$38

Bendi Landoll Forklift B55AC / B55AC HL Maintenance Manual F-594-R2- PDF DOWNLOAD

Bendi Landoll Forklift B55AC / B55AC HL Maintenance Manual F-594-R2- PDF DOWNLOAD

The Bendi Landoll Forklift B55AC/B55AC HL Maintenance Manual F-594-R2 provides essential guidance for maintaining B55AC/B55AC HL models, ensuring optimal performance and longevity.

FILE DETAILS:

Bendi Landoll Forklift B55AC / B55AC HL Maintenance Manual F-594-R2- PDF DOWNLOAD

Language : English

Pages : 194

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Bendi Landoll Forklift B55AC / B55AC HL Maintenance Manual F-594-R2- PDF DOWNLOAD

- Introduction: This manual aids service technicians with maintenance, troubleshooting, and repair info for B55 AC trucks.

- Operating Instructions: Not included. Contact Landoll Corporation for a replacement if missing (Part Number F-595).

- Service Training: Landoll Corporation offers training covering operation, repair, maintenance, hydraulic and electrical systems, and wire guidance. for details.

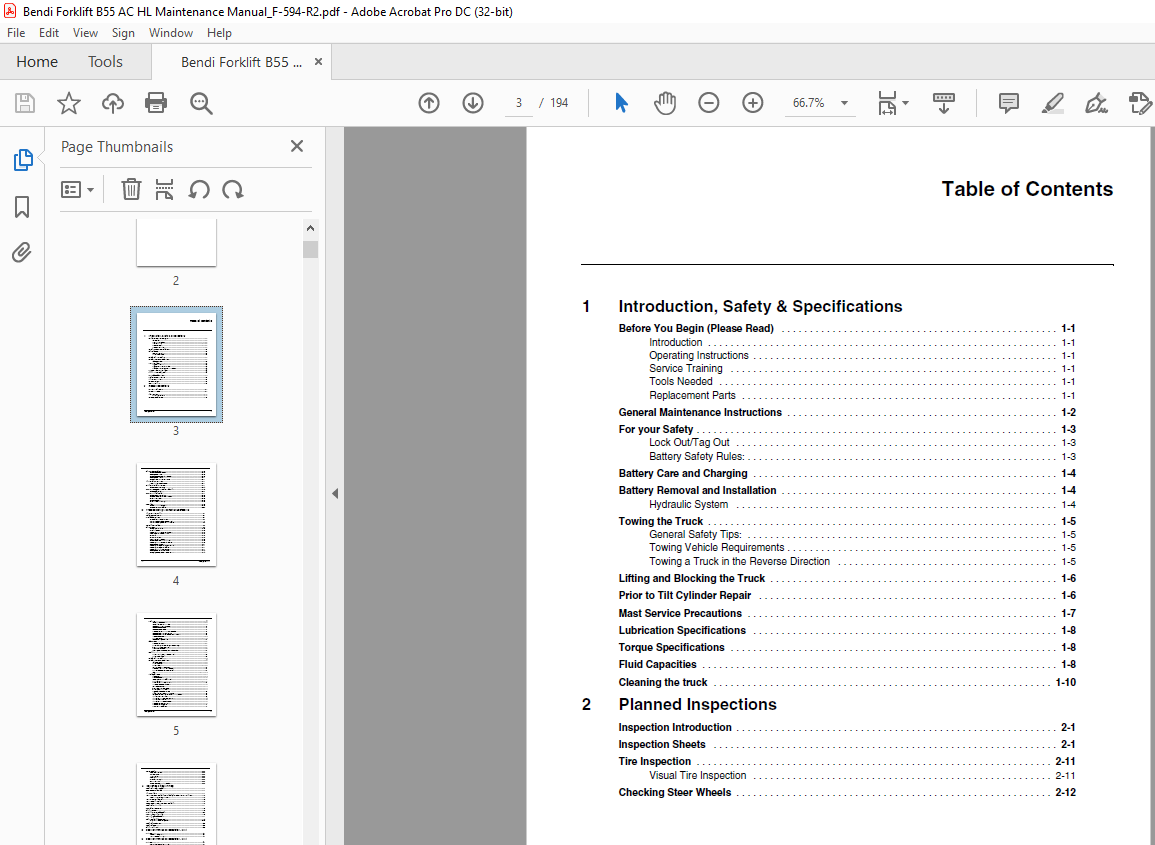

TABLE OF CONTENTS:

Bendi Landoll Forklift B55AC / B55AC HL Maintenance Manual F-594-R2- PDF DOWNLOAD

Introduction, Safety & Specifications 7

Before You Begin (Please Read) 7

Introduction 7

Operating Instructions 7

Service Training 7

Tools Needed 7

Replacement Parts 7

General Maintenance Instructions 8

For your Safety 9

Lock Out/Tag Out 9

Battery Safety Rules: 9

Battery Care and Charging 10

Battery Removal and Installation 10

Hydraulic System 10

Towing the Truck 11

General Safety Tips: 11

Towing Vehicle Requirements 11

Towing a Truck in the Reverse Direction 11

Lifting and Blocking the Truck 12

Prior to Tilt Cylinder Repair 12

Mast Service Precautions 13

Lubrication Specifications 14

Torque Specifications 14

Fluid Capacities 14

Cleaning the truck 16

Planned Inspections 17

Inspection Introduction 17

Inspection Sheets 17

Tire Inspection 27

Visual Tire Inspection 27

Checking Steer Wheels 28

Brake System Overview 28

Check Service Disc Brakes 28

Parking Brake Lever 29

Checking Parking Brake Adjustment 29

Parking Brake Switch 30

Check Master Cylinder Fluid Level 30

Traction Drive Assemblies 30

Inspecting the Drive Assembly 30

Steering Actuator Maintenance 30

Check Hydraulic Oil Level 31

Checking and Adjusting Hydraulic Pressure 31

Check Power Steering 33

Checking Steer Pressure 33

Check Hydraulic Functions 34

Check Side Shift Circuit Performance 34

Electrical Contactors 34

Checking Batteries 34

Electrical Static Discharge 35

ESD Strap 35

Check the Return-to-Neutral 35

Check Driver’s Seat Switch 36

Troubleshooting & Corrective Maintenance 37

Troubleshooting Charts 37

Corrective Maintenance 43

Mast & Front Rotation 43

Side Shift Circuit Maintenance 43

Hydraulic Steer Actuator Replacement 43

Hydraulic Steering Actuator Maintenance 44

Actuator Seal Lubrication 44

Brake System 45

Changing Brake Pads 46

Bleeding Brakes 46

Replacing the Brake Caliper Assembly 48

Repairing Brake Caliper Pistons 48

Disc Brakes 48

Disc Brake Rotors 48

Measuring Rotor Thickness 49

Check Lateral Run-Out (Warping) 49

Replacing the Brake Rotor Assemblies 49

Parking Brake Assembly 50

Replacing Parking Brake Lever Assembly 50

Replacing Parking Brake Switch 50

Replacing the Parking Brake Cable 50

Parking Brake Caliper Assembly 51

Changing Parking Brake Pads or Caliper 51

Hydraulic 52

Changing Hydraulic Oil 52

Change the Hydraulic Oil Filter 52

Hydraulic Motor(s) Reassembly 53

Hydraulic Pump Service 53

Hydraulic Components 53

Replacing the Hydraulic Pump and Motor 53

Hydraulic Control Valve Assembly 54

Hydraulic Control Valve and Switches Removal 54

Spool Section Rebuild 55

Lift Spool Sensor 55

Hydraulic Fittings and Hoses 56

Drive System 57

Replacing the Drive Tires 57

Disassembling and Inspecting Wheel Bearings 57

Assembling Wheel Bearings 57

Drive Wheel Assembly 58

Exposing and Maintaining the Traction Motors 59

Electrical 60

Battery – Safety, Care & Replacement 60

Battery Safety Rules: 60

Battery Care and Charging 61

Battery Removal and Installation 62

Cleaning the Battery 62

Battery Removal 62

Battery Installation 62

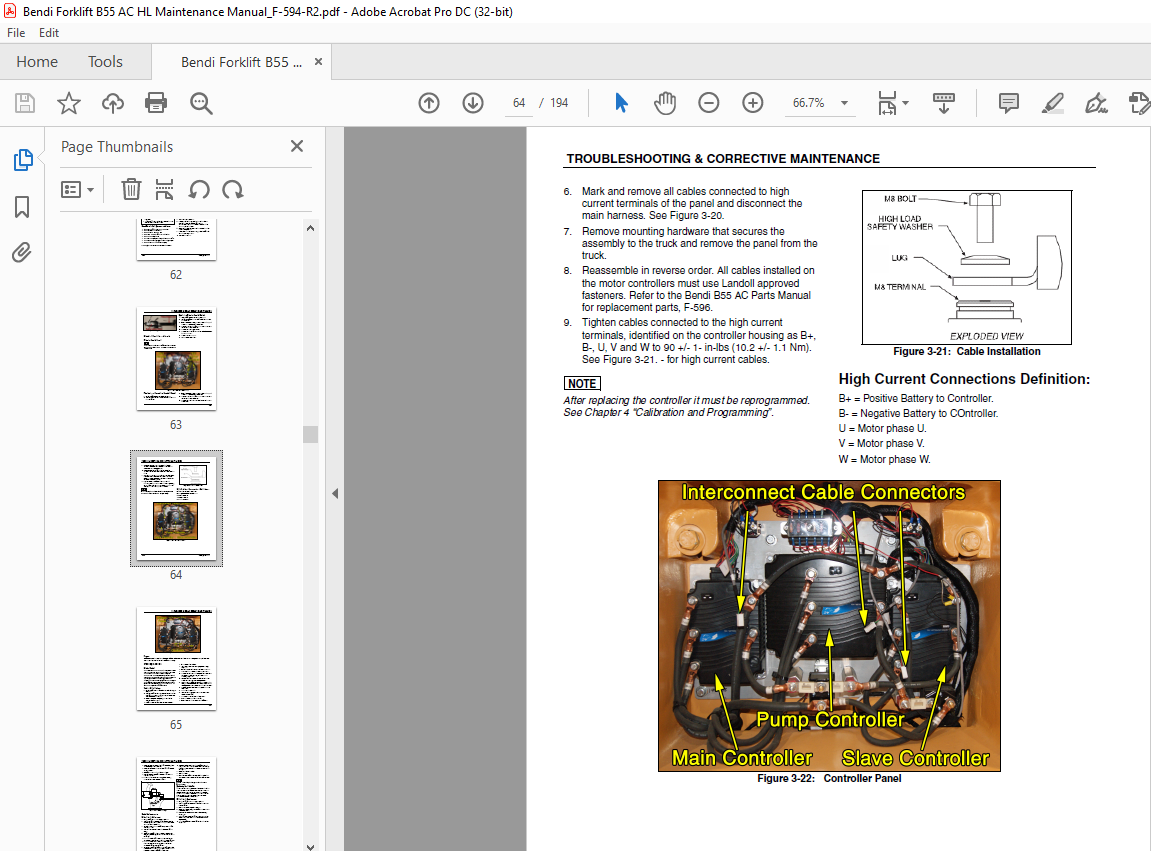

Electrical Controls and Levers 63

Replacing a Complete Control Panel 63

High Current Connections Definition: 64

Fuses 65

Steering & Pedals 65

Brake Pedal 65

Pedal Adjustments 66

Checking Accelerator Switch/Pot 67

Master Cylinder 67

Bench Bleed the Master Cylinder 68

Service Brake Pedal Assembly 68

Floor Plate Removal 69

Accelerator Pedal Assembly 69

Adjusting Accelerator Pedal 69

Replacing Accelerator Module 70

Power Steering System Maintenance 70

Filling and Air Bleeding the Power Steering System 70

Steering Wheel Removal 70

Steering Column (Console) Removal 71

Steering Orbital Control Unit 71

Steering Column/Dash Assembly 72

Replacing the Display Panel 72

Replacing the Keyswitch 73

Rocker (On/Off) Switches 73

Safety Features 74

Horn Control Service 74

Seat Assembly 74

Truck Lighting 74

Headlights 74

Brake and Tail Lights 74

Back Up Alarms 75

Overhead Guard, Lighting and Alarms 75

Calibration & Programming 77

Controller Theory of Operation 77

Dash Display Parameters 77

Truck Calibration 77

1314 Bendi 55 AC Controller Software Program Installation and Operation 79

USB to Serial Port Adaptor Cable 79

1314 Installation Procedure 81

1314 Update Procedure 84

Communicating with Bendi 55 AC Controllers 84

Controller Fault History 87

Familiarizing the Menus 88

Program’s Menus 88

Monitoring Default Parameters 109

Landoll_DD_S Parameters 116

Landoll_P_B55 Parameters 120

Curtis Controller Troubleshooting 121

Program Troubleshooting Chart 122

Controller Maintenance 128

Controller Cleaning 128

Programmer Menus 128

Supplier Provided Documentation – Mast 129

Lift Technologies Inc 129

30D-60D 3-Stage Masts 129

Table of Contents – page 4 129

Supplier Provided Documentation – Mast 174

Lift Technologies Inc 174

F60 MT 3-Stage Mast (High Lift) 174

Table of Contents – page 4 174

F60 MT R0 pdf 0

Cover 176

Contents 178

Introduction 177

Safety Decals 178

Freelift Cylinder 179

Mainlift Cylinder 181

Weldments 183

Hoist Chain Routing 184

Lowering Control Valve 185

4 Roller Carriage 186

Single Internal Hose Reeving 187

Double Internal Hose Reeving 188

Recommended Spare Parts List 189