$41

Crown Forklift ESR 5000 SERIES MAINTENANCE MANUAL – PDF DOWNLOAD

Crown Forklift ESR 5000 SERIES MAINTENANCE MANUAL – PDF DOWNLOAD

FILE DETAILS:

Crown Forklift ESR 5000 SERIES MAINTENANCE MANUAL – PDF DOWNLOAD

Language : English

Pages :666

Downloadable : Yes

File Type : PDF

TABLE OF CONTENTS:

Crown Forklift ESR 5000 SERIES MAINTENANCE MANUAL – PDF DOWNLOAD

TABLE OF CONTENTS

INTRODUCTION 1

Important Information 3

Service personnel qualification 3

Ordering Spare Parts 3

Ordering documentation 3

Manual structure 3

Conventions 3

Text mark-ups in the manual 3

Brief description of equipment 3

Truck Data Number 4

SAFETY 5

Safety Notices 7

Basic Safety Notices 8

Organisational measures 8

Truck modifications and additions 8

Personal safety equipment 8

Protecting the hazardous area 8

Hazards from stored energy 8

Maintenance work 9

Restoring the truck to service after maintenance work 9

Cleaning work 9

Handling batteries 9

Warning and instruction decals on the truck 9

Lifting gear and slings 9

Environmental protection 10

INSPECTION AND LUBRICATION 11

Cleaning the Truck and Components 13

Effects of incorrect cleaning 13

Electrical components 13

Roller and slide bearings 13

Corrosion-protected surfaces 13

Environmental protection 13

Cleaning the entire truck 13

Cleaning removed components 14

Cleaning other mechanical components 14

Transport and Storage 15

Safety notices 15

Lifting a non-cold store cab truck with a crane 15

Lifting a cold store cab truck by crane 15

Lifting the truck with a forklift truck 16

Towing the truck 16

Jacking up the truck 17

Truck Assembly and Commissioning 19

Truck assembly 19

Required tools 19

Erecting the chassis 19

Removing the transport retainers 20

Filling the drive transmission unit 22

II

ESR 5000 Series

TABLE OF CONTENTS

Erecting the mast and attaching it to the chassis 22

Placing the Truck in Storage 23

Testing trucks in storage 23

Restoring the truck to service 23

Battery maintenance 23

Component access 24

Accessing components under the panels 24

Components under the panels 25

Accessing the motor compartment 26

Motor compartment 27

Accessing components under the floorboard 28

Components below the floorboard 29

Recommended Lubricants and Consumables 30

Cold store truck requirements 30

Abbreviations used in the table 30

Planned Maintenance 32

Maintenance schedule 32

Annual inspection in accordance with FEM 4004 32

Terms and abbreviations used 32

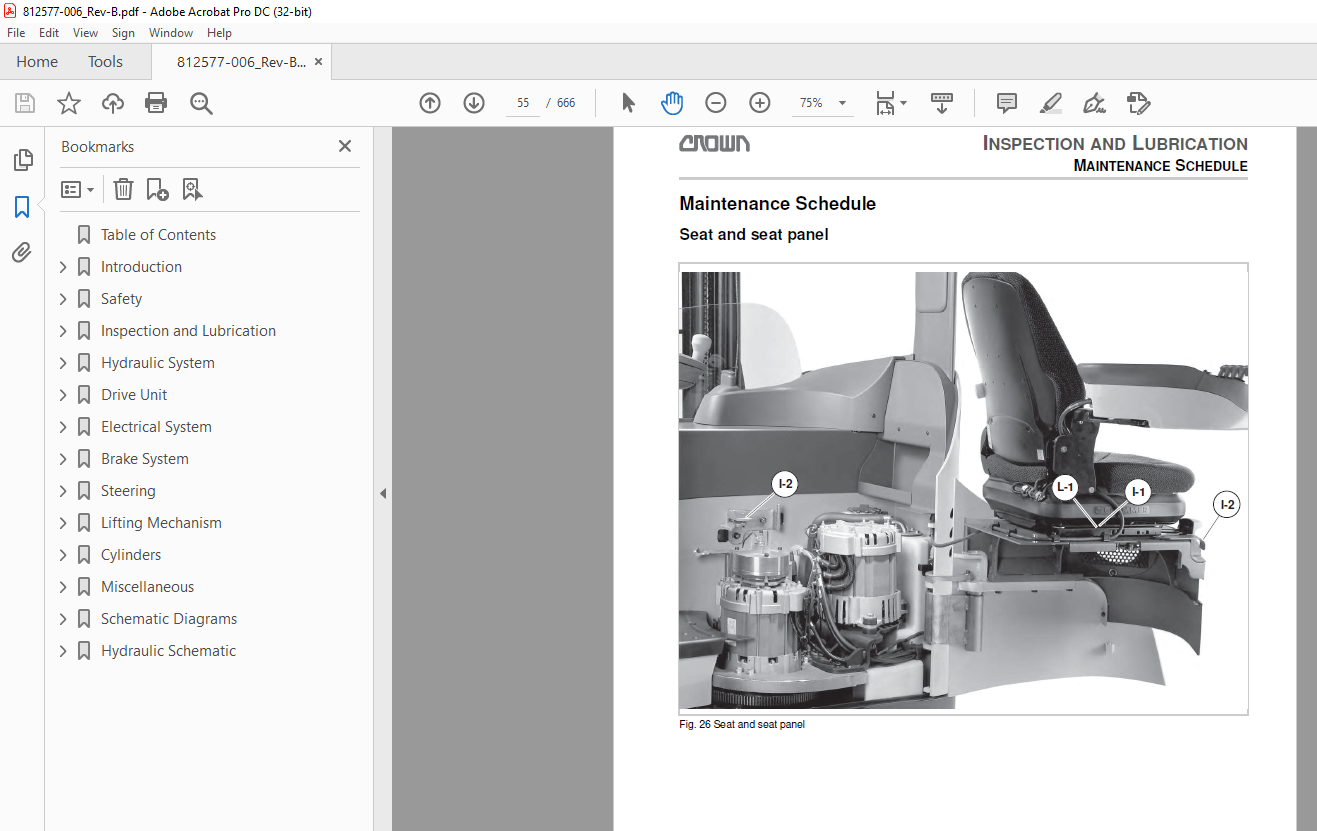

Maintenance Schedule 33

Seat and seat panel 33

Brake system and load wheels 35

Drive unit 37

Reach carriage 39

Hydraulic system 41

Electrical system – part 1 43

Electrical system – part 2 45

Traction and pump motors 47

Mast 49

Fork carriage 51

Torques 53

Standard torques 53

Load Wheels 54

Load wheel replacement 54

Special tools required 54

Load wheel removal 54

Load wheel assembly 55

Support Blocks 56

Checking the support block distance 56

Requirements 56

Measurement 56

Adjusting the support block height 56

Before adjusting 56

Replacing the support blocks 57

Live Ring Bearing Lubrication 58

Replacing the Heater Filter Element 59

HYDRAULIC SYSTEM 61

Abbreviations Used 63

Operation 65

Lifting 65

Lowering 67

Extending the mast reach carriage 69

Retracting the mast reach carriage 70

III

ESR 5000 Series

TABLE OF CONTENTS

Fork tilt back 71

Fork tilt down 72

Sideshift right 73

Sideshift left 74

Hydraulic Components 75

Hydraulic lines 75

Manifolds 75

Main manifold 75

“Accessories” manifold 76

Checking and adjusting relief valve RV1 76

Checking the emergency lowering valve MVL 77

Depressurising the Hydraulic System 78

Bleeding and Flushing the System 79

Safety notices 79

Bleeding the free lift cylinder 79

Bleeding the lift cylinders 79

Bleeding the reach cylinder 79

Bleeding the sideshift cylinder 79

Bleeding the tilt cylinder 79

Bleeding the 5th function cylinder 79

Flushing the lift cylinders 79

Drift tests 80

Requirements 80

Drift Tests 81

Safety notices 81

Lift cylinder drift test 81

Tilt cylinder drift test 81

Hydraulic oil reservoir 82

ESR 5000S hydraulic oil reservoir 82

ESR 5000 hydraulic oil reservoir 82

Replacing the Hydraulic Oil 83

Replacing the Filter 84

Replacing the return filter 84

Replacing the suction filter 84

Replacing the breather filter 85

Replacing the Hydraulic Pump 86

DRIVE UNIT 91

Gear Unit 93

Required tools 93

Removing the gear unit 93

Repairing the gear unit 95

Dismantling the gear unit 95

Assembling the gear unit 95

Assembling the gear unit 97

Drive Wheel 98

Drive wheel disassembly / assembly 98

Drive wheel disassembly 98

Drive wheel assembly 98

ELECTRICAL SYSTEM 99

Electrical Components 101

Service Menu Structure (Software V10) 106

Software version 106

Menu structure 106

Overview of menu items 106

Analyzer 106

A1Status 106

Calibration 107

C1 Acceleration Pedal 107

C2 Raiser/Lower Handle 107

107

C3 Reach Handle 107

C4 Tilt Handle 107

C5 Sice Shift Handle 107

C6 5th Function Handle 107

C7 Height 108

C8 Weight 108

C9 Fork Positioning 108

C10 Reach Retract Slow Down 108

C11 Save? 108

Features 108

Hour Meter 111

Log Events 111

Performance 111

Utilities 112

Performance level defaults 114

Standard settings 114

Service Menu – General (Software V10) 116

Access to service level 116

Trucks with key switch 116

Trucks without key switch 116

Navigation and entry keys 116

Display structure 116

Access to service menu and selecting a sub-menu 117

Analyzer Menu 118

A1 Status 118

A2 Inputs 119

A3 Outputs 124

C1 Accelerator Pedal 126

C2 Raise / Lower Handle 127

C3 Reach Handle 127

C4 Tilt Handle 128

VI

ESR 5000 Series

TABLE OF CONTENTS

C5 Side Shift 129

C6 5th Function 129

C7 Height 130

C73 Height Encoder 131

C8 Weight 134

C9 Fork Positioning 135

C10 Reach Retract 136

C11 Save ? 137

F1 Truck Size 138

F2 Free Lift Switch 139

F3 Height Encoder 139

F4 Lower Cut Out Switch 140

F5 5th Function 140

F6 Maximum Load 141

F7 Capacity Data Monitor 142

F8 Travel Alarm 143

F9 Beacon 143

F10 User Performance 144

F11 User Code 145

F12 Set Language 146

F13 Change Unit 147

F14 Set Rack Select 147

F15 Height/Weight 148

F16 Timer 148

F17 Error Log 148

F18 Operator Alarm 149

F19 Battery Alarm 150

F20 Fork Positioning 150

F21 Choose Steering 150

F25 Keyless Entry 151

F26 Right Handle 151

F27 Options Display 152

F28 Truck Lockout 152

F29 Direction Switch 153

F30 Save ? 153

H1 Truck Complete 154

H2 Traction Module 154

H3 Hydraulic Mod 155

H4 Key On Time 155

H5 Set Service Time 156

L1 History 157

L2 Totals 158

L3 Erase History 158

P1 Setup P1 159

P2 Setup P2 163

P3 Setup P3 163

P4 BDI Setting 163

P5 Travel > LCS 164

P6 Travel > FLS 164

P7 Travel > Custom 165

P8 Lower > Custom 165

P9 Reach > Custom 166

P10 5th Function Left 166

P11 5th Function Right 167

VII

ESR 5000 Series

TABLE OF CONTENTS

P12 Steer Sensitivity 167

P14 Brake at Ramp 168

P15 Set Default Values 168

P16 Save ? 168

U1 Software Version 169

U2 Hour Set 170

U3 Brake Override 170

U4 Check Fan 1 – 4 171

Service Menu Structure (Software V20) 172

Software version 172

Menu structure 172

Overview of menu items 172

Analyzer 172

A1Status 172

Calibration 173

Features 174

Hour Meter 175

Log Events 176

Performance 177

Utilities 178

Performance level defaults 179

PP4 BDI Setting 179

Service Menu – General (Software V20) 181

Access to service level 181

Trucks with key switch 181

Trucks without key switch 181

Navigation and entry keys 181

Display structure 181

Analyzer Menu (Software V20) 182

Access to service menu and selecting a sub-menu 182

A1 Status 182

A2 Inputs 183

A3 Outputs 189

C1 Accelerator Pedal 191

C2 Raise / Lower Handle 192

C3 Reach Handle 192

C4 Tilt Handle 193

C5 Side Shift 194

C6 Height 195

C63 Height Encoder 196

C64 Custom Height 198

C7 Weight 199

C8 Fork Positioning 200

C9 Reach Retract 201

C10 Save ? 202

F1 Truck Size 203

F2 Free Lift Switch 204

F3 Height Encoder 204

F4 Lower Cut Out Switch 205

F5 5th Function 205

F6 Maximum Load 206

F7 Capacity Data Monitor 207

F8 Travel Alarm 208

F9 Beacon 208

VIII

ESR 5000 Series

TABLE OF CONTENTS

F10 User Performance 209

F11 User Code 210

F12 Set Language 212

F13 Change Unit 213

F14 Set Rack Select 213

F15 Height/Weight 214

F16 Timer 214

F17 Error Log 214

F18 Operator Alarm 215

F19 Battery Alarm 216

F20 Fork Positioning 216

F21 Choose Steering 217

F23 Speed Reduction in Turns 217

F24 Sensitive Steering 218

F25 14 km/h 218

F26 Keyless Entry 219

F27 Operation Control 219

F28 Direction Switch 220

F29 Heated Seat 220

F30 InfoLink 221

F31 Save ? 221

H1 Truck Complete 222

H2 Traction Module 222

H3 Hydraulic Mod 223

H4 Key On Time 223

H5 Set Service Time 224

L1 History 225

L2 Totals 226

L3 Erase History 226

P1 Setup P1 227

P2 Setup P2 231

P3 Setup P3 231

P4 BDI Setting 231

P5 Travel > LCS 232

P6 Travel > FLS 232

P7 Travel > Custom 233

P8 Lower > Custom 233

P9 Reach > Custom 234

P10 5th Function Left 234

P11 5th Function Right 235

P12 Steer Sensitivity 235

P13 Brake at Ramp 236

P14 Set Default Values 236

P15 Save ? 236

U1 Software Version 237

U2 Hour Set 238

U3 Brake Override 238

U4 Check Fan 1 – 4 239

U5 Truck Lockout 239

Event Codes 240

Malfunctions with event code display 240

Log book display 240

Malfunctions without event code display 240

Locating malfunctions 240

IX

ESR 5000 Series

TABLE OF CONTENTS

Event Codes 100 – 186 241

Event Code 100 241

Event Code 101 241

Event Code 102 242

Event Code 110 242

Event Code 111 243

Event Code 112 243

Event Code 120 244

Event Code 121 245

Event Code 123 245

Event Code 124 245

Event Code 130 246

Event Code 131 247

Event Code 160 248

Event Code 180 249

Event Code 181 250

Event Code 182 251

Event Code 183 252

Event Code 184 253

Event Code 186 254

Event Codes 200 – 286 255

Event Code 200 255

Event Code 201 256

Event Code 210 257

Event Code 211 257

Event Code 212 259

Event Code 213 259

Event Code 214 260

Event Code 220 261

Event Code 221 262

Event Code 222 263

Event Code 223 264

Event Code 224 265

Event Code 225 266

Event Code 240 267

Event Code 241 268

Event Code 243 269

Event Code 244 270

Event Code 246 271

Event Code 247 272

Event Code 249 273

Event Code 250 274

Event Code 260 275

Event Code 261 276

Event Code 262 277

Event Code 263 278

Event Code 264 279

Event Code 265 280

Event Code 266 281

Event Code 267 282

Event Code 268 283

Event Code 280 285

Event Code 281 285

Event Code 282 285

X

ESR 5000 Series

TABLE OF CONTENTS

Event Code 283 286

Event Code 284 287

Event Code 285 287

Event Codes 300 – 385 289

Event Code 300 289

Event Code 301 289

Event Code 311 290

Event Code 312 291

Event Code 313 291

Event Code 314 291

Event Code 320 292

Event Code 321 293

Event Code 322 294

Event Code 323 295

Event Code 324 296

Event Code 325 297

Event Code 330 297

Event Code 340 299

Event Code 341 300

Event Code 343 301

Event Code 380 303

Event Code 381 303

Event Code 382 303

Event Code 383 304

Event Code 384 305

Event Codes 430 – 465 306

Event Code 430 306

Event Code 431 306

Event Code 460 308

Event Code 461 308

Event Code 462 309

Event Code 463 310

Event Code 464 312

Event Code 465 313

Event Codes 840 – 886 315

Event Code 840 315

Event Code 841 316

Event Code 880 316

Event Code 881 318

Event Code 883 320

Event Code 884 321

Event Code 885 323

Event Code 886 324

Control Modules and Display Screen 325

Replacing control modules 325

Replace the main control module 325

Replacing the traction control module 325

Replacing the hydraulic control module 326

Replacing the steering control module 326

Replacing the display panel 326

PMT Test 328

General 328

Safety Notices 328

Required tools 328

XI

ESR 5000 Series

TABLE OF CONTENTS

Preparing the control module safety test 329

Traction control module safety test 329

Hydraulic control module safety test 329

Steering control module safety test 330

Replacing the Height Encoder 332

Replacing the HGT(R)S Switch 333

Removing the HGT(R)S switch 333

Assembling the HGT(R)S switch 333

Trucks with fingertip control levers 334

Removing the controls 335

Assembling the controls 335

Trucks with dual axis hydraulic control levers 335

Trucks with multi-task handle 336

Removing the controls 337

Assembling the controls 337

Wiring the Multi-Task Control Handle 338

Wiring the Dual Axis Hydraulic Control Levers 339

Wiring the Fingertip Control Levers 340

Replacing the Mast Cables 341

Transfer Point Definition 341

Mast cable removal 341

Mast cable assembly 342

Attaching the mast cable clamps 343

Attaching clamping shoes for a 6 core mast cable 343

Attaching clamping shoes for a 10 core mast cable 343

Replacing the Camera Cable on the Fork Camera 344

Transfer Point Definition 344

Removing the camera cable 344

Camera cable assembly 345

Fitting the camera cable clamps 346

Replacing the Camera Cable on the Mast Camera 347

Transfer Point Definition 347

Removing the camera cable 347

Camera cable assembly 348

Fitting the camera cable clamps 349

Repairing Contactors 350

Wear test 350

Checking contacts 350

Checking the coils 350

Checking the springs 350

Repairing the Main Contactor 351

Replacing the Danaher Drive Motor 352

Drive motor disassembly 352

Drive motor assembly 352

Connecting the power cables 352

Sensor bearing disassembly 355

Sensor bearing assembly 355

Replacing the Crown Drive Motor 356

Drive motor disassembly 356

Drive motor assembly 356

Connecting the power cables 356

Replacing the Pump Motor 358

Removing the pump motor 358

Pump motor assembly 358

XII

ESR 5000 Series

TABLE OF CONTENTS

Connecting the power cables 359

Sensor bearing disassembly 361

Sensor bearing assembly 361

Battery Information 362

Charging the battery 362

Replacing the battery 362

Inserting the Battery Cable Guide 363

Battery with 420 Ah 366

Battery with 560 Ah 366

Battery with 720 Ah 367

Battery with 560 Ah 368

Battery with 720 Ah 368

Battery with 840 Ah 369

Choosing the Correct Battery Cable Length 370

Choosing cable lengths for a T-shaped battery (example) 370

Replacing the battery cable loom in the truck 372

Hole patterns for the battery connectors on the base plate 373

Battery connector DIN 160 (819801-001) 373

Battery connector DIN 160 (819801-101) 373

Battery connector SBE 160 (819801-002) 374

Battery connector SBE 160 (819801-102) 374

Battery connector SB 350 (819801-003) 374

Battery connector SB 350 (819801-103) 374

Heaters (Cold Store Cabs Only) 375

Door heater 375

Replacing and disassembling the heater 375

Replacing the fan 375

Replacing the heater element 376

Replacing the temperature gauge 376

Overhead console heater 376

Replacing and disassembling the heater 376

Replacing the fan 376

Replacing the heater element 377

Replacing the temperature gauge 377

BRAKE SYSTEM 379

Service and Parking Brake 381

Safety notices 381

Service and Parking Brake Danaher Motor 382

Disassembling the brake 382

Dismantling the brake 382

Fitting the brake 382

Assembling the brake 382

Adjusting the air gap 382

Measuring the coil resistance 383

Parking Brake Crown Motor 384

Disassembling the parking brake 384

Dismantling the brake 384

Fitting the brake 384

Assembling the parking brake 384

Adjusting the air gap 384

Measuring the coil resistance 385

Load Wheel Brake 386

General 386

XIII

ESR 5000 Series

TABLE OF CONTENTS

Checking the brake lining wear 386

Replacing the brake linings 386

Wheel brake cylinder 387

Wheel brake cylinder disassembly 387

Wheel brake cylinder assembly 387

Bleeding the load wheel brake 387

Replacing the brake fluid 387

Testing and Adjusting the Brake Pedal Clearance 388

Adding Brake Fluid 389

Brake Power Control 390

Requirements 390

Required tools 390

Brake test 390

STEERING 393

Function 395

Generating a steering signal 395

Steer motor activation 395

Steer system monitoring 395

Error correction 395

Quadrant – definition 396

Steering Errors 397

Error routine 397

Ending the error routine 397

Causes of error routine activation 397

Other error causes 397

Examples of steer faults 398

Proximity Switches up to Serial No 5A215757 400

Replacing and adjusting SFS2 or SFS1 SA 400

Proximity Switches from Serial No 5A215758 401

Replacing and adjusting SFS2 or SFS1 SA 401

Steer Motor and Steering Transmission 402

Removing the steer motor and steering transmission 402

Disconnecting the steering transmission and steer motor 402

Assembling the steering transmission and steer motor 403

Installing the steer motor and steering transmission 403

Steering Wheel 405

Steering wheel removal 405

Steering wheel assembly 405

Replacing Encoder ECR2 407

Removing ECR4 407

Assembling ECR4 407

LIFTING MECHANISM 409

Mast 411

Safety instructions for working on the mast 411

General 411

Torques 411

Lifting gear minimum capacities 411

Checking the assembled mast 411

Flaking 411

Checking the roller tracks 411

Checking the mast verticality 411

XIV

ESR 5000 Series

TABLE OF CONTENTS

Checking the pulleys, hoses and cables 412

Checking the end stops 412

Checking the fork setting 412

Checking the mast tilt 412

Mast tilt tolerance tables 413

Adjusting the Mast Tilt 414

Mast Removal / Assembly 415

General 415

Mast removal 415

Mast assembly 416

Mast checks and settings after assembly 417

Dismantling and Assembling the Mast 419

Safety notices 419

Tips & tricks 419

Dismantling the mast 419

Fork carriage removal 419

Removing the 2nd mast stage 419

Removing the 1st mast stage 419

Replacing the Mast Rollers 421

General 421

Safety notices 421

Preparation 421

Mast roller assembly 421

Calculating the roller diameter 421

Calculating the number of shims required 424

Final tasks and settings 426

Integrated sideshifter 427

Removing the integrated sideshifter 427

Assembling the integrated sideshifter 427

Lift Cylinder Removal and Assembly 429

Safety notices 429

Lift cylinder removal on masts up to 8 m 429

Lift cylinder assembly on masts up to 8 m 430

Lift cylinder removal on masts above 8 m 432

Lift cylinder assembly on masts above 8 m 432

Reach Cylinder Removal and Assembly 433

Safety notices 433

Removal 433

Assembly 434

Free Lift Cylinder Removal and Assembly 435

Safety notices 435

Removal 435

Installing the free lift cylinder in an upright mast 436

Installing the free lift cylinder in a horizontal mast 436

Chain Supports and Lift Chains 438

General 438

Periodic inspection of chain supports and lift chains 438

Periodic replacement of chain supports and lift chains 438

Cleaning lift chains 438

Inspecting Chain Supports and Lift Chains 439

Checking the service hours for the lift chains and anchor bolts 439

Checking the lift chain for elongation 439

General 439

Preparatory measures 439

XV

ESR 5000 Series

TABLE OF CONTENTS

Freedom of movement 440

Worn or missing plates 440

Turned pins 441

Corrosion 441

Chain lateral wear 441

Checking chain supports and anchor bolts 442

Checking the chain pulleys 442

Checking and adjusting the chain tension 442

Checking and adjusting the tension on the outer chains 442

Checking and setting the free lift chain tension 442

Checking the lifting components for misalignment 443

Lubricating Lift Chains 444

General information 444

Lubrication intervals and lubricants 444

Separating Lift Chains 445

Tools and equipment required 445

Forks 446

General 446

Terms 446

Fork marking 446

Fork Inspection 447

Checking fork tines for cracks 447

Checking fork tip straightness 447

Measuring the fork blade warping 448

Measuring the fork tip width 448

Measuring the fork tine height difference 448

Checking the fork stop 448

Measuring the fork blade wear 449

Reach Carriage, Terms and Definitions 450

Terms 450

“Left outrigger” and “Right outrigger” definition 450

Reach Carriage Removal and Assembly 451

Reach carriage removal 451

Reach carriage assembly 451

Adjusting the Reach Carriage (up to serial no 5A213106) 452

Adjusting the Reach Carriage (from serial no 5A213108) 454

CYLINDERS 457

General 459

Safety notices 459

Hydraulic System Repair Instructions 459

Tools 460

Small hook 460

Extractor 460

Producing extractors 460

Groove aligning arbor for small rod seals 460

Assembly devices for large rod seals 461

Protective mechanisms 461

Rod Seal Removal and Assembly 462

Removing a large rod seal 462

Removing a small rod seal 462

Inserting a large rod seal 462

Fitting a small rod seal 463

Rod seal assembly, sealing lip first 463

XVI

ESR 5000 Series

TABLE OF CONTENTS

Repairing Cylinders 464

Safety notices 464

General 464

Replacing the rod seals 464

Repairing Lift Cylinders 465

Dismantling lift cylinders 465

Lift cylinder assembly 465

Piston rod pre-assembly and installation 465

Piston cap pre-assembly and installation 465

Final tasks 466

Repairing the Free Lift Cylinder 468

Dismantling the free lift cylinder 468

Free lift cylinder assembly 468

Piston rod pre-assembly and installation 468

Piston cap pre-assembly and installation 468

Final tasks 469

Repairing the Reach Cylinder 471

Dismantling the reach cylinder 471

Piston rod pre-assembly and installation 471

Piston cap pre-assembly and installation 471

Final tasks 472

Repairing the Sideshifter Cylinder 474

Dismantling the sideshifter 474

Sideshifter cylinder assembly 474

Final tasks 474

MISCELLANEOUS 477

Replacing the Cold Store Cab Windows 479

Important notes 479

Engineer qualifications 479

Cure times 479

Approved adhesives and primers 479

Cleaning the glued surfaces and windows 479

Ambient conditions for repair work 479

Safety Notices 479

Tools required 479

Removing damaged windows 479

Fitting new windows 480

Gluing the window 480

Final tasks 482

SCHEMATIC DIAGRAMS 485

Wire Colour Code 487

General Contact Symbol Abbreviations 488

Electrical wiring diagrams 490

Power up circuit 492

Wire Harness / Wiring Diagram Assignment 493

Wiring Diagram, Fingertip and Dual Axis Hydraulic Control Levers No 822617 495

Wiring Diagram, Multi-Task Control Joystick 822618 498

Wiring Diagram No 822790 (All Joystick Versions) 501

Main Harness, Part Number 827090 504

Main Harness, Part Number 819849 507

Main Harness, Part Number 825335 509

XVII

ESR 5000 Series

TABLE OF CONTENTS

Replacement Parts 512

Main Harness, Part Number 819850 525

Harness, ESR 5000S Armrest 544

Connector table 545

Wire Harness Distributor Plate to Reach Carriage Part Number 822740 563

Wire Harness Distributor Plate to Reach Carriage Part Number 827091 564

Manifold, mast wire harness 569

Replacement Parts 569

Plug connector housing 571

Contact pins 571

Replacement Parts 571

Plug connector housing 573

Contact pins 573

Replacement Parts 573

Contact pins 574

Replacement Parts 574

Plug connector housing 575

Contact pins 575

Replacement Parts 575

Plug connector housing 576

Contact pins 576

Replacement Parts 576

576

Contact pins 577

Replacement Parts 577

Plug connector housing 578

Contact pins 578

Spare parts 578

Plug connector housing 579

Plug connector housing 580

Contact pins 580

Plug connector housing 581

Contact pins 581

Note on assembly: 582

Plug connector housing 582

Contact pins 582

Plug connector housing 583

Contact pins 583

Plug connector housing 584

Contact pins 584

Plug connector housing 585

Contact pins 585

Plug connector housing 586

Contact pins 586

Plug connector housing 587

Contact pins 587

Note on assembly: 588

Plug connector housing 588

Contact pins 588

Plug connector housing 589

Contact pins 589

Note on assembly: 590

Plug connector housing 590

Contact pins 590

XVIII

ESR 5000 Series

TABLE OF CONTENTS

Plug connector housing 593

Contact pins 593

Plug connector housing 594

Contact pins 594

Plug connector housing 595

Contact pins 595

Beacon Wire Harness, Option 599

Plug connector housing 599

Contact pins 599

24 V Work Lights Wire Harness, Option 600

Plug connector housing 600

Contact pins 600

Cable lugs and rings 600

600

Travel Alarm Wire Harness, Option 601

Plug connector housing 601

Contact pins 601

Plug connector housing 602

Contact pins 602

DC / DC Converter Wire Harness, Option 605

Replacement Parts 605

Plug connector housing 609

Contact pins 609

12 V Work Lights Wire Harness, Option 613

Plug connector housing 613

Contact pins 613

Cable lugs and rings 613

InfoLink, Wire Harness, Option 617

Plug connector housing 617

Contact pins 617

Cable lugs and rings 617

Replacement Parts 621

Plug connector housing 622

Contact pins 622

Replacement Parts 622

Replacement Parts 623

Replacement Parts 624

Cable lugs and rings 625

Replacement Parts 625

Cold Store Cab Main Harness 629

Door wire harness (cold store cab) 630

Sheet 1 (Cold Store Cab) 631

Sheet 2 (Cold Store Cab) 632

Sheet 3 (Cold Store Cab) 633

Sheet 4 (Cold Store Cab) 634

Sheet 5 (Cold Store Cab) 635

HYDRAULIC SCHEMATIC 637

Hydraulic Symbols 639

Hydraulic Diagram 643

1

INTRODUCTION

IMAGES PREVIEW OF THE MANUAL: