$38

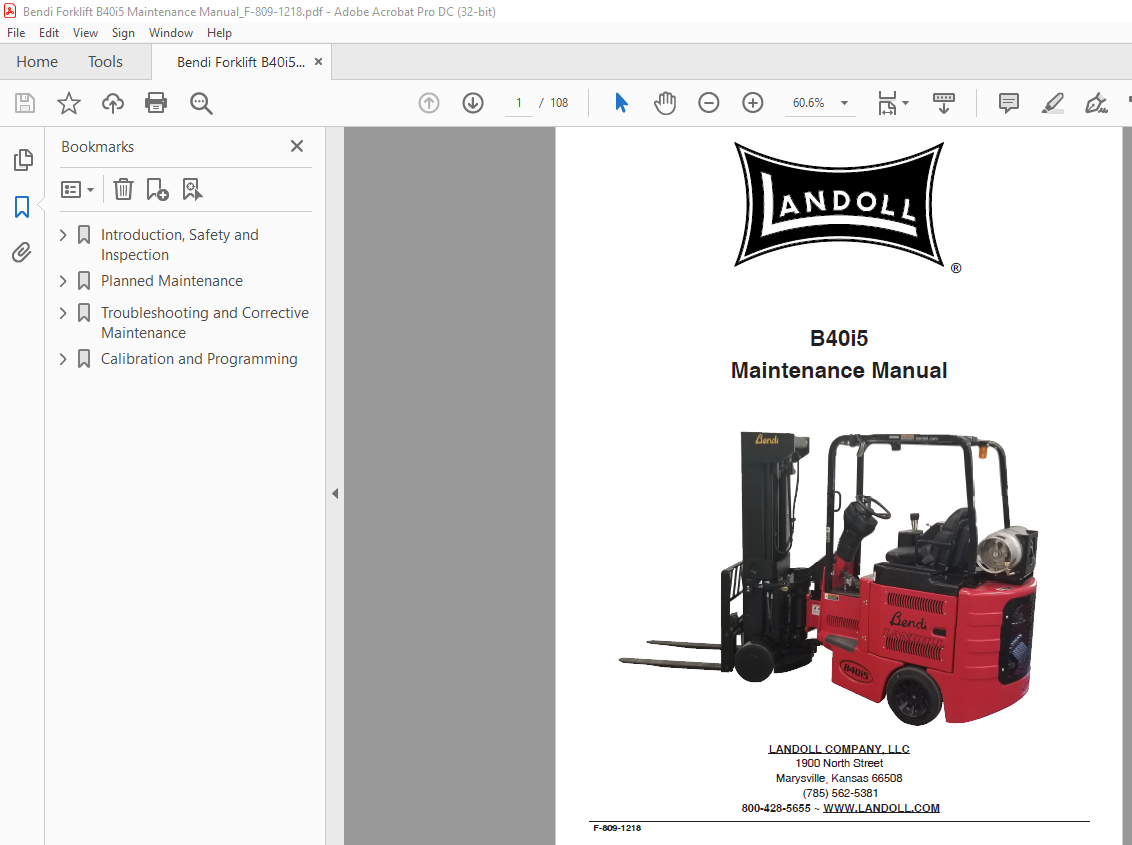

Bendi Landoll Forklift B40i5 Maintenance Manual F-809-1218 – PDF DOWNLOAD

Bendi Landoll Forklift B40i5 Maintenance Manual F-809-1218 – PDF DOWNLOAD

FILE DETAILS:

Bendi Landoll Forklift B40i5 Maintenance Manual F-809-1218 – PDF DOWNLOAD

Language : English

Pages : 108

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Bendi Landoll Forklift B40i5 Maintenance Manual F-809-1218 – PDF DOWNLOAD

Introduction, Safety and Inspection

- Introduction: This manual serves service technicians, offering maintenance and parts info, planned maintenance, troubleshooting, and repair guidance.

- Operating Instructions: Not included. Request a replacement from Landoll Company, LLC if missing.

- Service Training: Landoll Company, LLC provides training on operation, repair, maintenance, hydraulic and electrical systems, and wire guidance. for details.

TABLE OF CONTENTS:

Bendi Landoll Forklift B40i5 Maintenance Manual F-809-1218 – PDF DOWNLOAD

1 Introduction, Safety and Inspection

Before Beginning 1-1

Introduction 1-1

Operating Instructions 1-1

Service Training 1-1

Tools Needed 1-1

Replacement Parts 1-1

General Maintenance Instructions 1-2

For Your Safety 1-3

Battery Safety Rules: 1-3

Lock Out / Tag Out 1-3

Hydraulic System 1-3

Towing the Forklift 1-3

Towing Vehicle Requirements 1-4

Towing a Forklift in the Reverse Direction 1-4

Lifting and Blocking the Forklift 1-5

Prior to Mast Repair 1-5

Mast Removal 1-6

Cleaning & Inspecting the Forklift 1-6

Maintenance Introduction 1-7

Inspection Sheets 1-7

Lubrication Specifications 1-17

Torque Specifications 1-17

Fluid Capacities 1-17

General Torque Specifications (rev 4/97) 1-18

TORQUE SPECIFIED IN FOOT POUNDS 1-18

Hydraulic Fitting Torque Specifications 1-19

2 Planned Maintenance

Planned Maintenance Requirements 2-1

Tools or Equipment Required 2-1

Preparing for Inspection or Maintenance 2-2

Performance Testing 2-2

Completing Performance Testing 2-3

Daily Inspection 2-3

Fuel System Check 2-3

Power Steering Check 2-3

Checking the Battery 2-4

Check Hydraulic Functions 2-4

Check Driver’s Seat Switch 2-4

Check Hydraulic Oil Level 2-4

Check Engine Oil Level 2-5

Check Primary Lift Chain 2-6

Inspect Tires 2-7

Chunking (Chipping) or Embedded Objects 2-7

Undercutting and Uneven Wear 2-7

ii F-809-1218

TABLE OF CONTENTS

Flat-Spotting 2-8

To Extend Tire Life 2-8

50 Hours Inspection 2-8

Hydraulic Pressure Filter Replacement 2-8

200 Hours Inspection 2-9

Check Nuts, Bolts, and Screws 2-9

Check Lift Operation 2-9

Drive Wheel Lug Nuts 2-10

Hydraulic System Maintenance 2-10

Cylinders and Valves: 2-10

Hoses and Tube Lines: 2-10

Hydraulic Fluid: 2-10

Side Shift Circuit Maintenance 2-10

Identification Plate and Safety Warnings 2-11

Check Tilt Cylinder Racking 2-11

Tilt Cylinder Racking and Tilt Degree Settings 2-11

Racking 2-11

Tilt Degree Adjustment 2-12

Lubricating the Forklift 2-12

Tilt Cylinder Ends 2-13

Lubricate Front Steer Wheel Bearings 2-13

Grease/Inspect Bearings & Inner Seal 2-14

Mast Mounting Pins 2-14

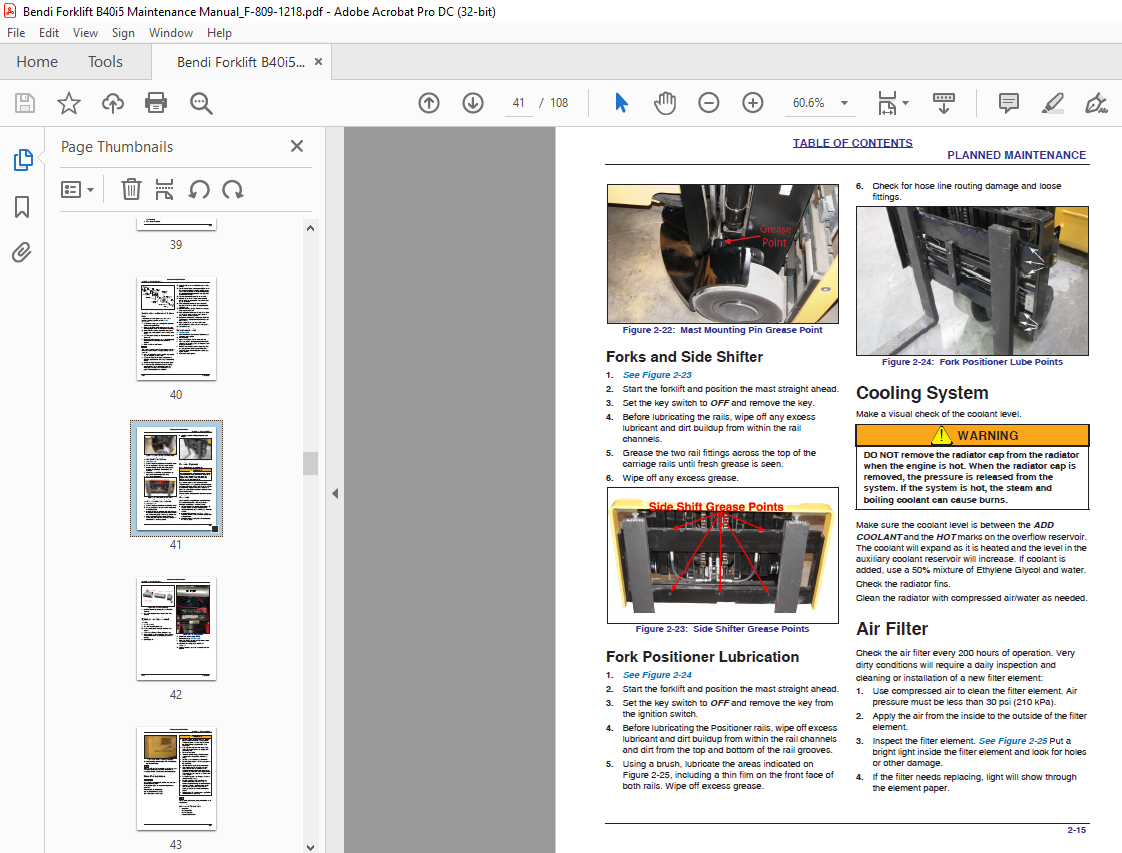

Forks and Side Shifter 2-15

Fork Positioner Lubrication 2-15

Cooling System 2-15

Air Filter 2-15

Change Engine Oil and Filter 2-16

Mast Maintenance 2-16

Inspection Check List 2-17

Load Roller Maintenance 2-17

Chain Maintenance 2-17

Chain Inspection 2-17

Chain Lubrication 2-18

Chain Adjustment 2-18

Measuring Chain Stretch 2-18

Fork Inspection 2-18

Rated Capacity and Load Center 2-19

Cracks 2-19

Straightness of Blade and Shank 2-19

Fork Angle 2-19

Difference in Height Between Fork Tips 2-19

Positioning Lock 2-19

Wear 2-19

Fork Blade and Shank 2-19

Fork Hooks 2-19

Fork Marking 2-19

Lubricate Steer Wheel Knob 2-20

4500 Hours Inspection 2-20

iii

TABLE OF CONTENTS

Change Hydraulic Oil 2-20

3 Troubleshooting and Corrective Maintenance

Troubleshooting 3-1

Engine problems 3-1

Hydraulic problems 3-1

Electrical problems 3-5

Audible problems 3-6

Visible problems 3-8

Corrective Maintenance 3-12

Replacement Parts 3-12

Lifting the Forklift 3-13

Floor Plate(s) Removal 3-13

Removing Forks 3-13

Repairing Forks 3-14

Load Testing Forks 3-14

Side Shifter 3-14

Mast Assembly Service 3-14

Removing the Mast From the Forklift 3-14

Tilt Cylinders 3-15

Wheel Bearings 3-16

Front Axle Assembly 3-17

To Check Load Wheels 3-17

Removing the Front Axle 3-17

Front Rotation Assembly 3-17

Removing the Steering Actuator 3-18

Stop Block 3-18

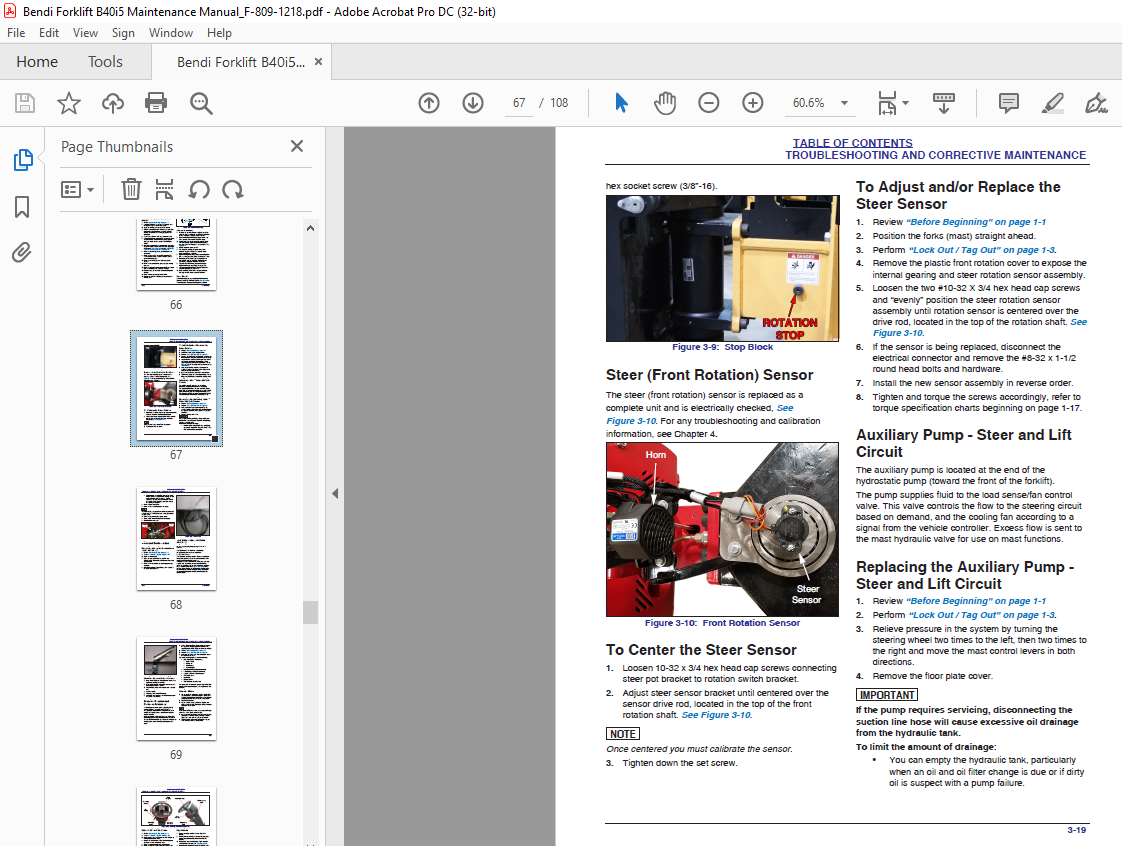

Steer (Front Rotation) Sensor 3-19

To Center the Steer Sensor 3-19

To Adjust and/or Replace the Steer Sensor 3-19

Auxiliary Pump – Steer and Lift Circuit 3-19

Replacing the Auxiliary Pump – Steer and Lift Circuit 3-19

Drive and Brake Pedals 3-20

Replacing the Drive (Accelerator) Pedal Assembly 3-20

Park Brake Pedal/Park Brake Assembly 3-20

Steering Column and Console Assembly 3-21

Steering Wheel 3-21

Remove Right Side Cover 3-22

Display 3-22

Key Switch 3-22

Option Rocker (On/Off) Switches 3-23

Steering Column (Console) 3-23

Orbital Steer Unit 3-24

Load Sense Steering System 3-24

Steering Counterbalance Valve 3-24

Hydraulic Control Valve Assembly 3-25

Hydraulic Control Valve 3-25

Spool Section Rebuild 3-27

Check and/or Adjust Control Valve Pressure 3-27

iv F-809-1218

TABLE OF CONTENTS

Hydrostatic Pump 3-28

Charge Pressure Check 3-28

Remove and Replace the Hydrostatic Pump 3-29

To Prime the Hydrostatic Pump 3-29

To Remove and Replace Hydrostatic Pump Manifold 3-29

Hydrostatic Drive Motor Assembly 3-30

To Remove Drive Wheels 3-30

Hydrostatic Drive Motors – Rear 3-30

Hydrostatic Drive Motor Assembly 3-31

Brake Service and Repair 3-31

Reassembly 3-33

Safety Features 3-39

Seat Switch 3-39

Horn 3-39

Direction Control Switch 3-40

Fuses 3-40

Overhead Guard/Lighting/Alarms 3-40

Engine Assembly 3-40

4 Calibration and Programming

Calibration 4-1

Getting Started 4-1

Programming 4-9

Monitor Parameters 4-9

Tuneable Parameters 4-13

Service Parts 4-15