$37

Crown Forklift FC 5200 Series Counter Balanced Service Manual – PDF DOWNLOAD

Crown Forklift FC 5200 Series Counter Balanced Service Manual – PDF DOWNLOAD

FILE DETAILS:

Crown Forklift FC 5200 Series Counter Balanced Service Manual – PDF DOWNLOAD

Language : English

Pages :339

Downloadable : Yes

File Type : PDF

TABLE OF CONTENTS:

Crown Forklift FC 5200 Series Counter Balanced Service Manual – PDF DOWNLOAD

Componentry 1

Introduction 1

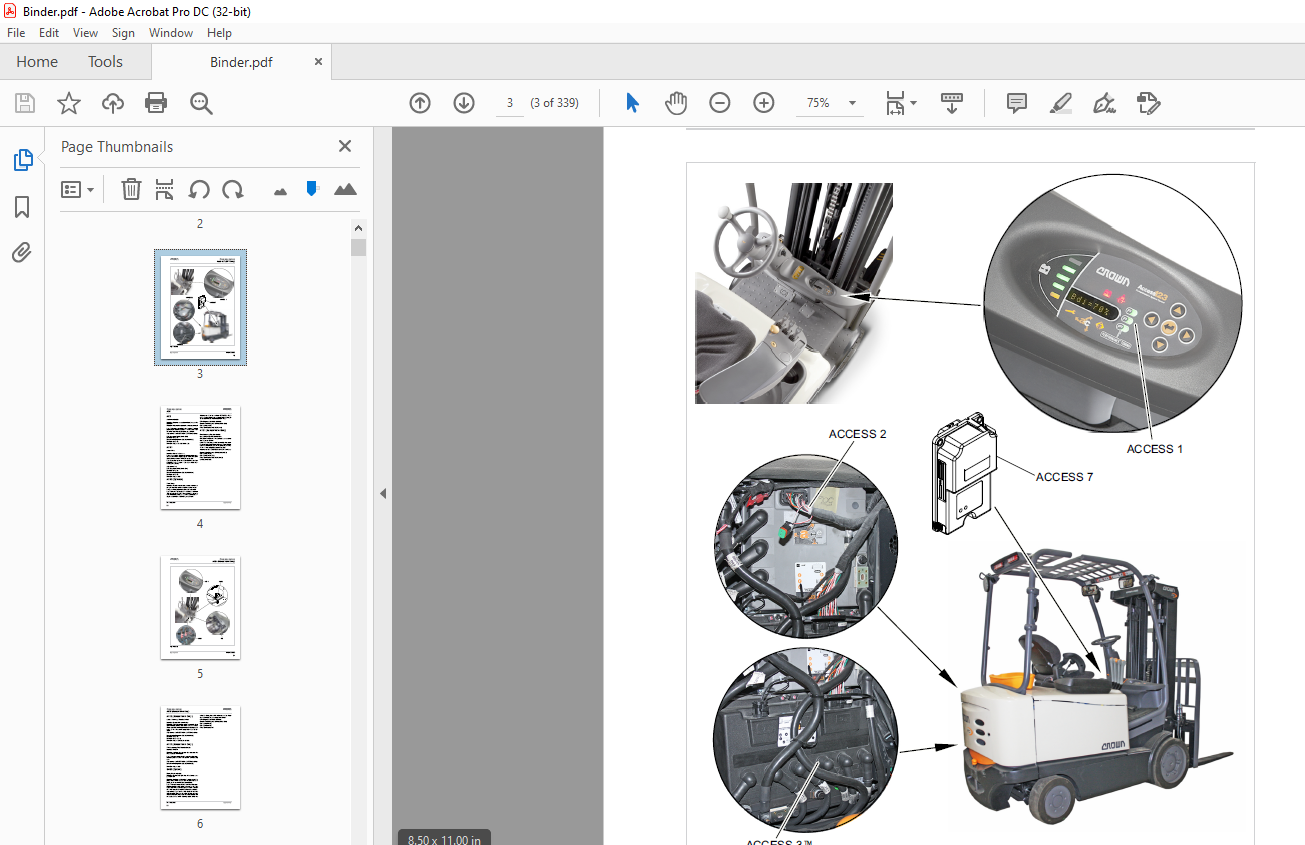

Access 1 2

Access 2 2

Access 3™ 2

Access 7 (EPV Only) 2

ACS 4

ALM1 4

ALM2 (Optional) 4

AXS1 (Manual Valve Only) 4

AXS2 (Manual Valve Only) 6

BRES (Option) 6

BRKS2 (Option) 8

CR7 (Not Shown) 12

CR38 (Not Shown) 12

DR1 12

DR2 14

DR3 14

DS20 14

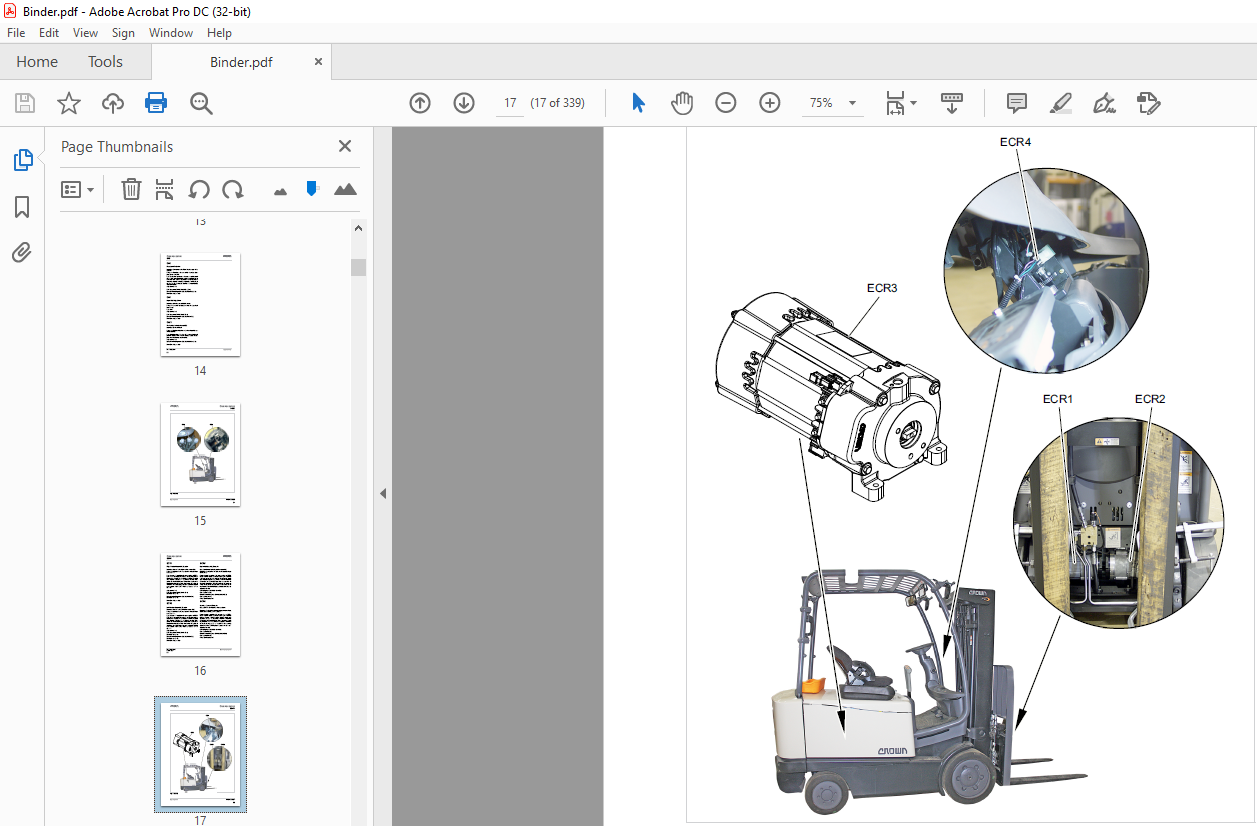

ECR1 16

ECR2 16

ECR3 16

ECR4 16

FAN1 18

FAN2 18

FAN4 18

FAN5 18

FAN6 18

FLS (Not Shown) 20

FNS 20

FS 20

FU1 20

FU2 20

FU4 22

FU6 22

FU7 22

FU8 (Not Shown) 22

HGTS1 24

HGTS2 24

HGTS3 24

HN1 26

HNS1 26

HNS2 26

HNS3 26

HNS4 (EPV Only) 26

HNS5 26

HR1 (Optional – Not Shown) 28

HR2 (Optional – Not Shown) 28

Impact Sensor 28

InfoLink® (Optional) 28

K1 30

K2 30

K5 30

KYS 30

L 32

LGS1 (Optional) 32

LGS2 (Optional) 32

LGT1 (Optional) 32

LGT2 (Optional) 32

LGT3 (Optional) 34

LGT4 (Optional) 34

LGT5 (Optional) 34

LGT6 (Optional) 34

M1 36

M2 36

M3 36

ORS (EPV Only) 38

ORS1 (Manual Valve Only – Not Shown) 38

ORS2 (Manual Valve Only – Not Shown) 38

ORS3 (Manual Valve Only – Not Shown) 38

POT1 40

POT2 40

POT3 40

POT4 40

POT5 (EPV Only) 42

POT6 (EPV Only) 42

POT7 (EPV Only) 42

POT8 42

PT1 44

RES1 (Optional) 44

RES2 (Optional) 44

RES3 (Optional) 44

RES4 (Optional – Not Shown) 44

RES39 (Optional – Not Shown) 44

RES5 (Optional – Not Shown) 46

RES6 (Optional – 48 V Trucks Only – Not Shown) 46

RES7 (Optional – 48 V Trucks Only – Not Shown) 46

RES50 (Optional – Not Shown) 46

RS 46

SB80 (Optional – Not Shown) 46

SBS (Optional) 48

SES 48

SPA1A (EPV Only) 48

SPA1B (EPV Only) 48

SPA2A (EPV Only) 50

Parts Breakdown: 024-2052-150 (1) 024-2052-200 (1) 50

SPA2B (EPV Only) 50

SPL (EPV Only) 50

SPR (EPV Only) 50

SPTE (EPV Only)153

SPTR (EPV Only) 52

SV1 (Manual Valve Only) 52

SV3 (Manual Valve Only) 52

SVBy (EPV Only) 54

SVC1 (EPV Only – Not Shown) 54

SVL (EPV Only – Not Shown) 54

SVOP (Manual Valve Only) 54

SVX (Manual Valve Only, Optional – Not Shown) 56

TBS (Manual Valve Only) 56

THS1 (Optional) 56

THS2 (Optional) 56

TLMS 56

TLT (Manual Valve Only) 58

TPAS (Optional) 58

TR1160

TR2 58

Parts Breakdown: N/A 58

TS1 58

TS2 58

TS3 60

TSS (Option) 60

VTS 60

Hydraulic System 63

Hydraulic Lines and Fittings 63

Avoid High Pressure Fluids-Escaping fluid under pressure can penetrate the skin causing serious injury Relieve pressure before disconnecting hydraulic lines Tighten all connections before applying pressure Keep hands and body away from pin-holes w 63

Reservoir 63

Capacity 63

Fig 1 (30576) 64

Fig 2 (17440) 64

Filters 64

Fig 3 (30567) 64

Drift Test 65

Never stand or work under a suspended load 65

Tilt Drift Test 65

Lift Drift Test 65

Cylinder and Circuit Bleeding 65

Do not attempt to bleed a line by cracking an O-ring face seal fitting This will result in damaging the O-ring which then must be replaced to prevent hydraulic fluid leakage 65

Lift Circuit 66

Fig 4 (30568) 66

Tilt Circuit 67

Fig 5 (30569) 67

Tilt Cylinder Bleeding 67

Do not attempt to bleed a line by cracking an O-ring face seal fitting This will result in damaging the O-ring which then must be replaced to prevent hydraulic fluid leakage 67

Sideshift Circuit 67

Steer Cylinder Circuit 67

Hydraulic Circuitry 68

Manual Steering 68

Fig 1 (30578) 68

No Demand for Steering 68

Fig 2 (30397) 69

Steer Left 70

Fig 3 (30398) 71

Steer Right 72

Fig 4 (30399) 73

Lift 74

Fig 5 (30400) 75

Lower Circuit 76

Fig 6 (30401) 77

Tilt Back Circuit 78

Tilt Position Assist 78

Fig 7 (30402) 79

Tilt Forward Circuit 80

Tilt Position Assist 80

Fig 8 (30403) 81

Sideshift Left Circuit 82

Fig 9 (30404) 83

Sideshift Right Circuit 84

Fig 10 (30405) 85

Notes: 86

Lift Pump 87

Disassembly 88

Assembly 88

Control Valve 89

Relief valve RV1 operation 89

Relief valve RV2 operation 89

Main pressure compensating element (MPCE) operation 91

Control valve disassembly 92

Inspecting and repairing the control valve 93

AXS1, AXS2, TLT107

TBS108

ACS109

BRKS1, BRKS2 (Optional)110

HGTS1110

TLMS112

Access 1 2 3® Menus113

Analyzer Menus151

Features Menus168

Performance Menus181

Calibration Menus202

Hours Menus209

Events Menus212

Utilities Menus214

Contactors219

132084-003/-004 Contactor L (Line) and P (Pump)219

Before any inspection, adjustments, servicing, parts replacement or any other act is performed requiring physical contact with the electrical working components or wiring of these contactors, disconnect battery, raise drive wheels clear of floor and 219

Inspection219

Contacts219

Line and Pump Contactor220

Coil220

Component Replacement220

Fig 1 (17400)220

Contact Replacement221

Coil Replacement221

“EE” Component Replacement221

Fig 2 (17401)221

Contact Replacement222

Coil Replacement222

Battery223

Safety Rules223

Checking the Battery223

Battery Care224

Charging the Battery224

Battery Removal225

Battery Installation226

Seat Deck Cover Adjustment227

Seat Deck Latch Adjustment227

Seat Deck Cylinders228

Battery Cleaning230

Troubleshooting230

Dual Voltage Conversion230

Battery Discharge Interrupt Performance (P4)230

Brake291

Checking Brake Wear291

Brake Disassembly292

Brake Assembly294

Steering Column297

Hydrostatic Steering Unit297

Fig 1 (30566)297

The steering on your lift truck can be reversed by incorrectly connecting the hydraulic hoses Care should be exercised when maintenance is performed on the steering system Prior to disassembly, mark hose and tube locations so they can be properly a297

Steering Column Assembly298

Fig 2 (15149-01)298

Column298

Fig 3 (20083)298

Fig 4 (15154-01)299

Gas Cylinder299

Fig 5 (20084)299

Fig 6 (20085)299

Directional Control299

Fig 7 (15157-01)299

Fig 8 (15158-01)300

Steering Wheel Removal300

Fig 9 (15159-01)300

Fig 10 (15160-01)300

Fig 11 (15161-01)301

Steering Wheel301

Fig 12 (20104)301

Final Assembly301

Steer Axle302

Mast306

Wear appropriate protective items such as eye protection, work gloves, and safety-toe shoes whenever performing maintenance work on Crown equipment306

Pivot Block Torque Requirements306

Fig 1 (25469)306

Mast Flaking306

Mast Testing (Assembled)307

Fig 2 (16947)307

Shim Basics307

Fig 3 (17406-02)307

Fig 4 (16950-01)308

Shim Removal309

Wear appropriate items, such as eye protection and safety-toe shoes whenever performing maintenance work Do not place fingers, hands or arms through mast or position them at pinch points In this section you may be required to lift and block the lif309

Mast Column Rollers309

Fig 5 (17407)309

Carriage Column Roller Adjustments310

Fig 6 (17408-01)310

Fig 7 (17409-01)310

Fig 8 (17410-01)310

Wear appropriate items, such as eye protection and safety-toe shoes whenever performing maintenance work Do not place fingers, hands, or arms through mast or position them at pinch points In this section you may be required to lift and block the li311

Carriage Side Thrust Roller Adjustments (TL, TF, and TT Masts)311

Fig 9 (17411-01)311

Fig 10 (17412-01)311

Mast Column Roller Removal – TT and TF Mast (Inner Mast)312

Mast Column Rollers Removal – TL and TF Mast313

Mast Assembly313

Lift Cylinder Removal – TL, TF, and TT313

Carriage Removal – TT and TF Mast314

Wear appropriate items, such as eye protection and safety-toe shoes whenever performing maintenance work Do not place fingers, hands, or arms through mast or position them at pinch points In this section you may be required to lift and block the li314

Carriage Removal – TL Mast314

Wear appropriate items, such as eye protection and safety-toe shoes whenever performing maintenance work Do not place fingers, hands, or arms through mast or position them at pinch points In this section you may be required to lift and block the li314

Mast Removal (TL and TT Mast)315

Wear appropriate items, such as eye protection and safety-toe shoes whenever performing maintenance work Do not place fingers, hands, or arms through mast or position them at pinch points In this section you may be required to lift and block the li315

Fig 11 (17413)315

Make sure lifting device and sling are sufficiently rated to withstand the weight being lifted Never work under or around a lift truck that is not properly secured See lift truck data plate for lift truck weight information315

Fig 12 (17414-01)316

Fig 13 (17415-01)316

Mast Assembly (TL and TT Mast)317

Fig 14 (25469)317

All hydraulic lines, hoses have an o-ring face seal to prevent hydraulic fluid leakage These o-ring face seals must be replaced to prevent hydraulic fluid leakage whenever the lines are disconnected317

Fig 15 (17416-02)318

Fig 16 (20922)318

TT Mast319

TL Mast319

Fig 17 (17417-02)319

Tilt Cylinder Adjustments320

Wear appropriate items, such as eye protection and safety-toe shoes whenever performing maintenance work Do not place fingers, hands, or arms through mast or position them at pinch points In this section you may be required to lift and block the li320

Quad Mast320

Mast Flaking320

Mast Testing (Assembled)321

Fig 18 (16947)321

Wear appropriate items, such as eye protection and safety-toe shoes whenever performing maintenance work Do not place fingers, hands, or arms through mast or position them at pinch points In this section you may be required to lift and block the li321

Mast Removal322

Wear appropriate items, such as eye protection and safety-toe shoes whenever performing maintenance work Do not place fingers, hands, or arms through mast or position them at pinch points In this section you may be required to lift and block the li322

Carriage Removal322

Carriage Inspection322

Lift Chain Tension322

Fig 19 (17419-01)323

Fig 20 (17420-01)324

Notes:325

Tilt Cylinder326

Bleeding the cylinder and the circuit329

Tilt drift test329

Tilt cylinder adjustments329

IMAGES PREVIEW OF THE MANUAL: