$30

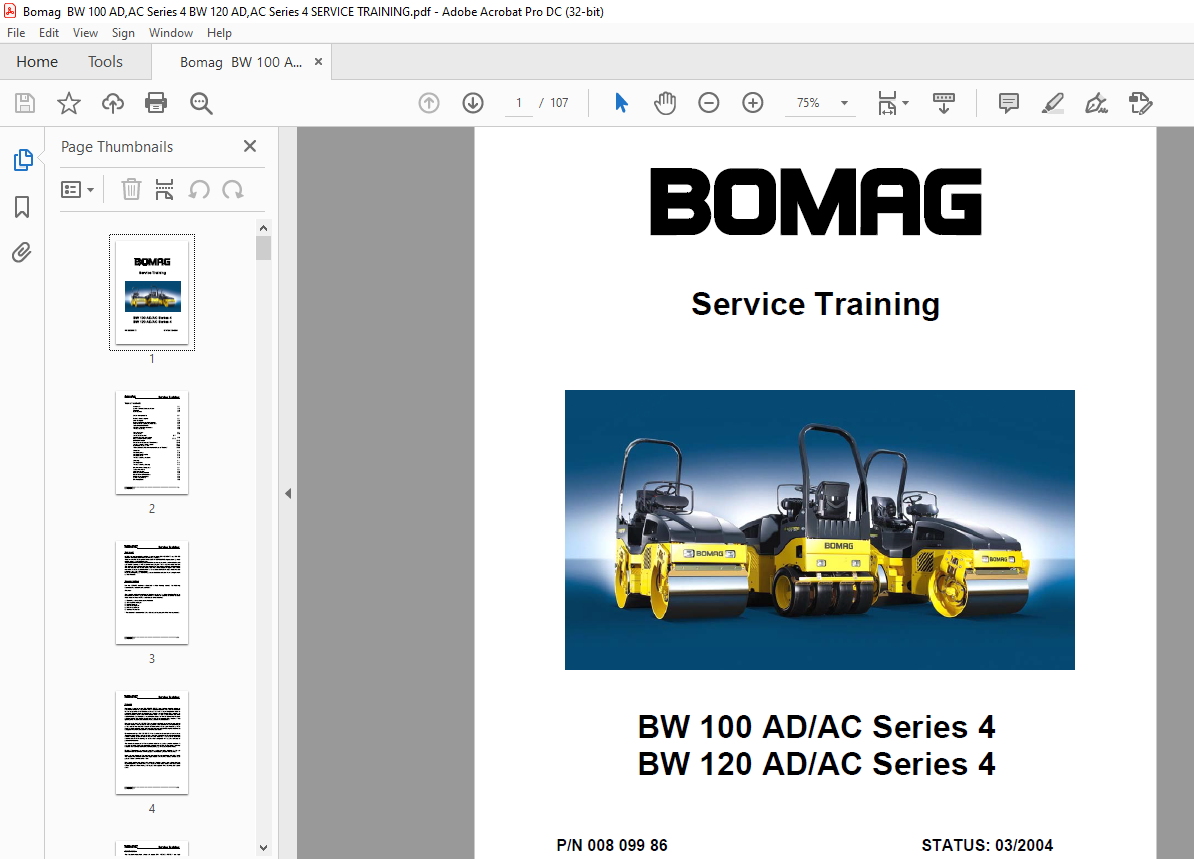

Bomag BW 100 AD AC Series 4 BW 120 AD AC Series 4 Service Training Manual – PDF DOWNLOAD

Bomag BW 100 AD AC Series 4 BW 120 AD AC Series 4 Service Training Manual – PDF DOWNLOAD

IMAGES PREVIEW OF THE MANUAL:

FILE DETAILS:

Bomag BW 100 AD AC Series 4 BW 120 AD AC Series 4 Service Training Manual – PDF DOWNLOAD

Language : English

Pages :107

Downloadable : Yes

File Type : PDF

Size:8.47 MB

DESCRIPTION:

Bomag BW 100 AD AC Series 4 BW 120 AD AC Series 4 Service Training Manual – PDF DOWNLOAD

Foreword

- In 2004 the tandem vibratory rollers of product range BW 100 AD/AC4 and BW 120 AD/AC4 were launched in the market for the first time. They are a further development of the old BW 100/120AD/AC of generation 3, which already were a great sales success.

- The contents of this training shall enable the service engineer to perform adjustments and trouble shooting as well as all necessary repair work in a professional manner.

- The owner of the machine should recognize that the service engineer is fully familiar with the machine. He should realize that the service engineer applies the correct measures to detect a possible fault on a machine and that all repair measures are performed with skill and knowledge. Persons participating on this training course should be confident when having to work on this machine.

General

- Machines of product range BW 100/120 AD/AC-4 are tandem vibratory rollers or combination rollers for compaction work in road construction. They are most suitable for the compaction of bituminous materials as well as light compaction tasks in earthwork. Compaction is achieved by the vibration of both drums or the vibration of the drum and the static load of the rubber tires.

- The power output from the water cooled Kubota diesel engine is transferred to drums or wheels (travel and vibration systems) and to the steering via the hydrostatic drive systems of the machine. This type of power transmission ensures lowest possible efficiency losses. Both drums of the BW 100/120 AD-4 are fitted with both travel motors as well as vibration motors.

- The motors for the respective drive systems are always arranged on one side of the machine. Since it is beneficial for many applications (e.g. when laying asphalt layers) to work with one vibrating and one static drum, the machine is equipped with a vibration shut-off valve for the rear drum. On machines of type BW 100/120 AC-4 the wheel set is driven by two travel motors.

- This roller combines the high compaction power of a vibration drum with the excellent surface sealing effect of rubber tires in one machine.

- This machine obviously achieves considerable savings in costs when compared with a pure vibratory or pneumatic tired roller. The standard equipment of the machine includes a gravity sprinkler system. A pressure sprinkler system is optionally available on request.

- In connection with the scrapers the water sprinkler system avoids picking up of material by the drums. On the AC-machines a pressure sprinkler system prevents sticking of dirt and bitumen to the rubber tires. For this purpose the tires are sprayed with emulsion.

- Front and rear frames of the machine are joined by an oscillating articulated joint. The amply dimensioned oscillation angle makes sure that the drums always have ground contact over the entire width. Both travel motors are fitted with integrated brakes working as parking brakes. Depending on the position of the brake solenoid valve these brakes are released by charge pressure when starting the engine and applied when shutting the engine down.

TABLE OF CONTENTS:

Bomag BW 100 AD AC Series 4 BW 120 AD AC Series 4 Service Training Manual – PDF DOWNLOAD

Table of contents

Foreword A 1

List of additional documentation A 2

General A 3

Maintenance A 4

List of components B 1

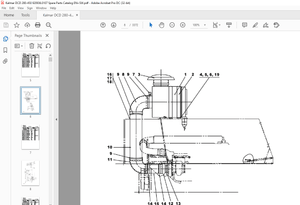

Kubota diesel engine C 1

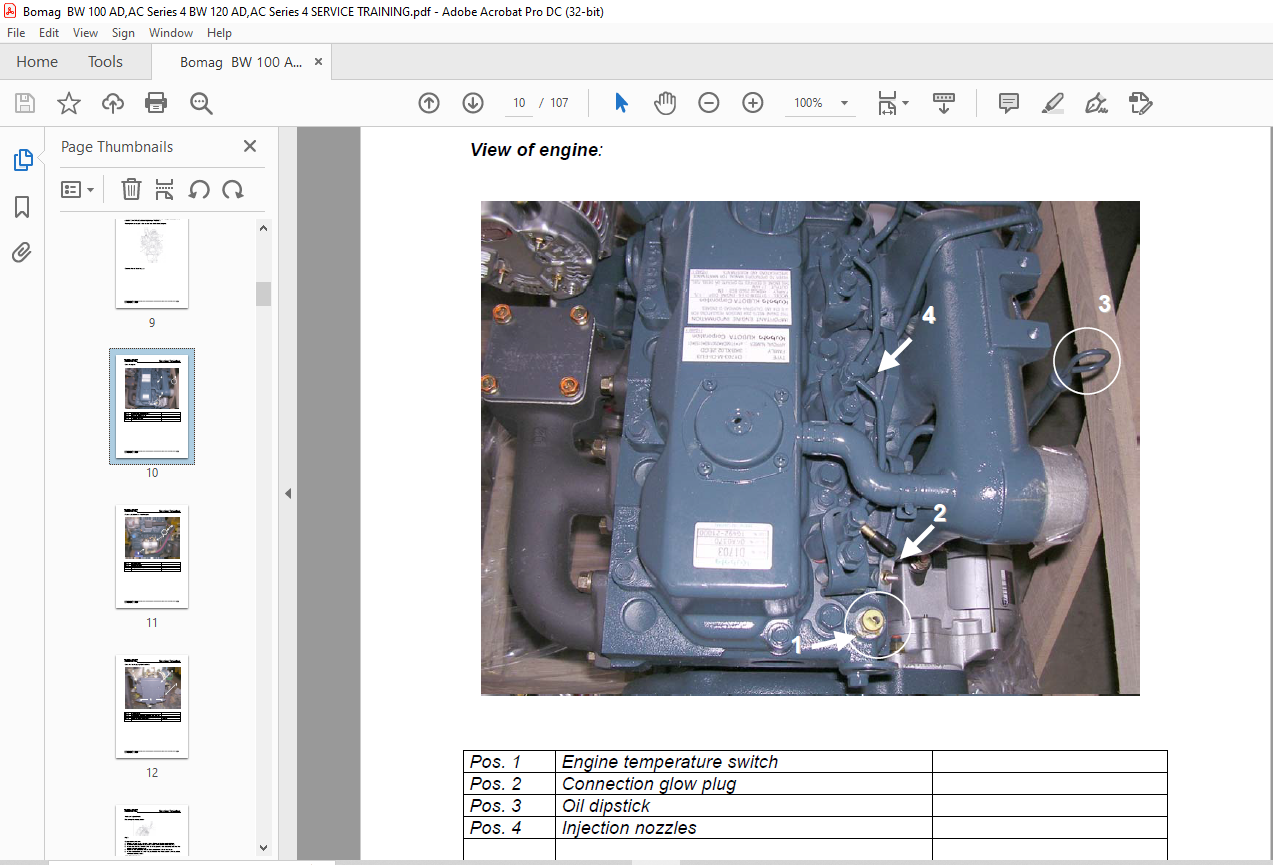

View of engine C 2

Pump installation on diesel engine C 3

View of diesel engine, flywheel side C 4

Tests and adjustments C 5

Adjusting the valve clearance C 6

Trouble Shooting C 8

Travel system D 1

Travel pump D 3

Travel pump control D 7

Charge pressure relief valve D 9

High pressure relief valves D 10

Drum drive motor D 12

Wheel drive motors on AC-machines D 16

Trouble shooting travel system D 17

Insufficient travel power D 28

The machine moves with the travel lever in “Neutral” D 30

Vibration E 1

Vibration pump E 3

Vibration control valve E 4

Vibration motor E 5

Trouble shooting vibration E 6

Steering F 1

Steering valve F 3

Trouble shooting steering F 5

Electric circuit diagrams G 1

Table of contents G 1

Function groups G 2

Reference lines, frames G 3

Potential cross references G 4

Relay cross references G 5

List of components G 5

Electric system G 6