$43

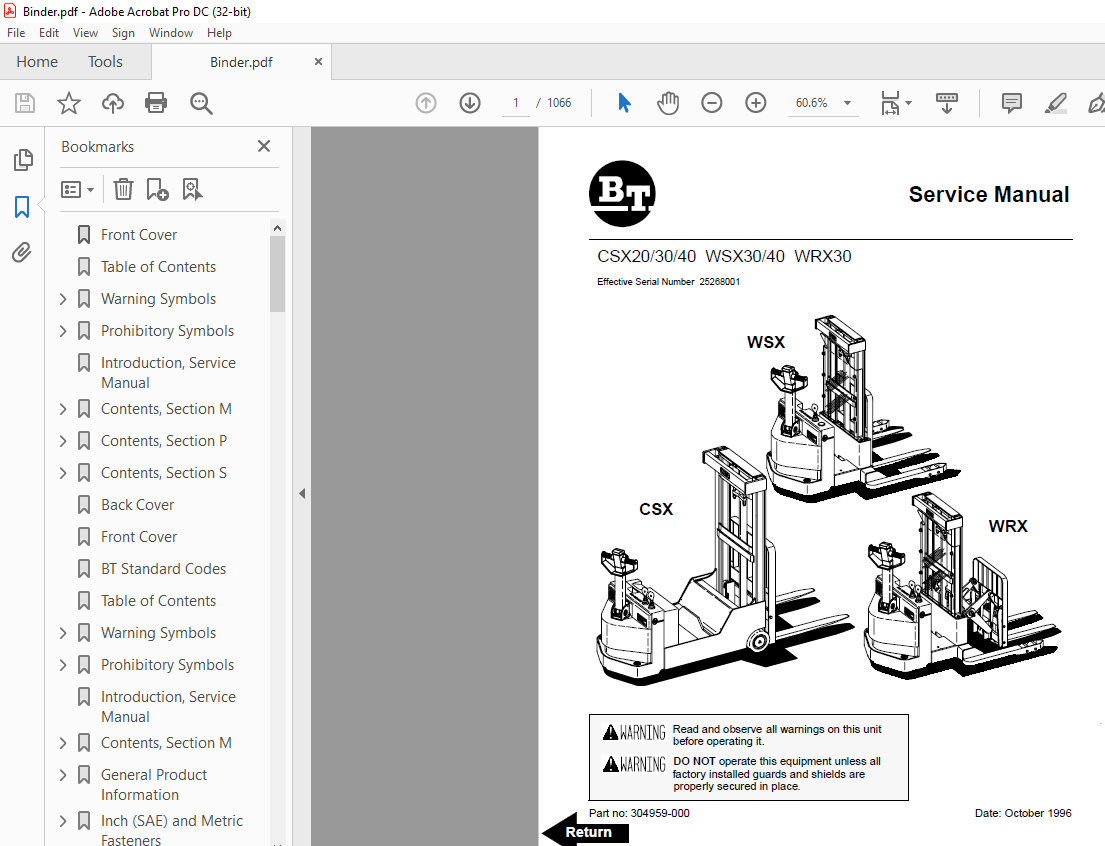

BT Prime-Mover Forklift CSX20/30/40 WSX30/40 WRX30 Service Manual – PDF DOWNLOAD

BT Prime-Mover Forklift CSX20/30/40 WSX30/40 WRX30 Service Manual – PDF DOWNLOAD

FILE DETAILS:

BT Prime-Mover Forklift CSX20/30/40 WSX30/40 WRX30 Service Manual – PDF DOWNLOAD

Language : English,

Pages :1066

Downloadable : Yes

File Type : PDF

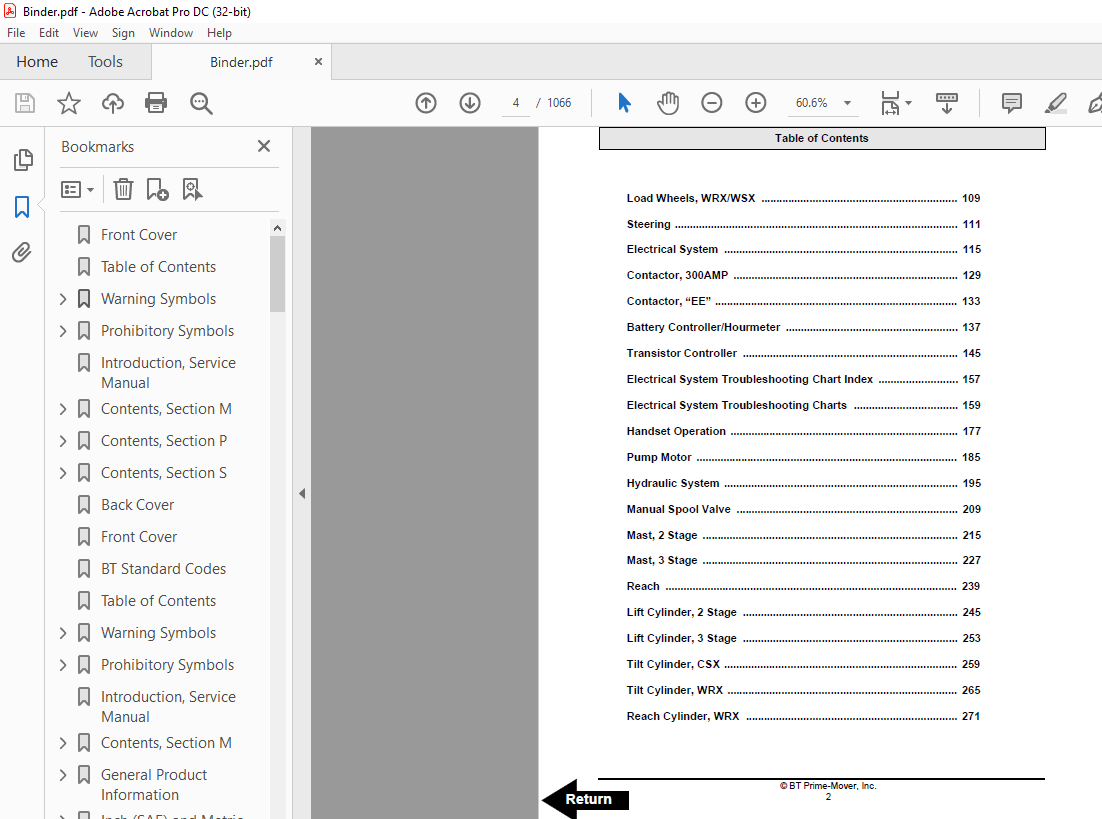

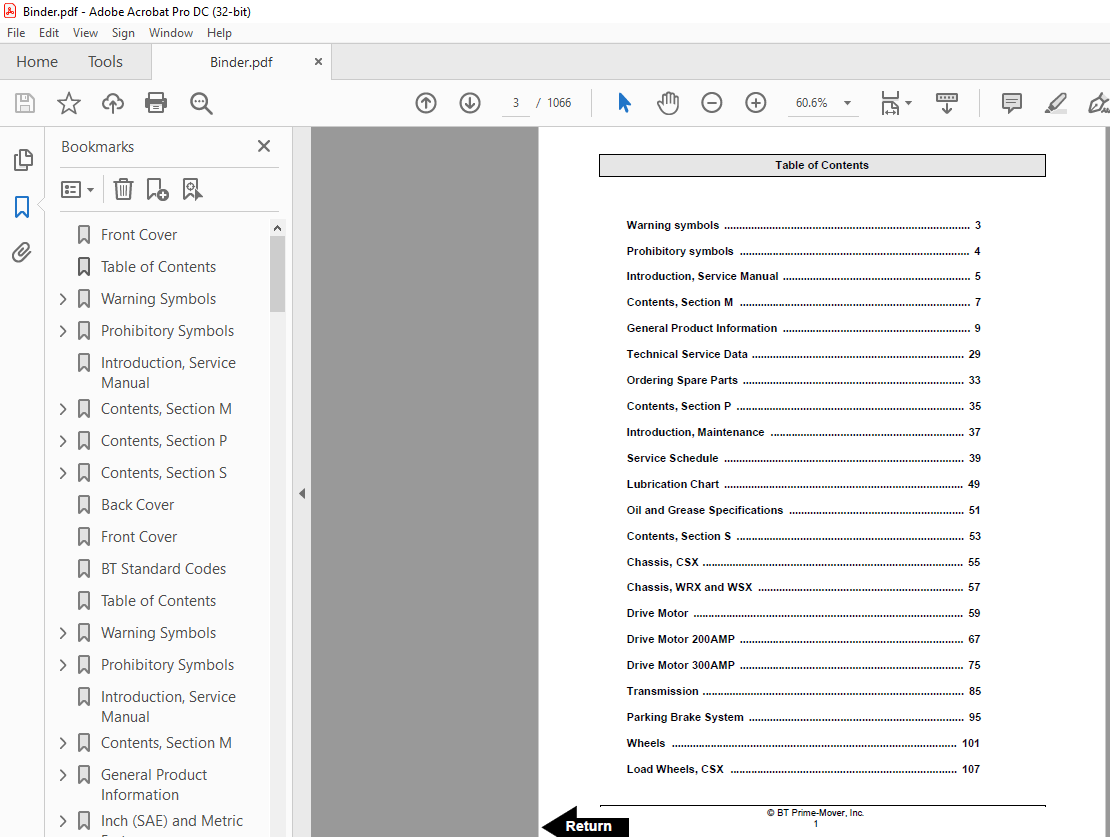

TABLE OF CONTENTS:

BT Prime-Mover Forklift CSX20/30/40 WSX30/40 WRX30 Service Manual – PDF DOWNLOAD

Front Cover 1

Table of Contents 3

Warning Symbols 5

1 Warning Levels 5

Prohibitory Symbols 6

11 Ordinance Symbols 6

Introduction, Service Manual 7

Contents, Section M 9

General Product Information 11

1 Presentation of the Walkie Trucks CSX20/30/40, WSX30/40, and WRX30 11

11 Intended Application of the Trucks 11

12 Forbidden Application of the Truck 12

13 Truck Data 12

14 CSX Dimensions 13

15 WSX Dimensions 14

16 WRX Dimensions 15

17 Data Plate 16

2 Main Components 18

Inch (SAE) and Metric Fasteners 21

Introduction 22

Nomenclature, Threads 22

Strength Identification 23

Table #1 Bolts and Screws 24

Table #2 Studs and Nuts 25

Table #3 Torque Nuts 26

Table #4 Torque Nuts with Nylon Insert 27

Table #5 Conversion Table for Metric and English Units 28

Table #6 30

Technical Service Data 31

Ordering Spare Parts 35

Contents, Section P 37

Introduction, Maintenance 39

1 Safe Jacking Procedure 39

Service Schedule 41

1 Preventive Maintenance Schedule 41

2 Planned Maintenance Procedures 45

Services to be Performed Daily or at Each 8 Hour Operating Shift 45

Battery 45

Hydraulic System 45

Frame/Sheet Metal 45

Wheels/Tires 46

Functions/Operations 46

Services to be Performed Monthly or Every 250 Operating Hours 46

Inspection 46

Transmission 46

Brakes 46

Battery 47

Electrical Connections 47

Line Contactor Tips (NOT Sealed) 47

Motor Brushes 47

Drive Motor 48

Hydraulic Reservoir 48

Frame Lube 48

Pivot Points 48

Services to be Performed Annually or Every 1000 Operating Hours 48

Inspection 49

Transmission 49

Battery 49

Hydraulic System 50

Brakes 50

Lubrication Chart 51

Oil and Grease Specifications 53

1 Approved Oils and Grease 53

Contents, Section S 55

Chassis, CSX 57

1 General 57

2 Main Components 58

Chassis, WRX and WSX 59

1 General 59

2 Support Arms 60

Drive Motor 61

1 General Information 61

2 Operating Conditions 61

3 Troubleshooting 61

Drive Motor 200 AMP 69

1 Component Repair 70

2 Inspection and Troubleshooting 71

21 Drive End Head 71

22 Commutator End Head 71

23 Bearings 71

24 Brush and Commutator 72

25 Armature 72

26 Frame and Field Assembly 73

27 Assembly 75

3 When Changing Brushes 76

Drive Motor 300 AMP 77

4 Component Repair 78

5 Inspection and Troubleshooting 81

51 Drive End Head 81

52 Commutator End Head 81

53 Bearings 81

54 Brush and Commutator 82

55 Armature 82

56 Frame and Field Assembly 83

57 Assembly 85

6 When Changing Brushes 86

Transmission 87

1 System Description 87

2 Troubleshooting 88

3 Axle Seal Removal and Installation 89

31 Removal 89

32 Installation 89

4 Transmission Removal/Installation 90

41 Removal 90

42 Installation 91

5 Transmission Assembly 93

51 Disassembly 94

52 Assembly 94

Parking Brake System 97

1 Brake Theory of Operation 99

2 Brake Adjustment 100

3 Brake Shoe Removal/Installation 101

Wheels 103

1 Stabilizing Caster 103

11 Maintenance and Adjustments 104

12 Caster Adjustment 104

13 Troubleshooting 105

14 Stabilizing Caster 105

2 Drive Wheel 107

21 Removal 107

22 Installation 108

Load Wheels, CSX 109

Load Wheels, WRX/WSX 111

Steering 113

1 Control Handle Head 113

11 Removal 113

12 Installation 114

2 Control Handle Stem 114

21 Removal 114

22 Installation 114

Electrical System 117

1 Electrical Panel Components 117

2 List of Symbols 118

21 Circuit Diagram 1(5) 120

22 Circuit Diagram 2(5) 121

23 Circuit Diagram 3(5) 122

24 Circuit Diagram 4(5) 123

25 Circuit Diagram 5(5) 124

3 Description of Function 125

31 General 125

32 Adjustable Settings 125

33 References 125

34 Key Switch S17 in the ON Position 125

35 The Operating Arm in Drive Position, S10, Brake Switch Closed 126

36 Driving, Fork Direction 126

37 Driving, Steer Wheel Direction 126

38 Reversing/Motor Brake Fork Direction to Steer Wheel Direction 126

39 Reversing/Motor Brake Steer Wheel Direction to Fork Direction 126

310 Reverser Switch 127

311 Lifting the Forks 127

312 Lowering the Forks 127

313 Horn 127

4 Options 128

41 Lifting the Forks (Manual Valve) 128

42 Tilting the Forks 128

43 Sideshifting the Forks 128

44 Extend/Retract the Forks 128

Contactor, 300 AMP 131

1 Maintenance 131

11 Removal/Replacement of Contact Tips 132

Contactor, “EE” 135

2 Maintenance 136

21 Removal/Replacement of Contact Tips 136

Battery Controller/Hourmeter 139

1 General 139

2 Electrical 139

21 Voltage 139

3 Battery Controller (BC) 140

31 General 140

32 Reset 142

33 Key Switch 142

34 Hourmeter 142

4 Troubleshooting 143

41 Battery Discharge Indicator (BDI) 143

42 Hourmeter 145

Transistor Controller 147

1 Motor Circuit 147

2 Control Circuit 148

3 Technical Specification 150

4 Adjustment of Controller 152

41 Connection of Handset 152

5 Maintenance 153

51 Safety 153

52 Cleaning 153

6 Diagnostics and Troubleshooting 154

61 Handset Diagnostics 154

62 Troubleshooting 154

63 Troubleshooting Chart Using the Handset 157

Electrical System Troubleshooting Chart Index 159

Electrical System Troubleshooting Charts 161

Handset Operation 179

1 Operating Modes 180

2 Peace of Mind Programming 184

3 Handset Self Test 185

Pump Motor 187

1 Component Repair 188

2 Inspection and Troubleshooting 190

21 Drive End Head 190

22 Commutator End Head 190

23 Bearings 190

24 Brush and Commutator 191

25 Armature 191

26 Frame and Field Assembly 192

27 Assembly 194

3 When Changing Brushes 195

Hydraulic System 197

1 General 197

2 Description of Function 197

21 Hydraulic Schematic 197

CSX Hydraulic Schematic 198

WRX Hydraulic Schematic 199

WSX Hydraulic Schematic 200

22 Main Components 201

23 Description 201

3 Maintenance 202

31 Maintenance and Adjustments 202

32 Troubleshooting 203

Relief Valve 205

Figure 6110 206

Solenoid Operated Valve 207

Pump and Motor 207

Reservoir and Pump 208

Manual Spool Valve 211

Figure 0640 211

Figure 6160 212

Removal 213

Disassembly and Inspection 214

Assembly 215

Mast, 2 Stage 217

1 Shimming 219

11 Shimming the Carriage 219

12 Shimming the Rails 220

2 Two Stage Mast 222

21 Removal 222

22 Installation 224

23 Disassembly 225

24 Assembly 226

Mast, 3 Stage 229

1 Shimming 230

11 Shimming the Carriage 230

12 Shimming the Rails 231

2 Three Stage Mast 234

21 Removal 234

22 Installation 235

23 Disassembly 236

24 Assembly 237

Reach 241

1 Maintenance 241

2 Reach Repair 242

21 Disassembly 242

22 Assembly 243

Lift Cylinder, 2 Stage 247

1 Two Stage Full Freelift Mast Freelift Cylinder Repair 248

12 Disassembly 248

13 Assembly 248

14 Installation 249

2 Two Stage Full Freelift Mast Staging Cylinder Repair 250

21 Removal 250

22 Disassembly 250

23 Assembly 250

24 Installation 251

3 Two Stage Mast Lift Cylinder Repair 252

31 Removal 252

32 Disassembly 252

33 Assembly 252

34 Installation 253

Lift Cylinder, 3 Stage 255

1 Freelift Cylinder Repair 256

11 Removal 256

12 Disassembly 256

13 Assembly 256

14 Installation 257

2 Staging Cylinder Repair 258

21 Removal 258

22 Disassembly 258

23 Assembly 258

24 Installation 259

Tilt Cylinder, CSX 261

1 Removal 262

2 Disassembly 262

3 Inspection 263

4 Assembly 264

5 Installation 264

Tilt Cylinder, WRX 267

1 Removal 268

2 Disassembly 268

3 Inspection 269

4 Assembly 269

5 Installation 270

Reach Cylinder, WRX 273

1 Removal 274

2 Disassembly 274

3 Inspection 275

4 Assembly 275

5 Installation 276

Back Cover 278

Front Cover 279

BT Standard Codes 281

Table of Contents 283

Warning Symbols 287

H 1 Warning Levels 287

Prohibitory Symbols 288

1 Ordinance Symbols 288

Introduction, Service Manual 289

Contents, Section M 291

1 Machine Information 291

General Product Information 293

1 Presentation of the Walkie Trucks 293

H Heading3 First – 11 Intended Application of the Trucks 293

H Heading3 – 12 Forbidden Application of the Truck 294

H Heading3 – 13 Truck Data 294

H Heading3 – 14 CSX Dimensions 295

H Heading3 – 15 WSX Dimensions 296

H Heading3 – 16 WRX Dimensions 297

H Heading3 – 17 Data Plate 298

2 Main Components 299

Inch (SAE) and Metric Fasteners 303

1 Introduction 303

2 Nomenclature, Threads 304

3 Strength Identification 305

4 Conversion of Metric and English Units 311

Technical Service Data 313

Ordering Spare Parts 317

Contents, Section P 319

1 Planned Maintenance 319

Introduction, Maintenance 321

1 Safe Jacking Procedure 321

Service Schedule 323

1 Planned Maintenance Schedule 323

2 Planned Maintenance Procedures 329

H Heading3 First – 21 Services to be performed daily 329

H Heading4 First – 211 Battery Discharge Indicator with slow down 329

H Heading4 – 212 Hydraulic System 329

H Heading4 – 213 Frame/Sheet Metal 330

H Heading4 – 214 Wheels/Tires 330

H Heading4 – 215 Functions/Operations 330

22 Services to be performed monthly 331

221 Inspection 331

222 Transmission 331

223 Brakes 331

224 Battery 331

225 Electrical Connections 331

226 Contactor Tips (NOT Sealed) 332

227 Motor Brushes 332

228 Drive Motor 332

229 Hydraulic Reservoir 332

2210 Frame Lube (“Lubrication Chart” on page 57) 332

2211 Pivot Points 333

23 Services to be performed annually 334

231 Inspection 334

232 Transmission 334

233 Battery 334

234 Hydraulic System 334

235 Brakes 335

Lubrication Chart 337

Oil and Grease Specifications 339

1 Approved Oils and Grease 339

Contents, Section S 341

1 Service Instructions 341

Chassis, CSX 343

1 General 343

2 Main Components 344

Chassis, WRX and WSX 345

1 General 345

2 Support Arms 346

Drive Motor 347

1 General Information 347

2 Operating Conditions 347

3 Troubleshooting 347

Drive Motor 200 AMP 353

1 Component Repair 354

11 Disassembly 354

2 Inspection and Troubleshooting 356

21 Drive End Head 356

22 Commutator End Head 356

23 Bearings 356

24 Brush and Commutator 357

25 Armature 357

26 Frame and Field Assembly 358

261 Testing 358

262 Frame and Field Service Notes 359

27 Assembly 360

271 Field Coil Installation 360

272 Bearing Installation 360

273 After Assembly 361

3 When Changing Brushes 361

Drive Motor 300 AMP 363

1 Component Repair 364

2 Inspection and Troubleshooting 367

21 Drive End Head 367

22 Commutator End Head 367

23 Bearings 367

24 Brush and Commutator 368

25 Armature 368

26 Frame and Field Assembly 369

261 Testing 369

262 Frame and Field Service Notes 370

27 Assembly 371

271 Field Coil Installation 371

272 Bearing Installation 371

273 After Assembly 372

3 When changing brushes 372

Transmission 373

1 System description 373

2 Troubleshooting 373

3 Removal 375

4 Installation 377

Transmission Axle Seal 379

1 General Information 379

11 Removal 379

12 Installation 379

Transmission Disassembly / Assembly 381

1 Disassembly 382

2 Assembly 382

Parking Brake System 385

1 Brake Theory of Operation 387

2 Brake Adjustment 388

3 Brake Shoe Removal / Installation 389

Drive Wheel 391

31 Removal 391

32 Installation 392

Load Wheels, CSX 393

1 Removeal and Installation 393

Load Wheels, WRX/WSX 395

1 Removal and Installation 395

Wheels 397

1 Stabilizing Caster 397

11 Maintenance and Adjustments 398

12 Caster Adjustment 398

13 Troubleshooting 399

14 Stabilizing Caster 399

141 Caster Replacement 399

Stabilizing Caster 401

1 Stabilizing Caster 401

11 Disassembly 402

12 Inspection 403

13 Assembly 404

Steering Arm / Handle 405

1 Control Handle Stem 406

11 Removal 406

12 Inspection 406

13 Installation 407

Steering Handle Head 409

1 Control Handle Head 411

11 Removal 411

12 Installation 411

2 Direction Control Switches 412

3 Horn, Raise, and Lower Switches 413

4 Potentiometer 415

Electrical System 417

1 Electrical Panel Components 417

2 List of Symbols 418

21 Circuit Diagram 1(5) 420

22 Circuit Diagram 2(5) 421

23 Circuit Diagram 3(5) 422

24 Circuit Diagram 4(5) 423

25 Circuit Diagram 5(5) 424

3 Description of Function 425

31 General 425

32 Adjustable Settings: 425

33 References: 425

34 Key Switch S17 in the ON Position 425

35 The Operating Arm in Drive Position, S10, Brake Switch Closed 426

36 Driving, Fork Direction 426

37 Driving, Steer Wheel Direction 426

38 Reversing/Motor Brake Fork Direction to Steer Wheel Direction 426

39 Reversing/Motor Brake Steer Wheel Direction to Fork Direction 426

310 Reverser switch 427

311 Lifting the Forks 427

312 Lowering the Forks 427

313 Horn 427

4 Options 428

41 Lifting the Forks (Manual Valve) 428

42 Tilting the Forks 428

43 Sideshifting the Forks 428

44 Extend/Retract the Forks 428

300/400 Amp Contactor 431

1 Maintenance 432

11 Removal/Replacement of Contact Tips 432

“EE” Contactor 435

1 Maintenance 436

11 Removal/Replacement of Contact Tips 436

Battery Controller / Hourmeter / Lift Interrupt 439

1 General Information 439

2 Electrical 439

21 Voltage 439

211 The Contact Voltage and Current Ratings for Switching Resistive Loads 440

212 Memory Retention 440

3 Battery Controller (BC) 440

31 General Information 440

311 Discharge Adjustment 440

32 Reset 442

33 Key Switch 442

34 Hourmeter 443

4 Troubleshooting 443

41 Battery Discharge Indicator (BDI) 443

411 No Reset 443

412 Reset After Break in Power 443

413 No Discharge, Gauge Does Not Run Down 444

414 No Lockout 444

415 No Lift 444

416 Early Lockout 445

417 LEDs Do Not Light 445

42 Hourmeter 445

421 No Display 445

422 Hourmeter Glass Icon Does Not Flash 445

423 Hourmeter Glass Icon Always Flashes 446

Transistor Controller 447

1 Motor Circuit 447

2 Control Circuit 448

3 Technical Specification 450

4 Adjustment of Controller 452

41 Connection of Handset 452

5 Maintenance 453

51 Safety 453

52 Cleaning 453

6 Diagnostics and Troubleshooting 454

61 Handset Diagnostics 454

62 Troubleshooting 454

621 Procedure Troubleshooting Instructions 456

63 Troubleshooting Chart Using the Handset 457

Electrical System Troubleshooting Chart Index 459

Electrical System Troubleshooting Charts 461

Handset Operation 479

1 Operating Modes: 480

2 Revert to Previous Settings 484

3 Handset Self Test 485

4 LED Diagnostics 486

Pump Motor 487

1 Component Repair 488

11 Disassembly 488

2 Inspection and Troubleshooting 490

21 Drive End Head 490

22 Commutator End Head 490

23 Bearings 490

24 Brush and Commutator 491

25 Armature 491

26 Frame and Field Assembly 492

261 Testing 492

262 Frame and Field Service Notes 493

27 Assembly 494

271 Field Coil Installation 494

272 Bearing Installation 494

273 After Assembly 495

3 When changing brushes 495

Hydraulic System 497

1 General 497

2 Description of Function 497

21 Hydraulic Schematic 497

22 CSX Hydraulic Schematic 498

23 WRX Hydraulic Schematic 499

24 WSX Hydraulic Schematic 500

3 Main Components 501

31 Description 501

311 Lift (Solenoid valve) 501

312 Lift (Mechanical Valve) 501

313 Lower (Solenoid Valve) 501

314 Lower (Mechanical Valve) 502

315 Relief Pressure 502

316 Compensating Cylinder 502

4 Maintenance 502

5 Adjustments 502

6 Troubleshooting 503

61 Primary Malfunctions 503

611 Failure to raise the load 504

612 Failure to raise the load 504

613 Failure to raise the load 504

7 Removal 505

8 Installation 507

Lift Pump Assembly 509

1 Disassembly 511

2 Inspection 512

3 Assembly 513

Manual Spool Valve 515

1 Removal 517

2 Disassembly and Inspection 518

3 Assembly 519

Mast, 2 Stage 521

1 Shimming Mast on Truck 523

11 Shimming the Carriage 523

12 Shimming the Rails 524

2 Two Stage Mast 526

21 Removal 526

22 Installation 528

23 Disassembly 529

24 Assembly 530

Mast, 3 Stage 533

1 Shimming Mast on Truck 534

11 Shimming the Carriage 534

12 Shimming the Rails 535

2 Three Stage Mast 539

21 Removal 539

22 Installation 540

23 Disassembly 541

24 Assembly 543

Sideshifter 547

1 Mounting Instructions 549

11 Installation 549

2 Operation and Maintenance 550

21 Lower Slides 551

22 Upper Slides 551

23 Cylinder 551

Reach, Single 553

1 Maintenance 553

2 Reach Repair 555

21 Disassembly 555

211 Front Frame Removal 555

212 Outer Arm Removal 555

213 Inner Arm Removal 555

214 Rear Frame Removal 556

215 Reach Cylinder Removal 556

22 Assembly 557

221 Reach Cylinder Installation 557

222 Rear Frame Installation 557

223 Inner Arm Installation 557

224 Outer Arm Installation 558

Lift Cylinder, 2 Stage 559

1 Two Stage Full Freelift Mast Freelift Cylinder Repair 560

11 Removal 560

12 Disassembly 561

13 Assembly 561

14 Installation 561

2 Two Stage Full Freelift Mast Staging Cylinder Repair 562

21 Removal 562

22 Disassembly 562

23 Assembly 563

24 Installation 563

3 Two Stage Mast Lift Cylinder Repair 564

31 Removal 564

32 Disassembly 564

33 Assembly 565

34 Installation 565

Freelift Cylinder, 3 Stage 567

1 Freelift Cylinder Repair 568

11 Removal 568

12 Disassembly 569

13 Assembly 569

14 Installation 569

Tilt Cylinder, CSX 571

1 Removal 572

2 Disassembly 573

3 Inspection 574

4 Assembly 575

5 Installation 576

Tilt Cylinder, WRX 577

1 Removal 578

2 Disassembly 579

3 Inspection 580

4 Assembly 581

5 Installation 582

Reach Cylinder 583

1 Removal 584

2 Disassembly 585

3 Inspection 586

4 Assembly 587

5 Installation 588

Back Cover 590

Front Cover 591

Standard Codes 593

Index 595

Warning Symbols 605

1 Warning Levels 605

Prohibitory Symbols 606

1 Ordinance Symbols 606

Safety 607

1 General Safety 607

Battery Safety 611

Static Safety 616

Welding Safety 617

Introduction, Service Manual 619

Contents, Section M 621

1 Machine Information 621

General Product Information 623

1 Presentation of Walkie Trucks 623

11 Truck Side Views 624

11 Intended Truck Application 624

12 Prohibited Truck Application 624

13 Truck Data 625

14 CSX10 Dimensions 626

15 CSX20 Dimensions 627

16 CSX30 Dimensions 628

17 CSX40 Dimensions 629

18 WSX22 Dimensions 630

19 WSX30 Dimensions 631

110 WSX40 Dimensions 632

111 WRX30 Dimensions 633

112 Data Plate 634

2 Main Components 636

Inch (SAE) and Metric Fasteners 639

1 Introduction 639

2 Nomenclature, Threads 640

3 Strength Identification 641

4 Conversion of Metric and English Units 648

Technical Service Data 651

Ordering Spare Parts 655

Contents, Section P 657

1 Planned Maintenance 657

Introduction, Maintenance 659

1 Jacking Truck Off The Floor 660

11 Elevate Rear of Truck 660

11 Elevate Either Side of Truck 660

2 Lubricants 661

21 Standard 661

22 Corrosion 661

23 Cold Storage 662

Service Schedule 665

1 Planned Maintenance Schedule 665

2 Planned Maintenance Procedures 670

21 Services Performed Daily or Every 8 Operating Hours 670

211 Battery Discharge Indicator with slow down 670

212 Hydraulic System 670

213 Frame/Sheet Metal 671

214 Wheels/Tires 671

215 Functions/Operations 671

22 Services Performed Monthly or Every 120 Operating Hours 671

221 Inspection 671

222 Transmission 671

223 Brakes 672

224 Battery 672

225 Electrical Connections 672

226 Contactor Tips (NOT Sealed) 672

227 Motor Brushes 672

228 Drive Motor 673

229 Hydraulic Reservoir 673

2210 Frame Lube 673

2211 Pivot Points 673

23 Services Performed Every 480 or 960 Operating Hours 674

231 Drive Motor 674

24 Services Performed Annually or Every 1400 Operating Hours 675

241 Inspection 675

242 Transmission 675

243 Battery 675

244 Hydraulic System 676

245 Brakes 676

246 Lift and Carriage Chains 676

Lubrication Chart 677

Oil and Grease Specifications 678

1 Approved Oils and Grease 678

2 CSX Grease & Mast Adjustment Points Location 679

3 WSX Grease & Mast Adjustment Points Location 680

4 WRX Grease & Mast Adjustment Points Location 681

Contents, Section S 683

1 Service Instructions 683

Frame/Chassis 685

1 General 687

2 Main Components 687

Inspection Covers 689

Battery Roller (Optional) 697

1 Battery Cover, Optional (WSX22 “EE” Trucks Only) 699

11 Inspection 699

12 Removal 699

13 Installation 700

2 Battery Rollers 700

21 Inspection 700

22 Replacement 700

Driver Controls, One Spool 701

1 Removal 703

2 Installation 704

Driver Controls, Two Spool 705

1 Removal 708

2 Installation 709

Decals 711

1 Decal with Protective Sheet 711

2 Decal without Protective Sheet 711

Motor Maintenance Schedule/Troubleshooting 715

1 General Information 715

2 Operating Conditions 715

3 Troubleshooting 716

Motor Repair 723

1 Pump Motor 723

11 Pump Motor Removal 724

12 Pump Motor Installation 724

2 Drive Motor 725

21 Brush Replacement 731

22 Drive Motor Removal 731

23 Drive Motor Installation 732

3 Component Repair 734

31 Disassembly 734

4 Inspection 736

41 Drive End head 736

42 Commutator End Head 736

43 Bearings 736

44 Brush and Commutator 737

45 Armature 739

46 Frame and Field Assembly 740

461 Testing 740

47 Assembly/Testing 741

471 Bearing Installation 741

472 Testing 742

Transmission 743

1 System Description 743

2 Troubleshooting 743

21 Kick Panel 744

3 Transmission Repair 745

31 Removal 746

32 Installation 747

4 Transmission Assembly 749

41 Disassembly 750

42 Assembly 750

5 Axle Seal 752

51 Removal 752

52 Installation 752

Parking Brake System 755

1 Brake Theory of Operation 757

2 Brake Adjustment 758

3 Brake Shoe Removal / Installation 759

Drive Wheel 761

1 Removal 761

2 Installation 762

3 Tire Pressing Procedure 763

Support/Swivel Wheel 765

1 Maintenance and Adjustments 768

11 Caster Adjustment 769

2 Troubleshooting 770

21 Stabilizing Caster 770

211 Caster Replacement 770

Load Wheels 771

1 Removal and Installation 774

Caster Assembly 775

1 Disassembly 776

2 Inspection 777

3 Assembly 778

Steering Arm/Wheel, Tiler Arm (Serial # 25268000 – 27323000) 779

1 Removal 780

2 Inspection 781

3 Installation 782

Steering Arm/Wheel, Tiler Arm (Serial # 27323001 – UP) 783

1 Removal 784

2 Inspection 785

3 Installation 786

Steering Arm/Wheel, Head 787

1 Control Handle Head 788

11 Removal 788

12 Installation 788

2 Direction Control Switches 789

3 Raise, Lower, and Horn Switches 791

4 Potentiometer 794

41 Removal 794

42 Installation 795

5 Reverser Assembly Replacement 799

Electrical Functions 801

1 General 801

11 Adjustable Settings 801

12 References 801

13 Key Switch S17 in ON Position 802

14 Operating Arm in Drive Position, S10, Brake Switch Closed 802

15 Travel Request, Forks First 802

16 Travel Request, Forks Trailing 802

17 Reversing/Motor Brake Forks First to Forks Trailing Direction 803

18 Reversing/Motor Brake Forks Trailing to Forks First Direction 803

19 Reverser switch 803

110 Lifting Forks 803

111 Lowering Forks 804

112 Horn 804

2 Options 804

21 Lifting Forks (Manual Valve) 804

22 Tilting Forks 804

23 Side Shifting Forks 804

24 Extend/Retract Forks 805

Electrical Symbols 807

Electrical Schematics 813

Battery 819

1 Removal 819

2 Installation 820

3 Battery Maintenance 821

31 Battery Inspection and Care 821

32 Battery Exterior Cleaning 822

33 Charging 822

4 Storage 823

5 Battery History Record 823

Battery Connector 825

1 Location 825

2 Inspection 826

3 Installation 826

200 Amp System Line Contactor 829

1 Replacement 829

11 Removal 829

12 Installation 829

300 Amp System Line Contactor (CSX30/40 only) 831

1 Maintenance 831

11 Removal/Replacement of Contact Tips 832

200/300 Amp System “EE” Line Contactor 833

1 Maintenance 833

11 Removal/Replacement of Contact Tips 834

Battery Controller/Hourmeter/Lift Interrupt 837

1 General Information 837

2 Electrical 838

21 Voltage 838

3 Battery Controller (BC) 839

31 General Information 839

311 Discharge Adjustment 839

32 Reset 841

33 Key Switch 841

34 Hourmeter 842

4 Troubleshooting 842

41 Battery Discharge Indicator (BDI) 842

411 No Reset 842

412 Reset After Break in Power 843

413 No Discharge, Gauge Does Not Run Down 843

414 No Lockout 843

415 No Lift 844

416 Early Lockout 844

417 LEDs Do Not Light 844

42 Hourmeter 845

421 No Display 845

422 Hourmeter Glass Icon Does Not Flash 845

423 Hourmeter Glass Icon Always Flashes 845

Start/Stop Switches 847

1 General 847

11 Test/Inspection 847

2 Master Control On/Off Switch (S21) 849

21 Inspection 849

22 Removal 849

23 Installation 849

Light Assemblies 851

1 Warning Lights (Option) 851

11 Removal 853

12 Installation 853

2 Travel/Back-up Alarm (Option) 854

21 Removal 854

22 Installation 854

Transistor Controller 855

1 Basics Of Circuit Operation 855

11 Control Features 857

2 Maintenance 858

21 Safety 858

22 Cleaning 858

3 Motor Circuit 859

4 Control Circuit 860

5 Troubleshooting Guidelines 861

51 General 863

6 Shorts to Frame Test 864

7 Definitions 868

8 Diagnostics and Troubleshooting 869

81 Handset Diagnostics 869

82 Troubleshooting 869

83 Troubleshooting Chart 871

84 Technical Specification 876

85 Troubleshooting Chart Using Handset 877

Transistor Controller Troubleshooting 879

1 Troubleshooting Chart Index 879

2 Troubleshooting Charts 880

Hydraulic System 899

1 General 899

2 Description of Function 899

3 Main Components 900

31 Lift (Solenoid valve) 900

32 Lift (Mechanical Valve) 900

33 Lower (Solenoid Valve) 900

34 Lower (Mechanical Valve) 900

35 Relief Pressure 900

36 Compensating Cylinder 901

37 Reach (Solenoid valve) 901

38 Tilt (Solenoid valve) 901

39 Sideshift (Solenoid valve) 901

4 Maintenance 902

5 Adjustments 903

6 Troubleshooting 904

61 Primary Malfunctions 905

611 Failure to raise load 905

612 Failure to raise load 905

613 Failure to raise load 906

7 Definitions 906

8 Removal 907

9 Installation 909

Hydraulic Schematics 911

Hydraulic Fluid 917

1 Hydraulic Fluid Selection 917

2 Changing Hydraulic System Fluid 917

3 System Draining 918

4 Refilling System 919

5 Bleeding Hydraulic System 920

Hydraulic Tank 921

1 Removal 922

2 Installation 922

Hydraulic Pump Assembly 923

1 Disassembly 925

2 Inspection 926

3 Assembly 927

One Spool Control Valve 929

1 Operators Controls Removal 930

2 Control Valve Disassembly and Inspection 930

3 Operators Controls Installation 931

Two Spool Control Valve 932

1 Operators Controls Removal 933

2 Control Valve Disassembly and Inspection 933

3 Operators Controls Installation 934

Lift Cylinder, Two Stage Mast 935

1 Lift Cylinder, Two Stage Mast 945

11 Removal 945

12 Disassembly 946

13 Assembly 946

14 Installation 946

2 Two Stage Full Freelift Mast Cylinder Repair 947

21 Removal 947

22 Disassembly 948

23 Assembly 948

24 Installation 948

3 Two Stage Full Freelift Mast Staging Cylinder Repair 949

31 Removal 949

32 Disassembly 950

33 Assembly 950

34 Installation 950

Lift Cylinder, Three Stage Mast 951

1 Repair 954

11 Removal 954

12 Disassembly 955

13 Assembly 955

14 Installation 955

Reach Cylinder, WRX30 957

1 Removal 959

2 Disassembly 960

3 Inspection 961

4 Assembly 962

5 Installation 963

Tilt Cylinder 965

1 Removal 967

2 Disassembly 968

3 Inspection 969

4 Assembly 970

5 Installation 971

1 Removal 974

2 Disassembly 975

3 Inspection 976

4 Assembly 977

5 Installation 978

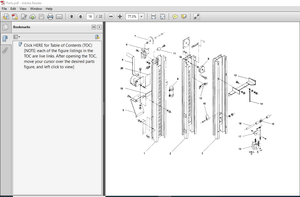

Mast, Two Stage 979

1 Shimming Carriage with Mast on Truck 987

2 Repair 989

21 Removal 989

22 Disassembly 990

23 Assembly 991

24 Installation 993

3 Lift Chain 994

31 Lift Chain Adjustment: 994

32 Lift Chain Maintenance 994

33 Lift Chain Inspection 994

331 Wear 995

332 Rust and Corrosion 995

333 Cracked Plates 996

334 Protruding or Turned Pins 998

335 Chain Side Wear 999

336 Chain Anchors and Sheaves 999

337 Lift Chain Lubrication 999

34 Lift Chain Replacement1001

Mast, Three Stage1003

1 Shimming Carriage with Mast on Truck1009

2 Repair1011

21 Removal1011

22 Disassembly1012

23 Assembly1013

24 Installation1015

3 Lift Chain1016

Sideshifter, Serial numbers 25268000 – 280770011017

1 Mounting Instructions1019

11 Installation1019

2 Operation1020

3 Maintenance1020

31 Lower Slides1020

32 Upper Slides1021

33 Cylinder1021

Sideshifter, Serial number 28077002 – UP1023

1 Mounting Instructions1025

11 Installation1025

2 Operation1026

3 Maintenance1026

31 Carriage Removal1027

32 Upper Pad Replacement1027

33 Lower Pad Replacement1028

34 Cylinder1029

4 Troubleshooting1030

41 No Sideshifting1030

42 Very Slow Sideshifting1030

43 Irregular Sideshifting1031

Single Reach, WRX301033

1 Maintenance1035

11 Inspection1035

12 Adjustment1036

2 Repair1040

21 Disassembly1040

211 Front Frame Removal1040

212 Outer Arm Removal1041

213 Inner Arm Removal1041

214 Rear Frame Removal1041

215 Reach Cylinder Removal1042

22 Assembly1042

221 Reach Cylinder Installation1042

222 Rear Frame Installation1042

223 Inner Arm Installation1043

224 Outer Arm Installation1043

225 Front Frame Installation1044

3 Carriage Bumpers1044

31 Reach Adjustment1044

4 Fork Carriage Pivot Pins1046

5 Carriage Roller Bearings1046

51 Removal1046

52 Installation1046

Forks1047

1 Removal1049

2 Inspection1049

3 Installation1050

Load Backrest1051

1 Removal1052

2 Installation1052

Handset Operation1053

1 Operating Modes1056

2 Revert to Previous Settings1059

3 Handset Self Test1059

A1061

B1061

C1061

D1061

E1062

F1062

G1062

H1062

I1062

J1062

L1062

M1063

O1063

P1063

R1063

S1063

T1063

U1064

W1064

Back Cover1066

IMAGES PREVIEW OF THE MANUAL: