-40

Hydrostatic Drive Motor Assembly 3-40

To Remove Drive Wheels 3-40

Hydrostatic Drive Motors – Rear 3-41

To Replace Hydrostatic Drive Motor Assembly 3-41

Brake Service and Repair 3-42

Reassembly 3-44

Seat Assembly/Horn 3-52

Seat Switch 3-52

Horn and Direction Control 3-52

Engine Assembly 3-54

Engine 3-54

Fuel System 3-54

Cooling Fan 3-54

Radiator/Oil Cooler 3-55

Overhead Guard/Lighting/Alarms 3-55

Back Up Alarms 3-55

Hydraulic Fittings and Hoses 3-56

F-503-0610 Edition

4 Calibration and Programming

Vehicle Controller “Plus 1” Calibration and Programming 4-1

Getting Started Using Plus 1 Software 4-1

ECU Downloading and Type 4-3

Log Functions 4-5

Dash Display Calibration and Operation 4-18

5 Engine with Fuel System

24 Liter GM 4 Cylinder Engine with GFI LPG Fuel Injection 5-1

24L LPG Engine GM Service Notes 5-2

24L LPG Engine System Operation Overview 5-2

24L LPG Engine System Operation 5-3

Fuel System Quick Troubleshooting Guide 5-8

24L LPG Engine Quick Trouble Shooting Guide 5-11

First Check For DTC Faults 5-11

If ECU Can Not Communicate With The S3000 Monitor: 5-11

Is The Throttle In Limp Home Mode? 5-12

If the Engine cranks but will not start or runs poorly, with no DTC’S 5-13

DTC codes 5-14

Getting Started Using Kvaser(S3000) Engine Diagnostics Software 5-17

24 Liter GM 4 Cylinder Engine 5-21

6 GM Engine Supplier Provided Documentation

24 Liter GM 4 Cylinder Engine with GFI LPG Fuel Injection 6-1

Table of Contents – page 3 6-1

7 Lift Tech Supplier Provided Documentation

Lift Technologies Mast Service Manual 7-1

Models 30D/35D/40D/50D/55D/60D 7-1

Table of Contents – page 5 7-1