$38

Crown Forklift ES ET 4000 Series Service Manual – PDF DOWNLOAD

Crown Forklift ES ET 4000 Series Service Manual – PDF DOWNLOAD

FILE DETAILS:

Crown Forklift ES ET 4000 Series Service Manual – PDF DOWNLOAD

Language : English

Pages :374

Downloadable : Yes

File Type : PDF

TABLE OF CONTENTS:

Crown Forklift ES ET 4000 Series Service Manual – PDF DOWNLOAD

Introduction 1

Important Information 1

Service personnel qualification 1

Ordering spare parts 1

Ordering documentation 1

Manual structure 1

Conventions 1

Text mark-ups in the manual 1

Brief description of equipment 1

Truck Data Number 3

Safety 4

Safety Notices 4

Basic Safety Notices 5

Organisational measures 5

Truck modifications and additions 5

Personal safety equipment 5

Protecting the hazardous area 5

Hazards from stored energy 5

Maintenance work 6

Restoring the truck to service after maintenance work 6

Cleaning work 6

Handling batteries 6

Warning and instruction decals on the truck 6

Lifting gear and slings 7

Environmental protection 7

Safety Mechanisms and Protective Guards 8

Truck safety mechanisms 8

Truck protective guards 8

Inspection and Lubrication 0

Cleaning the Truck and Components 0

Effects of incorrect cleaning 0

Electrical components 0

Roller and slide bearings 0

Corrosion-protected surfaces 0

Environmental protection 0

Cleaning the entire truck 0

Cleaning removed components 0

Cleaning other mechanical components 0

Raising the Truck 0

Securing the Truck for Transport on a Truck Bed 0

Towing the Truck 0

Jacking up the Truck 0

Placing the Truck in Storage 0

Taking the truck out of service 0

Testing trucks in storage 0

Restoring the truck to service 0

Recommended Lubricants and Consumables 0

Cold store truck requirements 0

Abbreviations used in the table 0

Planned Maintenance 0

Maintenance schedule 0

Annual inspection in accordance with FEM 4004 0

Terms and abbreviations used 0

Maintenance Schedule 0

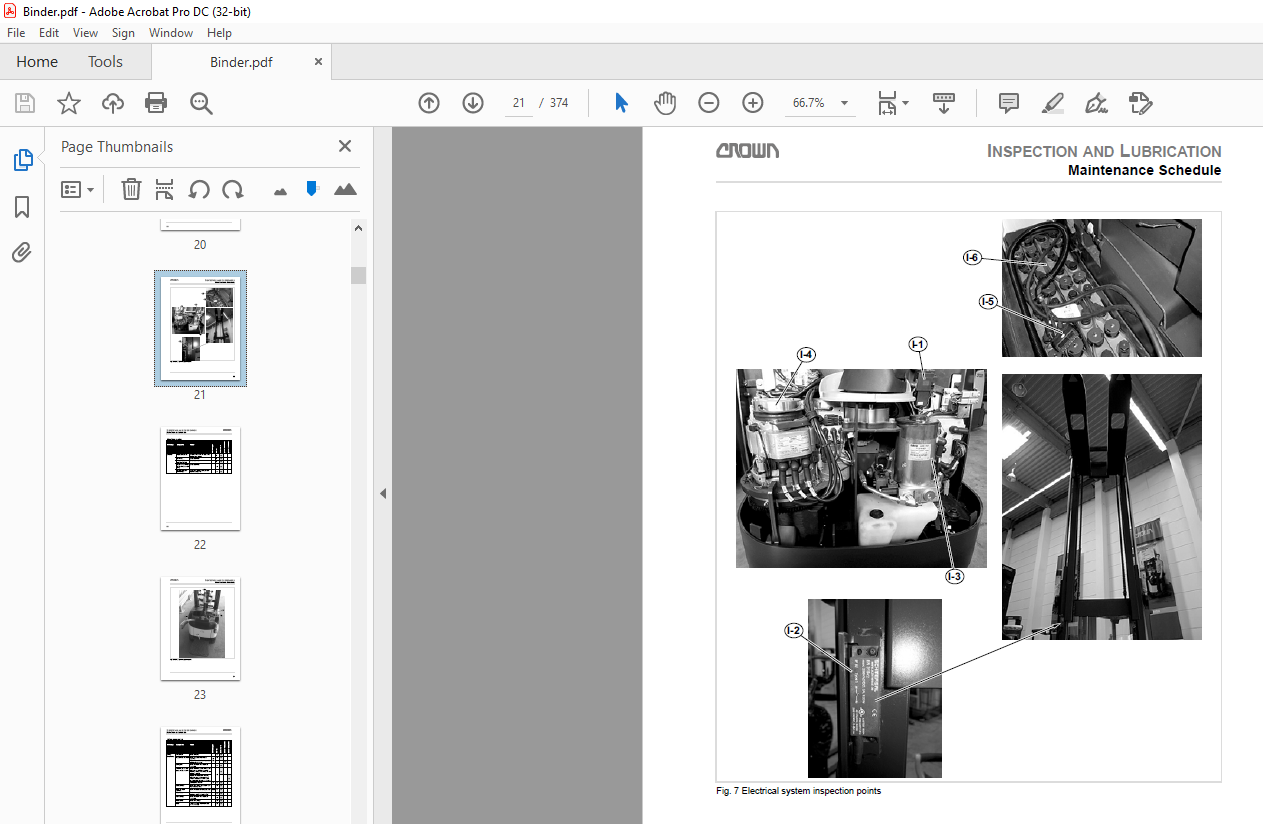

Electrical system 0

Electrical system 0

Lifting mechanism 0

Drive system, steering and wheels 0

Safety mechanisms 0

Removing the caster wheel assembly 0

Installing the caster wheel assembly 0

Requirements 0

Repairing the Caster Wheel Assembly 0

Replacing the Drive Wheel 0

Standard Torques 0

Metric screws and nuts without flange 0

Metric hex bolts and nuts with flange (Unbrako® type) 0

Main Components 0

Motor compartment 0

Inspection and Lubrication 0

Cleaning the Truck and Components 0

Effects of incorrect cleaning 0

Electrical components 0

Roller and slide bearings 0

Corrosion-protected surfaces 0

Environmental protection 0

Cleaning the entire truck 0

Cleaning removed components 0

Cleaning other mechanical components 0

Raising the Truck 0

Securing the Truck for Transport on a Truck Bed 0

Towing the Truck 0

Jacking up the Truck 0

Placing the Truck in Storage 0

Taking the truck out of service 0

Testing trucks in storage 0

Restoring the truck to service 0

Recommended Lubricants and Consumables 0

Cold store truck requirements 0

Abbreviations used in the table 0

Planned Maintenance 0

Maintenance schedule 0

Annual inspection in accordance with FEM 4004 0

Terms and abbreviations used 0

Maintenance Schedule 0

Electrical system 0

Electrical system 0

Lifting mechanism 0

Drive system, steering and wheels 0

Safety mechanisms 0

Removing the caster wheel assembly 0

Installing the caster wheel assembly 0

Requirements 0

Repairing the Caster Wheel Assembly 0

Replacing the Drive Wheel 0

Standard Torques 0

Metric screws and nuts without flange 0

Metric hex bolts and nuts with flange (Unbrako® type) 0

Main Components 0

Motor compartment 0

Componentry 65

Hydraulic System 67

Hydraulic Oil 67

Checking the hydraulic oil level 67

Adding hydraulic oil 67

Requirements 67

Replacing the Hydraulic Oil 68

Replacing the Hydraulic Filter 69

Bleeding the Hydraulic System 71

Replacing the Relief Valve RV1 72

Testing the relief valve 72

Flushing the Hydraulic System 73

Requirements 73

Drift Test 74

Preparing the drift test 74

Drift test 74

Hydraulic System Troubleshooting 75

Drive Unit 76

Components 76

Trucks with mechanical steering 76

Trucks with electric steering 76

Replacing the Drive Wheel 77

Drive wheel disassembly 77

Drive wheel assembly 77

Changing the Gear Oil 78

Drive Gear Disassembly / Installation 79

Drive gear unit removal 79

Drive gear unit assembly 80

Electrical System Part 1 0

Input Signals 0

Initial truck status 0

SAS and BRS 0

Operating mode definition 0

Pedestrian mode 0

Comfort mode 0

Rider mode 0

Quick Exit 0

Conventions 0

Brief description of equipment 0

Input Signals 0

Platform and Side Restraint Logic 0

Brief description of equipment 0

Folding platform 0

Side restraint and platform setting definition 0

Accessing the Service Levels 0

Software Versions 0

Menu Structure (without Quick Pick® Remote Lift Technology) 0

Operator Menu 0

Service menu 0

Access 3 – Analyzer Outputs 0

Calibration 0

Access 2 – Analyzer Outputs 0

Access 5 – Analyzer Outputs 0

Features – F1 to F3 0

Features – F4 0

Features – F5 to F12 0

Features – F13 to F18 0

Features – F7 Enable 0

Hour – H1 to H5 0

Events – E1 to E3 0

Performance P1 0

Performance P2 0

Performance P3 0

Performance P4 to P16 0

Utilities – U1 0

Test Outputs – A4 0

Quick Pick® Remote Lift Technology Option Menu Structure 0

Quick Pick® Remote Lift Technology – operator menu 0

Quick Pick® Remote Lift Technology- Analyzer menu A18 Status 0

Quick Pick® Remote Lift Technology- Access 82 Inputs 0

Quick Pick® Remote Lift Technology- Features menu F24 Remote System 0

Quick Pick® Remote Lift Technology- Hours menu H8 Access 82 0

Quick Pick® Remote Lift Technology- Performance menu P23 0

Quick Pick® Remote Lift Technology- Utilities menu U18 Access 82 0

Software Parameter Settings ES 4020-MW /- EW 0

Brief description of equipment 0

Markings 0

Software Parameter Settings ET 4040-MF / -EF 0

Brief description of equipment 0

Operation Modes 0

Markings 0

Electrical System Part 2124

Calibration124

Selecting the CALIBRATION Menu124

Electric steering calibration124

Calibrating proportional lifting and lowering126

Error codes127

Malfunctions with event code display127

Locating malfunctions127

Event code groups127

Event Code – Group 100 (ES/ET -M, -E)128

Event code 100128

Event Code 126 & 127130

Event code 144131

Event code 191132

Event Code – Group 200 (ES/ET -M, -E)133

Event Code 202133

Event Code 203135

Event Code 204135

Event Code 205137

Event code 208139

Event code 228140

Event code 229141

Event code 230142

Event code 231144

Event codes 232 and 233145

Event code 234146

Event code 235147

Event code 236148

Event Code – Group 300 (ES/ET -M, -E)149

Event code 300149

Event code 301150

Event code 302150

Event code 303151

Event code 304151

Event code 305153

Event code 306154

Event code 307154

Event code 308155

Event code 309156

Event code 310156

Event code 314156

Event code 315158

Event code 316158

Event code 317159

Event code 320161

Event code 334161

Event code 321162

Event code 322163

Event code 326164

Event code 328165

Event code 329165

Event code 333165

Event code 334166

Event code 335166

Event code 337167

Event code 338168

Event code 340170

Event code 341171

Event code 342171

Event code 343172

Event code 348174

Event code 351174

Event code 352175

Event code 353175

Event code 354176

Event code 355177

Event code 356177

Event code 357177

Event code 358179

Event code 359179

Event code 361181

Event code 362182

Event code 364183

Event code 365184

Event code 368185

Event Code – Group 500 (ES/ET -E)186

Event code 500186

Event code 501187

Event codes 502, 503, 504, 505187

Event code 506187

Event code 508188

Event code 509188

Event code 510189

Event code 511192

Event code 512192

Event code 513193

Event code 514193

Event code 515194

Event code 516195

Event code 517196

Event code 518198

Event code 519199

Event codes 520, 521200

Event code 522200

Event code 523201

Event code 524202

Event code 525203

Event code 526204

Event codes 527, 528205

Event code 529206

Event code 530207

Event code 531208

Event code 532209

Event code 535211

Event code 536211

Event code 537212

Event code 538213

Event code 539214

Event code 540215

Event code 541216

Event codes 542, 543216

Event code 544218

Event code 545219

Event code 547219

Event Code Group 800 (ES/ET -E)220

Event code 801220

Event code 802220

Event code 804221

Event Code Group 800222

Trucks with QuickPick® Remote Lift Technology222

Event code 801222

Event code 804224

Event code 805224

Event code 806224

Event code 816224

Event code 821225

Event code 832225

Event code 833226

Event code 834226

Event code 835227

Event Code 836 & 837227

Event code 838227

Event code 844227

Event Code 845 & 846228

Event Code – Group 1000229

Event code 1000229

Event code 1001 or 1002230

Events Displayed as Text231

Platform Error231

Stopped233

Traction control module hot234

Traction motor hot235

Release control handle236

Travel switch applied too soon237

Pedestrian mode only237

Lower forks237

Steering controller hot238

Steer motor hot240

Pairing Failed Enter to Retry242

Release remote brake button243

Low signal strength243

Electrical System Part 3244

Control Module PMT Test244

General244

Required tools244

PMT Test244

Testing Access 2244

Testing Access 3245

Testing Access 5246

Servicing and Replacing the Control Modules247

Discharging the capacitors247

Servicing the control modules247

Replacing control modules247

Removing the control module247

Assembling the control module248

Set the parameters after replacing a control module248

Modifications249

Converting the truck from Enter key to key switch power-up function249

Mechanical conversion249

Changing the software249

Converting the truck from key switch to Enter key power-up function250

Mechanical conversion250

Changing the software250

Battery Information251

Charging batteries251

Lithium ion battery251

Charging a lithium ion battery251

Lead Acid Battery251

Servicing a lead acid battery251

Replacing a lead acid battery251

Adjusting the BLS sensor252

General DC Motor Maintenance Instructions253

Brushes253

Motor253

Rotor253

Setting the Load Profile for the Battery Discharge Indicator (BDI)254

Load profile and discharge curve254

Assigning a load profile254

Checking and Adjusting the BDI Setting256

Requirements256

Checking the BDI Setting256

Adjusting the BDI setting257

Traction motor Installation and Removal258

Traction motor disassembly258

Traction motor assembly259

Repairing the Traction Motor260

Preparation260

Rotor and bearing disassembly260

Rotor and bearing assembly260

Final tasks260

Pump Motor (M2)261

Brushes261

Rotor261

Replacing the Steer Motor (M3)262

Special tools required263

Steer motor disassembly263

Steer motor assembly263

Repairing Contactors264

Wear test264

Checking the contacts264

Checking the coils264

Checking the springs264

Electrical Components265

ES4000 Model265

ET 4000 Model267

PWS, FLS, ALM and charger option271

InfoLink® option272

Quick Pick® Remote lift technology273

Braking System275

Components and Operation275

Service brake275

Parking brake275

Servicing the Parking Brake276

Measuring the air gap276

Troubleshooting276

Replacing the Parking Brake277

Parking brake disassembly277

Parking brake assembly277

Testing the Braking Distance279

Requirements279

Performing the test279

Braking distance tables279

Maximum braking distances ES 4000 -MW or -EW279

Maximum braking distances ET 4000 -MF or -EF279

Steering 0

Repairing the Tiller Handle280

Replacing the tiller handle shells281

Shell removal281

Shell assembly282

Replacing the switch unit282

Switch unit removal283

Switch unit assembly283

Replacing the “rabbit/turtle” toggle module283

Toggle module removal283

Toggle module assembly284

Replacing the tiller handle PC boards284

Hydraulic PC board removal284

Hydraulic PC board assembly284

Main PC board removal284

Main PC board assembly284

Replacing the traction potentiometer285

Traction potentiometer removal285

Traction potentiometer assembly286

Replacing the brake switch (BRS)286

Remove the brake switch (BRS)286

BRS switch assembly287

Replacing the grips and horn switch287

Repairing Tiller Handle Return Springs288

Removing the covers288

Return spring pre-tension adjustment288

Replacing the return springs289

Return spring removal289

Return spring assembly289

Tools required:289

Mechanical Steering290

Repairing the steering transmission290

Setting straight-ahead travel291

Lifting Mechanism292

Checking the Assembled Mast292

Checking the Fork Height293

Mast Removal and Assembly294

Mast disassembly294

Mast assembly295

Correct Use of Tool 833158296

Replacing the Fork Carriage Rollers and Adjusting the Slack297

Repairing the Mast298

TL Mast298

TF mast298

TT mast298

Mast disassembly299

Mast assembly300

Final tasks300

Replacing the Mast Rollers and Adjusting the Slack301

Fork Carriage Assembly and Removal304

Removing the fork carriage with the TF and TT masts304

Assembly304

Removing the fork carriage with a TL mast304

Assembly304

Lowering Plumb Test and Adjusting the Mast Tilt305

Requirements305

Preparing the lowering plumb test305

Lowering plumb test305

Adjusting the Mast Tilt305

Replacing the Mast Guard307

Preparation307

Removing the mast guard307

Installing the mast guard307

Repairing Lift Chains and Chain Tensioners308

Adapting the service intervals to the application conditions308

Periodic replacement of the chain tensioners and lift chains308

Servicing lift chains309

Service work309

Checking the service hours for the lift chains and anchor bolts309

Cleaning lift chains309

Lubricating and preserving lift chains309

Checking the Lift Chains for Wear and Damage311

Checking the lift chain elongation311

Tools required311

Test preparation311

Checking the lift chain elongation with the wear gauge312

Checking the lift chain elongation with the steel ruler313

Checking the chain for other damage314

Separating Lift Chains317

Tools and equipment required317

Forks318

General318

Fork inspection318

Checking forks for cracks318

Cylinders319

Safety notices319

Hydraulic system repair instructions319

Tools320

Small hook320

Extractor320

Producing extractors320

Groove aligning arbor for small rod seals320

Assembly devices for large rod seals321

Protective mechanisms321

Rod Seal Removal and Assembly322

Removing a large rod seal322

Removing a small rod seal322

Inserting a large rod seal322

Fitting a small rod seal323

Rod seal assembly, sealing lip first323

Lift Cylinder Removal and Assembly324

Removing the lift cylinder (TL mast)324

Lift cylinder (TL mast) assembly325

Lift cylinder (TF and TT mast) removal327

Lift cylinder (TF and TT mast) removal327

Lift cylinder (TF and TT mast) assembly327

Free lift cylinder removal and assembly329

Free Lift Cylinder Removal (Method 1)330

Free Lift Cylinder Assembly (Method 2)331

Free Lift Cylinder Removal (Method 2)332

Free Lift Cylinder Assembly (Method 2)333

Repairing the Lift Cylinders on the TL and TT Masts335

Repairing the Lift Cylinder for the TF Mast337

Repairing the left lift cylinder337

Repairing the right lift cylinder339

Repairing the Free Lift Cylinder for the 12 and 14 ES/ET – TF341

Repairing the Free Lift Cylinder for the 16 ES/ET – TF or TT343

Platform345

Adjusting the Folding Platform Switch345

Pre-tensioning the spring assembly345

Checking and adjusting switch PLS1 for rider mode345

Adjusting switch PLS2 for pedestrian mode346

Replacing the Folding Platform Springs347

Spring removal347

Spring assembly347

Schematic Diagrams348

Wire Colour Code348

General Contact Symbol Abbreviations349

Electrical Wiring Symbols351

ES -M with standard equipment (up to S/N 5A151757)353

ES -M with options (up to S/N 5A151757)354

ES -M with standard equipment (from S/N 5A151758)355

ES -M with options (from S/N 5A151758)356

ES -E with standard equipment (from S/N 5A151758)357

ES -E with options (from S/N 5A151758)358

ES/ET CAN-Bus connections, mechanical steering359

ES/ET CAN-Bus connections, electric steering360

Lithium Ion Battery Provision Option361

With Key Switch361

With Keypad362

Main Wire Harness ES 4000363

Main wire harness ET 4000364

Electric steering harness for ES 4000365

Electric steering harness for ET366

InfoLink® wire harness for ES/ET 4000367

Hydraulic Schematic368

Hydraulic Symbols368

ES 4000 with TT Mast372

ET 4000 with TF Mast373

ET 4000 with TL Mast374

IMAGES PREVIEW OF THE MANUAL: