$45

CAT Bucyrus CONTINUOUS MINER 25M Series Operation Manual 03-29-05 - PDF DOWNLOAD

CAT Bucyrus CONTINUOUS MINER 25M Series Operation Manual 03-29-05 - PDF DOWNLOAD

FILE DETAILS:

CAT Bucyrus CONTINUOUS MINER 25M Series Operation Manual 03-29-05 - PDF DOWNLOAD

Language :English

Pages :150

Downloadable : Yes

File Type : PDF

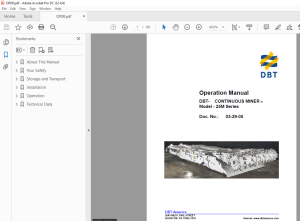

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

CAT Bucyrus CONTINUOUS MINER 25M Series Operation Manual 03-29-05 - PDF DOWNLOAD

preface

- This manual is intended to provide basic operating information on DBT 25M Series class continuous miners. Additional information can be obtained by referring to the Parts Book supplied with your machine, or by contacting your local DBT representative.

- The illustrations, descriptions and procedures contained in this manual pertained to the machine as it was originally manufactured and delivered to your mine, and when the manual was approved for printing. DBT reserves the right to discontinue or revise machine models at any time, or change specifications, designs or procedures, without notice and without incurring obligations.

- The machine was manufactured under the guidelines, procedures and requirements of the appropriate government regulatory agencies. At the completion of manufacturing, this machine was issued the appropriate approval numbers and nameplates indicating that it met the technical requirements of the appropriate agencies. Any change to the design or structure of this machine, without the consent of DBT and these agencies, may void these approvals and render the machine illegal or dangerous for use.

- Strict compliance with all local and national laws, regulations and practices regarding the safe operation and maintenance of underground mining equipment is necessary to ensure the personal safety of those working on, or around, this machine. While this manual attempts to anticipate the most important operations and maintenance needs for this equipment, unforeseen circumstances may arise that have not been addressed in this manual.

- If any concerns or questions arise, please contact your DBT America Service Representative immediately. This work contains information protected under trade secret and other intellectual property laws, and is protected under the U. S. Copyright Act of 1976, as amended. This work is provided under license and the license is non-transferable. Distribution and access is limited only to authorized personnel. Disclosure, reproduction, distribution or unauthorized use may be a violation of federal and state laws and may subject the unauthorized user to criminal liability.

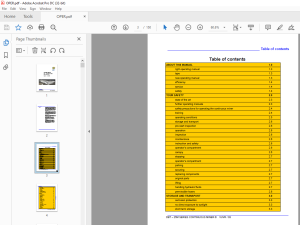

TABLE OF CONTENTS:

CAT Bucyrus CONTINUOUS MINER 25M Series Operation Manual 03-29-05 - PDF DOWNLOAD

About This Manual 9

Right Operating Manual 11

Type 11

New Operating Manual 11

Efficiency 12

Service 12

Safety 12

Your Safety 13

State of the Art 15

Further Operating Manuals 15

Safety Precautions 16

Training 16

Operating Conditions 17

Storage and transport 18

Pre-Start Inspection 18

Operation 18

Inspection 18

Maintenance 18

Instruction and Safety 18

Operator's Compartment 18

Canopy 18

Stopping 19

Operator's Compartment 19

Parking 19

Securing 19

Replacing Components 19

Original Parts 19

Lifting 19

Handling Hydraulic Fluids 19

Permissible Hoses 20

Storage and Transport 23

Corrosion Protection 25

No Direct Exposure to Sunlight 25

Short Term Storage 25

Long Term Storage 25

Plastic Deformation 26

Random Sample Inspection 26

Natural Aging 26

HFA Fluids 26

Before Transport 26

Temperature Below Freezing 27

Antifreeze Measures for Oil Cooler 27

Electrical and Electronic Components 27

Installation 29

Special Tools 31

General Safety Rules 32

General Safety Maintenance 33

Lubricate Every Shift 35

Inspect Daily 35

Lubricate Weekly 35

Lubricate Daily 35

Check Daily 36

Replace When Necessary 36

Electric Motor Maintenance 36

Every Month 36

Electric Motor Maintenance 38

Every Three Months 38

Every Six Months 38

Annually 38

Notes on Installation 39

Installation Plan 39

Supper Bolt Installation & Specifications 40

Tightening Procedures 40

Loosening Procedures 41

Lubicants 42

Safety Features 44

Panic Strip (s) 44

Canopy 44

Fire Suppression 44

Guards and Covers 44

Circuit Breaker Reset 44

Operation 45

Cutting Head Assembly 47

Cutting Support Frame Pivot Pin 48

Drum Drive Torque Limiting Switch 49

Drum Drive Motor: 25M0 & 25M1 49

Drum Drive Motor: 25M2 & 25M3 50

Shear Cylinder: 25M0, 25M1 & 25M2 51

Shear Cylinder: 25M3 52

25M0 Cutting Drum Installation & Removal 52

Center Cutting Drums 52

End Cutting Drums 53

Main Cutting Drums 53

25M1 Cutting Drum Installation & Removal 54

Center Cutting Drum 54

End Cutting Drum 55

Main Cutting Drum 55

25M2 / 25M3 Cutting Drum Installation & Removal 56

End Cutting Drum 57

Center Cutting Drum 58

End Cutting Drum 58

25M0 Drum Drive Gear Case Installation / Removal 59

Figure 21 / 25M0 62

25M1 Drum Drive Gear Case Installation / Removal 60

Figure 22 / 25M1 63

25M2 / 25M3 Drum Drive Gear Case Installation / Removal 61

Figure 23 / 25M2 / 25M3 64

Gathering Head Assembly Installation / Removal 65

CLA Installation / Removal 66

Gathering Head Motor Installation / Removal 67

Foot Shaft Installation / Removal 67

Gear Case Installation / Removal 68

Lift Cylinder Installation / Removal 69

Tram Case Installation / Removal From Tractor Frame 70

Tram Sprocket Installation / Removal 75

Crawler Front Idler Installation / Removal 78

Crawler Chain Tension Adjustment 76

Crawler Chain Take-Up Jack Assembly 79

Tram Planetary Installation / Removal 71

Tram Secondary Planetary Installation / Removal 72

Tram Case Installation / Removal 73

Stabilizing Cylinder Installation / Removal 74

Hydraulic Pump Installation / Removal 79

Hydraulic Pump Motor Installation / Removal 80

Conveyor Assembly Installation / Removal 81

Conveyor Lift Cylinder Installation / Removal 85

Tail Conveyor Shim Adjustment 84

Tail Roller Installation / Removal 84

Conveyor Swivel Pin Installation / Removal 83

Swing Cylinder Installation / Removal 82

Conveyor Chain Installation / Removal 86

Conveyor Chain Tension Adjustment 86

Scrubber System 88

Scrubber Motor 89

Scrubber Cleaning 89

Electrical Components 90

Power Schematic 90

Motor Overloads 90

Motor Control 91

Cutting Motor Feedback 91

Radio Control Schematic 92

Tram Dead Man Switch 92

Methane Monitor 93

Low Oil Level Switch 93

E-Stop Bypass 93

Battery Back-Up System 93

Scrubber Fan 93

Cutting Motor Feedback Adjustment 94

Armature Voltage 95

Radio Remote Control 96

Receiver, Power Supply & Tram Case Module 96

Diagnostic Display 97

Radio Transmitter 97

Batery Charger 97

Permissibility 97

Trouble Shooting 98

Dual Systems 98

Diagnostic Display 99

Component Change Out 99

Technical Data 101

Tractor Frame (Figure 1) 104

Tram Motor (Figure 2) 105

Tram In-Put Planetary (Figure 3) 106

Tram Secondary Planetary (Figure 4) 107

Tram Case (Figure 5) 108

Tram Case (Figure 6) 109

Stabilizing Cylinder (Figure 7) 110

Tram Sprocket (Figure 8) 111

Crawler Chain Adjustment (Figure 9) 112

Crawler Front Idler (Figure 10) 113

Crawler Take-Up Jack (Figure 11) 114

Hydraulic Pump (Figure 12) 115

Hydraulic Pump Motor (Figure 13) 116

Gathering Head (Figure 14) 117

Gathering Head Assembly (Figure 15) 118

Gathering Head CLA Installation / Removal (Figure 16) 119

Gathering Head Motor Installation / Removal (Figure 17) 120

Gathering Head Foot Shaft Installation / Removal (Figure 18) 121

Foot Shaft Assembly (Figure 19) 122

Gathering Head Gear Case Installation / Removal (Figure 20) 123

Gathering Head Gear Case Assembly (Figure 21) 124

Gathering Head Gear CaseAssembly (Figure 22) 125

Gathering Head Lift Cylinder Installation / Removal (Figure 23) 126

Cutting Head Assembly (Figure 24) 127

Cutting Head Support Frame Assembly (Figure 25) 128

Cutting Head Pivot Pin 25M0 / 1 / 2 (Figure 26) 129

Cutting Head Pivot Pin 25M3 (Figure 27) 130

Cutting Head Torque Limiting Clutch 25M2 & 25M3 (Figure 28) 131

Cutting Head Motor 25M2 & 25M3 (Figure 29) 132

Cutting Head Motor 25M0 & 25M1 (Figure 30) 133

Cutting Head Shear Jack 25M0, 25M1 & 25M2 (Figure 32) 134

Cutting Head Shear Jack 25M3 (Figure 33) 135

Drum Drive Gear Case 25M0 (Figure 34) 136

Drum Drive Gear Case 25M1 (Figure 35) 137

Drum Drive Gear Case 25M2 (Figure 36) 138

Drum Drive Gear Case 25M3 (Figure 37) 139

Conveyor (Figure 38) 140

Conveyor (Figure 39) 141

Swing Cylinder (Figure 40) 142

Conveyor Swivel Pin (Figure 41) 143

Conveyor Tail Roller (Figure 42) 144

Tail Conveyor Shim Set (Figure 43) 145

S.M 30/3/2025