$32

Bendi Landoll Forklift AC Series Maintenance Manual F-528-0511 PDF

Bendi Landoll Forklift AC Series Maintenance Manual F-528-0511 – PDF DOWNLOAD

The Bendi Landoll Forklift AC Series Maintenance Manual F-528-0511 – PDF DOWNLOAD provides comprehensive guidance for maintaining AC Series forklifts, ensuring optimal performance and longevity.

FILE DETAILS:

Bendi Landoll Forklift AC Series Maintenance Manual F-528-0511 – PDF DOWNLOAD

Language : English

Pages : 130

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

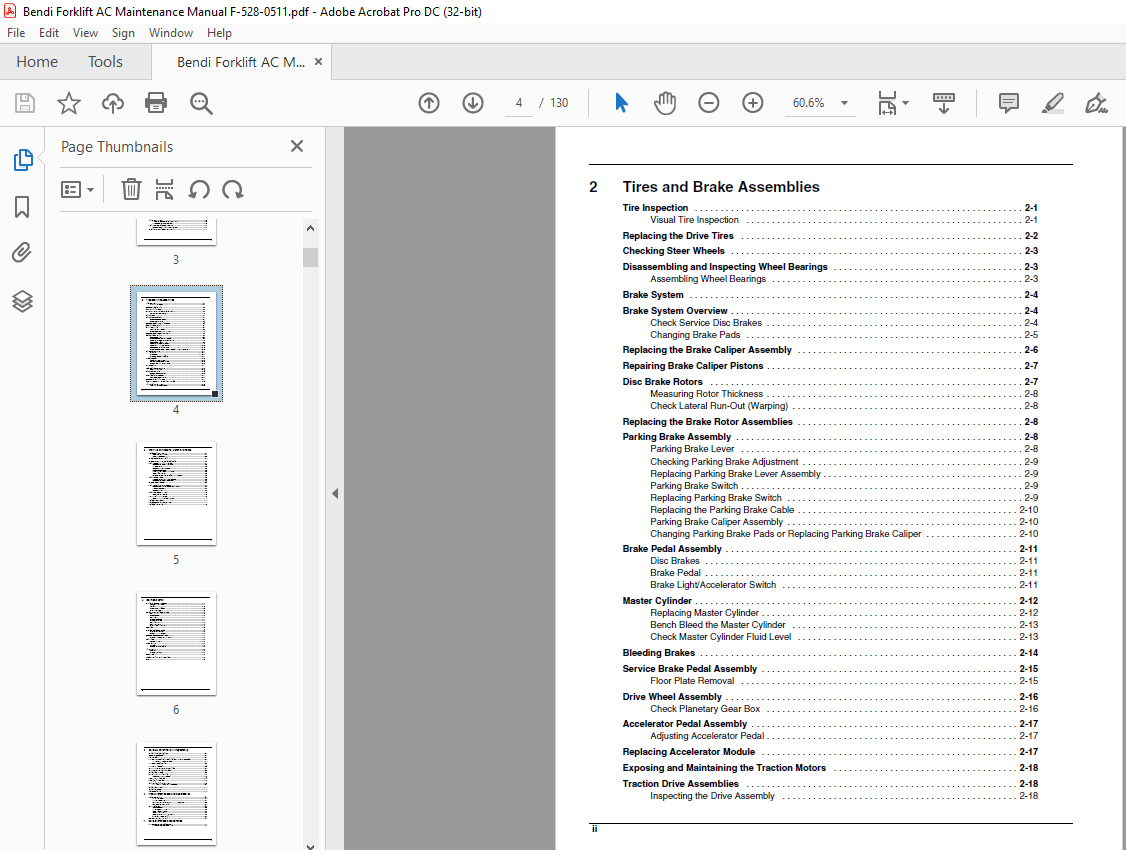

TABLE OF CONTENTS:

Bendi Landoll Forklift AC Series Maintenance Manual F-528-0511 – PDF DOWNLOAD

Introduction,Safety,Preventative Maintenance

Before You Begin (Please Read) 1-1

Introduction 1-1

Operating Instructions 1-1

Service Training 1-1

Tools Needed 1-1

Replacement Parts 1-1

General Maintenance Instructions 1-2

For your Safety 1-3

Special Notices and Safety Indicators 1-3

Lock Out/Tag Out 1-3

Battery Care and Charging 1-4

Battery Removal and Installation 1-4

Hydraulic System 1-5

Towing the Truck 1-5

General Safety Tips: 1-5

Towing Vehicle Requirements 1-5

Towing a Truck in the Reverse Direction 1-5

Lifting and Blocking the Truck 1-6

Mast Service Precautions 1-6

Prior to Tilt Cylinder Repair 1-7

Prior to Mast Removal 1-7

Cleaning the truck 1-7

Maintenance Introduction 1-7

Inspection Sheets 1-7

Lubrication Specifications 1-17

Fluid Capacities 1-18

Torque Specifications 1-18

General Torque Specifications (Rev 4/97) 1-18

Torque Specified In Foot Pounds 1-19

Hydraulic Fitting Torque Specifications 1-20

Hydraulic Torque Specified In Foot Pounds 1-20

General Bendi AC Troubleshooting Chart 1-21

ii

2 Tires and Brake Assemblies

Tire Inspection 2-1

Visual Tire Inspection 2-1

Replacing the Drive Tires 2-2

Checking Steer Wheels 2-3

Disassembling and Inspecting Wheel Bearings 2-3

Assembling Wheel Bearings 2-3

Brake System 2-4

Brake System Overview 2-4

Check Service Disc Brakes 2-4

Changing Brake Pads 2-5

Replacing the Brake Caliper Assembly 2-6

Repairing Brake Caliper Pistons 2-7

Disc Brake Rotors 2-7

Measuring Rotor Thickness 2-8

Check Lateral Run-Out (Warping) 2-8

Replacing the Brake Rotor Assemblies 2-8

Parking Brake Assembly 2-8

Parking Brake Lever 2-8

Checking Parking Brake Adjustment 2-9

Replacing Parking Brake Lever Assembly 2-9

Parking Brake Switch 2-9

Replacing Parking Brake Switch 2-9

Replacing the Parking Brake Cable 2-10

Parking Brake Caliper Assembly 2-10

Changing Parking Brake Pads or Replacing Parking Brake Caliper 2-10

Brake Pedal Assembly 2-11

Disc Brakes 2-11

Brake Pedal 2-11

Brake Light/Accelerator Switch 2-11

Master Cylinder 2-12

Replacing Master Cylinder 2-12

Bench Bleed the Master Cylinder 2-13

Check Master Cylinder Fluid Level 2-13

Bleeding Brakes 2-14

Service Brake Pedal Assembly 2-15

Floor Plate Removal 2-15

Drive Wheel Assembly 2-16

Check Planetary Gear Box 2-16

Accelerator Pedal Assembly 2-17

Adjusting Accelerator Pedal 2-17

Replacing Accelerator Module 2-17

Exposing and Maintaining the Traction Motors 2-18

Traction Drive Assemblies 2-18

Inspecting the Drive Assembly 2-18

iii

3 Hydraulic Components: Motors and Pumps

Steering Motor Maintenance 3-1

Check Hydraulic Oil Level 3-1

Changing Hydraulic Oil 3-2

Change the Hydraulic Oil Filter 3-2

Checking and Adjusting Hydraulic Pressure 3-3

Hydraulic Steering Motor Maintenance 3-4

Hydraulic Steer Motor Disassembly 3-4

Parts Inspection 3-4

Hydraulic Motor(s) Reassembly 3-4

Hydraulic Pump Service 3-4

Power Steering System Maintenance 3-4

Check Power Steering 3-4

Filling and Air Bleeding the Power Steering System 3-5

Hydraulic Components 3-5

Replacing the Hydraulic Pump and Motor 3-5

Hydraulic Steer Motor Replacement 3-6

Checking Steer Pressure 3-6

Hydraulic Control Valve Assembly 3-7

Hydraulic Control Valve and Switches Removal 3-8

Spool Section Rebuild 3-9

Hydraulic Lift Pot 3-9

Hydraulic Fittings and Hoses 3-10

Check Hydraulic Functions 3-10

Side Shift Circuit Maintenance 3-10

Check Side Shift circuit performance 3-11

Steering Wheel Removal 3-11

Steering Column (Console) Removal 3-11

Steering Orbital Control Unit 3-12

iv

4 Electrical System

Steering Column/Dash Assembly 4-1

Remove the Display Panel 4-1

Keyswitch 4-2

Rocker (On/Off) Switches 4-2

Electrical Contactors 4-2

Battery – Safety, Care & Replacement 4-3

Battery Safety 4-3

Checking Batteries 4-3

Battery Care 4-4

Charging the Battery 4-4

Cleaning the Battery 4-4

Battery Removal 4-5

Battery Installation 4-5

Electrical Static Discharge 4-5

ESD Strap 4-5

Electrical Controls and Levers 4-6

Direction Control Lever 4-6

Check the Return-to-Neutral 4-6

Replacing a Complete Control Panel 4-7

High Current Connections Definition: 4-7

Horn Service 4-8

Removing the horn 4-8

Seat Assembly 4-8

Seat Switch 4-8

Check Driver’s Seat Switch 4-8

Truck Lighting 4-9

Headlights 4-9

Brake and Tail Lights 4-9

Back Up Alarms 4-9

Overhead Guard, Lighting and Alarms 4-9

5 Bendi AC Calibration and Programming

Controller Theory of Operation 5-1

Dash Display Parameters 5-1

Truck Calibration 5-1

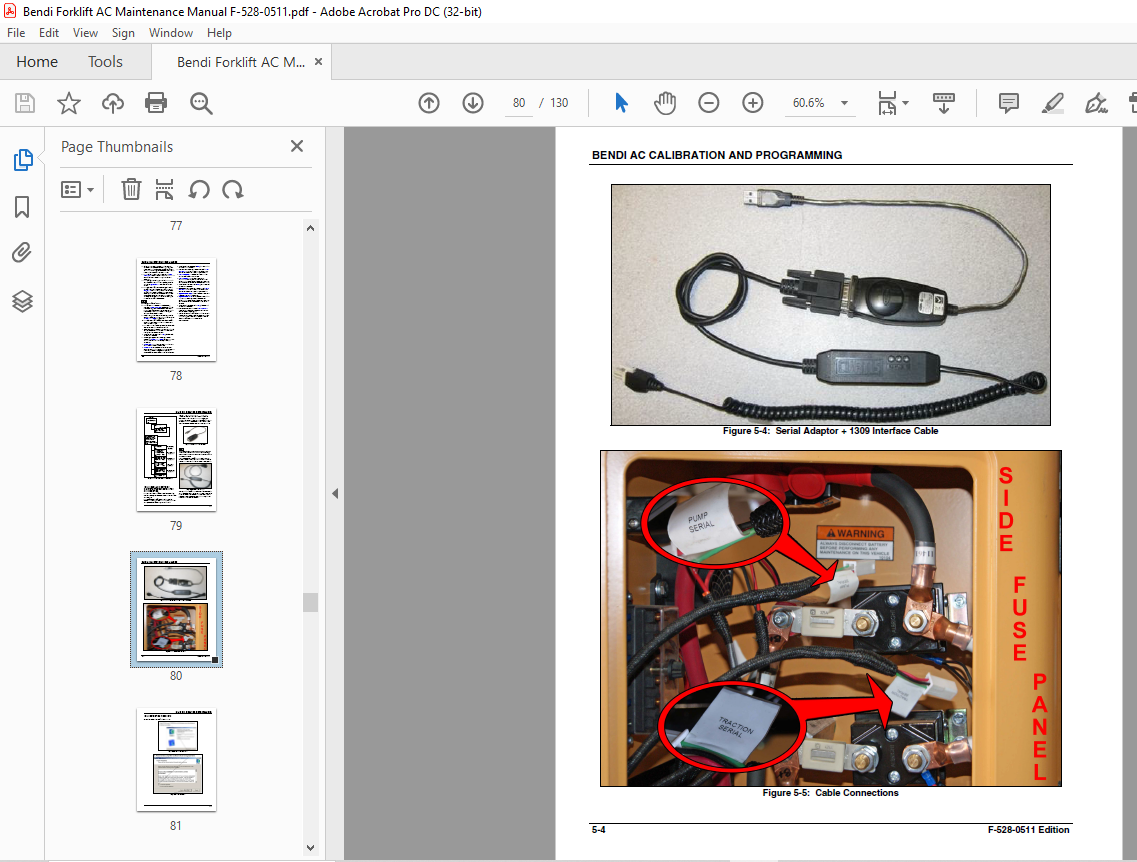

1314 Bendi AC Controller Software Program Installation and Operation 5-3

USB to Serial Port Adaptor Cable 5-3

1314 Installation Procedure 5-5

1314 Update Procedure 5-6

Communicating with Bendi AC Controllers 5-7

Additional 1314 Controller Features 5-8

Controller Fault History 5-9

Monitoring Default Parameters 5-32

Factory Set Parameter Details: 5-33

Landoll_TM_S Parameters 5-36

Landoll_P_S Parameters 5-39

Curtis Controller Troubleshooting 5-40

PROGRAM TROUBLESHOOTING CHART 5-41

Controller Maintenance 5-47

Controller Cleaning 5-47

Programmer Menus 5-47

6 Truck Lubrication and Chain Maintenance

Lubricating the Truck 6-1

Tilt Cylinder Clevis 6-1

Main Rotation Bearings 6-1

Fork Positioner Lubrication, Non-Side Shifting (Option) 6-2

Lubricate Steer Wheel Knob 6-2

Chain Lubrication 6-2

Chain Adjustment 6-2

Measuring Chain Stretch 6-2

Check Primary Lift Chain 6-3

Check Lift Operation 6-3

Checking and Adjusting Degree of Tilt 6-3

Adjusting the degree of tilt: 6-3

Disconnecting the Tilt Cylinder 6-4

7 Supplier Provided Documentation

Lift Technologies Mast Service Manual 7-1

Models 30D/35D/40D/50D/55D/60D 7-1

DESCRIPTION:

Bendi Landoll Forklift AC Series Maintenance Manual F-528-0511 – PDF DOWNLOAD

- Introduction: For service technicians seeking maintenance and parts info, troubleshooting tips, and repair guidance.

- Operating Instructions: Not included. Request a replacement operator’s manual from Landoll Company, LLC.

- Service Training: Landoll Company, LLC offers training covering operation, repair, maintenance, hydraulic and electrical systems, and wire guidance. Contact your regional Landoll service technician for details.