$33

Bomag BW 216 D-40 PD-40 BW 218 D-40 Single Drum Roller Service Manual 00891812 – PDF DOWNLOAD

Bomag BW 216 D-40 PD-40 BW 218 D-40 Single Drum Roller Service Manual 00891812 – PDF DOWNLOAD

FILE DETAILS:

Bomag BW 216 D-40 PD-40 BW 218 D-40 Single Drum Roller Service Manual 00891812 – PDF DOWNLOAD

Language : English

Pages : 1446

Downloadable : Yes

File Type : PDF

Size: 73 MB

DESCRIPTION:

Bomag BW 216 D-40 PD-40 BW 218 D-40 Single Drum Roller Service Manual 00891812 – PDF DOWNLOAD

1.1Introduction:

- This manual addresses the professionally qualified personnel or the after sales service of BOMAG, and should be of help and assistance in correct and efficient repair and maintenance work.

- This manual describes the disassembly, dismantling, assembly, installation and repair of components and assemblies. The repair of components and assemblies is only described as this makes sense under due consideration of working means and spare parts supply.

Documentation:

For the BOMAG machines described in this manual the following documentation is additionally available:

1Operating and maintenance instructions

2Spare parts catalogue

3Service information

- Use only genuine BOMAG spare parts.

- Spare parts needed for repairs can be taken from the spare parts catalogue for the machine.

- This manual is not subject of an updating service; for this reason we would like to draw your attention to our additional “Technical Service Bulletins”.

- In case of a new release all necessary changes will be included.

- In the course of technical development we reserve the right for technical modifications without prior notification.

- Information and illustrations in this manual must not be reproduced and distributed, nor must they be used for the purpose of competition. All rights according to the copyright law remain expressly reserved.

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Bomag BW 216 D-40 PD-40 BW 218 D-40 Single Drum Roller Service Manual 00891812 – PDF DOWNLOAD

General 7

1.1 Introduction 8

1.2 Safety regulations 9

1.3 General repair instructions 14

1.4 Tightening torques 26

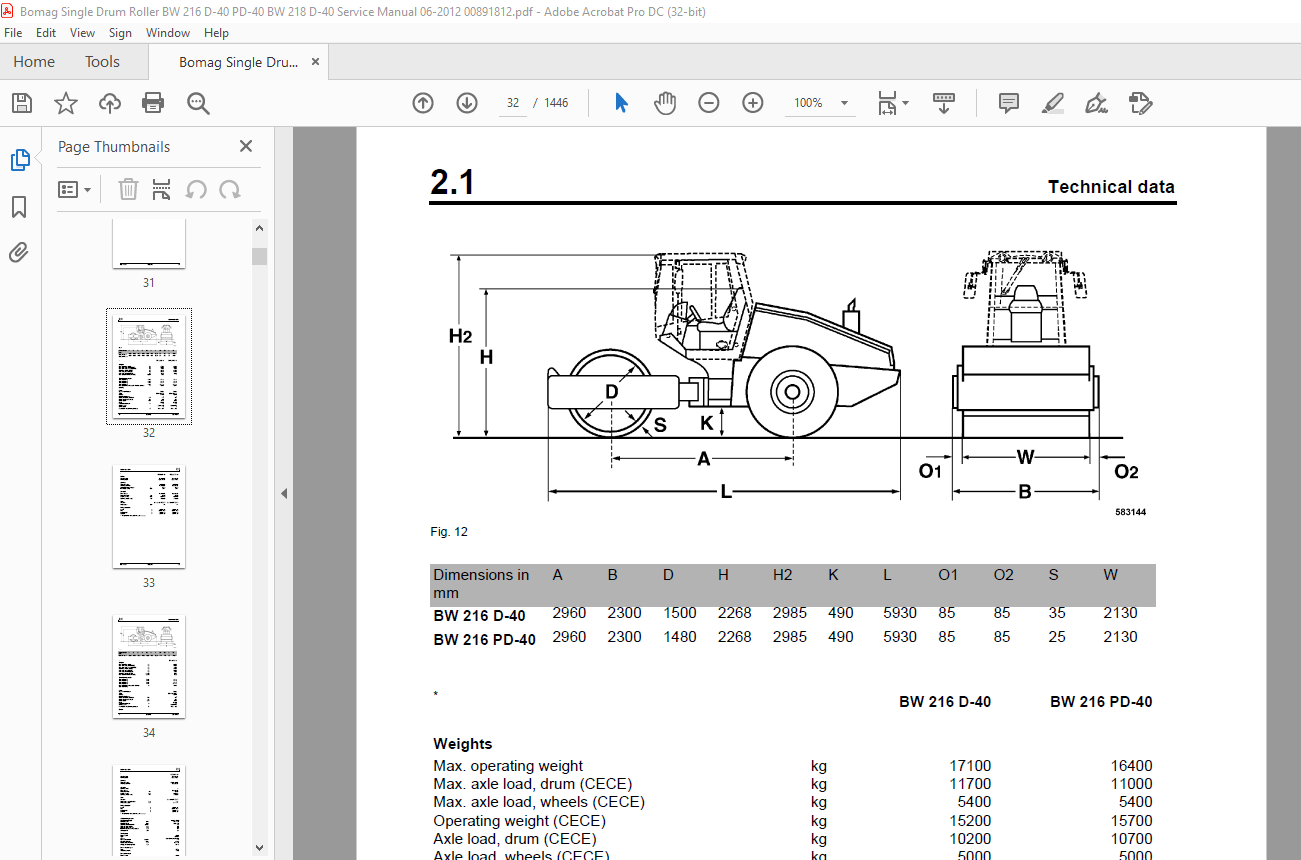

Technical data 31

2.1 Technical data 32

Maintenance 39

3.1 General notes on maintenance 40

3.2 Fuels and lubricants 41

3.3 Table of fuels and lubricants 44

3.4 Running-in instructions 45

Caddy wiring diagrams 47

4.1 Understanding circuit diagrams 48

4.2 Circuit symbols in the circuit diagram 53

4.3 Identification of switch blocks in the Caddy wiring diagram 54

4.4 Designation of components in the wiring diagram 55

4.5 Terminal designations in wiring diagram 56

E-Plan wiring diagrams 59

5.1 Understanding wiring diagrams 60

5.2 Circuit symbols in the circuit diagram 69

5.3 Identification of switch blocks in the wiring diagram 72

5.4 Designation of components in the wiring diagram 73

5.5 Terminal designations in wiring diagram 74

Electrics 77

6.1 Designation of components in the wiring diagram 78

6.2 Terminal designations in wiring diagram 79

6.3 Battery ground and analog ground 81

6.4 Current and voltage 81

6.5 Resistance 83

6.6 Series / parallel connection 85

6.7 Ohm’s law 87

6.8 Electrical energy 88

6.9 Formula diagram 89

6.10 Metrology 90

6.11 Diodes, relays, fuses 94

6.12 Telemecanique switch 97

6.13 Plug connectors 99

6.14 Magnetic coil plug 99

6.15 Deutsch plug, series DT and DTM 101

6.16 Plugs and terminals in spring clamping technology 106

6.17 Proximity switches 110

6.18 Level sensor in diesel tank (R03) 111

6.19 Differential pressure switch for hydraulic oil filter, B21 112

6.20 Acceleration transducer 114

6.21 Batteries 115

Table of Contents

4 BOMAG 008 918 12

6.22 Service the battery 119

6.23 Main battery fuse 120

6.24 Starting with jump wires 120

6.25 Generator 121

6.26 Replacing the voltage regulator 130

6.27 Electric starter 132

6.28 Coolant temperature switch 138

6.29 Oil pressure switch and low oil pressure circuitry 139

6.30 Boost fuel solenoid valve 141

6.31 Engine shut-down solenoid 142

6.32 Electric throttle control 143

6.33 Heating flange on engine 145

6.34 Checking the heating flange control 148

6.35 Engine monitoring 149

6.36 Overview of electric components 152

6.37 Operator’s stand, old design 163

6.38 Operator’s stand, new design 165

6.39 Cabin 166

6.40 Fuses, old design 167

6.41 Fuses, new design 168

6.42 Electronic control units 169

6.43 Checking the voltage supply for the control unit 172

6.44 Diagnostics concept 180

Electronic modules 183

7.1 BEM, BOMAG Evib-meter 185

7.2 Electrics module A68 249

7.3 Electric module K04 257

7.4 Electric module A72, old design 261

7.5 Electric module A108 267

Speedometer Module 271

8.1 Speedometer module 272

582 502 15 dust protection / 582 502 16 gasket 275

9.1 Assembling the dust protection 276

Hydraulics 281

10.1 Hydraulic circuit 282

10.2 Connection overview 284

10.3 Travel pump 075 286

10.4 Vibration pumps 42R041 & 42R055 292

10.5 Axial piston swash plate principle / pump 295

10.6 Troubleshooting axial piston pumps 297

10.7 Travel motor 51 C/D 110 300

10.8 Trouble shooting, variable displacement axial piston motor 302

10.9 Vibration motor A10FM 45 304

10.10 Vibration motor 90M 055 305

10.11 Axial piston swash plate principle / motor 307

10.12 External gear pumps 309

10.13 Travel circuit 311

Table of Contents

008 918 12 BOMAG 5

10.14 Adjust the parking brake 316

10.15 Stopping the machine, operating the parking brake 318

10.16 Towing in case of an engine failure 318

10.17 Vibration circuit 321

10.18 Steering circuit 326

10.19 Check the hydraulic oil level 332

10.20 Changing hydraulic oil and breather filter 332

10.21 Replace hydraulic oil filter 333

10.22 Changing the bypass filter 334

Tests and adjustments 335

11.1 Special tools, tests and adjustments 336

11.2 Adjusting the solenoid for engine speed control 340

11.3 Checking the rotation speeds 341

11.4 Checking / adjusting the neutral positions of the travel pump 343

11.5 Pressure tests in the travel circuit 345

11.6 Checking / adjusting the vibrator shaft speeds 347

11.7 Pressure measurements in the vibration circuit 348

11.8 Check the leakage rate of the vibration motor 349

11.9 Pressure test in steering circuit 350

Flushing and bleeding 353

12.1 Special tools for flushing 354

12.2 Flushing – general 359

12.3 Flushing schematic travel circuit (distribution travel pump) 361

12.4 Flushing the travel circuit (travel pump distribution) 363

12.5 Flushing schematic travel circuit (distribution axle motor) 369

12.6 Flushing the travel circuit (axle motor distribution) 374

12.7 Flushing schematic for vibration drive 379

12.8 Flushing the vibration circuit 380

12.9 Bleeding the travel circuit 384

12.10 Bleeding the vibration circuit 386

Air conditioning system 389

13.1 Physical basics 390

13.2 Refrigerant R134a 393

13.3 Compressor oil / refrigeration oil 394

13.4 Working principle of the air conditioning system 395

13.5 Monitoring devices 395

13.6 Description of components 396

13.7 Measuring the compressor oil level 402

13.8 Checking the magnetic clutch 402

13.9 Inspection and maintenance work 403

13.10 Checking, replacing the refrigerant compressor V-belt 404

13.11 Air conditioning service (old design) 405

13.12 Service the air conditioning 407

13.13 Drying and evacuation 410

13.14 Emptying in case of repair 410

13.15 Leak test 411

13.16 Filling instructions 412

13.17 Trouble shooting in refrigerant circuit, basic principles 415

Table of Contents

6 BOMAG 008 918 12

13.18 Trouble shooting, refrigerant circuit diagram 419

13.19 Trouble shooting procedure 420

13.20 Steam table for R134a 430

Cabin assembly 435

14.1 Preparations 437

14.2 Cabin assembly 438

14.3 Final function tests and checks 443

Replacing the cab window panes 445

15.1 Assembly of window panes 446

15.2 Special tools, cabin windows 447

15.3 Auxiliary materials 448

15.4 Removing and installing the window pane 450

Drum 455

16.1 Special tools, drum, single drum rollers 456

16.2 Repair overview for drum 458

16.3 Removing and installing the drum 467

16.4 Repairing the drum 473

16.5 Dismantling, assembling the change-over weights 504

16.6 Changing the rubber buffers and adjusting the pretension 507

Oscillating articulated joint 511

17.1 Special tools, oscillating articulated joint (BW177 to BW 216) 512

17.2 Repair overview oscillating articulated joint 514

17.3 Removing and installing the oscillating articulated joint 518

17.4 Dismantling the oscillating articulated joint 520

17.5 Assembling the oscillating articulated joint 525

Suppliers documentation 535

18.1 Travel pump 537

18.2 Vibration pump 691

18.3 Travel motor 761

18.4 Vibration motor 855

18.5 Vibration motor 879

18.6 Drum reduction gear 899

18.7 Steering valve 925

18.8 Axle 959

18.9 Diesel engine 1049

Circuit diagrams 1347

19.1 Hydraulic diagram 581 202 01 1349

19.2 Hydraulic diagram 581 202 06 1353

19.3 Wiring diagram 582 702 41 1357