$41

Crown Forklift GPC 3000 Series Service Manual – PDF DOWNLOAD

Crown Forklift GPC 3000 Series Service Manual – PDF DOWNLOAD

FILE DETAILS:

Crown Forklift GPC 3000 Series Service Manual – PDF DOWNLOAD

Language : English

Pages :680

Downloadable : Yes

File Type : PDF

GPC 3020

GPC 3040

GPC 3045

GPC 3050

GPC 3055

GPC 3060

TABLE OF CONTENTS:

Crown Forklift GPC 3000 Series Service Manual – PDF DOWNLOAD

Introduction 0

Safety 0

Organisation of the Safety Messages 2

Basic Safety Messages 3

Organisational measures 3

Modifications to the forklift truck 3

Personal protection equipment 3

Securing hazardous areas 3

Hazards posed by stored energy 3

Maintenance work 4

Restoring the forklift truck to service after maintenance work 4

Cleaning work 4

Handling batteries 4

Warning and instruction decals on the forklift truck 4

Lifting equipment and lifting accessories 5

Environmental protection 5

Inspection and Lubrication 0

Storing and Returning the Forklift Truck to Service 2

Cleaning the Forklift Truck and Componentry 3

Effects of incorrect cleaning 3

Electrical components 3

Roller and slide bearings 3

Corrosion-protected surfaces 3

Environmental protection 3

Cleaning the entire forklift truck 4

Cleaning removed componentry 5

Cleaning other mechanical componentry 5

Jacking up the Forklift Truck 6

Lifting the Forklift Truck by Crane 8

Towing the Forklift Truck 10

Securing the Forklift Truck on a Loading Surface 11

Securing GPC 3020, 3040, 3060 11

Securing GPC 3045 und 3055 12

Planned Maintenance 13

Maintenance schedule 13

Annual inspection in accordance with FEM 4004 13

Used terms and abbreviations 13

Maintenance Schedule 14

General 14

Covers 15

Hydraulic system 16

Power unit 17

Electrical system 18

Braking system 19

Steering 19

Lifting mechanism 20

Cylinders 21

Platform 21

Miscellaneous 22

GPC 3020/40/50/60 Inspection and Lubrication Points 23

GPC 3045 Inspection and Lubrication Points 25

GPC 3055 Inspection and Lubrication Points 27

Lubricants and Auxiliary Materials 29

Cold store truck requirements 29

Abbreviations used 29

Componentry 0

Componentry 2

Audible Indicators 3

HORN 3

ALM 3

Encoders 4

ECR1 4

ECR2 4

ECR3 4

Valves 5

CV 5

PV 5

RV1 6

RV2 6

SV 6

SV1 6

SV2 7

Motors 8

M1 8

M2 8

M3 8

Potentiometers 9

POT 9

Relay 10

K1 10

Switch 11

BLS 11

BLS2 11

BLS3 11

BRS 11

FS (PF) 11

HNS1 12

HNS2 12

HSS 12

KYS 12

LMS5 13

LMS6 13

LMS7 13

LMS71 14

LMS8 14

LMS9 14

LMS10 14

LOS1 14

LOS2 15

LOS3 15

LOS4 15

LOS5 15

LOS6 15

LOS7 15

PPCS1 16

PPCS2 16

RAS 16

RAS2 16

RAS3 16

RAS4 17

RAS5 17

SAS 17

Contactors 18

LINE 18

Sensors 19

FPS1 19

FPS2 19

LS 19

SAHS 19

TS1 20

TS2 20

STEER SENSOR 20

Fuses 21

FU1 21

FU2 21

FU3 21

FU7 21

FU8 22

Control Modules 23

Access 1 23

Access 2/3 23

Access 5 23

Access 81 23

Access 82 24

Miscellaneous 25

BRK 25

DC-DC CONVERTER 25

FAN 25

Keypad 25

PWS 26

RT PCB 26

TFD UNIT 26

Hydraulic Cylinder 27

Lift cylinder 27

Platform cylinder 27

Up to S/N 5A416979: Overview 28

Starting with S/N 5A416980: Overview 29

Electrical Components 30

Hydraulic System 0

Safety and Maintenance Instructions 2

Hydraulic lines and ports 2

Bleeding the hydraulic system 2

Drift test 2

Changing the Hydraulic Oil 3

Overview of Pressure Relief Valves 4

12-kW unit, hydraulic unit with single function (up to S/No 5A409929) 4

13-kW unit, hydraulic unit with single function (from S/No 5A409930) 4

22-kW hydraulic unit with single function 4

22-kW hydraulic unit with dual function 4

Replacing the Pressure Relief Valve 5

Testing and Adjusting the Pressure-Relief Valves 6

RV1 test 6

RV2 test 6

Adjusting RV1 or RV2 6

Removing and Installing the Hydraulic Unit 7

Removing the hydraulic unit 7

Installing the hydraulic unit 7

Repairing the 12-kW Hydraulic Unit (Up to S/No 5A409929) 8

Starting up the hydraulic unit 8

Repairing the 13-kW Hydraulic Unit (From S/No 5A409930) 10

Starting up the hydraulic unit 11

Repairing the 22-kW Hydraulic Unit 12

Starting up the hydraulic unit 12

Drive Unit 0

Changing the Transmission Oil 2

Change interval 2

Permissible oil types 2

Special features 2

Preparing to change the oil 2

Draining the oil 2

Adding the oil 2

Power Unit Componentry 3

Electrical System 0

Control Modules and Power Fuses 2

General 2

Power fuses 2

Servicing and Replacing the Control Modules 3

Discharging the capacitors 3

Servicing the control modules 3

Replacing the control module 3

Selecting Service Levels 5

Select service preset 2 5

Select service preset 3 5

With QuickPick® Remote: Determining the Software Version 6

Retrieving the forklift truck code 6

Retrieve individual modules 6

Without QuickPick® Remote: Menu Structure – Overview 7

With QuickPick® Remote: Pairing Submenu 8

With QuickPick® Remote: Operator Menu 9

With QuickPick® Remote: Operator Menu 10

With QuickPick® Remote: Service Menu, Analyzer A1 11

With QuickPick® Remote: Service Menu, Analyzer A2 12

With QuickPick® Remote: Service Menu, Analyzer A3 13

With QuickPick® Remote: Service Menu, Analyzer A3 14

With QuickPick® Remote: Service Menu, Analyzer A2 Inputs 15

With QuickPick® Remote: Service Menu, Analyzer A3 Inputs 16

With QuickPick® Remote: Service Menu, Analyzer A5 Inputs 17

With QuickPick® Remote: Service Menu, Analyzer A6 Inputs 18

With QuickPick® Remote: Service Menu, Analyzer A8 Inputs 19

With QuickPick® Remote: Service Menu, Analyzer A8 Inputs 20

With QuickPick® Remote: Service Menu, Analyzer A8 Output 21

With QuickPick® Remote: Service Menu, C1 and C3 Calibration 22

With QuickPick® Remote: Service Menu, C2 Calibration 23

With QuickPick® Remote: Service Menu, F1 Features 24

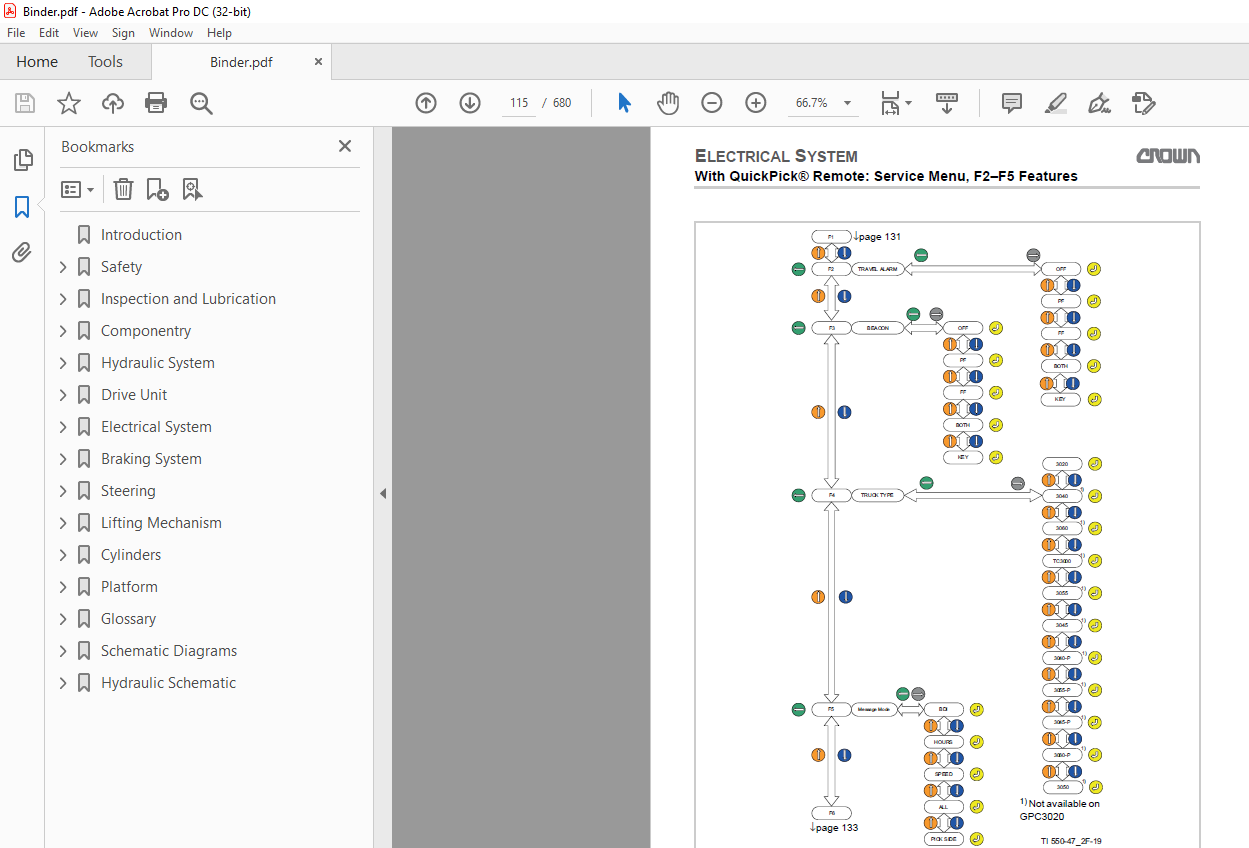

With QuickPick® Remote: Service Menu, F2–F5 Features 25

With QuickPick® Remote: Service Menu, F6–F12 Features 26

With QuickPick® Remote: Service Menu, F73–F74 Features 27

With QuickPick® Remote: Service Menu, F13–F20 Features 28

With QuickPick® Remote: Service Menu, F21 Features 29

With QuickPick® Remote: Service Menu, F22–F26 Features 30

With QuickPick® Remote: Service Menu, Hours 31

With QuickPick® Remote: Service Menu, Events 32

With QuickPick® Remote: Service Menu, P1 Performance 33

With QuickPick® Remote: Service Menu, P2 Performance 34

With QuickPick® Remote: Service Menu, P3 Performance 35

With QuickPick® Remote: Service Menu, P4–P16 Performance 36

With QuickPick® Remote: Service Menu, P16–P99 Performance 37

With QuickPick® Remote: Service Menu, U1 Utilities 38

With QuickPick® Remote: Service Menu, U1–U2 Utilities 39

With QuickPick® Remote: Service Menu, U1–U2 Utilities 40

Without QuickPick® Remote: Determining the Software Version 41

Without QuickPick® Remote: Menu Structure – Overview 42

Without QuickPick® Remote: Operator Menu 43

Without QuickPick® Remote: Analyzer Menu A1 Status 45

Without QuickPick® Remote: Analyzer Menu Access 3 Outputs 46

Without QuickPick® Remote: Analyzer Menu A2 Inputs 48

Without QuickPick® Remote: Analyzer Menu Access 3 Inputs 49

Without QuickPick® Remote: Analyzer Menu Access 5 Inputs 50

Without QuickPick® Remote: Analyzer Menu Test Outputs 51

Without QuickPick® Remote: Calibration Menu 52

Without QuickPick® Remote: Features Menu 55

Without QuickPick® Remote: Hours Menu 59

Without QuickPick® Remote: Events Menu 60

Without QuickPick® Remote: Performance Menu 61

Without QuickPick® Remote: Utilities Menu 66

Parameter GPC 3020/40/50/60 without QuickPick® Remote 68

Parameter GPC 3045/55 without QuickPick® Remote 72

GPC 3020 Parameter without QPR up to 08/2012 76

Parameter GPC 3020/40/45/50/ 55/60 without QPR Starting with 09/2012 77

With QuickPick® Remote: Calibration 80

Navigation in the Service menu 80

Selecting the Calibration menu 80

Calibrating the Traction Potentiometer 81

Requirements 81

Calibration 81

Calibrating the Steering 82

Requirements 82

Starting the calibration 82

Calibrating the control handle centre position 82

Calibrating the steering locks 82

Calibrating the left steering lock 83

Calibrate forward travel 83

Calibrating the Load Sensor 84

Without QuickPick® Remote: Calibration 85

Selecting the CALIBRATION menu 85

Calibrating the traction potentiometer 85

Calibrating the steering 85

Calibrating the load sensor 86

With QuickPick® Remote: Check the Safety of the Laser System 88

Description of functionality 88

Required tools and equipment 88

Requirements 88

Carry out test 88

Check functions of the QPR system 88

Check safety functions of the forklift truck 88

Check safety functions of the point laser 89

Checking safety function of the scanning laser 90

With QuickPick® Remote: Adjust Laser System 92

Requirements 92

Required tools 92

Preparing the forklift truck 92

Setting the point lasers 92

Setting the scanning laser 93

Event Codes 94

Malfunctions with display of event code 94

Locating malfunctions 94

Event code groups 94

With QuickPick® Remote: Event Code Group 100 95

Event code 100 95

Event code 103 95

Event code 105 96

Event codes 106 and 108 97

Event code 109 99

Event code 110100

Event code 111101

Event code 125102

Event codes 126 and 127103

Event code 132104

Event code 144104

Event code 145105

Event code 146105

Event code 148105

Event code 191106

With QuickPick® Remote: Event Code Group 200107

Event code 200107

Event code 201107

Event code 202107

Event code 203109

Event code 204110

Event code 205111

Event code 206113

Event code 207114

Event code 208115

Event code 209 to 215116

Event code 218117

Event code 219118

Event code 220119

Event code 221120

Event code 223120

Event code 224122

Event code 225123

Event code 226123

Event code 228125

Event code 229126

Event code 230127

With QuickPick® Remote: Event Code – Group 300129

Event code 300129

Event code 301130

Event code 302130

Event code 303131

Event code 304131

Event code 305133

Event code 306134

Event code 307134

Event code 308135

Event code 309136

Event code 310136

Event code 314137

Event code 315138

Event code 316139

Event code 317140

Event code 319141

Event code 320143

Event code 321144

Event code 322145

Event code 324145

Event code 325146

Event code 326147

Event code 328148

Event code 329148

Event code 330149

Event code 332150

Event code 333151

Event code 334151

Event code 335152

Event code 337154

Event code 338155

Event code 340156

Event code 341157

Event code 342158

Event code 343159

Event code 344161

Event code 347162

Event code 348164

With QuickPick® Remote: Event Code Group 500165

Event code 500165

Event code 501165

Event code 502166

Event code 503166

Event code 504166

Event code 505166

Event code 506167

Event code 507167

Event code 508168

Event code 509168

Event code 510169

Event code 511172

Event code 512172

Event code 513172

Event code 514173

Event code 515174

Event code 516174

Event code 517175

Event code 518177

Event code 519177

Event code 520178

Event code 522179

Event code 523179

Event code 524180

Event code 525181

Event code 526182

Event code 527183

Event code 528184

Event code 529184

Event code 530185

Event code 531186

Event code 532187

Event code 533188

Event code 535188

Event code 536189

Event code 537190

Event code 538190

Event code 539192

Event code 540193

Event code 541193

Event code 542194

Event code 543195

Event code 544195

With QuickPick® Remote: Event Code Group 800197

Event code 801197

Event code 803198

Event code 804198

Event code 805199

Event code 806199

Event code 807199

Event code 808200

Event code 812200

Event code 813201

Event code 816201

Event code 817201

Event code 821202

Event code 822202

Event code 823203

Event code 824203

Event code 825204

Event code 826204

Event code 827205

Event code 832205

Event code 833206

Event code 834207

Event code 835207

Event code 836 and 837207

Event code 838208

Event code 839208

Event codes 840, 841 and 842209

Event code 844209

Event codes 845 and 846210

Event code 847211

With QuickPick® Remote: Event Code Group 900213

Event Code 901 to 905213

With QuickPick® Remote: Event Code Group 1000214

Event code 1000214

Event code 1001 or 1002215

Without QuickPick® Remote: Event Code Group 200 (GPC 3020 up to 08/2012)216

Without QuickPick® Remote: Event Code Group 300 (GPC 3020 up to 08/2012)220

Without QuickPick® Remote: Event Code Group 500 (GPC 3020 up to 08/2012)227

Without QPR: Event Code Group 100 (All GPCs Starting with 09/ 2012)234

Event code 100234

Without QPR: Event Code Group 200 (All GPCs Starting with 09/ 2012)236

Event code 200236

Event code 201236

Event code 202237

Event code 203239

Event code 204239

Event code 205241

Event code 206242

Event code 207243

Event code 208245

Event code 209 to 215245

Event code 218246

Event code 219247

Event code 220248

Event code 221249

Event code 223250

Event code 224251

Event code 225252

Event code 226253

Event code 228254

Event code 229255

Event code 230256

Without QPR: Event Code Group 300 (All GPCs Starting with 09/ 2012)258

Event code 300258

Event code 301259

Event code 302259

Event code 303260

Event code 304260

Event code 305262

Event code 306263

Event code 307263

Event code 308264

Event code 309265

Event code 310265

Event code 314266

Event code 315267

Event code 316268

Event code 317269

Event code 319270

Event code 320272

Event code 321273

Event code 322274

Event code 324274

Event code 325275

Event code 326276

Event code 328277

Event code 329277

Event code 330278

Event code 332279

Event code 333280

Event code 334280

Event code 335281

Event code 337282

Event code 338283

Event code 340284

Event code 341285

Event code 342286

Event code 343287

Event code 344289

Event code 347290

Event code 348292

Without QPR: Event Code Group 500 (All GPCs Starting with 09/ 2012)293

Event code 500293

Event code 501294

Event code 502294

Event code 503294

Event code 504295

Event code 505295

Event code 506295

Event code 507296

Event code 508297

Event code 509297

Event code 510299

Event code 511301

Event code 512301

Event code 513301

Event code 514302

Event code 515303

Event code 516303

Event code 517304

Event code 518306

Event code 519306

Event code 520307

Event code 522308

Event code 523308

Event code 524310

Event code 525311

Event code 526312

Event code 527313

Event code 528313

Event code 529313

Event code 530314

Event code 531316

Event code 532317

Event code 533318

Event code 535319

Event code 536319

Event code 537320

Event code 538321

Event code 539322

Event code 540323

Event code 541323

Event code 542324

Event code 543325

Event code 544325

Event code 545326

Event Code Group 800 and 900 (From 09/2012)327

Event code 8xx327

Event code 9xx327

Without QPR: Event Code Group 800 (All GPCs Starting with 09/ 2012)328

Event code 800328

Event code 801329

Without QPR: Event Code Group 900 (All GPCs Starting with 09/ 2012)331

Event code 9xx331

Without QPR: Event Code Group 1000 (All GPCs Starting with 09/ 2012)332

Event code 1000332

Event code 1001 or 1002333

With QuickPick® Remote: Events with Plain Text Display334

Check Forklift Truck Path334

Laser Not Ready335

Pairing failed Enter to Retry336

Release remote brake button337

Low signal strength337

GO disabled when on platform337

Release Go338

Enter truck and exit338

Press Go twice339

####? J339

### cm Max Load Width—Press Enter339

Without QuickPick® Remote: Events with Plain Text Display340

Default settings loaded340

Lifting and lowering activated340

Platform error341

Platform up342

Stopped342

Traction control module hot343

Traction motor hot345

Travel switch applied too soon346

Steer control module hot346

Steer motor hot348

Battery not latched350

QP and PPC applied350

Repairing the ABM Traction Motor352

Removing and installing the traction motor352

Removing the traction motor352

Installing the traction motor352

Repairing the ABM Traction Motor353

Preparations353

Dismantling the rotor assembly353

Assembling the rotor assembly353

Maintaining the Crown Traction Motor354

Removing the traction motor354

Installing the traction motor355

Repairing the Crown Traction Motor356

Preparations356

Removing the rotor and bearing356

Installing the rotor and bearing356

Final tasks356

General DC Motor Maintenance Instructions357

Brushes357

Rotor357

Commutator357

Removing and Installing the Steer Motor358

Special tools required359

Removing the steer motor359

Installing the steer motor359

Repairing the Steer Motor360

Final tasks360

Repairing Pump Motors361

Repairing the 12-kW and 13-kW pump motors361

Checking the carbon brushes361

Checking the armature361

Repairing the 22-kW pump motor361

Checking the carbon brushes361

Checking the armature361

Battery Information362

Charging batteries362

Lithium-ion battery362

Charging a lithium-ion battery362

Lead acid battery362

Maintaining lead acid batteries362

Replacing a lead acid battery362

Battery Discharge Indicator (BDI)363

Load profile and discharge curve363

Adapting the BDI setting363

Replacing the Batteries365

Required tools365

Removing battery from the forklift truck365

Installing the batteries in the forklift truck368

Repairing the Contactor370

Dismantling the contactor370

Checking Contacts and Springs370

Checking the Coil371

Reassembling the Contactor371

Perform PMT Test372

Required tools372

Preparing the forklift truck for the test372

Check Access 2372

Testing Access 3373

Checking phase U373

Requirements373

Testing phase V373

Requirements373

Testing phase W373

Requirements373

Braking System 0

Componentry and Operation 2

Service brake 2

Parking brake 2

Servicing the Parking Brake 3

Measuring the air gap 3

Troubleshooting 3

Replacing the Parking Brake 4

Removing the parking brake 4

Installing the parking brake 4

Steering 0

Steering Assembly 2

Steering assembly components 3

Remove the steering assembly 3

Installing the steering assembly 3

Final tasks 3

Repairing the Steering Transmission 4

Preparations 4

Dismantling 4

Assembly 4

Final tasks 5

Up to S/N 5A416979: Removing and Installing the X10® Control Handle 6

Removing the control handle 6

Installing the control handle 6

Up to S/N 5A416979: Replacing the X10® Handle Return Springs 7

Removing the return spring 7

Installing the return spring 7

Up to S/N 5A416979: Removing and Installing the Steer Sensor 9

Removing the steer sensor 9

Installing the steer sensor 9

Up to S/N 5A416979: Checking the Operation of the Steer Sensor 10

Starting with S/N 5A416980: Removing and Installing the X10® Control Handle 11

Removing the X10® Control Handle 11

Installing the X10® Control Handle 12

Repairing the X10® Control Handle 14

Replacing the X10 Control Handle shells 15

Removing the shells 15

Installing the shells 16

Replacing the switch unit 17

Removing the switch unit 17

Installing the switch unit 17

Replacing the rabbit/turtle switch (HSS) 18

Removing the rabbit/turtle switch 18

Installing the rabbit/turtle switch 18

Replacing the printed circuit boards of the X10® Control Handle 19

Removing the hydraulic printed circuit board (HYD PCB) 19

Installing the hydraulic printed circuit board 19

Removing the main printed circuit board (MAIN PCB) 19

Installing the main printed circuit board 20

Replacing the traction potentiometer (POT) 20

Removing the Traction Potentiometer 20

Installing the traction potentiometer (POT) 22

Replacing the brake switch (BRS) 22

Removing the brake switch (BRS) 22

Installing the BRS switch 23

Replacing the grips and horn switch (HNS) 23

Replacing and Adjusting the SAHS 24

Up to S/N 5A416979: Replacing the Control Handle Cable 26

Removing the control handle cable 26

Installing the control handle cable 27

Final tasks 28

Starting with S/N 5A416980: Replacing the X10® Control Handle Cable 29

Previous tasks 29

Removing the cable of the X10® Control Handle 29

Replacing the cable of the X10® Control Handle 31

Installing the cable of the X10® Control Handle 31

Final tasks 33

Starting with S/N 5A416980: Replacing the X10® Control Handle Return Springs 34

Previous tasks 34

Replacing the X10® Control Handle return springs 34

Checking the bearings of the X10® Control Handle 36

Disassembling the X10 Control Handle 36

Installing the X10® Control Handle return springs 37

Final tasks 39

Starting with S/N 5A416980: Replacing the Steer Sensor 40

Removing the steer sensor 40

Installing the steer sensor 40

Lifting Mechanism 0

Checking and Adjusting the Fork Height 2

Checking the fork height 2

Adjusting the fork height 3

Previous tasks: 3

Removing the lifting mechanism cover 3

Presetting the end stops 3

Adjusting fork height at the front 4

Adjusting the fork height at the back 4

Checking the adjustment of the fork height 4

Installing the lifting mechanism cover 5

Checking the Forks 6

Retrofitting a Load Backrest 7

Repairing Lift chains and Chain Anchors 8

Adapting the maintenance intervals to the application conditions 8

Periodic replacement of chain anchors and lift chains 8

Servicing Lift Chains 9

Scope of service work 9

Checking the service hours for the lift chains and chain anchors 9

Cleaning the lift chain 9

Lubricating and preserving lift chains 10

Checking the Lift Chains for Wear and Damage 11

Checking the lift chain elongation 11

Required tools 11

Test preparation 11

Checking the lift chain elongation with the wear gauge 12

Checking the lift chain elongation with the steel ruler 13

Checking the chain for other damage 14

Repairing lift Chains and Chain Anchors 17

Adapting the maintenance intervals to the application conditions 17

Periodic replacement of chain anchors and lift chains 17

Servicing Lift Chains 18

Scope of service work 18

Checking the service hours for the lift chains and chain anchors 18

Cleaning the lift chain 18

Lubricating and preserving lift chains 19

Checking the Lift Chains for Wear and Damage 20

Checking the lift chain elongation 20

Required tools 20

Test preparation 20

Checking the lift chain elongation with the wear gauge 21

Checking the lift chain elongation with the steel ruler 22

Checking the chain for other damage 23

Cylinders 0

Repair Tools 2

Small hook 2

Extractor 2

Producing extractors 2

Groove aligning arbour for small rod packings 2

Assembly devices for large rod packings 3

Protective mechanisms 3

Rod Packing Removal and Assembly 4

Removing a large rod packing 4

Removing a small rod packing 4

Inserting a large rod packing 4

Fitting a small rod packing 5

Rod packing assembly, sealing lip first 5

Important Repair Notes 6

General 6

Removing cylinders 6

Seal Replacement 7

GPC 3020/3040/3060: Repair the Lift Cylinder 8

GPC 3045: Repair the Lift Cylinder 10

GPC 3055: Repair the Lift Cylinder 12

Platform 0

Up to S/N 5A416979: Platform Sensors FPS1 and FPS2 2

Starting with S/N 5A416980: Platform Sensors FPS1 and FPS2 4

Removing and installing platform sensor 4

Previous tasks 4

Removing the platform sensor 4

Glossary 0

Electronic Power Steering 2

Schematic Diagrams 0

Wire Colour Code 2

General Abbreviations of Contact Symbols 3

Electrical Circuit Symbols 5

Electrical Diagrams: Forklift Truck without QPR up to S/N 5A416979 7

Without Key Switch (up to 03/2012) 8

With Key Switch and Keypad Option (up to 03/2012) 9

TCM — Combi AC1 Power Unit Side (up to 03/2012) 10

TCM — Combi AC1 Logic Side (up to 03/2012) 11

SCM -pdf AC0 Logic Side (up to 03/2012) 12

Interface 1, Control Handle (up to 03/2012) 13

Interface 2, Backrest (up to 03/2012) 14

Interface 2, Backrest (up to 03/2012) 16

Interface 2, Backrest (up to 03/2012) 17

GPC 3045, 3055 Connections (up to 03/2012) 18

Switch Connections (up to 03/2012) 19

Control Handle Circuits (up to 03/2012) 21

Display with Options (up to 03/2012) 22

CAN Connection (up to 03/2012) 24

GPC 3000 Power Cable (up to 03/2012) 25

Wiring Harness, Pedestrian Switch, GPC 3055 (up to 03/2012) 26

GPC 3055 without PPC (up to 03/2012) 27

CAN Interface Jumper, GPC 3055 (up to 03/2012) 28

Scissor Lift — Lower Function Wiring Harness (up to 03/2012) 29

GPC3040/3060, GPC3045 29

Scissor RAS — LOS (up to 03/2012) 30

GPC 3055 (no PPC) 30

Wiring Harness, Pedestrian Switch, F/C (up to 03/2012) 31

Microswitch (up to 03/2012) 33

Horn Wiring Harness (up to 03/2012) 34

Horn Switch (up to 03/2012) 35

SAS Switch (up to 03/2012) 36

GPC 3000 Main Wiring Harness (up to 03/2012) 37

Wiring Harness, X10® Control Handle (up to 03/2012) 41

GPC 3000 Display Wiring Harness (up to 03/2012) 43

ZAPI Console Adapter (up to 03/2012) 45

Brake Switch (up to 03/2012) 46

X10 Control Handle 46

GPC 3000 Standard Version (up to 03/2012) 47

CAN Control handle connection wiring harness 47

Steer sensor 48

Walk-along switch 49

Contact pins 49

Platform Lift Wiring Harness (up to 03/2012) 50

Backrest 2 Wiring Harness, Platform Lift (up to 03/2012) 52

Straight-Ahead Sensor (up to 03/2012) 53

CAN Interface Jumper (up to 03/2012) 54

Scissor Lift — Lower Function Wiring Harness (up to 03/2012) 55

Scissor Lift LMS Wiring Harness (up to 03/2012) 56

Scissor RAS—LOS GPC 3000 (up to 03/2012) 57

Platform Lift Fork Switch RAS/LOS 2-5 (up to 03/2012) 58

Backrest 2 Wiring Harness, Platform/Forks (up to 03/2012) 59

Battery Latch Switch (BLS) (up to 03/2012) 60

Key Switch Adapter (up to 03/2012) 61

Wiring Harness, Pedestrian Switch, F/C (up to 03/2012) 62

Heater Assembly (up to 03/2012) 64

Travel Alarm Connector Cable (up to 03/2012) 65

Without Key Switch (from 04/2012) 66

With Key Switch and Keypad Option (Starting with 04/2012) 67

With TFD Unit (Starting with 04/2012) 68

Platform Lift, Combi Lift and Scissor Lift (from 04/2012) 69

CAN Bus Connections (from 04/2012) 70

InfoLink® (Starting with 04/2012) 71

ICM InfoLink® (Starting with 04/2012) 72

Electrical Diagrams: Forklift Trucks with QPR up to S/N 5A416979 73

QuickPick® Remote, Standard Version 74

QuickPick® Remote, with Options 75

QuickPick Remote, Freezer Condition Version, Heating of Point Laser 76

QuickPick Remote, CAN Bus Connections 77

Main Wiring Harness, Standard Forklift Truck 78

Main Wiring Harness, with InfoLink® 79

LSR/OCM Wiring Harness 80

LSR Connecting Cable 82

QuickPick Remote, LSR/OCM Wiring Harness Extension 83

Electrical Diagram: All Forklift Trucks Starting with S/N 5A416980 84

QuickPick® Remote, Standard Version 86

QuickPick® Remote, with Options 87

QuickPick Remote, Freezer Condition Version, Heating of Point Laser 88

QuickPick Remote, CAN Bus Connections 89

Main Wiring Harness, Standard Forklift Truck 90

Main Wiring Harness, with InfoLink® 91

LSR/OCM Wiring Harness 92

LSR Connecting Cable 94

QuickPick Remote, LSR/OCM Wiring Harness Extension 95

Sheet 1: ACCESS 1 96

Sheet 2: ACCESS 3/2 97

Sheet 3: Fuses 98

Sheet 4: ACCESS 3/2 Connections 1 of 4 99

Sheet 5: ACCESS 3/2 Connections 2 of 4100

Sheet 6: ACCESS 3/2 Connections 3 of 4101

Sheet 7: ACCESS 3/2 Connections 4 of 4102

Sheet 8: ACCESS 5103

Sheet 9: ACCESS 81104

Sheet 10: ACCESS 81 Connections105

Sheet 11: ACCESS 82106

Sheet 12: ACCESS 82 Connections 1 of 2107

Sheet 13: ACCESS 82 Connections 2 of 2108

Sheet 14: InfoLink109

Sheet 15: TFD Unit and Proportional Valve110

Sheet 16: LI-ION Battery111

Optional Equipment for all Forklift Truck112

Hydraulic Schematic 0

Hydraulic Symbols 2

GPC 3020 6

IMAGES PREVIEW OF THE MANUAL: