$50

Bobcat 371 Loader Gasoline & L.P. Gas Service Manual 6545574 (6-12) – PDF DOWNLOAD

Bobcat 371 Loader Gasoline & L.P. Gas Service Manual 6545574 (6-12) – PDF DOWNLOAD

FILE DETAILS:

Bobcat 371 Loader Gasoline & L.P. Gas Service Manual 6545574 (6-12) – PDF DOWNLOAD

Language : English

Pages : 88

Downloadable : Yes

File Type : PDF

DESCRIPTION:

Bobcat 371 Loader Gasoline & L.P. Gas Service Manual 6545574 (6-12) – PDF DOWNLOAD

FOREWORD:

This manual is written in two parts: To provide instruction for proper routine servicing and adjustments of the Bobcat such as the 50 hour check and regularly scheduled periodic inspections established by the Service Schedule, and to provide detailed overhaul instructions of the power train, loader hydraulic system and general machine main frame components. Refer to the Owners Manual for general operating instructions (Starting Procedure, Daily Checks, Bucket Operation, Minor Maintenance, etc).

INSPECTION:

A general inspection of the following items should be made whenever the machine has been serviced of repaired:

1. Check hydraulic fluid level, engine oil level and fuel supply.

2. Check for any sign of fuel, oil or hydraulic fluid leaks.

3. Lubricate the machine.

4. Check battery condition, electrolyte level and cables.

5. Check air cleaner for damage or leaks. Check element and replace if necessary.

6. Check transmission drive belt and hydraulic drive belt for wear and tension.

7. Check tires for wear and pressure.

8. Check Bob–Tach wedges for condition.

9. Check safety items for condition. (Operator Protective Guard, Seat Belt, Safety Treads on

steps, Boom Stop).

10. Make a visual inspection for loose or broken parts or connections.

Advise the owner if any of the above items require service or repair.

TABLE OF CONTENTS:

Bobcat 371 Loader Gasoline & L.P. Gas Service Manual 6545574 (6-12) – PDF DOWNLOAD

MAINTENANCE SAFETY 3

CONTENTS 5

FOREWORD 5

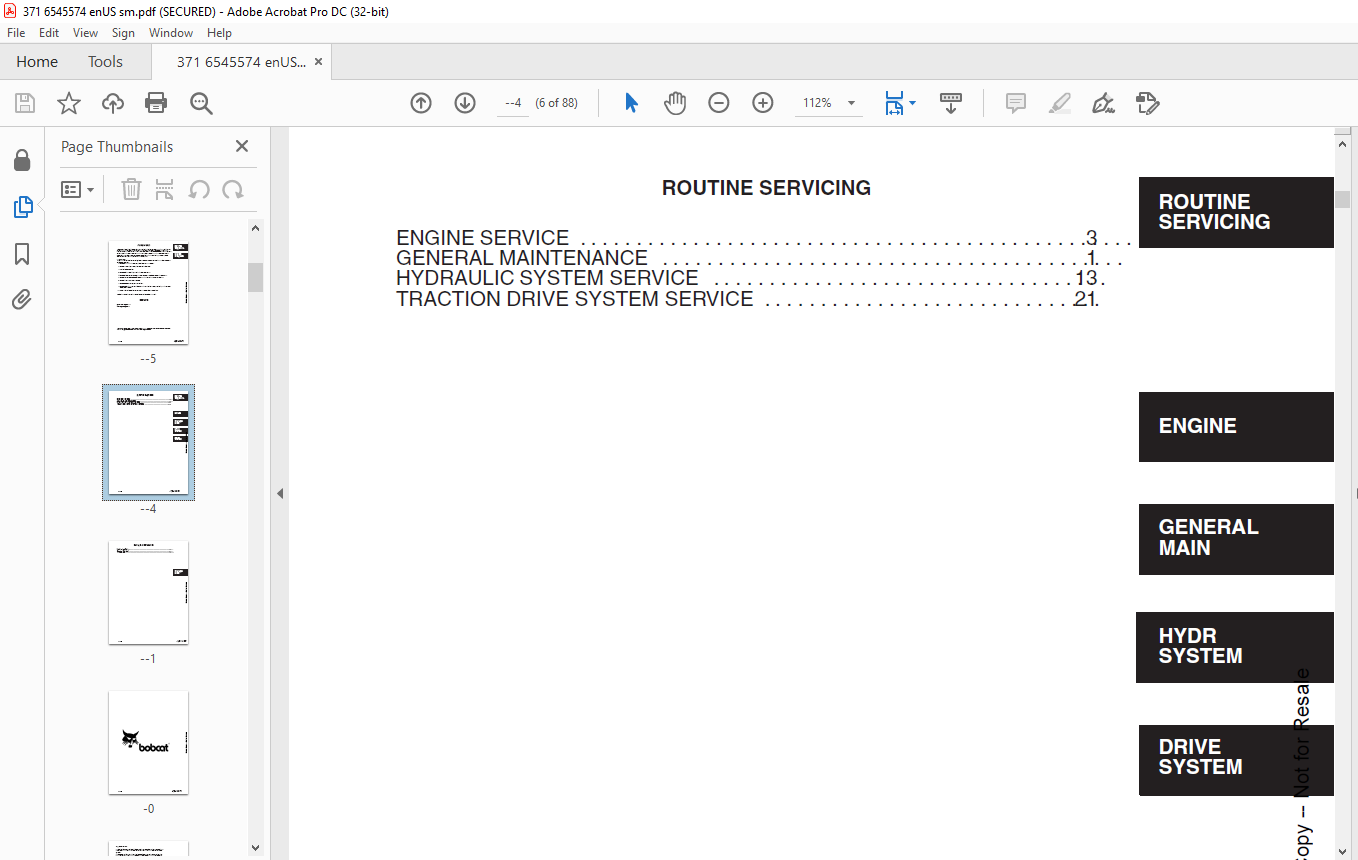

ROUTINE SERVICING 6

GENERAL MAINTENANCE 7

TIRE INFLATION 9

TIRE ROTATION 9

TIRE REPLACEMENT 9

LUBRICATION 9

GENERAL MAINTENANCE 10

ENGINE SERVICE 11

CHANGING ENGINE OIL 13

OIL SPECIFICATIONS 13

ENGINE AIR CLEANER 13

CRANKCASE BREATHER 13

AIR COOLING SYSTEM 13

CARBURETOR 14

FUEL PUMP 14

LP GAS FUEL SYSTEM 15

IGNITION SYSTEM 15

OPERATIONAL TEST 15

SPARK PLUG 15

BREAKER POINTS 16

CONDENSER 16

IGNITION TIMING PROCEDURE 16

GOVERNOR 16

Initial Adjustment 16

Speed Adjustment 16

Sensitivity Adjustment 16

AUTOMATIC COMPRESSION RELEASE 17

COMPRESSION 17

ELECTRICAL SYSTEM 17

RECTIFIER–REGULATOR 18

HYDRAULIC SYSTEM SERVICE 23

DESCRIPTION OF HYDRAULIC CIRCUIT 25

CHECKING HYDRAULIC FLUID 25

DRAINING CONDENSATION 25

CHANGING HYDRAULIC FLUID 26

HYDRAULIC FLUID FILTER 26

CHECKING THE HYDRAULIC SYSTEM 27

TESTING THE HYDRAULIC SYSTEM 27

PUMP DRIVE BELT ADJUSTMENT 28

PEDAL LINKAGE ADJUSTMENT 28

CONTROL VALVE 28

TRACTION DRIVE SYSTEM SERVICE 33

DESCRIPTION OF DRIVE 35

CLUTCH ADJUSTMENT 35

DRIVE CHAIN ADJUSTMENT 36

MAJOR OVERHAUL 41

ENGINE OVERHAUL 43

ENGINE SHOCK MOUNTS AND STABILIZER ROD 45

REPAIR–REPLACEMENT METHODS 45

INSPECTION–DISASSEMBLY 46

SCORING OF THE CYLINDER WALL 46

SEVERE PISTON DAMAGE 46

EVIDENCE OF EXTERNAL OIL LEAKAGE 46

DISASSEMBLY PROCEDURE 46

ENGINE RECONDITIONING 47

CYLINDER BLOCK 47

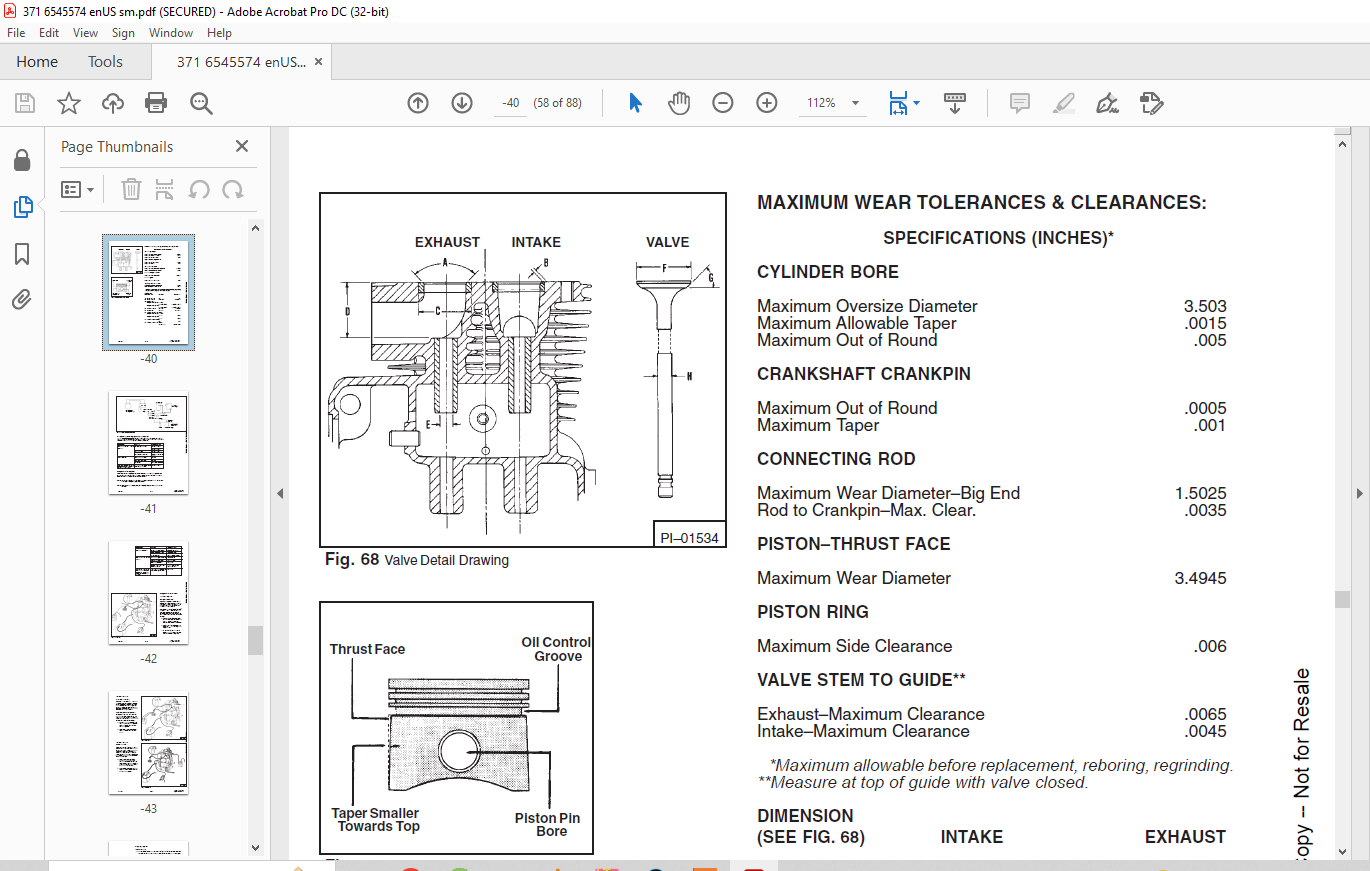

CRANKSHAFT 48

CONNECTING ROD 48

PISTON–PISTON RINGS 48

PISTON–ROD ASSEMBLY 49

VALVES–VALVE MECHANISM 49

CYLINDER HEAD 49

RING GEAR 49

DYNAMIC BALANCE SYSTEM 50

TIMING THE BALANCE GEARS 50

REASSEMBLY 51

FINAL ADUSTMENTS 54

RUN–IN PROCEDURES (Re–Conditioned Engines) 54

CARBURETOR RECONDITIONING (Gasoline) 54

DISASSEMBLY OF CARBURETOR 54

ASSEMBLY OF CARBURETOR 54

LPG FUEL SYSTEM RECONDITIONING 55

PRIMARY REGULATOR 55

SECONDARY REGULATORS 56

ENGINE SPECIFICATIONS 57

TORQUES 57

FITS & CLEARANCES 57

MAXIMUM WEAR TOLERANCES & CLEARANCES 58

ALTERNATOR/RECTIFIER–REGULATOR SERVICE 59

CHARGE SYSTEM SERVICE 59

CHARGE SYSTEM CHECKS 60

STARTER SERVICE 62

To Check Starter 62

Removal of Starter 62

HYDRAULIC SYSTEM OVERHAUL 63

HYDRAULIC SYSTEM 65

HYDRAULIC CYLINDER REPAIR 65

HYDRAULIC PUMP REPAIR 66

CONTROL VALVE BANK REPAIR 67

LIFT CYLINDER LINE RESTRICTOR 68

WARD CONTROL VALVE REPAIR 69

TRACTION DRIVE SYSTEM OVERHAUL 71

TRACTION DRIVE SYSTEM CHAIN REMOVAL 73

CHAIN REINSTALLATION 73

REMOVING STEERING LINKAGE 74

REMOVING CLUTCHES 74

REPLACING CLUTCH NEEDLE BEARINGS 75

REMOVING THE LOWER JACKSHAFT 75

REPLACING SPROCKET BEARINGS 75

Removing Upper Jackshaft 76

To Disassemble the Upper Jackshaft 76

REMOVING AN AXLE 77

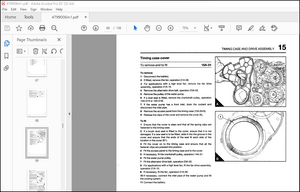

TRANSMISSION CASE & COVER 78

DRIVE AND DRIVEN SHEAVES 78

LOADER MAIN FRAME OVERHAUL 79

BOOM ALIGNMENT 81

STRAIGHTENING BENT BOOMS 81

OPERATOR PROTECTIVE GUARD 81

THE BOB–TACH 81

BOOM CYLINDER SUPPORT BRACKET 81

FUEL TANK 81

ENGINE VIBRATION MOUNTS 82

SPECIFICATIONS 83

LOADER SPECIFICATIONS 85

OPERATIONAL & PERFORMANCE 85

ENGINE 85

LOADER HYDRAULICS 85

ELECTRICAL 85

POWER TRAIN 85

CAPACITIES 85

TIRES 85

MACHINE WEIGHT (w/o bucket) 85

Hydraulic Fluid 86

TABLE OF MACHINE TORQUES 86

SERVICE MANUAL REVISIONS 87

371-1 87

IMAGES PREVIEW OF THE MANUAL: