$38

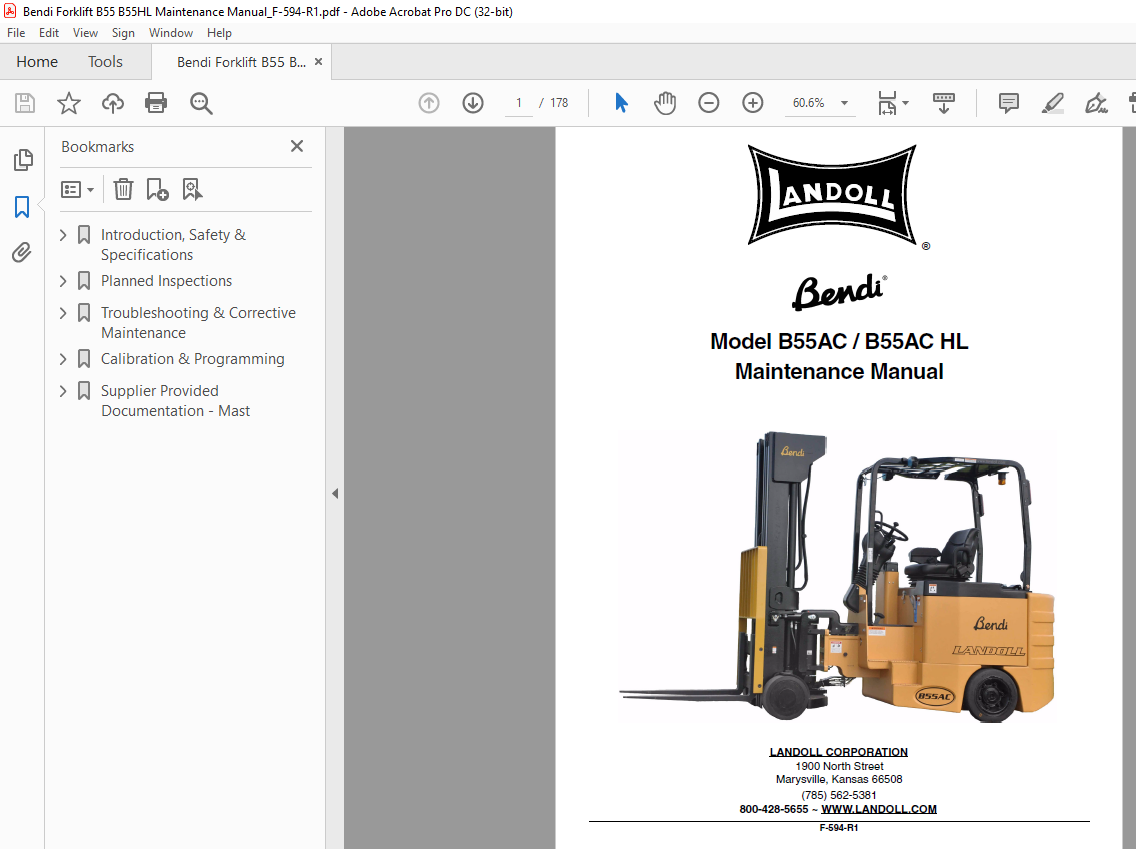

Bendi Landoll Forklift B55AC / B55AC HL Maintenance Manual F-594-R1 – PDF DOWNLOAD

Bendi Landoll Forklift B55AC / B55AC HL Maintenance Manual F-594-R1 – PDF DOWNLOAD

The Bendi Landoll Forklift B55AC/B55AC HL Maintenance Manual F-594-R1 – PDF DOWNLOAD offers comprehensive guidance for maintaining B55AC/B55AC HL models, ensuring efficient operation and longevity.

FILE DETAILS:

Bendi Landoll Forklift B55AC / B55AC HL Maintenance Manual F-594-R1 – PDF DOWNLOAD

Language : English

Pages : 178

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Bendi Landoll Forklift B55AC / B55AC HL Maintenance Manual F-594-R1 – PDF DOWNLOAD

- Introduction: This manual aids service technicians with maintenance, troubleshooting, and repair info for B55 AC trucks.

- Operating Instructions: Not included. Contact Landoll Corporation for a replacement if missing (Part Number F-595).

- Service Training: Landoll Corporation offers training covering operation, repair, maintenance, hydraulic and electrical systems, and wire guidance. or details.

TABLE OF CONTENTS:

Bendi Landoll Forklift B55AC / B55AC HL Maintenance Manual F-594-R1 – PDF DOWNLOAD

1 Introduction, Safety & Specifications

Before You Begin (Please Read) 1-1

Introduction 1-1

Operating Instructions 1-1

Service Training 1-1

Tools Needed 1-1

Replacement Parts 1-1

General Maintenance Instructions 1-2

For your Safety 1-3

Lock Out/Tag Out 1-3

Battery Safety Rules: 1-3

Battery Care and Charging 1-4

Battery Removal and Installation 1-4

Hydraulic System 1-4

Towing the Truck 1-5

General Safety Tips: 1-5

Towing Vehicle Requirements 1-5

Towing a Truck in the Reverse Direction 1-5

Lifting and Blocking the Truck 1-6

Prior to Tilt Cylinder Repair 1-6

Mast Service Precautions 1-7

Lubrication Specifications 1-8

Torque Specifications 1-8

Fluid Capacities 1-8

Cleaning the truck 1-10

ii F-594-R1 Edition

2 Planned Inspections

Inspection Introduction 2-1

Inspection Sheets 2-1

Tire Inspection 2-11

Visual Tire Inspection 2-11

Checking Steer Wheels 2-12

Brake System Overview 2-12

Check Service Disc Brakes 2-12

Parking Brake Lever 2-13

Checking Parking Brake Adjustment 2-13

Parking Brake Switch 2-14

Check Master Cylinder Fluid Level 2-14

Traction Drive Assemblies 2-14

Inspecting the Drive Assembly 2-14

Steering Actuator Maintenance 2-14

Check Hydraulic Oil Level 2-15

Checking and Adjusting Hydraulic Pressure 2-15

Check Power Steering 2-17

Checking Steer Pressure 2-17

Check Hydraulic Functions 2-18

Check Side Shift Circuit Performance 2-18

Electrical Contactors 2-18

Checking Batteries 2-18

Electrical Static Discharge 2-19

ESD Strap 2-19

Check the Return-to-Neutral 2-19

Check Driver’s Seat Switch 2-20

F-594-R1 Edition iii

3 Troubleshooting & Corrective Maintenance

Troubleshooting Charts 3-1

Corrective Maintenance 3-7

Mast & Front Rotation 3-7

Side Shift Circuit Maintenance 3-7

Hydraulic Steer Actuator Replacement 3-7

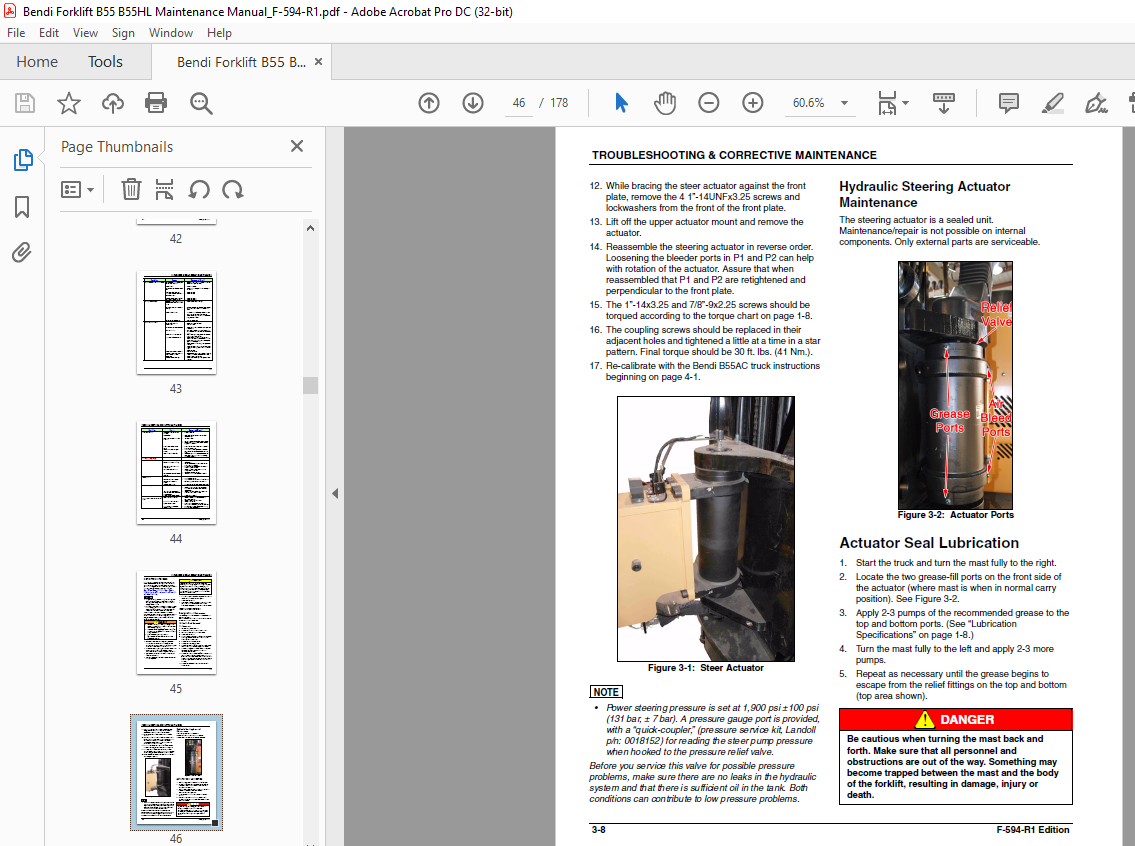

Hydraulic Steering Actuator Maintenance 3-8

Actuator Seal Lubrication 3-8

Brake System 3-9

Changing Brake Pads 3-10

Bleeding Brakes 3-10

Replacing the Brake Caliper Assembly 3-12

Repairing Brake Caliper Pistons 3-12

Disc Brakes 3-12

Disc Brake Rotors 3-12

Measuring Rotor Thickness 3-13

Check Lateral Run-Out (Warping) 3-13

Replacing the Brake Rotor Assemblies 3-13

Parking Brake Assembly 3-14

Replacing Parking Brake Lever Assembly 3-14

Replacing Parking Brake Switch 3-14

Replacing the Parking Brake Cable 3-14

Parking Brake Caliper Assembly 3-15

Changing Parking Brake Pads or Caliper 3-15

Hydraulic 3-16

Changing Hydraulic Oil 3-16

Change the Hydraulic Oil Filter 3-16

Hydraulic Motor(s) Reassembly 3-17

Hydraulic Pump Service 3-17

Hydraulic Components 3-17

Replacing the Hydraulic Pump and Motor 3-17

Hydraulic Control Valve Assembly 3-18

Hydraulic Control Valve and Switches Removal 3-18

Spool Section Rebuild 3-19

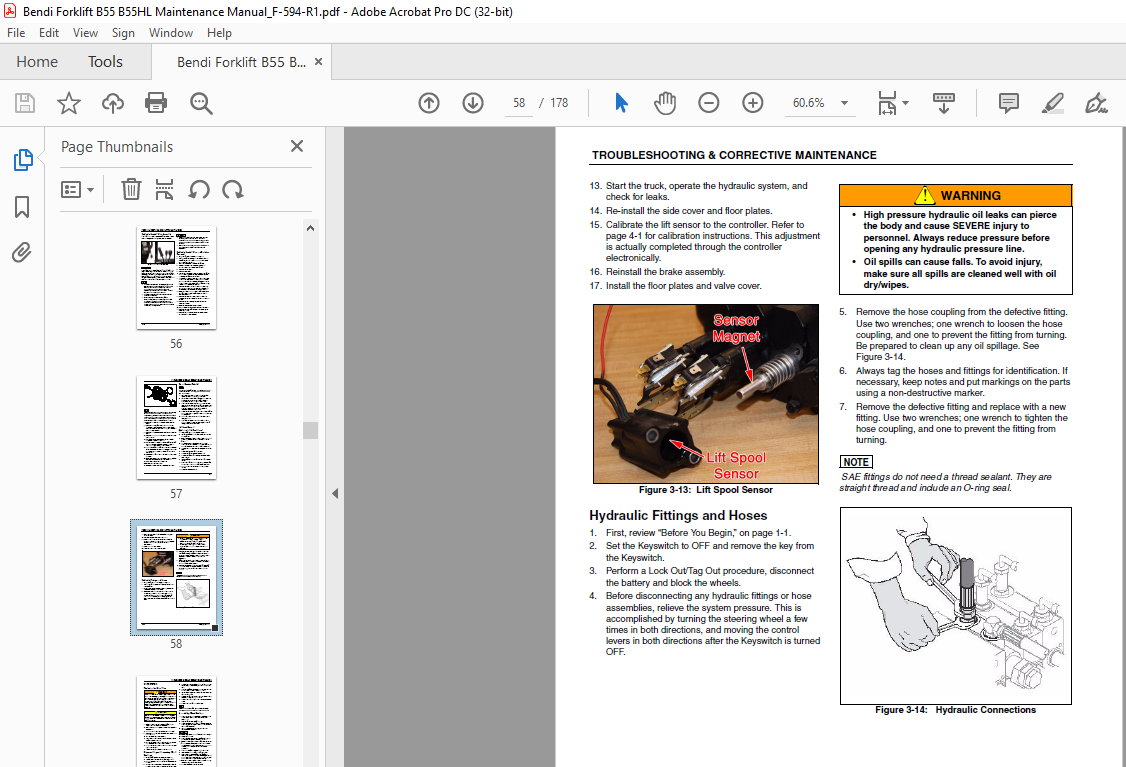

Lift Spool Sensor 3-19

Hydraulic Fittings and Hoses 3-20

Drive System 3-21

Replacing the Drive Tires 3-21

Disassembling and Inspecting Wheel Bearings 3-21

Assembling Wheel Bearings 3-21

Drive Wheel Assembly 3-22

Exposing and Maintaining the Traction Motors 3-23

Electrical 3-24

Battery – Safety, Care & Replacement 3-24

Battery Safety Rules: 3-24

Battery Care and Charging 3-25

iv F-594-R1 Edition

Battery Removal and Installation 3-26

Cleaning the Battery 3-26

Battery Removal 3-26

Battery Installation 3-26

Electrical Controls and Levers 3-27

Replacing a Complete Control Panel 3-27

High Current Connections Definition: 3-28

Fuses 3-29

Steering & Pedals 3-29

Brake Pedal 3-29

Pedal Adjustments 3-30

Checking Accelerator Switch/Pot 3-31

Master Cylinder 3-31

Bench Bleed the Master Cylinder 3-32

Service Brake Pedal Assembly 3-32

Floor Plate Removal 3-33

Accelerator Pedal Assembly 3-33

Adjusting Accelerator Pedal 3-33

Replacing Accelerator Module 3-34

Power Steering System Maintenance 3-34

Filling and Air Bleeding the Power Steering System 3-34

Steering Wheel Removal 3-34

Steering Column (Console) Removal 3-35

Steering Orbital Control Unit 3-35

Steering Column/Dash Assembly 3-36

Replacing the Display Panel 3-36

Replacing the Keyswitch 3-37

Rocker (On/Off) Switches 3-37

Safety Features 3-38

Horn Control Service 3-38

Seat Assembly 3-38

Truck Lighting 3-38

Headlights 3-38

Brake and Tail Lights 3-38

Back Up Alarms 3-39

Overhead Guard, Lighting and Alarms 3-39

F-594-R1 Edition v

4 Calibration & Programming

Controller Theory of Operation 4-1

Dash Display Parameters 4-1

Truck Calibration 4-1

1314 Bendi 55 AC Controller Software Program Installation and Operation 4-3

USB to Serial Port Adaptor Cable 4-3

1314 Installation Procedure 4-5

1314 Update Procedure 4-8

Communicating with Bendi 55 AC Controllers 4-8

Controller Fault History 4-11

Familiarizing the Menus 4-12

Program’s Menus 4-12

Monitoring Default Parameters 4-33

Landoll_DD_S Parameters 4-40

Landoll_P_B55 Parameters 4-44

Curtis Controller Troubleshooting 4-45

Program Troubleshooting Chart 4-46

Controller Maintenance 4-52

Controller Cleaning 4-52

Programmer Menus 4-52

5 Supplier Provided Documentation – Mast

Lift Technologies Inc 5-1

30D-60D 3-Stage Masts 5-1

Table of Contents – page 4 5-1