$38

BT Prime-Mover Forklift ELECTRIC STAND-UP RIDER TRUCK SERVICE MANUAL – PDF DOWNLOAD

BT Prime-Mover Forklift ELECTRIC STAND-UP RIDER TRUCK SERVICE MANUAL – PDF DOWNLOAD

FILE DETAILS:

BT Prime-Mover Forklift ELECTRIC STAND-UP RIDER TRUCK SERVICE MANUAL – PDF DOWNLOAD

Language : English,

Pages :493

Downloadable : Yes

File Type : PDF

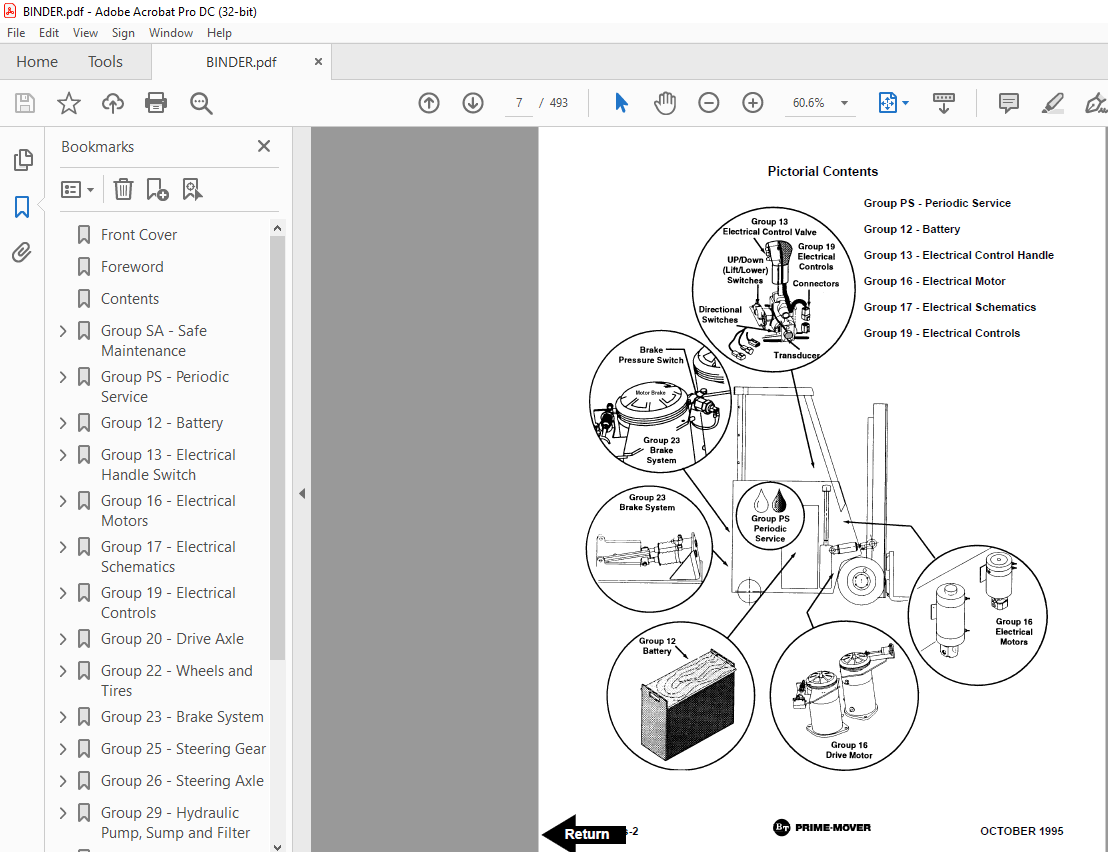

TABLE OF CONTENTS:

BT Prime-Mover Forklift ELECTRIC STAND-UP RIDER TRUCK SERVICE MANUAL – PDF DOWNLOAD

Front Cover 2

Foreword 4

Contents 6

Group SA – Safe Maintenance 10

Section 1 – Safety 12

Safety Signs and Messages 13

Safety Maintenance Practices 13

General Shop Precautions 15

Section 2 – Machine Jacking and Blocking 18

Raising Drive Wheels 19

Blocking the Upright in Raised Position 20

Raising Rear of Truck 20

Raising Truck with a Hoist 21

Group PS – Periodic Service 22

Section 1 – Maintenance Schedules 24

Maintenance Schedules 25

Lubrication Points 26

Lubrication Chart Key 27

Miscellaneous Lubricants 28

Section 2 – Planned Maintenance 30

Use PM Report Form 31

How to Perform the PM Periodic Inspections and Maintenance 31

Visual Inspection 31

Functional Checks 34

Test Drive Truck with Load 37

Lift Mechanism and Controls 38

Battery Compartment Inspection 39

Motor SCR Control Inspection 40

Control and Hydraulic Compartment Inspection 40

Control Levers and Linkage Inspection 40

Air Cleaning 40

Critical Fastener Torque Checks 40

Lubrication, Fluids and Filters 41

Hydraulic Sump 41

Hydraulic Fluid and Filter Change 41

Hydraulic Oil Filter 41

Sump Tank Breather Maintenance 41

Access to the Drive Axle 41

Drive Axle Fluid 41

Drive Axle Fluid Change 42

Truck Chassis Inspection and Lubrication 42

Uprights and Tilt Cylinder Lubrication 42

Lift Chains 42

Group 12 – Battery 44

Section 1 – Battery Handling 46

Typical Battery Service Area 47

Battery Handling 48

Battery Maintenance 51

How to Get Maximum Life Out of Your Battery 51

Battery Vents 52

Battery Cleaning 52

Battery Charging 52

Battery Electrolyte 52

Clean Battery Compartment 52

Replacement Battery 52

Install Battery 53

Keeping Battery Records 53

Group 13 – Electrical Handle Switch 54

Section 1 – Control Handle Switch 56

Tilt, Auxiliary 1 and Auxiliary 2 (Attachment) Switches 59

Remove and Install 59

Up and Down Switches 60

Remove and Install 60

Forward and Reverse Switches, Transducer (Speed Control) 61

Remove and Install Switches 61

Remove and Install Transducer 61

Group 16 – Electrical Motors 62

Section 1 – General Information 64

Safety 65

Servicing Electric Motors 65

Electric Motor Maintenance 66

Inspection Procedures 66

Motor Cleanliness 66

Motor Inspection 66

Test for Motor Insulation “Resistance to Ground” 67

Using a 500 Volt Megger 67

Using a Simpson 260-6p Volt Ohmmeter or Equivalent Calibrated on the Rx 10,000 Scale 67

Brush and Commutator Inspection 68

Operating Conditions 68

Brush and Commutator Inspection 68

Brush Inspection Chart 70

Section 2 – Drive Motors 72

Safety 73

General Information 74

Operating Conditions 74

Drive Motor Description 75

Drive Motor Removal 75

Drive Motor 75

Drive Motor 77

Disassembly 77

Component Inspection and Troubleshooting 79

Testing 80

Frame and Field Service Notes 80

Assembly 80

36 Volt Drive Motor Specifications 82

Brush Inspection Chart 83

Section 3 – Hydraulic Pump Motors 84

Safety 85

General Information 86

Operating Conditions 86

Hydraulic Pump Motor 87

Disassembly 87

Component Inspection and Troubleshooting 89

Testing 90

Frame and Field Service Notes 90

Assembly 90

36 Volt Drive Motor Specifications 92

Brush Inspection Chart 93

Section 4 – Steer Pump Motor 94

Safety 95

General Information 96

Operating Conditions 96

Steer Pump Motor (Permanent Magnet Type) 97

Troubleshooting Prior to Disassembly 97

Disassembly 99

Component Inspection and Troubleshooting101

Assembly102

36 Volt Drive Motor Specifications103

Motor Specifications103

Brush Inspection Chart104

Group 17 – Electrical Schematics106

Section 1 – Wiring Schematics and Diagrams108

Standard Wiring Schematic109

Standard Wiring Diagram110

Optional Wiring Schematic111

Optional Wiring Diagram112

Lights Wiring Schematic113

Lights Wiring Diagram114

Strobe and Alarm Wiring Schematic115

Strobe and Alarm Wiring Diagram116

Group 19 – Electrical Controls118

Section 1 – Control Panel120

Control Panel Description121

Control Features123

Control Panel Maintenance124

Control Panel Troubleshooting124

Troubleshooting Notes125

Control and Contactor Panel Removal125

Control and Contactor Panel Component Identification127

Contactor Inspection131

1A and Main Pump Contactors131

Plugging and Power Steering Contactor133

Forward and Reverse Contactor134

Oscillator Card138

Control and Contactor Panel Installation139

Section 2 – EV-100MK Troubleshooting144

Check #1, 2, 5 REC’s (SCR’s)145

Check Capacitor (1C)149

Checking Component with VOM (Only)150

#22, 23, 24 and 25 Filter Blocks150

#3 and 4 Rectifiers151

Filter Mounting Terminal Block152

Sensor153

Thermal Protector154

Reactor/Choke Module155

EV-100 MK Card Factory Settings156

Oscillator Card Voltage Checks157

Oscillator Card Wiring Schematic158

Solenoid Function Control Card Voltage Checks159

Solenoid Function Control Card Wiring Schematic160

Section 3 – Recommended Tests, Equipment, and Procedures162

Recommended Tests163

Test Equipment163

Test Procedures163

Test Procedures163

Ground Fault Condition163

Power Steer Idle Current164

SCR Current Limit164

1A Free-Wheeling Current164

1A Time Delay165

Creep Speed Motor Volts165

Plugging166

Section 4 – Drive Motor Cut-Out Switch Check and Adjustment168

Drive Motor Cut-Out Switch Check169

Drive Motor Cut-Out Switch Adjustment170

Section 5 – Forward and Reverse Switches, Up and Down Switches, and Transducer Adjustments172

Multi-Function Control Handle Connector Identification173

Switches and Transducer Adjustments174

Section 6 – Periodic Electrical Checks184

Truck Preparation185

Electrical Connectors186

Power Cables188

Fasteners189

Motor Connections190

Control Panel Connections191

Cable Routing and Connections192

Control Cards Connections196

Section 7 – Battery Tests198

Battery Tests199

Section 8 – Solenoid Control Card Troubleshooting200

Indicator Lights201

Troubleshooting Solenoid Control Card202

Lift Function ONLY Disabled204

Install New Solenoid Control Card206

Section 14 – EV100 LXT Control Panel208

General209

Operation209

Function Set-Up Procedures210

Description of Function Numbers for:211

IC3645EVLXCDI1TT211

IC3645EVLXCDI1TX211

IC3645EVLXCDI1TK211

IC3645EVLXCDI1MT214

IC3645EVLXCDI1MX214

IC3645EVLXCDI1MK214

IC3645EVLXCDI1PX217

Section 15 – EV100 LXT Control Panel Status Codes220

Section 16 – Checking Components254

Main Logic Card255

Capacitor256

Contactors F, R, 1A, SP, FW, D, Regen, and P256

Potentiometer in Accelerator256

SCR’s (1REC, 2REC, 3REC)256

Rectifiers (3REC, 4REC, Diode Blocks)257

Thermal Protector (TP)257

Filter Block (23FIL, etc)257

1X Choke and Reactor T3-T4257

Replacement of EV-100 Components258

1REC, 2REC, or 5REC258

Capacitor258

22REC, 23REC, and 25REC258

Group 20 – Drive Axle260

Section 1 – Drive Axle262

General Description263

Service Notes263

Drive Axle Maintenance263

Fluid Level Checks263

Fluid Change Procedure263

Drive Axle Removal264

Drive Axle Special Tools265

Drive Axle Disassembly269

Drive Axle Notes269

Drive Axle Assembly272

Drive Axle Installation275

Group 22 – Wheels and Tires278

Section 1 – Cushion Wheels and Tires280

Cushion Drive and Steering Tire Specifications281

Cushion Drive Tire Removal281

Cushion Drive Tire Inspection281

Cushion Drive Tire Removal and Replacement282

Cushion Drive Wheel Installation282

Steering Wheel Removal283

Steering Tire Inspection284

Steering Wheel Installation284

Section 2 – Pneumatic Drive Tire and Wheel Maintenance286

Pneumatic Tire Warning287

Safety Procedures288

Pneumatic Drive Tire Specifications289

Pneumatic Tire Maintenance289

Pneumatic Drive Wheel and Tire Removal and Disassembly290

Pneumatic Drive Tire Assembly295

Filling Tires with Air295

Filling Tires with Nitrogen295

Procedures for Adding Air Pressure to Mounted Tire and Wheel Assembly297

Directional Thread Tires298

Pneumatic Drive Wheel and Tire Installation298

Group 23 – Brake System300

Section 1 – Brake System and Bleeding302

Brake System Description303

Bleeding the Brake System304

Section 2 – Brake Adjustment306

Brake Lining Wear Check307

Brake Lining Wear Adjustment308

Minor Brake Adjustment308

Major Brake Adjustment309

Replacing Brake Linings310

Section 3 – Brake Slave Cylinder312

Brake Slave Cylinder313

Removal313

Disassembly314

Inspection314

Assembly314

Installation315

Group 25 – Steering Gear316

Section 1 – Steering Gear318

Steering Gear Description319

Steering Gear Troubleshooting320

Steering Gear Removal320

Steering Gear Disassembly321

Steering Gear Parts Inspection323

Steering Gear Assembly323

Steering Gear Installation326

Group 26 – Steering Axle328

Section 1 – Steering Axle Repair330

Steering Axle Removal331

Steering Axle Installation332

Section 2 – Power Steering Pump334

Steering Pump Description335

Steering Pump Troubleshooting335

Steering Pump Removal335

Steering Pump Disassembly337

Steering Pump Parts Inspection338

Steering Pump Assembly339

Steering Pump Installation340

Steering Pump Installation Specifications341

Steering Lines Installation Specifications342

Reverse Steering Lines Installation Specifications344

Section 3 – Steering Torque Generator346

Steering Torque Generator Description347

Steering Torque Generator Removal347

Steering Torque Generator Disassembly349

Steering Torque Generator Parts Inspection350

Steering Torque Generator Assembly351

Steering Torque Generator Installation352

Steering Torque Generator Assembly Specifications354

Steering Torque Generator Lines Installation Specifications355

Group 29 – Hydraulic Pump, Sump and Filter356

Section 1 – Hydraulic Pump358

Main Hydraulic Pump359

Removal359

Preparation for Disassembly359

Disassembly359

Parts Inspection359

Assembly361

Hydraulic Pump Installation363

Hydraulic Pump Installation Specifications363

Section 2 – Hydraulic Sump and Filter364

Hydraulic Sump and Filter Assembly365

Section 3 – Hydraulic Schematics366

Hydraulic Diagram367

Group 30 – Hydraulic Control Valves368

Section 1 – Main Control Valve370

Servicing Main Control Valve371

Relief Valve Assembly373

Procedure for Cartridge Seal Replacement373

Adjustable Relief Valve Seal Nut Replacement374

Non-Adjustable Relief Valve374

Load Check Valve375

Disassembly375

Inspection375

Assembly375

Main Control Valve End Cap and Components376

Disassembly376

Assembly376

Main Control Valve378

Disassembly378

Assembly379

Section 2 – Face Seal Fittings380

Face Seal Fittings382

Assembly Suggestions382

Hydraulic Hose or Tube Installation382

Section 3 – Hydraulic System Pressure Checks – Lift Circuit384

Test Ports385

Hydraulic Lift Circuits Pressure Checks386

Check Lift Circuit Relief Valve Setting386

Relief Valve Adjustment386

Section 4 – Hydraulic System Pressure Checks – Steering Circuit388

Test Ports389

Hydraulic Steering Circuit Pressure Checks390

Check Steering Circuit Relief Valve Setting390

Relief Valve Adjustment390

Section 5 – Hydraulic System Pressure Checks – Auxiliary and Tilt Circuits392

Test Ports393

Hydraulic Pressure Checks394

Check Auxiliary and Tilt Circuits Relief Valve Setting394

Relief Valve Adjustment395

Section 6 – Flow Controls – Selector Solenoid Valve396

Valve Identification397

Hydraulic Solenoid Valves398

Cartridge Valve Installation Procedure398

Service Specifications399

Optional Auxiliary 2 Valve Specifications400

Group 31 – Hydraulic Supply System402

Section 1 – Hydraulic System404

General Description405

Hydraulic Fluid and Filter Change405

Remote Pump Method405

Truck Pump Method406

Hydraulic Sump Tank408

Group 32 – Cylinders410

Section 1 – Tilt Cylinder412

Tilt Cylinder Components413

Tilt Cylinder Plumbing Layout414

Tilt Cylinder Drift Test415

Tilt Cylinder Removal415

Tilt Cylinder Rod End Removal417

Tilt Cylinder Disassembly417

Tilt Cylinder Inspection417

Tilt Cylinder Assembly419

Tilt Cylinder Installation419

Face Seal Fittings421

Assembly Suggestions421

Tilt Check and Adjustment423

Group 33 – Selector Solenoid Valve426

Section 1 – Selector Solenoid Valve428

Selector Solenoid Valve Description429

Selector Solenoid Valve Troubleshooting429

Selector Solenoid Valve Removal430

Selector Solenoid Valve Repair430

Selector Solenoid Valve Installation430

Device Selector Solenoid Valve431

Group 34 – Uprights432

Section 1 – Upright434

Upright Maintenance435

Triple Stage Upright435

Upright Rail Shim Inspection435

Carriage Shim Inspection437

Disassembly for Shim Adjustments437

Assembly for Shim Adjustments443

Lift Cylinder Drift Check444

Hydraulic Cylinder Repair445

Standard (Two Stage) Upright447

Upright Rail Shim Inspection447

Carriage Shim Inspection449

Disassembly for Shim Adjustments449

Assembly for Shim Adjustment453

Lift Cylinder Drift Check454

Upright Cylinder Repair454

Section 2 – Chain Inspection, Adjustment, and Replacement460

Periodic Inspection463

Elongation463

Edge Wear463

Turning or Protruding Pins463

Cracked Plate463

Ultimate Strength Failure464

Tight Joints464

Chain Length Adjustments464

Standard Upright Chain Length Adjustments465

Triple-Stage Upright (TSU) Chain Length Adjustment465

Chain Lubrication467

Chain Removal and Replacement467

General Guidelines467

Lift Chains (Standard and TSUs)468

Carriage Chains (TSUs)468

Other Chain Service Notes469

Group 40 – Specifications470

Section 1 – Specifications472

Group 12 – Battery473

Group 16 – Motors474

Group 19 – Electrical Controls474

Group 20 – Drive Axle475

Group 22 – Wheels and Tires475

Group 23 – Brakes475

Group 25/26 – Steering System475

Group 29/30 – Hydraulic System475

Group 32 – Tilt Cylinder476

Group 34 – Uprights477

Group 40 – Specifications478

Section 2 – Data Plate480

How to Read Data Plate481

Battery Weight Chart483

Section 3 – Lubricants and Shop Supplies484

Lubricants and Shop Supplies485

Lubricants485

Sealants487

Gasket Materials488

Threadlocks and Threadsealers489

Cleaners490

Back Cover493

IMAGES PREVIEW OF THE MANUAL: