$38

Bomag BW177 D, DH, PDH-40 Single Drum Roller Instructions For Repair Manual – PDF DOWNLOAD

Bomag BW177 D, DH, PDH-40 Single Drum Roller Instructions For Repair Manual – PDF DOWNLOAD

FILE DETAILS:

Bomag BW177 D, DH, PDH-40 Single Drum Roller Instructions For Repair Manual – PDF DOWNLOAD

Language : English

Pages : 818

Downloadable : Yes

File Type : PDF

Size: 71.1 MB

DESCRIPTION:

Bomag BW177 D, DH, PDH-40 Single Drum Roller Instructions For Repair Manual – PDF DOWNLOAD

SERVICE AND REPAIR PRECAUTIONS:

ALWAYS inspect all slings, chains, or cables when lifting components. Be sure that they are properly tied,

fastened and balanced before lifting. Be sure that the lifting device is capable of retaining the

weight to be lifted.

NEVER attempt to lift heavy parts by hand when a lifting device should be used.

ALWAYS wear safety glasses when performing any maintenance or repair work on the machine.

NEVER attempt to remove or repair any component on the machine while the engine is running.

NEVER leave the machine and/or heavy parts in an unstable position during repair.

ALWAYS support the machine with sound blocking.

ALWAYS keep the machine and work area clear of lubricants and dirt.

ALWAYS use the correct tools for the repair procedures being done on the machine.

ALWAYS keep tools in a good and clean condition.

ALWAYS use approved parts that are designed for the machine being repaired. This helps to ensure

maximum service life of the machine.

ALWAYS be sure that all necessary nuts, bolts, snap rings, and other fastening devices are removed before

using force to remove components.

ALWAYS attach a sign in the machine operator’s area, stating “DO NOT OPERATE” when the machine is

being repaired.

ALWAYS observe ALL WARNING AND CAUTION statements given in the Operating Manual and Service

Manual and found on the machine decals.

General:• For repair work stand the machine on level and firm ground an shut down.• Secure the machine against unintentional rolling.• Secure the engine .reliably against unintentional starting.• Always mark a defective machine by attaching a respective note to the steering wheel.• During work secure the articulated joint with the articulation lock.• Use your protective outfit, such as hard hat and protective boots.• Keep unauthorized persons away from the machine while the repair work is going on.• Tools, lifting gear, lifting tackle, trestles and other auxiliary equipment must be fully functional and in safe condition.• Use only safe and approved lifting gear of sufficient load bearing capacity to removal and install parts or components from and to the machine.• Be careful with cleansing agents. Gasoline or other easily inflammable substances must not be used for cleaning purposes.• Cleaning and repair work on the fuel tank is dangerous. When repairing or cleaning the fuel tank do not smoke in the immediate vicinity, avoid ignition sparks and do not use open fire.• Always observe the welding instructions when performing welding work.

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Bomag BW177 D, DH, PDH-40 Single Drum Roller Instructions For Repair Manual – PDF DOWNLOAD

SYMBOLS USED IN THIS MANUAL 8

SERVICE AND REPAIR PRECAUTIONS 10

Poisonous Substances 14

Engine 14

Air Conditioning System 14

Battery 15

Special safety notes 15

Electrics 16

Hydraulic system 17

Air conditioning system 18

Fuel hoses 20

Gaskets and mating surfaces 20

Feather keys and keyways 21

Ball and roller bearings 22

Screws and nuts 23

Tightening torque 23

Torques for bolts with metric unified threads 26

Torques for bolts with metric unified fine threads 27

Torques for screws treated with anti-seizure paste 28

The values specified in the table apply for screws: 29

Tightening torques for screws with UNF thread, 1 UNF Unified National Fine Thread Series, American

Unified Fine Thread 30

Tightening torques for screws with UNF thread 30

Specifications 31

General notes on maintenance 34

Fuels and lubricants 35

Engine oil 35

Approved engine oils 35

Fuels 36

Hydraulic oil 38

Running-in instructions 39

Maintenance schedule 40

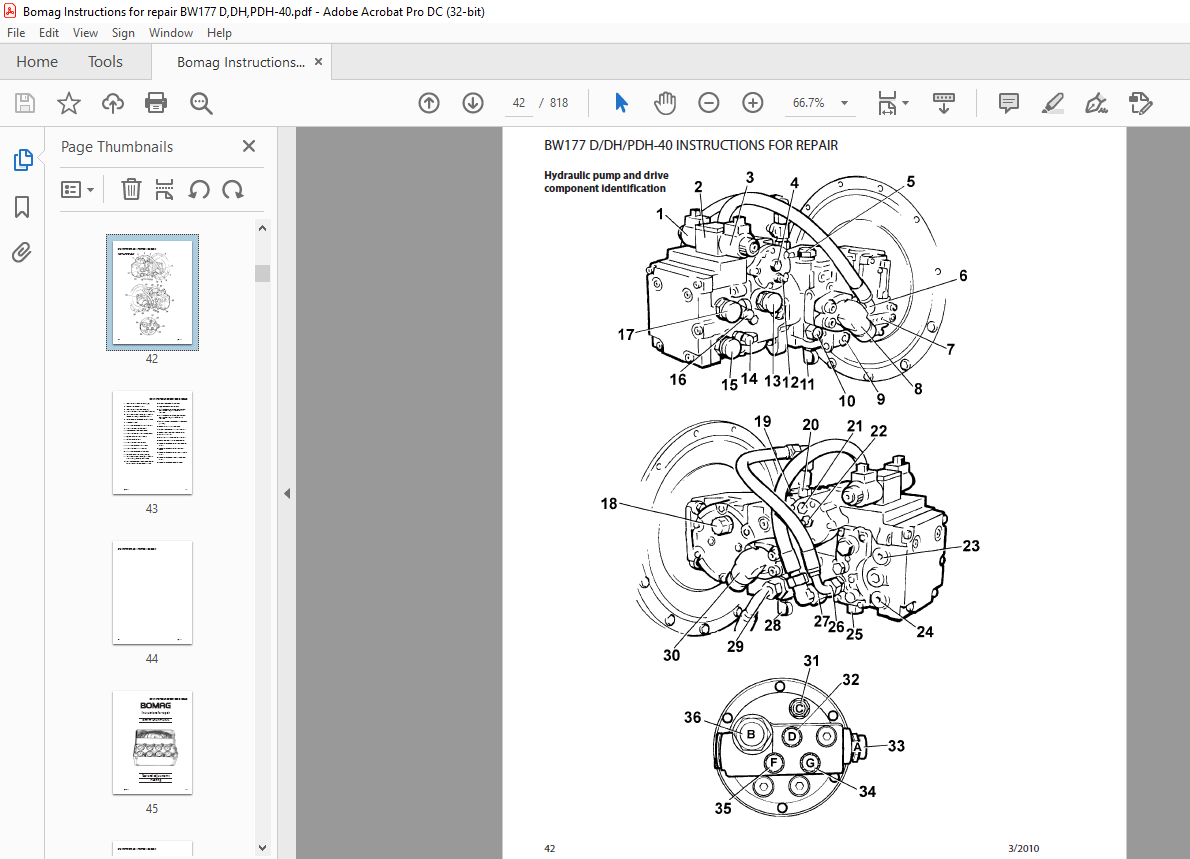

Hydraulic pump and drive component identification 42

Test and adjustments flushing 45

Special Tools 48

Checking the rotary speeds 53

Checking I adjusting the mechanical neutral position of the travel pump 54

Pressure tests in the travel circuit 56

Measurement with quickly operated travel lever 57

Adjusting the vibrator shaft speed 58

Pressure tests in the vibration circuit 59

Checking the leak oil rate of the vibration motor 60

Pressure test in the steering circuit 62

Special tools for flushing 64

Special tools for flushing 64

Flushing – general 66

Hose routing for flushing 68

Flushing the travel circuit 70

Cleaning the hydraulic oil tank 70

Filter installation to flush the travel circuit 70

Bleeding the travel circuit 72

Flushing the hoses in the travel circuit 74

Flushing the drum drive motor 75

Flushing the travel motor 76

Function test 77

Flushing schematic, vibration drive 78

Flushing the vibration circuit 79

Flushing the entire system 79

Flushing the vibration circuit 80

Cleaning the hydraulic oil tank 80

Filter installation to flush the vibration circuit 80

Bleeding the vibration circuit 82

Flushing the hydraulic hoses 83

Flushing the vibration system 83

Function test 84

Maintenance of the flushing kit 84

Trouble shooting 85

General 88

Trouble shooting charts 90

Check the neutral position 91

Check the mechanical O-position 91

Adjust the mechanical 0-position 92

Check the servo control 92

The machine does not drive 93

Check the travel control cable 93

Check high and charge pressure 93

Check the magnetic coil of the brake valve 93

Check the brake releasing pressure 94

Check the steering/charge pump 95

Check the charge pressure relief valve 96

Check the flushing valve for the axle drive motor 96

Check the individual components 97

Check the drum drive motor 97

Check axle drive motor / travel pump 97

Check the servo control 98

Insufficient travel power, max speed not reached 99

Check the engine speed 99

Check trouble travel cable 99

Check the charge pressure 100

Check the steering/charge pump 101

Check the leakage of the brake 101

Check the charge pressure relief valve 102

Check the flushing valve for the axle drive motor 102

Check the individual components 103

Check the drum drive motor 103

Check axle drive motor / travel pump 103

Check the servo control 104

Hydraulic oil overheating 105

Check the thermostat valve 105

Check the multi-function valves 105

No vibration 106

Check the magnetic coil of the vibration valve 106

Check the pilot pressure 106

Check the vibration pump 107

Check the vibrator shaft bearings 107

Check the engine speed 108

Check the vibration pump 108

Vibrator shaft speed too low 108

Check flushing valve and flushing spool 109

Check the steering / charge pump 109

Check the charge pressure relief valve 110

Check the leak oil rate of the vibration motor 110

Check the vibration shaft bearings 111

Check the multi-function valve 111

Check the individual components 111

Check the way-valve 112

No steering function / steering sticky / end stops not reached 113

Check the steering pressure 113

Check the steering cylinders 113

Check the steering/charge pump 114

Drum 115

Special tools 118

Removing the drum 120

Removing and installing the drum 120

Installing the drum 122

Repair overview drum 124

Repairing the drum 126

Disassembling the bearing cover 127

Removing the vibrator shaft 128

Dismantling the vibrator shaft 129

Removing the cover 131

Installing the cover 132

Assembling the vibrator shaft 132

Assembling the vibrator shaft 135

Assembling the bearing cover 139

Dismantling, assembling the change-over weight 141

Dismantling the change-over weight 141

Assembling the change-over weight 142

Changing the rubber buffers 143

Oscillating articulated joint 145

Special tools 148

Removing and installing the oscillating articulated joint 149

Overview Articulated Joint 151

Dismantling the oscillating articulated joint 152

Assembling the oscillating articulated joint 156

Service Training 165

Diesel engine monitoring: 166

Travel pump 169

Cross-sectional view of travel pump 171

View of the rotating group 172

Description of function 173

Tandem pump 175

Tandem pump, connections an adjustment points 176

Servo control 178

Multi-function valves 180

Flushing valve 183

Axle drive motor 184

Rear axle 186

Front drum drive motor: Radial piston motor MSE 18 2 CX 187

Travel circuit: Drum drive with radial piston motor 190

Brake control: Travel motor in axle 191

Travel drive, components and test points 192

Travel pump: right hand side 193

Front travel motor, without brake (radial piston motor) 194

Rear travel motor: Axle motor 195

Rear travel motor: Axle motor 196

Travel lever console 197

Travel lever 198

Trouble shooting 199

Vibration system 200

Vibration system 202

Function 203

Vibration pump 204

High pressure relief valves 206

High pressure relief valves 207

High pressure relief valves 210

Vibration system: Components and test ports 211

Vibration pump 211

Vibration pump 212

Vibration motor 213

Trouble shooting 214

Trouble shooting 215

Steering pump 216

Working principle of the gear pumps 217

Steering valve 218

Articulated joint 220

Steering: Components and test ports 222

Steering pump 222

Vibration and noise damper 223

Steering valve 224

Trouble shooting 225

Electrics: Single drum rollers D-40 226

Function test: 226

Instrument cluster 227

Electric control cabinet with vibration module 227

Plug assignment with operating hour meter 229

Electrics 321

BW177D-40 321

BW177DH/PDH-40 355

Air Conditioning 393

Sauer Danfoss Series 90 Axial Piston Pumps and Motors 442

Sauer Danfoss Series 42 Axial Piston Closed Circuit Pump 530

Poclain MS Hydraulic Motors 598

Sauer Danfoss Series 51 Bent Axis Variable Motors 678

Dana 192 Axle 758

Detroit Locker NoSpin 794