$28

Bendi Landoll Narrow Aisle Forklift B40i3 Planned Maintenance Manual_F-502-0709 – PDF DOWNLOAD

Bendi Landoll Narrow Aisle Forklift B40i3 Planned Maintenance Manual_F-502-0709 – PDF DOWNLOAD

The Bendi Landoll Narrow Aisle Forklift B40i3 Planned Maintenance Manual_F-502-0709 – PDF DOWNLOAD offers detailed guidance for planned maintenance, ensuring optimal performance and longevity of the B40i3 model.

FILE DETAILS:

Bendi Landoll Narrow Aisle Forklift B40i3 Planned Maintenance Manual_F-502-0709 – PDF DOWNLOAD

Language : English

Pages : 77

Downloadable : Yes

File Type : PDF

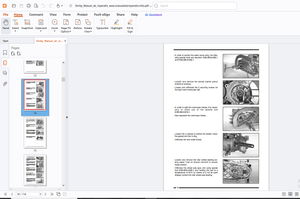

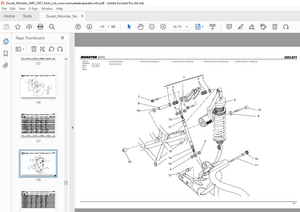

IMAGES PREVIEW OF THE MANUAL:

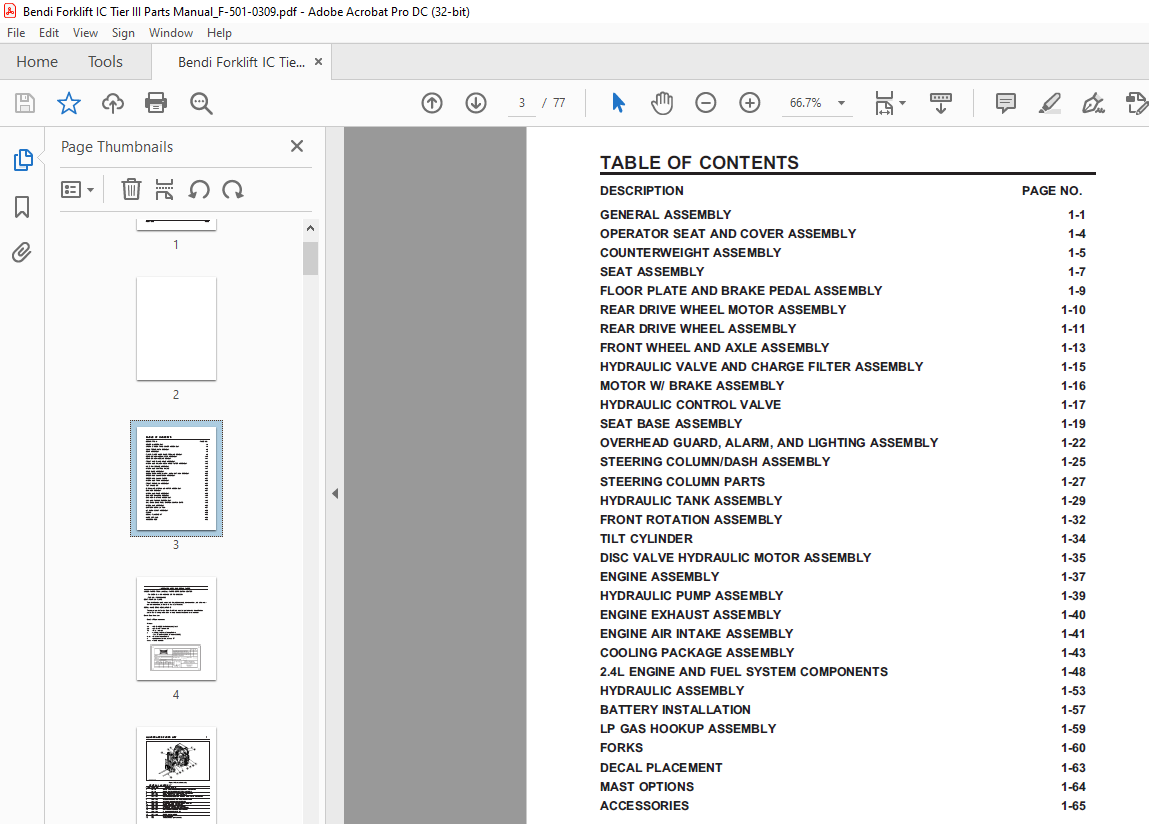

TABLE OF CONTENTS:

Bendi Landoll Narrow Aisle Forklift B40i3 Planned Maintenance Manual_F-502-0709 – PDF DOWNLOAD

DESCRIPTION PAGE NO

Using This Manual 1-1

Planned Maintenance 2-1

Overview 2-2

Tools or Equipment Required 2-3

Special Tools Required 2-3

Inspection and Maintenance Program 2-3

Inspection Program 2-3

Maintenance Program 2-4

Inspection and Maintenance Responsibilities 2-4

Operator’s Daily Checklist 2-4

Shift Inspection 2-5

Hourly Inspection Checklists 2-5

Installation Inspection 2-5

Routine Maintenance Schedule for Bendi Forklifts 2-6

Inspection and Maintenance Practices 2-6

Inspection and Maintenance Practices for

Bendi B40i3 Forklift Operators 2-7

Inspection and Maintenance Practices for

Authorized Facilities ONLY 2-8

Preparing for Inspection or Maintenance 2-8

Performance Testing 2-9

Completing Performance Testing 2-10

Daily Inspection 2-10

Fuel System Maintenance 2-11

Check Power Steering 2-11

Check Batteries 2-12

Check Hydraulic Functions 2-12

Check Driver’s Seat Switch 2-13

Check Hydraulic Oil Level 2-14

Check Engine Oil Level 2-15

Check Primary Lift Chain 2-16

Inspect Tires 2-17

Chunking (Chipping) or Embedded Objects 2-18

Undercutting and Uneven Wear 2-18

Flat-spotting 2-19

To Extend Tire Life 2-19

Monthly Inspection (300 Hours) 2-20

Check Nuts, Bolts, and Screws 2-20

Check Lift Operation 2-21

Drive Wheel Lug Nuts 2-21

Hydraulic System Maintenance 2-22

Side Shift Circuit Maintenance 2-23

Checking for Leaks 2-23

Identification Plate and Safety Warnings 2-24

Check Tilt Cylinder Racking 2-24

Tilt Cylinder Racking and Tilt Degree Setting 2-25

Lubricating the Truck 2-28

Tilt Cylinder Clevises 2-29

Lubricate Front Steer Wheel Bearings 2-30

Inspecting the Bearings, Race and Inner Seal 2-31

Front Column Rotation Bearings/Gears 2-33

Mast Mounting Pins 2-34

Forks and Side Shifter 2-35

Fork Positioner Lubrication, Non-Side Shifting 2-36

Check Radial Piston Hydraulic Motor 2-36

Cooling System 2-37

Air Filter 2-37

Change Engine Oil and Filter 2-38

Bendi B40i3 Forklift Service Manual

ii

Quarterly Inspection (600 Hours) 2-40

Change Hydraulic Oil Filter and Tank Filter 2-40

Floor Plate Removal 2-41

Mast Maintenance 2-42

Inspection Check List 2-43

Load Roller Maintenance 2-43

Chain Maintenance 2-44

Lubricate Steer Wheel Knob 2-46

Fork Inspection 2-47

Measuring Fork Thickness and Distortion 2-48

Annual Inspection (2000 Hours) 2-50

Change Hydraulic Oil 2-50