$45

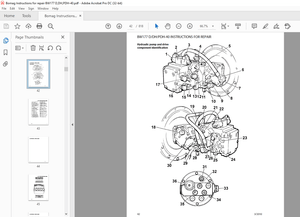

Crown Forklift ESR 1000 Series Service Manual - PDF DOWNLOAD

Crown Forklift ESR 1000 Series Service Manual - PDF DOWNLOAD

FILE DETAILS:

Crown Forklift ESR 1000 Series Service Manual - PDF DOWNLOAD

Language : English

Pages :1093

Downloadable : Yes

File Type : PDF

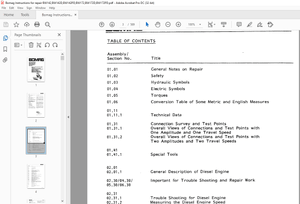

TABLE OF CONTENTS:

Crown Forklift ESR 1000 Series Service Manual - PDF DOWNLOAD

Introduction 0

Overview 1

General Information 1

Operator Information 1

How to Use This Manual 1

Model Number Information 6

Data Number Information 8

Capacity Plate and Serial Number Information 11

Global Contact Information 12

Safety 0

General Safety 1

Introduction 1

Safety Messages 1

Standards and Regulations 2

Environmental Protection 3

Organizational Requirements 3

General Maintenance 3

General Hot Work Instructions 4

Personal Protective Equipment (PPE) 4

Hazards From Stored Energy 5

Returning the Lift Truck to Service 5

Lift Truck Cleaning 5

Safe Battery Handling 5

Hydraulic System Safety 6

Safety Labels on the Lift Truck 6

Lifting Equipment 6

Cleaning the Lift Truck 7

Cleaning the Lift Truck 7

Preparing for Cleaning 7

General Cleaning 7

Steam Cleaning and Power Washing 8

Returning to Operation 8

Control of Hazardous Energy 10

Control of Hazardous Energy (Lockout/Tagout) 10

Lockout/Tagout Procedures 10

Tagout Procedure 11

Lockout Procedure with the Battery Installed 11

Lockout Procedure Without the Battery Installed 11

Preparing the Lift Truck for Maintenance 11

Battery 12

Battery Care 12

Preparing the Battery for Removal 12

Removing the Battery 13

Removal Procedure With a Battery Roller Stand 13

Removal Procedure With a Lifting Device 13

General Maintenance 0

Standard Torque Values 1

Lubricants 4

Handling of Static Sensitive Components 7

Slide Blocks 8

Theory of Operation 8

Theory of Operation 8

Disassembly 8

Inspecting the Slide Block Distance 8

Analyzing the Measurements 9

Measuring the Remaining Slide Block Height 10

Adjusting the Slide Block Distance 10

Assembly 12

Installing the Slide Block 12

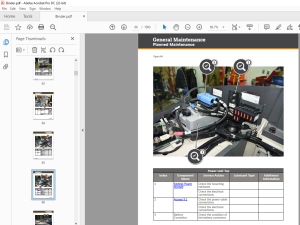

Planned Maintenance 13

Introduction 13

Guideline FEM 4004 13

Lubricants 13

Power Source 0

General Information 1

Componentry 0

5th Function Switch (ESR1060) 5

6th Function Switch (ESR1060) 6

A21 Fan 7

A31 Fan 8

Access 11 9

Access 12 10

Access 13 11

Access 21 12

Access 22 (ESR1060 -RX) 13

Electrical 0

Contactor 1

Theory of Operation 1

Theory of Operation 1

Tools and Equipment 1

Recommended Tools and Equipment 1

Additional Tools and Equipment 1

Disassembly 1

Preparing the Lift Truck for Maintenance 1

Removing the Line Contactor 2

Inspecting the Line Contactor 3

Assembly 3

Installing the Line Contactor 3

Preparing the Lift Truck for Operation 5

Troubleshooting 5

Troubleshooting 5

Emergency Disconnect Contactor 6

Theory of Operation 6

Theory of Operation 6

Tools and Equipment 6

Recommended Tools and Equipment 6

Additional Tools and Equipment 6

Disassembly 7

Preparing the Lift Truck for Maintenance 7

Removing the Emergency Disconnect Contactor 7

Assembly 8

Installing the Emergency Disconnect Contactor 8

Preparing the Lift Truck for Operation 10

Troubleshooting 10

Troubleshooting 10

Reach Sensor 11

Technician Tips 11

Technician Tips 11

Tools and Equipment 11

Recommended Tools and Equipment 11

Additional Tools and Equipment 11

Disassembly 11

Inspecting the Reach Sensor 11

Assembly 12

Reach Sensor Adjustment 12

Event Codes 0

Introduction 1

Event Codes 9

000002006 10

000002058 10

000003006 11

000003058 11

000004000 12

000004003 12

000004004 13

000005000 13

Hydraulic 0

Theory of Operation 1

Motor - M21 2

Theory of Operation 2

Theory of Operation 2

Tools and Equipment 2

Recommended Tools and Equipment 2

Additional Tools and Equipment 2

Disassembly 3

Preparing the Lift Truck for Maintenance 3

Removing the Main Pump Motor 3

Inspecting the Main Pump Motor 5

Assembly 5

Installing the Main Pump Motor 5

Preparing the Lift Truck for Operation 8

Pump - Accessory 9

Tools and Equipment 9

Recommended Tools and Equipment 9

Additional Tools and Equipment 9

Disassembly 9

Preparing the Lift Truck for Maintenance 9

Removing the Accessory Pump 10

Inspecting the Accessory Pump 10

Assembly 10

Installing the Accessory Pump 10

Removing Air from the Circuit for the Accessory Pump 11

Preparing the Lift Truck for Operation 11

Pump - Main 13

Tools and Equipment 13

Recommended Tools and Equipment 13

Additional Tools and Equipment 13

Disassembly 13

Preparing the Lift Truck for Maintenance 13

Lifting Mechanism 0

Theory of Operation 1

Carriage - Fork 2

Tools and Equipment 2

Recommended Tools and Equipment 2

Additional Tools and Equipment 2

Disassembly 2

Preparing the Lift Truck for Maintenance 2

Removing the Fork Carriage 3

Inspecting the Fork Carriage 3

Assembly 4

Installing the Fork Carriage 4

Preparing the Lift Truck for Operation 4

Carriage - Mast 5

Theory of Operation 5

Theory of Operation 5

Tools and Equipment 5

Recommended Tools and Equipment 5

Additional Tools and Equipment 5

Disassembly 6

Preparing the Lift Truck for Maintenance 6

Removing the Free-Lift Switch 6

Removing the Mast Carriage 8

Inspecting the Mast Carriage 8

Assembly 8

Installing the Mast Carriage 8

Installing the Free-Lift Switch 9

Troubleshooting 10

Troubleshooting 10

Control Cable 11

Technician Tips 11

Technician Tips 11

Tools and Equipment 11

Recommended Tools and Equipment 11

Additional Tools and Equipment 11

Disassembly 12

Preparing the Lift Truck for Maintenance 12

Removing the Mast Control Cable 12

Power Unit 0

Cab 1

Technician Tips 1

Technician Tips 1

Tools and Equipment 1

Recommended Tools and Equipment 1

Additional Tools and Equipment 1

Cab Heater and Filter Element 2

Disassembly 2

Preparing the Lift Truck for Maintenance 2

Removing the Cab Heater Filter Element 2

Inspecting the Cab Heater Filter Element 3

Assembly 4

Installing the Cab Heater Filter Element 4

Preparing the Lift Truck for Operation 5

Cab Window 5

Disassembly 5

Preparing the Lift Truck for Maintenance 5

Removing the Cab Window 5

Assembly 6

Installing the Cab Window 6

Preparing the Lift Truck for Operation 8

Polycarbonate Door Window 8

Disassembly 8

Preparing the Lift Truck for Maintenance 8

Removing the Polycarbonate Door Window 9

Assembly 9

Installing the Polycarbonate Door Window 9

Preparing the Lift Truck for Operation 11

Cab Fuses 11

Disassembly 11

Improved Fuse Holder on the Control Board 11

Access to the Fuses 11

Assignment of the Fuses in the Overhead Console to the Power Circuits 12

Assembly 12

Installing the Fuse Cover 12

Steering 0

Theory of Operation 1

Motor - M51 and Gearbox Assembly 3

Tools and Equipment 3

Recommended Tools and Equipment 3

Additional Tools and Equipment 3

Disassembly 3

Preparing the Lift Truck for Maintenance 3

Removing the Steer Motor and Gearbox Assembly 4

Removing M51 Sensor 1 and M51 Sensor 2 5

Disassembling the Steer Motor and the Gearbox Assembly 5

Inspecting the Steer Motor and the Gearbox Assembly 6

Assembly 6

Assembling the Steer Motor and Gearbox Assembly 6

Installing M51 Sensor 1 and M51 Sensor 2 8

Installing the Steer Motor and Gearbox Assembly 9

Preparing the Lift Truck for Operation 10

Troubleshooting 10

Troubleshooting 10

Steering Sensor 11

Tools and Equipment 11

Recommended Tools and Equipment 11

Additional Tools and Equipment 11

Disassembly 11

Preparing the Lift Truck for Maintenance 11

Removing Steering Sensor 1 or Steering Sensor 2 12

Assembly 12

Adjusting the Steering Sensor 1 or Steering Sensor 2 12

Installing Steering Sensor 1 or Steering Sensor 2 13

User Interface 0

Software Installation 1

System Interaction 1

Software Installation - Serial Number Search 1

After Software Installation 3

Start up Process for Trucks not connected to InfoLink 4

System Interaction 4

Start up Process for Trucks not connected to InfoLink® 4

Parameterization of the Steering Motor 6

System Interaction 6

Parameterization of the Steer Motor 6

Display Overview 7

Touchscreen 7

Dashboard 7

Turning on the Lift Truck 8

System Interaction 8

InfoLink® or Login Required is Enabled 8

InfoLink® or Login Required Is Disabled 9

Main Menu Overview 12

Main Menu Overview 12

Traction and Brake 0

Brake - Load Wheel 1

Technician Tips 1

Technician Tips 1

Tools and Equipment 1

Recommended Tools and Equipment 1

Additional Tools and Equipment 2

Disassembly 2

Preparing the Lift Truck for Maintenance 2

Removing the Brake Linings 3

Removing the Load Wheel Brake Cylinder 3

Inspecting the Brake Linings 4

Assembly 5

Installing the Load Wheel Brake Cylinder 5

Installing the Brake Linings 6

Bleeding the Load Wheel Brake 8

Adding Brake Fluid 9

Replacing the Brake Fluid 10

Adjusting the Hydraulic Brake Pedal Clearance 12

Adjusting the Electric Brake Pedal Clearance 13

Diagrams 0

Introduction 1

Introduction 1

Schematics 1

Pictorials 1

Components 1

Connectors 1

Wiring 1

Wire Numbers and Colors 2

Reference Designators 2

Introduction 0

Overview 1

General Information 1

Operator Information 1

How to Use This Manual 1

Model Number Information 6

Data Number Information 8

Capacity Plate and Serial Number Information 11

Global Contact Information 12

Safety 0

General Safety 1

Introduction 1

Safety Messages 1

Standards and Regulations 2

Environmental Protection 3

Organizational Requirements 3

General Maintenance 3

General Hot Work Instructions 4

Personal Protective Equipment (PPE) 4

Hazards From Stored Energy 5

Returning the Lift Truck to Service 5

Lift Truck Cleaning 5

Safe Battery Handling 5

Hydraulic System Safety 6

Safety Labels on the Lift Truck 6

Lifting Equipment 6

Cleaning the Lift Truck 7

Cleaning the Lift Truck 7

Preparing for Cleaning 7

General Cleaning 7

Steam Cleaning and Power Washing 8

Returning to Operation 8

Control of Hazardous Energy 10

Control of Hazardous Energy (Lockout/Tagout) 10

Lockout/Tagout Procedures 10

Tagout Procedure 11

Lockout Procedure with the Battery Installed 11

Lockout Procedure Without the Battery Installed 11

Preparing the Lift Truck for Maintenance 11

Battery 12

Battery Care 12

Preparing the Battery for Removal 12

Removing the Battery 13

Removal Procedure With a Battery Roller Stand 13

Removal Procedure With a Lifting Device 13

Installing the Battery 14

Installation Procedure With a Battery Roller Stand 14

Installation Procedure With a Lifting Device 14

Securing the Battery in the Lift Truck 14

Discharging the Capacitors 15

General Hot Work Instructions 16

Releasing the Hydraulic Pressure 17

Parking Brake 17

Releasing the Parking Brake 17

Applying the Parking Brake 18

Towing the Lift Truck 18

Preparing for Towing the Lift Truck 19

Towing the Lift Truck by Lifting and Pulling in the Power Unit First Direction 19

Towing the Lift Truck by Pulling in the Forks First Direction 20

Lifting and Blocking 21

Lifting and Blocking the Outriggers 21

Lifting and Blocking the Power Unit 21

Blocking the Masts 22

Securing the Fork Carriage 23

Blocking the Reach Mechanism 23

Preparing the Mast for Removal 24

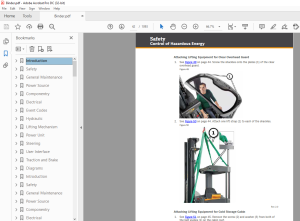

Lifting the Lift Truck 25

Lifting the Lift Truck 25

Preparing for Lifting the Lift Truck 25

Attaching the Lifting Equipment to the Overhead Guard 26

Attaching Lifting Equipment for Standard Overhead Guard 26

Attaching Lifting Equipment for Clear Overhead Guard 27

Attaching Lifting Equipment for Cold Storage Cabin 27

Completing Preparation for Lifting the Lift Truck 28

Transporting the Lift Truck 30

Securing a Lift Truck on a Loading Surface for Transport 30

Securing the Mast to a Loading Surface for Transport 31

General Maintenance 0

Standard Torque Values 1

Lubricants 4

Handling of Static Sensitive Components 7

Slide Blocks 8

Theory of Operation 8

Theory of Operation 8

Disassembly 8

Inspecting the Slide Block Distance 8

Analyzing the Measurements 9

Measuring the Remaining Slide Block Height 10

Adjusting the Slide Block Distance 10

Assembly 12

Installing the Slide Block 12

Planned Maintenance 13

Introduction 13

Guideline FEM 4004 13

Lubricants 13

Icons 14

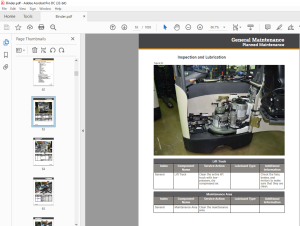

Visual Inspection 14

Operational Check and Test Drive 15

Preparing the Lift Truck for Maintenance 15

Inspection and Lubrication 16

Power Source 0

General Information 1

Componentry 0

5th Function Switch (ESR1060) 5

6th Function Switch (ESR1060) 6

A21 Fan 7

A31 Fan 8

Access 11 9

Access 12 10

Access 13 11

Access 21 12

Access 22 (ESR1060 -RX) 13

Access 31 14

Access 41 15

Access 51 16

Accessory Pump (ESR1060 -RX) 17

Accessory Pump Motor (ESR1060 -RX) 18

19

Adjustment Valve Lowering Speed 20

Auto Height Select Switch 22

Battery Latch Switch 23

Brake Fluid Switch 24

Brake Potentiometer 25

Brake Pressure Switch 26

Camera Switch 27

CAN Card 28

Card Reader 29

Emergency Disconnect Contactor 30

Emergency Disconnect Switch 1 31

Electrical 0

Contactor 1

Theory of Operation 1

Theory of Operation 1

Tools and Equipment 1

Recommended Tools and Equipment 1

Additional Tools and Equipment 1

Disassembly 1

Preparing the Lift Truck for Maintenance 1

Removing the Line Contactor 2

Inspecting the Line Contactor 3

Assembly 3

Installing the Line Contactor 3

Preparing the Lift Truck for Operation 5

Troubleshooting 5

Troubleshooting 5

Emergency Disconnect Contactor 6

Theory of Operation 6

Theory of Operation 6

Tools and Equipment 6

Recommended Tools and Equipment 6

Additional Tools and Equipment 6

Disassembly 7

Preparing the Lift Truck for Maintenance 7

Removing the Emergency Disconnect Contactor 7

Assembly 8

Installing the Emergency Disconnect Contactor 8

Preparing the Lift Truck for Operation 10

Troubleshooting 10

Troubleshooting 10

Reach Sensor 11

Technician Tips 11

Technician Tips 11

Tools and Equipment 11

Recommended Tools and Equipment 11

Additional Tools and Equipment 11

Disassembly 11

Inspecting the Reach Sensor 11

Assembly 12

Reach Sensor Adjustment 12

Event Codes 0

Introduction

Hydraulic 0

Theory of Operation 1

Motor - M21 2

Theory of Operation 2

Theory of Operation 2

Tools and Equipment 2

Recommended Tools and Equipment 2

Additional Tools and Equipment 2

Disassembly 3

Preparing the Lift Truck for Maintenance 3

Removing the Main Pump Motor 3

Inspecting the Main Pump Motor 5

Assembly 5

Installing the Main Pump Motor 5

Preparing the Lift Truck for Operation 8

Pump - Accessory 9

Tools and Equipment 9

Recommended Tools and Equipment 9

Additional Tools and Equipment 9

Disassembly 9

Preparing the Lift Truck for Maintenance 9

Removing the Accessory Pump 10

Inspecting the Accessory Pump 10

Assembly 10

Installing the Accessory Pump 10

Removing Air from the Circuit for the Accessory Pump 11

Preparing the Lift Truck for Operation 11

Pump - Main 13

Tools and Equipment 13

Recommended Tools and Equipment 13

Additional Tools and Equipment 13

Disassembly 13

Preparing the Lift Truck for Maintenance 13

Removing the Main Pump 14

Inspecting the Main Pump 14

Assembly 15

Installing the Main Pump 15

Priming the Main Pump 16

Preparing the Lift Truck for Operation 16

Manifold - Main 18

Checking the 18

System 20

Functional Descriptions (ESR-F) 20

Lifting 20

Lowering 21

Extending the Reach Mechanism 23

Retracting the Reach Mechanism 25

Tilting the Fork Up 26

Tilting the Fork Down 28

Sideshift Right 29

Sideshift Left 31

Lifting Mechanism 0

Theory of Operation 1

Carriage - Fork 2

Tools and Equipment 2

Recommended Tools and Equipment 2

Additional Tools and Equipment 2

Disassembly 2

Preparing the Lift Truck for Maintenance 2

Removing the Fork Carriage 3

Inspecting the Fork Carriage 3

Assembly 4

Installing the Fork Carriage 4

Preparing the Lift Truck for Operation 4

Carriage - Mast 5

Theory of Operation 5

Theory of Operation 5

Tools and Equipment 5

Recommended Tools and Equipment 5

Additional Tools and Equipment 5

Disassembly 6

Preparing the Lift Truck for Maintenance 6

Removing the Free-Lift Switch 6

Removing the Mast Carriage 8

Inspecting the Mast Carriage 8

Assembly 8

Installing the Mast Carriage 8

Installing the Free-Lift Switch 9

Troubleshooting 10

Troubleshooting 10

Control Cable 11

Technician Tips 11

Technician Tips 11

Tools and Equipment 11

Recommended Tools and Equipment 11

Additional Tools and Equipment 11

Disassembly 12

Preparing the Lift Truck for Maintenance 12

Removing the Mast Control Cable 12

Removing the Fork Carriage Control Cable 15

Removing the Camera Control Cable 18

Inspecting the Control Cables 21

Assembly 21

Installing the Camera Control Cable 21

Installing the Fork Carriage Control Cable 24

Installing the Mast Control Cable 27

Adjusting the Tension 30

Preparing the Lift Truck for Operation 30

Troubleshooting 30

Troubleshooting 30

Cylinder - Primary 31

Technician Tips 31

Technician Tips 31

Theory of Operation 31

Theory of Operation 31

Tools and Equipment 31

Recommended Tools and Equipment 31

Power Unit 0

Cab 1

Technician Tips 1

Technician Tips 1

Tools and Equipment 1

Recommended Tools and Equipment 1

Additional Tools and Equipment 1

Cab Heater and Filter Element 2

Disassembly 2

Preparing the Lift Truck for Maintenance 2

Removing the Cab Heater Filter Element 2

Inspecting the Cab Heater Filter Element 3

Assembly 4

Installing the Cab Heater Filter Element 4

Preparing the Lift Truck for Operation 5

Cab Window 5

Disassembly 5

Preparing the Lift Truck for Maintenance 5

Removing the Cab Window 5

Assembly 6

Installing the Cab Window 6

Preparing the Lift Truck for Operation 8

Polycarbonate Door Window 8

Disassembly 8

Preparing the Lift Truck for Maintenance 8

Removing the Polycarbonate Door Window 9

Assembly 9

Installing the Polycarbonate Door Window 9

Preparing the Lift Truck for Operation 11

Cab Fuses 11

Disassembly 11

Improved Fuse Holder on the Control Board 11

Access to the Fuses 11

Assignment of the Fuses in the Overhead Console to the Power Circuits 12

Assembly 12

Installing the Fuse Cover 12

Load Wheel 14

Theory of Operation 14

Theory of Operation 14

Tools and Equipment 14

Recommended Tools and Equipment 14

Additional Tools and Equipment 14

Load Wheel Attached with a Snap Ring 15

Disassembly 15

Preparing the Lift Truck for Maintenance 15

Removing a Load Wheel Attached with a Snap Ring 15

Inspecting the Load Wheel 15

Assembly 16

Installing a Load Wheel Attached with a Snap Ring 16

Preparing the Lift Truck for Operation 16

Load Wheel Attached with a Nut 16

Disassembly 16

Preparing the Lift Truck for Maintenance 16

Removing a Load Wheel Attached with a Nut 17

Inspecting the Load Wheel 18

Assembly 18

Installing a Load Wheel Attached with a Nut 18

Preparing the Lift Truck for Operation 19

Steering 0

Theory of Operation 1

Motor - M51 and Gearbox Assembly 3

Tools and Equipment 3

Recommended Tools and Equipment 3

Additional Tools and Equipment 3

Disassembly 3

Preparing the Lift Truck for Maintenance 3

Removing the Steer Motor and Gearbox Assembly 4

Removing M51 Sensor 1 and M51 Sensor 2 5

Disassembling the Steer Motor and the Gearbox Assembly 5

Inspecting the Steer Motor and the Gearbox Assembly 6

Assembly 6

Assembling the Steer Motor and Gearbox Assembly 6

Installing M51 Sensor 1 and M51 Sensor 2 8

Installing the Steer Motor and Gearbox Assembly 9

Preparing the Lift Truck for Operation 10

Troubleshooting 10

Troubleshooting 10

Steering Sensor 11

Tools and Equipment 11

Recommended Tools and Equipment 11

Additional Tools and Equipment 11

Disassembly 11

Preparing the Lift Truck for Maintenance 11

Removing Steering Sensor 1 or Steering Sensor 2 12

Assembly 12

Adjusting the Steering Sensor 1 or Steering Sensor 2 12

Installing Steering Sensor 1 or Steering Sensor 2 13

Preparing the Lift Truck for Operation 14

Steering Wheel 15

Technician Tips 15

Technician Tips 15

Theory of Operation 15

Theory of Operation 15

Tools and Equipment 15

Recommended Tools and Equipment 15

Additional Tools and Equipment 15

Disassembly 16

Preparing the Lift Truck for Maintenance 16

Removing the Steering Wheel 16

Inspecting the Steering Wheel 18

Assembly 18

Installing the Steering Wheel 18

Preparing the Lift Truck for Operation 19

Troubleshooting 20

Troubleshooting 20

User Interface 0

Software Installation 1

System Interaction 1

Software Installation - Serial Number Search 1

After Software Installation 3

Start up Process for Trucks not connected to InfoLink 4

System Interaction 4

Start up Process for Trucks not connected to InfoLink® 4

Parameterization of the Steering Motor 6

System Interaction 6

Parameterization of the Steer Motor 6

Display Overview 7

Touchscreen 7

Dashboard 7

Turning on the Lift Truck 8

System Interaction 8

InfoLink® or Login Required is Enabled 8

InfoLink® or Login Required Is Disabled 9

Main Menu Overview 12

Main Menu Overview 12

Menu Structure 14

Introduction 14

Adjusting the Settings 16

Menus 16

Traction and Brake 0

Brake - Load Wheel 1

Technician Tips 1

Technician Tips 1

Tools and Equipment 1

Recommended Tools and Equipment 1

Additional Tools and Equipment 2

Disassembly 2

Preparing the Lift Truck for Maintenance 2

Removing the Brake Linings 3

Removing the Load Wheel Brake Cylinder 3

Inspecting the Brake Linings 4

Assembly 5

Installing the Load Wheel Brake Cylinder 5

Installing the Brake Linings 6

Bleeding the Load Wheel Brake 8

Adding Brake Fluid 9

Replacing the Brake Fluid 10

Adjusting the Hydraulic Brake Pedal Clearance 12

Adjusting the Electric Brake Pedal Clearance 13

Preparing the Stopping Distance Test Route 14

Testing the Stopping Distance 14

Preparing the Lift Truck for Operation 15

Troubleshooting 16

Troubleshooting 16

Brake - M31 17

Theory of Operation 17

Theory of Operation 17

Tools and Equipment 17

Recommended Tools and Equipment 17

Additional Tools and Equipment 17

Disassembly 17

Preparing the Lift Truck for Maintenance 17

Removing the M31 Traction Brake 18

Disassembling the M31 Traction Brake 19

Inspecting the M31 Traction Brake 19

Assembly 19

Assembling the M31 Traction Brake 19

Installing the M31 Traction Brake 20

Checking the Brake Torque 21

Checking and Adjusting the Air Gap 22

Preparing the Lift Truck for Operation 22

Troubleshooting 23

Troubleshooting 23

Drive Tire 24

Tools and Equipment 24

Recommended Tools and Equipment 24

Additional Tools and Equipment 24

Disassembly 24

Preparing the Lift Truck for Maintenance 24

Removing the Drive Tire 25

Inspecting the Drive Tire 25

Assembly 25

Installing the Drive Tire 25

Preparing the Lift Truck for Operation 26

Drive Unit 27

Tools and Equipment 27

Recommended Tools and Equipment 27

Additional Tools and Equipment 27

Disassembly 27

Preparing the Lift Truck for Maintenance 27

Removing the Drive Unit 28

Inspecting the Drive Unit 28

Assembly 29

Installing the Drive Unit 29

Preparing the Lift Truck for Operation 29

Troubleshooting 30

Troubleshooting 30

Pinion Repair Set 31

Theory of Operation 31

Theory of Operation 31

Tools and Equipment 31

Recommended Tools and Equipment 31

Additional Tools and Equipment 31

Disassembly 31

Inspecting the Gearbox Pinion 31

Diagrams 0

Introduction 1

Introduction 1

Schematics 1

Pictorials 1

Components 1

Connectors 1

Wiring 1

Wire Numbers and Colors 2

Reference Designators 2

Diagram Key 14

Main Harness and Connector Figure 17

Pictorials - Electrical 19

Pictorials - Electrical (ESR1020 -F and ESR1040 -F) 19

Introduction 0

Overview 1

General Information 1

Operator Information 1

How to Use This Manual 1

Model Number Information 6

Data Number Information 8

Capacity Plate and Serial Number Information 11

Global Contact Information 12

Safety 0

General Safety 1

Introduction 1

Safety Messages 1

Standards and Regulations 2

Environmental Protection 3

Organizational Requirements 3

General Maintenance 3

General Hot Work Instructions 4

Personal Protective Equipment (PPE) 4

Hazards From Stored Energy 5

Returning the Lift Truck to Service 5

Lift Truck Cleaning 5

Safe Battery Handling 5

Hydraulic System Safety 6

Safety Labels on the Lift Truck 6

Lifting Equipment 6

Cleaning the Lift Truck 7

Cleaning the Lift Truck 7

Preparing for Cleaning 7

General Cleaning 7

Steam Cleaning and Power Washing 8

Returning to Operation 8

Control of Hazardous Energy 10

Control of Hazardous Energy (Lockout/Tagout) 10

Lockout/Tagout Procedures 10

Tagout Procedure 11

Lockout Procedure with the Battery Installed 11

Lockout Procedure Without the Battery Installed 11

Preparing the Lift Truck for Maintenance 11

Battery 12

Battery Care 12

Preparing the Battery for Removal 12

Removing the Battery 13

Removal Procedure With a Battery Roller Stand 13

Removal Procedure With a Lifting Device 13

Installing the Battery 14

Installation Procedure With a Battery Roller Stand 14

Installation Procedure With a Lifting Device 14

Securing the Battery in the Lift Truck 14

Discharging the Capacitors 15

General Hot Work Instructions 16

Releasing the Hydraulic Pressure 17

Parking Brake 17

Releasing the Parking Brake 17

Applying the Parking Brake 18

Towing the Lift Truck 18

Preparing for Towing the Lift Truck 19

Towing the Lift Truck by Lifting and Pulling in the Power Unit First Direction 19

Towing the Lift Truck by Pulling in the Forks First Direction 20

Lifting and Blocking 21

Lifting and Blocking the Outriggers 21

Lifting and Blocking the Power Unit 21

Blocking the Masts 22

Securing the Fork Carriage 23

Blocking the Reach Mechanism 23

Preparing the Mast for Removal 24

Lifting the Lift Truck 25

Lifting the Lift Truck 25

Preparing for Lifting the Lift Truck 25

Attaching the Lifting Equipment to the Overhead Guard 26

Attaching Lifting Equipment for Standard Overhead Guard 26

Attaching Lifting Equipment for Clear Overhead Guard 27

Attaching Lifting Equipment for Cold Storage Cabin 27

Completing Preparation for Lifting the Lift Truck 28

Transporting the Lift Truck 30

Securing a Lift Truck on a Loading Surface for Transport 30

Securing the Mast to a Loading Surface for Transport 31

General Maintenance 0

Standard Torque Values 1

Lubricants 4

Handling of Static Sensitive Components 7

Slide Blocks 8

Theory of Operation 8

Theory of Operation 8

Disassembly 8

Inspecting the Slide Block Distance 8

Analyzing the Measurements 9

Measuring the Remaining Slide Block Height 10

Adjusting the Slide Block Distance 10

Assembly 12

Installing the Slide Block 12

Planned Maintenance 13

Introduction 13

Guideline FEM 4004 13

Lubricants 13

Icons 14

Visual Inspection 14

Operational Check and Test Drive 15

Preparing the Lift Truck for Maintenance 15

Inspection and Lubrication 16

Preparing the Lift Truck for Operation110

Final Operational Check and Test Drive110

Planned Maintenance Completion110

Power Source 0

General Information 1

Componentry 0

5th Function Switch (ESR1060) 5

6th Function Switch (ESR1060) 6

A21 Fan 7

A31 Fan 8

Access 11 9

Access 12 10

Access 13 11

Access 21 12

Access 22 (ESR1060 -RX) 13

Access 31 14

Access 41 15

Access 51 16

Accessory Pump (ESR1060 -RX) 17

Accessory Pump Motor (ESR1060 -RX) 18

19

Adjustment Valve Lowering Speed 20

Auto Height Select Switch 22

Battery Latch Switch 23

Brake Fluid Switch 24

Brake Potentiometer 25

Brake Pressure Switch 26

Camera Switch 27

CAN Card 28

Card Reader 29

Emergency Disconnect Contactor 30

Emergency Disconnect Switch 1 31

Emergency Disconnect Switch 2 32

Xpress Lower Proportional Valve 1 (ESR1060 -RX) 33

Xpress Lower Proportional Valve 2 (ESR1060 -RX) 34

Xpress Lower Proportional Valve 3 (ESR1060 -RX) 35

Forks First Switch 36

Free-Lift Switch 37

Fuse 1 39

Fuse 2 41

Fuse 3 43

Fuse 4 44

Fuse 5 45

Fuse 6 46

Fuse 7 47

Fuse 8 48

Fuse 9 49

Fuse 10 50

Fuse 11 (ESR1060 -RX) 51

Height Encoder 1 52

Height Encoder 2 53

Height Reset Switch 1 54

Height Reset Switch 2 55

Hoist Solenoid Valve 56

Horn 58

Horn Switch 59

Impact Sensor 60

Key Switch 61

Keyless Power Module 62

Left Accessory Proportional Valve 63

Left Accessory Solenoid Valve (ESR1060 -RX) 64

Main Pump 65

Line Contactor 66

Load Sensor 1 67

Load Sensor 2 68

Lower Proportional Valve 69

Lower Solenoid Valve (ESR1060 -RX) 71

M21 Encoder 72

M21 Fan (ESR1060) 73

M21 Thermal Sensor 74

M22 Encoder (ESR1060 -RX) 75

M22 Thermal Sensor (ESR1060 -RX) 76

M31 Encoder 77

M31 Fan (ESR1060) 78

M31 Thermal Sensor 79

M31 Traction Brake 80

M51 Sensor 1 81

M51 Sensor 2 82

M51 Thermal Sensor 83

Main Hoist Sensor 84

Main Pump Motor 86

Manual Lowering Valve 88

Override Switch 90

Power Unit First Switch 91

Reach Position Sensor 1 92

Reach Position Sensor 2 93

Reach Proportional Valve 94

Reach Sensor 96

Reach Solenoid Valve (ESR1060 -RX) 98

Relay 1 99

Relay 2100

Relay 3101

Relay 4102

Relay 5103

Relay 6104

Relay 9105

Relay 10106

Relay 22107

Relay 23108

Relief Valve 1109

Electrical 0

Contactor 1

Theory of Operation 1

Theory of Operation 1

Tools and Equipment 1

Recommended Tools and Equipment 1

Additional Tools and Equipment 1

Disassembly 1

Preparing the Lift Truck for Maintenance 1

Removing the Line Contactor 2

Inspecting the Line Contactor 3

Assembly 3

Installing the Line Contactor 3

Preparing the Lift Truck for Operation 5

Troubleshooting 5

Troubleshooting 5

Emergency Disconnect Contactor 6

Theory of Operation 6

Theory of Operation 6

Tools and Equipment 6

Recommended Tools and Equipment 6

Additional Tools and Equipment 6

Disassembly 7

Preparing the Lift Truck for Maintenance 7

Removing the Emergency Disconnect Contactor 7

Assembly 8

Installing the Emergency Disconnect Contactor 8

Preparing the Lift Truck for Operation 10

Troubleshooting 10

Troubleshooting 10

Reach Sensor 11

Technician Tips 11

Technician Tips 11

Tools and Equipment 11

Recommended Tools and Equipment 11

Additional Tools and Equipment 11

Disassembly 11

Inspecting the Reach Sensor 11

Assembly 12

Reach Sensor Adjustment 12

Event Codes 0

Introduction 1

Event Codes 9

Hydraulic 0

Theory of Operation 1

Motor - M21 2

Theory of Operation 2

Theory of Operation 2

Tools and Equipment 2

Recommended Tools and Equipment 2

Additional Tools and Equipment 2

Disassembly 3

Preparing the Lift Truck for Maintenance 3

Removing the Main Pump Motor 3

Inspecting the Main Pump Motor 5

Assembly 5

Installing the Main Pump Motor 5

Preparing the Lift Truck for Operation 8

Pump - Accessory 9

Tools and Equipment 9

Recommended Tools and Equipment 9

Additional Tools and Equipment 9

Disassembly 9

Preparing the Lift Truck for Maintenance 9

Removing the Accessory Pump 10

Inspecting the Accessory Pump 10

Assembly 10

Installing the Accessory Pump 10

Removing Air from the Circuit for the Accessory Pump 11

Preparing the Lift Truck for Operation 11

Pump - Main 13

Tools and Equipment 13

Recommended Tools and Equipment 13

Additional Tools and Equipment 13

Disassembly 13

Preparing the Lift Truck for Maintenance 13

Removing the Main Pump 14

Inspecting the Main Pump 14

Assembly 15

Installing the Main Pump 15

Priming the Main Pump 16

Preparing the Lift Truck for Operation 16

Manifold - Main 18

Checking the 18

System 20

Functional Descriptions (ESR-F) 20

Lifting 20

Lowering 21

Extending the Reach Mechanism 23

Retracting the Reach Mechanism 25

Tilting the Fork Up 26

Tilting the Fork Down 28

Sideshift Right 29

Sideshift Left 31

5th Function A 32

5th Function B 33

Functional Descriptions (ESR-T) 35

Lifting 35

Lowering 36

Extending the Reach Mechanism 38

Retracting the Reach Mechanism 39

Tilting the Mast Towards the Operator 41

Tilting the Mast in the Direction of the Forks 42

Sideshift Right 43

Sideshift Left 45

Functional Descriptions (ESR-RX) 46

Lifting 46

Regenerative Lowering 47

Extending the Reach Mechanism 48

Retracting the Reach Mechanism 49

Tilting the Fork Up 50

Tilting the Fork Down 52

Sideshift Right 53

Sideshift Left 55

5th Function A 56

5th Function B 58

Drift Tests 59

Preparing the Lift Truck for Maintenance 59

Drift Tests 59

Recommended Tools and Equipment 59

Additional Tools and Equipment 60

Requirements 60

Performing a Drift Test on the Primary and Secondary Cylinders 60

Performing a Drift Test on the Tilt Cylinder 61

Checking and Adjusting the Relief Valve 1 62

Preparing the Lift Truck for Operation 63

Lifting Mechanism 0

Theory of Operation 1

Carriage - Fork 2

Tools and Equipment 2

Recommended Tools and Equipment 2

Additional Tools and Equipment 2

Disassembly 2

Preparing the Lift Truck for Maintenance 2

Removing the Fork Carriage 3

Inspecting the Fork Carriage 3

Assembly 4

Installing the Fork Carriage 4

Preparing the Lift Truck for Operation 4

Carriage - Mast 5

Theory of Operation 5

Theory of Operation 5

Tools and Equipment 5

Recommended Tools and Equipment 5

Additional Tools and Equipment 5

Disassembly 6

Preparing the Lift Truck for Maintenance 6

Removing the Free-Lift Switch 6

Removing the Mast Carriage 8

Inspecting the Mast Carriage 8

Assembly 8

Installing the Mast Carriage 8

Installing the Free-Lift Switch 9

Troubleshooting 10

Troubleshooting 10

Control Cable 11

Technician Tips 11

Technician Tips 11

Tools and Equipment 11

Recommended Tools and Equipment 11

Additional Tools and Equipment 11

Disassembly 12

Preparing the Lift Truck for Maintenance 12

Removing the Mast Control Cable 12

Removing the Fork Carriage Control Cable 15

Removing the Camera Control Cable 18

Inspecting the Control Cables 21

Assembly 21

Installing the Camera Control Cable 21

Installing the Fork Carriage Control Cable 24

Installing the Mast Control Cable 27

Adjusting the Tension 30

Preparing the Lift Truck for Operation 30

Troubleshooting 30

Troubleshooting 30

Cylinder - Primary 31

Technician Tips 31

Technician Tips 31

Theory of Operation 31

Theory of Operation 31

Tools and Equipment 31

Recommended Tools and Equipment 31

Additional Tools and Equipment 32

Small Hook Tool 32

Disassembly 32

Preparing the Lift Truck for Maintenance 32

Removing the Primary Cylinder 33

Disassembling the Primary Cylinder 34

Inspecting the Primary Cylinder 34

Assembly 35

Assembling the Primary Cylinder 35

Installing the Primary Cylinder 36

Bleeding the Cylinder 36

Testing the Cylinder Seal for Leaks 38

Preparing the Lift Truck for Operation 39

Cylinder - Reach 40

Tools and Equipment 40

Recommended Tools and Equipment 40

Additional Tools and Equipment 40

Disassembly 41

Preparing the Lift Truck for Maintenance 41

Removing the Reach Cylinder 41

Disassembling the Reach Cylinder 43

Inspecting the Reach Cylinder 44

Assembly 44

Assembling the Reach Cylinder 44

Installing the Reach Cylinder 45

Bleeding the Reach Cylinder 45

Preparing the Lift Truck for Operation 45

Testing the Cylinder Seal for Leaks 46

Troubleshooting 47

Troubleshooting 47

Cylinder - Secondary 48

Tools and Equipment 48

Recommended Tools and Equipment 48

Additional Tools and Equipment 48

Disassembly 49

Preparing the Lift Truck for Maintenance 49

Removing the Secondary Cylinder from Masts with a Lift Height up to 8 m (315 in) 49

Removing the Secondary Cylinder from Masts with a Lift Height Greater Than 8 m (315 in) 52

Disassembling the Secondary Cylinder 55

Disassembling the Secondary Cylinder with Regen Lower and Xpress™ Lower Option 57

Inspecting the Secondary Cylinder 59

Assembly 59

Assembling the Secondary Cylinder 59

Assembling the Secondary Cylinder with Regen Lower and Xpress™ Lower Option 61

Installing the Secondary Cylinder on Masts with a Lift Height up to 8 m (315 in) 63

Installing the Secondary Cylinder on Masts with a Lift Height Greater than 8 m (315 in) 66

Bleeding the Secondary Cylinder 69

Preparing a Test Load 69

Secondary Cylinder Drift Test 69

Preparing the Lift Truck for Operation 70

Troubleshooting 71

Troubleshooting 71

Cylinder - Sideshift 72

Tools and Equipment 72

Recommended Tools and Equipment 72

Additional Tools and Equipment 72

Disassembly 73

Preparing the Lift Truck for Maintenance 73

Disassembling the Sideshift Cylinder 73

Inspecting the Sideshift Cylinder 74

Assembly 75

Assembling the Sideshift Cylinder 75

Bleeding the Sideshift Cylinder 76

Preparing the Lift Truck for Operation 76

Troubleshooting 76

Troubleshooting 76

Cylinder - Tilt 77

Theory of Operation 77

Theory of Operation 77

Tools and Equipment 77

Recommended Tools and Equipment 77

Additional Tools and Equipment 77

Disassembly 78

Preparing the Lift Truck for Maintenance 78

Removing the Tilt Cylinder 78

Inspecting the Tilt Cylinder 79

Assembly 80

Installing the Tilt Cylinder 80

Bleeding the Tilt Cylinder 81

Preparing the Lift Truck for Operation 81

Troubleshooting 81

Troubleshooting 81

Fork Inspection 82

Tools and Equipment 82

Recommended Tools and Equipment 82

Additional Tools and Equipment 82

Inspection 82

Preparing the Lift Truck for Maintenance 82

Introduction 83

Identification 84

Measuring the Fork Blade for Wear 84

Checking for Fatigue Cracks 86

Bent or Twisted Forks 86

Checking the Fork Tip for Straightness 87

Fork Locking Pin 88

Preparing the Lift Truck for Operation 88

Height Encoder 90

Tools and Equipment 90

Recommended Tools and Equipment 90

Disassembly 90

Preparing the Lift Truck for Maintenance 90

Removing Height Encoder 1 (ESR -F) 90

Removing Height Encoder 2 (ESR -F) 91

Assembly 92

Installing Height Encoder 1 (ESR -F) 92

Installing Height Encoder 2 (ESR -F) 92

Preparing the Lift Truck for Operation 93

Hydraulic Lines and Fittings 94

Technician Tips 94

Technician Tips 94

Lift Chains 95

Tools and Equipment 95

Recommended Tools and Equipment 95

Additional Tools and Equipment 95

Lift Chains - Primary Cylinder 95

Disassembly 95

Preparing the Lift Truck for Maintenance 95

Removing the Lift Chains from the Primary Cylinder 96

Inspecting the Lift Chains 96

Checking the Lift Chain Stretch 98

Assembly 99

Installing the Lift Chains on the Primary Cylinder 99

Inspecting the Fork Height101

Preparing the Lift Truck for Operation102

Lift Chains - Secondary Cylinder102

Disassembly102

Preparing the Lift Truck for Maintenance102

Removing the Lift Chains from the Secondary Cylinder102

Inspecting the Lift Chains103

Checking the Lift Chain Stretch105

Assembly106

Installing the Lift Chains on the Secondary Cylinder106

Inspecting the Fork Height108

Preparing the Lift Truck for Operation109

Mast110

Technician Tips110

Technician Tips110

Tools and Equipment110

Recommended Tools and Equipment110

Additional Tools and Equipment110

Power Unit 0

Cab 1

Technician Tips 1

Technician Tips 1

Tools and Equipment 1

Recommended Tools and Equipment 1

Additional Tools and Equipment 1

Cab Heater and Filter Element 2

Disassembly 2

Preparing the Lift Truck for Maintenance 2

Removing the Cab Heater Filter Element 2

Inspecting the Cab Heater Filter Element 3

Assembly 4

Installing the Cab Heater Filter Element 4

Preparing the Lift Truck for Operation 5

Cab Window 5

Disassembly 5

Preparing the Lift Truck for Maintenance 5

Removing the Cab Window 5

Assembly 6

Installing the Cab Window 6

Preparing the Lift Truck for Operation 8

Polycarbonate Door Window 8

Disassembly 8

Preparing the Lift Truck for Maintenance 8

Removing the Polycarbonate Door Window 9

Assembly 9

Installing the Polycarbonate Door Window 9

Preparing the Lift Truck for Operation 11

Cab Fuses 11

Disassembly 11

Improved Fuse Holder on the Control Board 11

Access to the Fuses 11

Assignment of the Fuses in the Overhead Console to the Power Circuits 12

Assembly 12

Installing the Fuse Cover 12

Load Wheel 14

Theory of Operation 14

Theory of Operation 14

Tools and Equipment 14

Recommended Tools and Equipment 14

Additional Tools and Equipment 14

Load Wheel Attached with a Snap Ring 15

Disassembly 15

Preparing the Lift Truck for Maintenance 15

Removing a Load Wheel Attached with a Snap Ring 15

Inspecting the Load Wheel 15

Assembly 16

Installing a Load Wheel Attached with a Snap Ring 16

Preparing the Lift Truck for Operation 16

Load Wheel Attached with a Nut 16

Disassembly 16

Preparing the Lift Truck for Maintenance 16

Removing a Load Wheel Attached with a Nut 17

Inspecting the Load Wheel 18

Assembly 18

Installing a Load Wheel Attached with a Nut 18

Preparing the Lift Truck for Operation 19

Steering 0

Theory of Operation 1

Motor - M51 and Gearbox Assembly 3

Tools and Equipment 3

Recommended Tools and Equipment 3

Additional Tools and Equipment 3

Disassembly 3

Preparing the Lift Truck for Maintenance 3

Removing the Steer Motor and Gearbox Assembly 4

Removing M51 Sensor 1 and M51 Sensor 2 5

Disassembling the Steer Motor and the Gearbox Assembly 5

Inspecting the Steer Motor and the Gearbox Assembly 6

Assembly 6

Assembling the Steer Motor and Gearbox Assembly 6

Installing M51 Sensor 1 and M51 Sensor 2 8

Installing the Steer Motor and Gearbox Assembly 9

Preparing the Lift Truck for Operation 10

Troubleshooting 10

Troubleshooting 10

Steering Sensor 11

Tools and Equipment 11

Recommended Tools and Equipment 11

Additional Tools and Equipment 11

Disassembly 11

Preparing the Lift Truck for Maintenance 11

Removing Steering Sensor 1 or Steering Sensor 2 12

Assembly 12

Adjusting the Steering Sensor 1 or Steering Sensor 2 12

Installing Steering Sensor 1 or Steering Sensor 2 13

Preparing the Lift Truck for Operation 14

Steering Wheel 15

Technician Tips 15

Technician Tips 15

Theory of Operation 15

Theory of Operation 15

Tools and Equipment 15

Recommended Tools and Equipment 15

Additional Tools and Equipment 15

Disassembly 16

Preparing the Lift Truck for Maintenance 16

Removing the Steering Wheel 16

Inspecting the Steering Wheel 18

Assembly 18

Installing the Steering Wheel 18

Preparing the Lift Truck for Operation 19

Troubleshooting 20

Troubleshooting 20

User Interface 0

Software Installation 1

System Interaction 1

Software Installation - Serial Number Search 1

After Software Installation 3

Start up Process for Trucks not connected to InfoLink 4

System Interaction 4

Start up Process for Trucks not connected to InfoLink® 4

Parameterization of the Steering Motor 6

System Interaction 6

Parameterization of the Steer Motor 6

Display Overview 7

Touchscreen 7

Dashboard 7

Turning on the Lift Truck 8

System Interaction 8

InfoLink® or Login Required is Enabled 8

InfoLink® or Login Required Is Disabled 9

Main Menu Overview 12

Main Menu Overview 12

Menu Structure 14

Introduction 14

Adjusting the Settings 16

Menus 16

Auto Height Select 34

Theory of Operation 34

Theory of Operation 34

System Interaction 34

System Interaction 34

Raise and Lower Cutouts 40

Theory of Operation 40

Theory of Operation 40

System Interaction 40

Raise and Lower Cutouts 40

5th and 6th Function 44

System Interaction 44

5th and 6th Function 44

User Performance 47

Theory of Operation 47

Theory of Operation 47

System Interaction 47

System Interaction 47

Performance Settings 50

System Interaction 50

Performance Settings 50

Performance Settings and Effects 54

Performance Settings and Effects 54

Operational Hours 76

System Interaction 76

Set the Operational Hours After Replacing the Access 41 76

Widgets 79

System Interaction 79

System Interaction 79

Widgets 80

Adding a Widget to the Home Screen 82

Traction and Brake 0

Brake - Load Wheel 1

Technician Tips 1

Technician Tips 1

Tools and Equipment 1

Recommended Tools and Equipment 1

Additional Tools and Equipment 2

Disassembly 2

Preparing the Lift Truck for Maintenance 2

Removing the Brake Linings 3

Removing the Load Wheel Brake Cylinder 3

Inspecting the Brake Linings 4

Assembly 5

Installing the Load Wheel Brake Cylinder 5

Installing the Brake Linings 6

Bleeding the Load Wheel Brake 8

Adding Brake Fluid 9

Replacing the Brake Fluid 10

Adjusting the Hydraulic Brake Pedal Clearance 12

Adjusting the Electric Brake Pedal Clearance 13

Preparing the Stopping Distance Test Route 14

Testing the Stopping Distance 14

Preparing the Lift Truck for Operation 15

Troubleshooting 16

Troubleshooting 16

Brake - M31 17

Theory of Operation 17

Theory of Operation 17

Tools and Equipment 17

Recommended Tools and Equipment 17

Additional Tools and Equipment 17

Disassembly 17

Preparing the Lift Truck for Maintenance 17

Removing the M31 Traction Brake 18

Disassembling the M31 Traction Brake 19

Inspecting the M31 Traction Brake 19

Assembly 19

Assembling the M31 Traction Brake 19

Installing the M31 Traction Brake 20

Checking the Brake Torque 21

Checking and Adjusting the Air Gap 22

Preparing the Lift Truck for Operation 22

Troubleshooting 23

Troubleshooting 23

Drive Tire 24

Tools and Equipment 24

Recommended Tools and Equipment 24

Additional Tools and Equipment 24

Disassembly 24

Preparing the Lift Truck for Maintenance 24

Removing the Drive Tire 25

Inspecting the Drive Tire 25

Assembly 25

Installing the Drive Tire 25

Preparing the Lift Truck for Operation 26

Drive Unit 27

Tools and Equipment 27

Recommended Tools and Equipment 27

Additional Tools and Equipment 27

Disassembly 27

Preparing the Lift Truck for Maintenance 27

Removing the Drive Unit 28

Inspecting the Drive Unit 28

Assembly 29

Installing the Drive Unit 29

Preparing the Lift Truck for Operation 29

Troubleshooting 30

Troubleshooting 30

Pinion Repair Set 31

Theory of Operation 31

Theory of Operation 31

Tools and Equipment 31

Recommended Tools and Equipment 31

Additional Tools and Equipment 31

Disassembly 31

Inspecting the Gearbox Pinion 31

Preparing the Lift Truck for Maintenance 32

Removing the Gearbox Pinion 33

Assembly 34

Installing the Gearbox Pinion 34

Preparing the Lift Truck for Operation 36

Rotor Repair Set 37

Theory of Operation 37

Theory of Operation 37

Tools and Equipment 37

Recommended Tools and Equipment 37

Disassembly 38

Inspecting the Rotor Teeth 38

Preparing the Lift Truck for Maintenance 38

Removing the Rotor 38

Assembly 42

Installing the Rotor 42

Preparing the Lift Truck for Operation 46

Motor - M31 47

Technician Tips 47

Technician Tips 47

Theory of Operation 47

Theory of Operation 47

Tools and Equipment 47

Recommended Tools and Equipment 47

Additional Tools and Equipment 48

Disassembly 48

Preparing the Lift Truck for Maintenance 48

Removing the Traction Motor 48

Disassembling the Traction Motor 49

Inspecting the Traction Motor 51

Assembly 51

Assembling the Traction Motor 51

Installing the Traction Motor 53

Preparing the Lift Truck for Operation 53

Troubleshooting 54

Troubleshooting 54

Diagrams 0

Introduction 1

Introduction 1

Schematics 1

Pictorials 1

Components 1

Connectors 1

Wiring 1

Wire Numbers and Colors 2

Reference Designators 2

Diagram Key 14

Main Harness and Connector Figure 17

Pictorials - Electrical 19

Pictorials - Electrical (ESR1020 -F and ESR1040 -F) 19

Pictorials - Electrical (ESR1020 -T and ESR1040 -T) 42

Pictorials - Electrical (ESR1060, Standard) 61

Pictorials - Electrical (ESR1060 -RX) 86

Schematics - Electrical110

Schematics - Electrical (ESR 1020/1040)110

Introduction 0

Overview 1

General Information 1

Operator Information 1

How to Use This Manual 1

Safety 0

General Safety 1

Introduction 1

Safety Messages 1

General Maintenance 0

Standard Torque Values 1

Power Source 0

General Information 1

Componentry 0

Electrical 0

Contactor 1

Theory of Operation 1

Theory of Operation 1

Tools and Equipment 1

Recommended Tools and Equipment 1

Additional Tools and Equipment 1

Disassembly 1

Preparing the Lift Truck for Maintenance 1

Event Codes 0

Introduction 1

Hydraulic 0

Theory of Operation 1

Lifting Mechanism 0

Theory of Operation 1

Power Unit 0

Cab 1

Technician Tips 1

Technician Tips 1

Tools and Equipment 1

Recommended Tools and Equipment 1

Additional Tools and Equipment 1

Steering 0

Theory of Operation 1

User Interface 0

Software Installation 1

System Interaction 1

Software Installation - Serial Number Search 1

Traction and Brake 0

Brake - Load Wheel 1

Technician Tips 1

Technician Tips 1

Tools and Equipment 1

Recommended Tools and Equipment 1

Diagrams 0

Introduction 1

Introduction 1

Schematics 1

Pictorials 1

Components 1

Connectors 1

Wiring 1

Introduction 0

Overview 1

General Information 1

Operator Information 1

How to Use This Manual 1

Model Number Information 6

Data Number Information 8

Capacity Plate and Serial Number Information 11

Global Contact Information 12

Safety 0

General Safety 1

Introduction 1

Safety Messages 1

Standards and Regulations 2

Environmental Protection 3

Organizational Requirements 3

General Maintenance 3

General Hot Work Instructions 4

Personal Protective Equipment (PPE) 4

Hazards From Stored Energy 5

Returning the Lift Truck to Service 5

Lift Truck Cleaning 5

Safe Battery Handling 5

Hydraulic System Safety 6

Safety Labels on the Lift Truck 6

Lifting Equipment 6

Cleaning the Lift Truck 7

Cleaning the Lift Truck 7

Preparing for Cleaning 7

General Cleaning 7

Steam Cleaning and Power Washing 8

Returning to Operation 8

Control of Hazardous Energy 10

Control of Hazardous Energy (Lockout/Tagout) 10

Lockout/Tagout Procedures 10

Tagout Procedure 11

Lockout Procedure with the Battery Installed 11

Lockout Procedure Without the Battery Installed 11

Preparing the Lift Truck for Maintenance 11

Battery 12

Battery Care 12

Preparing the Battery for Removal 12

Removing the Battery 13

Removal Procedure With a Battery Roller Stand 13

Removal Procedure With a Lifting Device 13

Installing the Battery 14

Installation Procedure With a Battery Roller Stand 14

Installation Procedure With a Lifting Device 14

Securing the Battery in the Lift Truck 14

Discharging the Capacitors 15

General Hot Work Instructions 16

Releasing the Hydraulic Pressure 17

Parking Brake 17

Releasing the Parking Brake 17

Applying the Parking Brake 18

Towing the Lift Truck 18

Preparing for Towing the Lift Truck 19

Towing the Lift Truck by Lifting and Pulling in the Power Unit First Direction 19

Towing the Lift Truck by Pulling in the Forks First Direction 20

Lifting and Blocking 21

Lifting and Blocking the Outriggers 21

Lifting and Blocking the Power Unit 21

Blocking the Masts 22

Securing the Fork Carriage 23

Blocking the Reach Mechanism 23

Preparing the Mast for Removal 24

Lifting the Lift Truck 25

Lifting the Lift Truck 25

Preparing for Lifting the Lift Truck 25

Attaching the Lifting Equipment to the Overhead Guard 26

Attaching Lifting Equipment for Standard Overhead Guard 26

Attaching Lifting Equipment for Clear Overhead Guard 27

Attaching Lifting Equipment for Cold Storage Cabin 27

Completing Preparation for Lifting the Lift Truck 28

Transporting the Lift Truck 30

Securing a Lift Truck on a Loading Surface for Transport 30

Securing the Mast to a Loading Surface for Transport 31

General Maintenance 0

Standard Torque Values 1

Lubricants 4

Handling of Static Sensitive Components 7

Slide Blocks 8

Theory of Operation 8

Theory of Operation 8

Disassembly 8

Inspecting the Slide Block Distance 8

Analyzing the Measurements 9

Measuring the Remaining Slide Block Height 10

Adjusting the Slide Block Distance 10

Assembly 12

Installing the Slide Block 12

Planned Maintenance 13

Introduction 13

Guideline FEM 4004 13

Lubricants 13

Icons 14

Visual Inspection 14

Operational Check and Test Drive 15

Preparing the Lift Truck for Maintenance 15

Inspection and Lubrication 16

Preparing the Lift Truck for Operation110

Final Operational Check and Test Drive110

Planned Maintenance Completion110

Power Source 0

General Information 1

Componentry 0

5th Function Switch (ESR1060) 5

6th Function Switch (ESR1060) 6

A21 Fan 7

A31 Fan 8

Access 11 9

Access 12 10

Access 13 11

Access 21 12

Access 22 (ESR1060 -RX) 13

Access 31 14

Access 41 15

Access 51 16

Accessory Pump (ESR1060 -RX) 17

Accessory Pump Motor (ESR1060 -RX) 18

19

Adjustment Valve Lowering Speed 20

Auto Height Select Switch 22

Battery Latch Switch 23

Brake Fluid Switch 24

Brake Potentiometer 25

Brake Pressure Switch 26

Camera Switch 27

CAN Card 28

Card Reader 29

Emergency Disconnect Contactor 30

Emergency Disconnect Switch 1 31

Emergency Disconnect Switch 2 32

Xpress Lower Proportional Valve 1 (ESR1060 -RX) 33

Xpress Lower Proportional Valve 2 (ESR1060 -RX) 34

Xpress Lower Proportional Valve 3 (ESR1060 -RX) 35

Forks First Switch 36

Free-Lift Switch 37

Fuse 1 39

Fuse 2 41

Fuse 3 43

Fuse 4 44

Fuse 5 45

Fuse 6 46

Fuse 7 47

Fuse 8 48

Fuse 9 49

Fuse 10 50

Fuse 11 (ESR1060 -RX) 51

Height Encoder 1 52

Height Encoder 2 53

Height Reset Switch 1 54

Height Reset Switch 2 55

Hoist Solenoid Valve 56

Horn 58

Horn Switch 59

Impact Sensor 60

Key Switch 61

Keyless Power Module 62

Left Accessory Proportional Valve 63

Left Accessory Solenoid Valve (ESR1060 -RX) 64

Main Pump 65

Line Contactor 66

Load Sensor 1 67

Load Sensor 2 68

Lower Proportional Valve 69

Lower Solenoid Valve (ESR1060 -RX) 71

M21 Encoder 72

M21 Fan (ESR1060) 73

M21 Thermal Sensor 74

M22 Encoder (ESR1060 -RX) 75

M22 Thermal Sensor (ESR1060 -RX) 76

M31 Encoder 77

M31 Fan (ESR1060) 78

M31 Thermal Sensor 79

M31 Traction Brake 80

M51 Sensor 1 81

M51 Sensor 2 82

M51 Thermal Sensor 83

Main Hoist Sensor 84

Main Pump Motor 86

Manual Lowering Valve 88

Override Switch 90

Power Unit First Switch 91

Reach Position Sensor 1 92

Reach Position Sensor 2 93

Reach Proportional Valve 94

Reach Sensor 96

Reach Solenoid Valve (ESR1060 -RX) 98

Relay 1 99

Relay 2100

Relay 3101

Relay 4102

Relay 5103

Relay 6104

Relay 9105

Relay 10106

Relay 22107

Relay 23108

Relief Valve 1109

Relief Valve 2111

Retract Proportional Valve112

Retract Solenoid Valve (ESR1060 -RX)114

Right Accessory Proportional Valve115

Right Accessory Solenoid Valve (ESR1060 -RX)116

Safety Pedal Sensor117

Seat Heater Switch118

Seat Switch119

Selector Encoder120

Selector Switch121

Sideshift Left Solenoid Valve (ESR1020 -T and ESR1040 -T)122

Sideshift Position Sensor123

Sideshift Right Solenoid Valve (ESR1020 -T and ESR1040 -T)124

Sideshift Sensor125

Sideshift Solenoid Valve127

Speaker129

Steer Motor130

Steer Sensor 1132

Steer Sensor 2133

Steering Sensor 1134

Steering Sensor 2135

Temperature Sensor136

Tilt Down Solenoid Valve (ESR1020 -T and ESR1040 -T)137

Tilt Position Sensor138

Tilt Sensor139

Tilt Solenoid Valve141

Tilt Up Solenoid Valve (ESR1020 -T and ESR1040 -T)143

Traction Motor144

Traction Potentiometer146

Traction Switch147

Travel Alarm148

Warning Light 1149

Warning Light 2150

Warning Light 3151

Worklight 1152

Worklight 2153

Worklight Switch154

Electrical 0

Contactor 1

Theory of Operation 1

Theory of Operation 1

Tools and Equipment 1

Recommended Tools and Equipment 1

Additional Tools and Equipment 1

Disassembly 1

Preparing the Lift Truck for Maintenance 1

Removing the Line Contactor 2

Inspecting the Line Contactor 3

Assembly 3

Installing the Line Contactor 3

Preparing the Lift Truck for Operation 5

Troubleshooting 5

Troubleshooting 5

Emergency Disconnect Contactor 6

Theory of Operation 6

Theory of Operation 6

Tools and Equipment 6

Recommended Tools and Equipment 6

Additional Tools and Equipment 6

Disassembly 7

Preparing the Lift Truck for Maintenance 7

Removing the Emergency Disconnect Contactor 7

Assembly 8

Installing the Emergency Disconnect Contactor 8

Preparing the Lift Truck for Operation 10

Troubleshooting 10

Troubleshooting 10

Reach Sensor 11

Technician Tips 11

Technician Tips 11

Tools and Equipment 11

Recommended Tools and Equipment 11

Additional Tools and Equipment 11

Disassembly 11

Inspecting the Reach Sensor 11

Assembly 12

Reach Sensor Adjustment 12

Event Codes 0

Introduction 1

Event Codes 9

000002006 10

000002058 10

000003006 11

000003058 11

000004000 12

000004003 12

000004004 13

000005000 13

000006059 14

000008001 15

000021000 17

000021001 17

000021016 17

000086000 18

000086016 18

000087000 18

000088003 20

000088004 20

000091003 21

000091004 22

000091061 23

000158003 23

000158004 23

000233003 24

000233004 24

000237002 25

000441000 25

000441001 26

000441016 26

000441018 26

000444001 26

000447002 27

000501002 28

000502059 29

000503004 30

000505004 30

000506003 30

000506004 30

000508000 31

000508001 32

000508016 32

000508018 32

000509002 33

000586003 34

000586004 35

000587003 37

000587004 38

000588003 38

000588004 38

000599000 40

000600003 41

000600004 42

000601003 43

000601004 43

000602003 43

000602004 43

000602058 45

000605004 45

000605059 46

000609012 47

000609052 48

000609100 49

000622002 49

000625003 49

000625004 51

000625009 51

000627003 52

000627004 52

000629012 54

000629052 54

000629056 55

000629057 55

000819000 55

000819016 56

000820000 57

000820016 57

000821003 57

000821004 57

000823003 58

000823004 58

000824000 59

000824016 59

000826003 60

000826004 61

000826005 61

000826006 62

000826059 63

000827016 63

000871009 63

000874003 64

000874004 64

000879006 65

000882003 66

000882004 67

000883003 67

000883004 68

000911003 68

000911004 69

000912003 69

000912004 70

000913003 70

000913004 71

000929003 71

000929004 72

000930003 72

000930004 73

000930053 73

000944003 74

000944004 74

000960006 74

000960058 75

000964061 76

000989003 76

001005003 76

001194003 76

001195004 77

001196003 78

001196004 79

001198003 79

001198004 79

001491003 80

001491004 80

001492003 80

001492004 81

001497001 81

001498001 82

001502004 82

001502005 83

001502006 84

001505005 85

001505006 86

001506005 86

001507004 88

001507005 89

001509004 89

001509005 91

001509006 92

001511004 93

001511005 94

001511006 94

001512003 95

001512004 96

001512005 97

001512006 97

001513003 97

001513004 98

001513006 98

001514003 98

001514004 99

001514005100

001514006100

001515003100

001515004101

001515006102

001517003102

001517004102

001517006104

001520004104

001520005105

001520006105

001521004106

001521006107

001523005107

001523006109

001524005110

001524006111

001525005112

001525006113

001526005114

001526006116

001527005117

001527006118

001528003119

001528004120

001528005120

001528006121

001529003121

001529004121

001529005122

001529006122

001530001122

001531005123

001531006124

001532005124

001532006126

001533005127

001533006128

001534005128

001534006130

001535005131

001535006132

001807003132

001807004133

002000009135

002001009136

002003009138

002004009138

002005009140

002007009142

002009009142

002010009142

002012009143

002018009143

002020009143

002348003144

002348004145

002349003145

002349004147

002350052147

002600005148

002600006148

002931003148

003318016149

003512003149

003512004150

003513003150

003513004151

003514003151

003514004152

003597003152

003597004153

003598003154

Hydraulic 0

Theory of Operation 1

Motor - M21 2

Theory of Operation 2

Theory of Operation 2

Tools and Equipment 2

Recommended Tools and Equipment 2

Additional Tools and Equipment 2

Disassembly 3

Preparing the Lift Truck for Maintenance 3

Removing the Main Pump Motor 3

Inspecting the Main Pump Motor 5

Assembly 5

Installing the Main Pump Motor 5

Preparing the Lift Truck for Operation 8

Pump - Accessory 9

Tools and Equipment 9

Recommended Tools and Equipment 9

Additional Tools and Equipment 9

Disassembly 9

Preparing the Lift Truck for Maintenance 9

Removing the Accessory Pump 10

Inspecting the Accessory Pump 10

Assembly 10

Installing the Accessory Pump 10

Removing Air from the Circuit for the Accessory Pump 11

Preparing the Lift Truck for Operation 11

Pump - Main 13

Tools and Equipment 13

Recommended Tools and Equipment 13

Additional Tools and Equipment 13

Disassembly 13

Preparing the Lift Truck for Maintenance 13

Removing the Main Pump 14

Inspecting the Main Pump 14

Assembly 15

Installing the Main Pump 15

Priming the Main Pump 16

Preparing the Lift Truck for Operation 16

Manifold - Main 18

Checking the 18

System 20

Functional Descriptions (ESR-F) 20

Lifting 20

Lowering 21

Extending the Reach Mechanism 23

Retracting the Reach Mechanism 25

Tilting the Fork Up 26

Tilting the Fork Down 28

Sideshift Right 29

Sideshift Left 31

5th Function A 32

5th Function B 33

Functional Descriptions (ESR-T) 35

Lifting 35

Lowering 36

Extending the Reach Mechanism 38

Retracting the Reach Mechanism 39

Tilting the Mast Towards the Operator 41

Tilting the Mast in the Direction of the Forks 42

Sideshift Right 43

Sideshift Left 45

Functional Descriptions (ESR-RX) 46

Lifting 46

Regenerative Lowering 47

Extending the Reach Mechanism 48

Retracting the Reach Mechanism 49

Tilting the Fork Up 50

Tilting the Fork Down 52

Sideshift Right 53

Sideshift Left 55

5th Function A 56

5th Function B 58

Drift Tests 59

Preparing the Lift Truck for Maintenance 59

Drift Tests 59

Recommended Tools and Equipment 59

Additional Tools and Equipment 60

Requirements 60

Performing a Drift Test on the Primary and Secondary Cylinders 60

Performing a Drift Test on the Tilt Cylinder 61

Checking and Adjusting the Relief Valve 1 62

Preparing the Lift Truck for Operation 63

Lifting Mechanism 0

Theory of Operation 1

Carriage - Fork 2

Tools and Equipment 2

Recommended Tools and Equipment 2

Additional Tools and Equipment 2

Disassembly 2

Preparing the Lift Truck for Maintenance 2

Removing the Fork Carriage 3

Inspecting the Fork Carriage 3

Assembly 4

Installing the Fork Carriage 4

Preparing the Lift Truck for Operation 4

Carriage - Mast 5

Theory of Operation 5

Theory of Operation 5

Tools and Equipment 5

Recommended Tools and Equipment 5

Additional Tools and Equipment 5

Disassembly 6

Preparing the Lift Truck for Maintenance 6

Removing the Free-Lift Switch 6

Removing the Mast Carriage 8

Inspecting the Mast Carriage 8

Assembly 8

Installing the Mast Carriage 8

Installing the Free-Lift Switch 9

Troubleshooting 10

Troubleshooting 10

Control Cable 11

Technician Tips 11

Technician Tips 11

Tools and Equipment 11

Recommended Tools and Equipment 11

Additional Tools and Equipment 11

Disassembly 12

Preparing the Lift Truck for Maintenance 12

Removing the Mast Control Cable 12

Removing the Fork Carriage Control Cable 15

Removing the Camera Control Cable 18

Inspecting the Control Cables 21

Assembly 21

Installing the Camera Control Cable 21

Installing the Fork Carriage Control Cable 24

Installing the Mast Control Cable 27

Adjusting the Tension 30

Preparing the Lift Truck for Operation 30

Troubleshooting 30

Troubleshooting 30

Cylinder - Primary 31

Technician Tips 31

Technician Tips 31

Theory of Operation 31

Theory of Operation 31

Tools and Equipment 31

Recommended Tools and Equipment 31

Additional Tools and Equipment 32

Small Hook Tool 32

Disassembly 32

Preparing the Lift Truck for Maintenance 32

Removing the Primary Cylinder 33

Disassembling the Primary Cylinder 34

Inspecting the Primary Cylinder 34

Assembly 35

Assembling the Primary Cylinder 35

Installing the Primary Cylinder 36

Bleeding the Cylinder 36

Testing the Cylinder Seal for Leaks 38

Preparing the Lift Truck for Operation 39

Cylinder - Reach 40

Tools and Equipment 40

Recommended Tools and Equipment 40

Additional Tools and Equipment 40

Disassembly 41

Preparing the Lift Truck for Maintenance 41

Removing the Reach Cylinder 41

Disassembling the Reach Cylinder 43

Inspecting the Reach Cylinder 44

Assembly 44

Assembling the Reach Cylinder 44

Installing the Reach Cylinder 45

Bleeding the Reach Cylinder 45

Preparing the Lift Truck for Operation 45

Testing the Cylinder Seal for Leaks 46

Troubleshooting 47

Troubleshooting 47

Cylinder - Secondary 48

Tools and Equipment 48

Recommended Tools and Equipment 48

Additional Tools and Equipment 48

Disassembly 49

Preparing the Lift Truck for Maintenance 49

Removing the Secondary Cylinder from Masts with a Lift Height up to 8 m (315 in) 49

Removing the Secondary Cylinder from Masts with a Lift Height Greater Than 8 m (315 in) 52

Disassembling the Secondary Cylinder 55

Disassembling the Secondary Cylinder with Regen Lower and Xpress™ Lower Option 57

Inspecting the Secondary Cylinder 59

Assembly 59

Assembling the Secondary Cylinder 59

Assembling the Secondary Cylinder with Regen Lower and Xpress™ Lower Option 61

Installing the Secondary Cylinder on Masts with a Lift Height up to 8 m (315 in) 63

Installing the Secondary Cylinder on Masts with a Lift Height Greater than 8 m (315 in) 66

Bleeding the Secondary Cylinder 69

Preparing a Test Load 69

Secondary Cylinder Drift Test 69

Preparing the Lift Truck for Operation 70

Troubleshooting 71

Troubleshooting 71

Cylinder - Sideshift 72

Tools and Equipment 72

Recommended Tools and Equipment 72

Additional Tools and Equipment 72

Disassembly 73

Preparing the Lift Truck for Maintenance 73

Disassembling the Sideshift Cylinder 73

Inspecting the Sideshift Cylinder 74

Assembly 75

Assembling the Sideshift Cylinder 75

Bleeding the Sideshift Cylinder 76

Preparing the Lift Truck for Operation 76

Troubleshooting 76

Troubleshooting 76

Cylinder - Tilt 77

Theory of Operation 77

Theory of Operation 77

Tools and Equipment 77

Recommended Tools and Equipment 77

Additional Tools and Equipment 77

Disassembly 78

Preparing the Lift Truck for Maintenance 78

Removing the Tilt Cylinder 78

Inspecting the Tilt Cylinder 79

Assembly 80

Installing the Tilt Cylinder 80

Bleeding the Tilt Cylinder 81

Preparing the Lift Truck for Operation 81

Troubleshooting 81

Troubleshooting 81

Fork Inspection 82

Tools and Equipment 82

Recommended Tools and Equipment 82

Additional Tools and Equipment 82

Inspection 82

Preparing the Lift Truck for Maintenance 82

Introduction 83

Identification 84

Measuring the Fork Blade for Wear 84

Checking for Fatigue Cracks 86

Bent or Twisted Forks 86

Checking the Fork Tip for Straightness 87

Fork Locking Pin 88

Preparing the Lift Truck for Operation 88

Height Encoder 90

Tools and Equipment 90

Recommended Tools and Equipment 90

Disassembly 90

Preparing the Lift Truck for Maintenance 90

Removing Height Encoder 1 (ESR -F) 90

Removing Height Encoder 2 (ESR -F) 91

Assembly 92

Installing Height Encoder 1 (ESR -F) 92

Installing Height Encoder 2 (ESR -F) 92