$45

CAT Load Haul Dump Equipment Crawler Units (Size 9) Operators Manual -PDF DOWNNLOAD

CAT Load Haul Dump Equipment Crawler Units (Size 9) Operators Manual -PDF DOWNNLOAD

FILE DETAILS:

CAT Load Haul Dump Equipment Crawler Units (Size 9) Operators Manual -PDF DOWNNLOAD

Language :English

Pages :50

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

CAT Load Haul Dump Equipment Crawler Units (Size 9) Operators Manual -PDF DOWNNLOAD

Section 1

General Safety

- Isolation and tagging procedures must be followed when working on equipment.

- Isolate and tag any other related equipment where its operation will cause danger to personnel or damage to equipment.

- Before operating equipment make sure that nobody is inside or in the immediate area of the equipment.

- Maintenance and repair should be undertaken by trained personnel.

- Always wear safety glasses when working on hydraulics systems.

- Ensure that any relevant circuits are depressurised. Release of high pressure fluids can be fatal. As a final check twist the hose to ensure it is loose before removing staples.

- Always be aware of E Stop locations, in case of emergency.

- Before attempting to free-wheel the machine, ensure the hydraulic power to the crawler circuit is switched off, the machine is positioned on a level ground and not moving, and the towing vehicle has the capacity to brake this additional load in up and down grades.

- Do not disengage the hubs until the Towing vehicle is attached to this machine

- Once both hubs are disengaged, this machine will not have any sort of brake capability and there is a danger of running away on grades if the towing vehicle does not have the braking capacity

- High pressure fluids can penetrate skin and enter a human body. These fluid injections may cause severe tissue damage and loss of limb. If a fluid-injection accident occurs, see a doctor immediately. DO NOT DELAY OR TREAT AS A SIMPLE CUT!

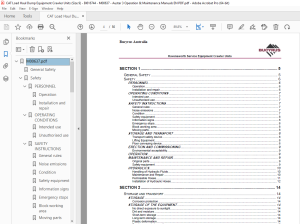

TABLE OF CONTENTS:

CAT Load Haul Dump Equipment Crawler Units (Size 9) Operators Manual -PDF DOWNNLOAD

SECTION 1 5

GENERAL SAFETY 5

SAFETY 6

PERSONNEL 6

Operation 6

Installation and repair 6

OPERATING CONDITIONS 7

Intended use 7

Unauthorised use 7

SAFETY INSTRUCTIONS 7

General rules: 7

Noise emissions 7

Condition 7

Safety equipment 8

Information signs 8

Emergency stops 8

Block working area 8

Moving parts 8

STORAGE AND TRANSPORT 8

Transport safety device 8

Lifting Equipment 8

Floor conveying device 8

ERECTION AND COMMISSIONING 9

Environmental acceptability 9

OPERATION 9

MAINTENANCE AND REPAIR 9

Original parts 9

Safety equipment 9

HYDRAULICS 10

Handling of Hydraulic Fluids 10

Maintenance and Repair 10

Permissible Hoses 11

Installation of Hydraulic Hoses 12

SECTION 2 14

STORAGE AND TRANSPORT 14

STORAGE 14

Corrosion protection 14

STORAGE OF THE EQUIPMENT 14

No direct exposure to sunlight 14

Dirt and moisture 14

Short-term storage 14

Long-term storage 14

Plastic deformation 14

Random sample inspection 15

Natural ageing 15

HFA fluids 15

TRANSPORT 16

Load units; dimensions and weights 16

BEFORE TRANSPORT 16

Temperatures below freezing 16

Electrical and electronic components 16

TRANSPORT OF THE COMPONENTS 17

Machine parts 17

SECTION 3 18

PUMP AND TRANSFORMER STATION CRAWLER UNITS 18

DESCRIPTION 18

SECTION 4 21

TOWING CRAWLER UNITS 21

CONNECT TOWING UNIT TO DRAW BAR 21

DISENGAGE TRACKS 23

Oct 2010 3 of 49 Manual No M00637

BI616744

Bucyrus Australia

Service Equipment Crawler Units

SECTION 5 29

HOOKING UP AND DRIVING TRACK UNITS 29

TRANSFORMER STATION CONNECTION AND OPERATION 29

PUMP STATION CONNECTION AND OPERATION 31

SECTION 6 34

DISCONNECTING THE CRAWLER UNIT 34

SECTION 7 35

TRACK MAINTENANCE 35

TENSIONING TRACKS 35

General 35

Procedure 35

REPLACEMENT OF TRACK TENSIONING CYLINDER 38

General 38

Procedure 38

REPLACEMENT OF TRACK FROM TRACK FRAME 41

General 41

Procedure 41

TRACK ASSEMBLY REMOVAL COMPLETE 43

General 43

Procedure - Removal 43

Procedure - Refitting 46

SECTION 8 48

OIL FILLING OF PLANETARY HUBS 48

Manual

S.M 27/3/2025