$40

CAT Bucyrus Continuous Miner Operation and Maintenance Manual - PDF DOWNLOAD

CAT Bucyrus Continuous Miner Operation and Maintenance Manual - PDF DOWNLOAD

FILE DETAILS:

CAT Bucyrus Continuous Miner Operation and Maintenance Manual - PDF DOWNLOAD

Language :English

Pages :336

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

CAT Bucyrus Continuous Miner Operation and Maintenance Manual - PDF DOWNLOAD

About this manual

This chapter provides important information making it easier for you to use this manual. It contains information on the structure of the manual and the symbols and characters used

Before starting to work

applicable operating manual :Take care to ensure that the operating manual available to you is applicable

for the type of equipment or machine used.

machine type : This operating manual is intended for:

Bucyrus Model 30M4-NP Continuous Miner

Serial No.: N/A and is only permitted to be used for equipment of this type.

new operation manual : The operating manual must be accessible at all times to all persons working on or with the machine. It should, if possible, always be available at the place of operation. Send for a new operation manual immediately if the present manual is no longer complete or has become illegible

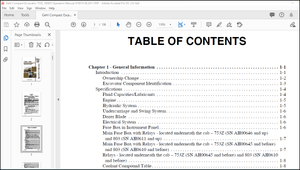

TABLE OF CONTENTS:

CAT Bucyrus Continuous Miner Operation and Maintenance Manual - PDF DOWNLOAD

Table of contents

1 About this manual

About this manual 1 3

Before starting to work 1 3

Who is this operating manual intended for? 1 3

What is the purpose of this operating manual? 1 4

Characters and symbols 1 5

2 Your safety

Your safety 2 3

Personnel 2 4

Operation 2 4

Installation and repair 2 4

Operating conditions 2 5

Intended use 2 5

Unauthorized use 2 5

Safety instructions 2 7

General rules: 2 7

Storage and transport 2 8

Pre-start inspection 2 8

Installation and start-up 2 9

Operation 2 9

Stopping 2 10

Maintenance and repair 2 10

3 Storage and transport

Storage and transport 3 3

Storage 3 3

Storage of the machine and spare parts 3 3

Long-term storage of spare components 3 4

Transport 3 5

Hoisting of heavy components 3 6

4 Installation

Installation 4 3

Points to observe prior to installation 4 3

Who is allowed to carry out installation? 4 3

Which tools are required for installation? 4 3

Notes on installation 4 4

Pre-installation check list 4 5

Safety features 4 6

Bucyrus – Model 30M4-NP Continuous Miner

© BUCYRUS

5 Operation

Operation 5 3

How to operate the Continuous Miner 5 3

Who is allowed to operate the Continuous Miner 5 3

When can operation be started? 5 3

Controls and indicators 5 4

Machine control system 5 18

Red zone 5 34

Safety precautions for underground operation 5 37

Tramming safety rules 5 37

Starting procedure in radio remote 5 38

Shutdown procedure in radio remote 5 40

Tramming the miner in radio remote 5 42

Cutter head operation in radio remote 5 44

Conveyor operation in radio remote 5 45

Scrubber motor in radio remote 5 47

Control headlights in radio remote 5 48

Fire suppression in radio remote 5 49

Shear up/down in radio remote 5 49

Gathering head raise/float in radio remote 5 49

Stabilizer shoe in radio remote 5 49

Conveyor raise/lower in radio remote 5 50

Tramming with pendant controls 5 51

Starting procedure from operator’s pit 5 52

Shutdown procedure form operator’s pit 5 54

Tramming the miner from operator’s pit 5 55

Cutter head operation from operator’s pit 5 56

Conveyor operation from operator’s pit 5 57

Mechanical assemblies 5 58

Hydraulic system 5 64

Electrical system 5 110

Instructions on the maintenance 5 138

Important notes 5 138

Before maintenance 5 138

Torque values 5 140

Lubricants, fluids and capacities 5 140

Specific lubrication and maintenance instructions 5 146

Every shift 5 146

Every third shift (daily) 5 149

Weekly 5 156

Monthly 5 161

Every three months 5 167

Every six months 5 173

Instructions on the adjustment procedures 5 176

Pilot pressure circuit relief/reducing valve 5 178

Direction control valve (main control and cutter head) 5 180

Cutter head port reliefs 5 185

Multi-purpose valve 5 185

Conveyor chain tension pressure 5 186

Tram track 5 187

Tail shim 5 192

A6474X337 VLSS/0 ©

BUCYRUS

Replacement of wear parts 5 197

Cutter head (boom) assembly 5 197

Cutter head assembly removal/installation 5 197

Shear cylinder 5 201

Center cutter drum 5 206

End cutter drum 5 209

Drum drive motor 5 212

Drum drive gear case 5 217

Gathering head assembly 5 220

Gathering head assembly removal/installation 5 221

Gathering head drive motor 5 226

Gathering head gear case 5 229

Gathering head foot shaft 5 232

CLA 5 235

CLA tip replacement 5 237

Gathering head lift cylinder 5 238

Crawler assembly 5 242

AC drive encoder removal/installation 5 246

Tram motor 5 248

Tram case 5 250

Crawler chain 5 255

Tram track front idler 5 259

Tram brake 5 262

Conveyor assembly 5 267

Conveyor chain 5 268

Conveyor assembly removal/installation 5 272

Discharge conveyor 5 275

Tail roller 5 280

Troubleshooting procedures 5 283

Typical hydraulic problems 5 284

Contaminants in hydraulic systems 5 285

Specific hydraulic circuits 5 286

General safety procedures for shutdown 5 290

Excessive noise 5 291

Excessive heat 5 292

Incorrect flow 5 293

Incorrect pressure 5 294

Faulty operation 5 295

Restarting checklist 5 296

Bearings 5 297

E-tram pendant LEDs 5 298

S.M 23/3/2025