$37

crown Forklift GPC 3000 Service Manual – PDF DOWNLOAD

crown Forklift GPC 3000 Service Manual – PDF DOWNLOAD

FILE DETAILS:

Crown Forklift GPC 3000 Service Manual – PDF DOWNLOAD

Language : English

Pages :701

Downloadable : Yes

File Type : PDF

GPC 3020

GPC 3040

GPC 3045

GPC 3050

GPC 3055

GPC 3060

TABLE OF CONTENTS:

Crown Forklift GPC 3000 Service Manual – PDF DOWNLOAD

Introduction

Safety

Organisation of the Safety Messages Basic Safety Messages

Organisational measures

Modifications to the forklift truck

Personal protection equipment

Securing hazardous areas

Hazards posed by stored energy

Maintenance work

Restoring the forklift truck to service after maintenance work

Cleaning work

Handling batteries

Warning and instruction decals on the forklift truck

Lifting equipment and lifting accessories

Environmental protection

Safety Mechanisms and Protective Guards

Forklift truck safety mechanisms

Forklift truck protective guards

Safety

Organisation of the Safety Messages

Basic Safety Messages

Safety Mechanisms and Protective Guards

Inspection and Lubrication

Storing and Returning the Forklift Truck to Service

Cleaning the Forklift Truck and Componentry

Effects of incorrect cleaning

Environmental protection

Cleaning the entire forklift truck

Cleaning removed componentry

Cleaning other mechanical componentry

Jacking up the Forklift Truck

Lifting the Forklift Truck by Crane

Towing the Forklift Truck

Securing the Forklift Truck on a Loading Surface

Securing GPC 3020, 3040, 3060

Securing GPC 3045 und 3055

Hydraulic Cylinder Lift cylinder

Platform cylinder

Up to S/N 5A416979: Overview

Starting with S/N 5A416980: Overview

Electrical Components

QuickPickR Remote

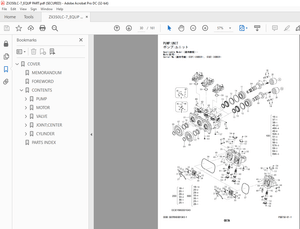

Hydraulic System

Safety and Maintenance Instructions

Hydraulic lines and ports

Bleeding the hydraulic system

Drift test

Changing the Hydraulic Oil

Overview of Pressure Relief Valves

1.2-kW unit, hydraulic unit with single function (up to S/No. 5A409929)

1.3-kW unit, hydraulic unit with single function (from S/No. 5A409930)

2.2-kW hydraulic unit with single function

2.2-kW hydraulic unit with dual function

Safety

Organisation of the Safety Messages

Basic Safety Messages

Safety Mechanisms and Protective Guards

Inspection and Lubrication

Storing and Returning the Forklift Truck to Service

Cleaning the Forklift Truck and Componentry

Effects of incorrect cleaning

Environmental protection

Cleaning the entire forklift truck

Cleaning removed componentry

Cleaning other mechanical componentry

Jacking up the Forklift Truck

Lifting the Forklift Truck by Crane

Towing the Forklift Truck

Securing the Forklift Truck on a Loading Surface

Securing GPC 3020, 3040, 3060

Securing GPC 3045 und 3055

Safety

Organisation of the Safety Messages

Basic Safety Messages

Safety Mechanisms and Protective Guards

Inspection and Lubrication

Storing and Returning the Forklift Truck to Service

Cleaning the Forklift Truck and Componentry

Effects of incorrect cleaning

Environmental protection

Cleaning the entire forklift truck

Cleaning removed componentry

Cleaning other mechanical componentry

Jacking up the Forklift Truck

Lifting the Forklift Truck by Crane

Towing the Forklift Truck

Securing the Forklift Truck on a Loading Surface

Securing GPC 3020, 3040, 3060

Securing GPC 3045 und 3055

Hydraulic Cylinder Lift cylinder

Platform cylinder

Up to S/N 5A416979: Overview

Starting with S/N 5A416980: Overview

Electrical Components

QuickPickR Remote

Hydraulic System

Safety and Maintenance Instructions

Hydraulic lines and ports

Bleeding the hydraulic system

Drift test

Changing the Hydraulic Oil

Overview of Pressure Relief Valves

1.2-kW unit, hydraulic unit with single function (up to S/No. 5A409929)

1.3-kW unit, hydraulic unit with single function (from S/No. 5A409930)

2.2-kW hydraulic unit with single function

2.2-kW hydraulic unit with dual functionTesting and Adjusting the Pressure-Relief Valves

RV1 test

RV2 test

Adjusting RV1 or RV2

Removing and Installing the Hydraulic Unit

Removing the hydraulic unit

Installing the hydraulic unit

Repairing the 1.2-kW Hydraulic Unit (Up to S/No. 5A409929)

Starting up the hydraulic unit

Repairing the 1.3-kW Hydraulic Unit (From S/No. 5A409930)

Starting up the hydraulic unit

Repairing the 2.2-kW Hydraulic Unit

Starting up the hydraulic unit

Bleeding and Flushing the System

Safety messages

Before flushing and bleeding the system

Bleeding

Flushing

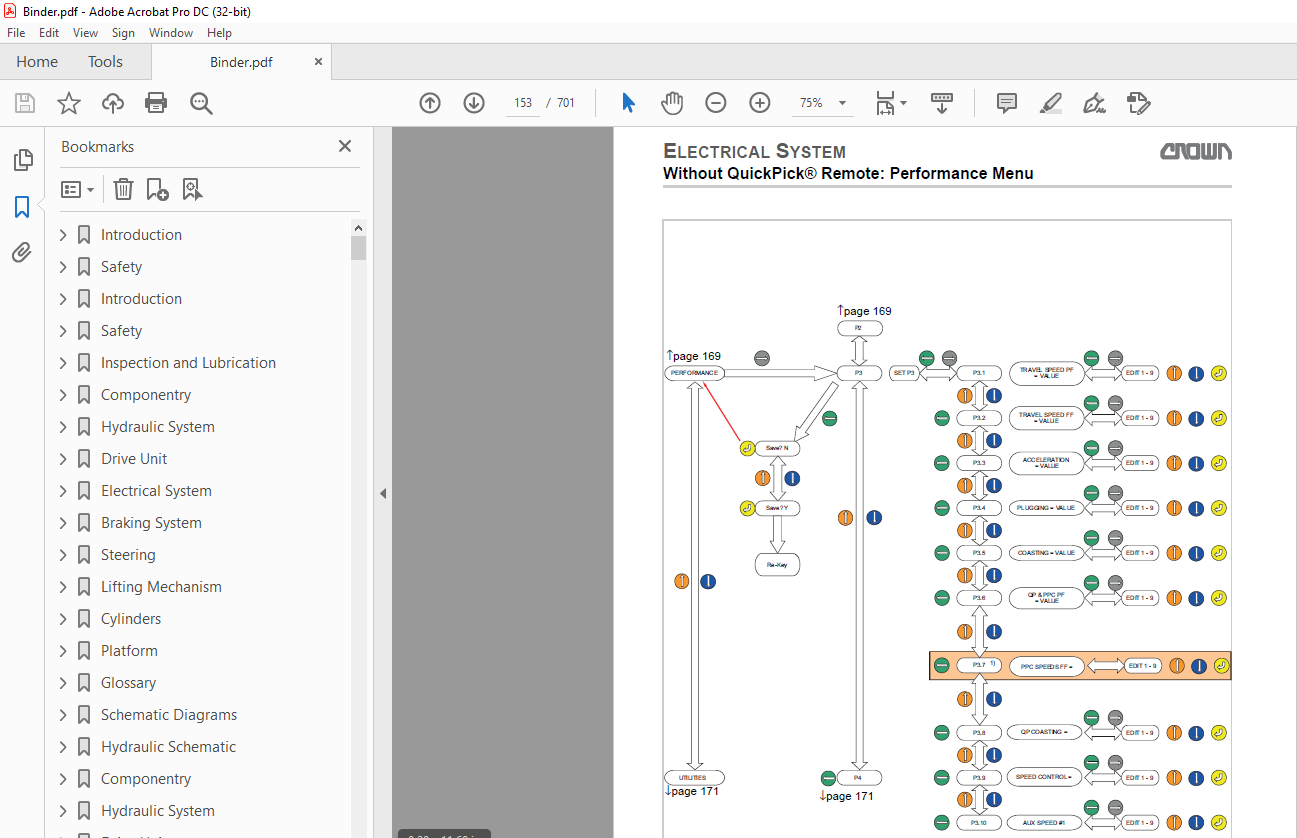

Drift testWithout QuickPickR Remote: Menu Structure – Overview

With QuickPickR Remote: Pairing Submenu

With QuickPickR Remote: Operator Menu

With QuickPickR Remote: Operator Menu

With QuickPickR Remote: Service Menu, Analyzer A1

With QuickPickR Remote: Service Menu, Analyzer A2

With QuickPickR Remote: Service Menu, Analyzer A3

With QuickPickR Remote: Service Menu, Analyzer A3

With QuickPickR Remote: Service Menu, Analyzer A2

Inputs With QuickPickR Remote:

Service Menu, Analyzer A3 Inputs With QuickPickR Remote:

Service Menu, Analyzer A5 Inputs With QuickPickR Remote:

Service Menu, Analyzer A6 Inputs With QuickPickR Remote:

Service Menu, Analyzer A8 Inputs With QuickPickR Remote:

Service Menu, Analyzer A8 Inputs With QuickPickR Remote:

Service Menu, Analyzer A8 Output With QuickPickR Remote:

Service Menu, C1 and C3 Calibration With QuickPickR Remote:

Service Menu, C2 Calibration

With QuickPickR Remote: Service Menu, F1 FeaturesWithout QuickPickR Remote: Menu Structure – Overview

With QuickPickR Remote: Pairing Submenu

With QuickPickR Remote: Operator Menu

With QuickPickR Remote: Operator Menu

With QuickPickR Remote: Service Menu,

Analyzer A1 With QuickPickR Remote:

Service Menu, Analyzer A2 With QuickPickR

Remote: Service Menu, Analyzer A3 With QuickPickR Remote:

Service Menu, Analyzer A3 With QuickPickR Remote:

Service Menu, Analyzer A2 Inputs With QuickPickR Remote:

Service Menu, Analyzer A3 Inputs With QuickPickR Remote:

Service Menu, Analyzer A5 Inputs With QuickPickR Remote:

Service Menu, Analyzer A6 Inputs With QuickPickR Remote:

Service Menu, Analyzer A8 Inputs With QuickPickR Remote:

Service Menu, Analyzer A8 Inputs With QuickPickR Remote:

Service Menu, Analyzer A8 Output With QuickPickR Remote:

Service Menu, C1 and C3 Calibration With QuickPickR Remote:

Service Menu, C2 Calibration

With QuickPickR Remote: Service Menu, F1 Features

Parameter GPC 3045/55 without QuickPick® Remote

GPC 3020 Parameter without QPR up to 08/2012

Parameter GPC 3020/40/45/50/55/60 without QPR Starting with 09/2012

With QuickPick® Remote: Calibration

Calibrating the Traction Potentiometer

Calibrating the Steering

Calibrating the Load Sensor

Without QuickPick® Remote: Calibration

With QuickPick® Remote: Check the Safety of the Laser System

With QuickPick® Remote: Adjust Laser System

Event Codes

With QuickPick® Remote: Event Code Group 100

With QuickPick® Remote: Event Code Group 200

With QuickPickR Remote: Event Code – Group 300

With QuickPick® Remote: Event Code Group 500

With QuickPick® Remote: Event Code Group 800

With QuickPick® Remote: Event Code Group 900

With QuickPick® Remote: Event Code Group 1000

Without QuickPick® Remote: Event Code Group 200

(GPC 3020 up to 08/2012) Without QuickPickR Remote: Event Code Group 300 (GPC 3020 up to 08/2012)Event Code Group 800 and 900 (From 09/2012)

Without QPR: Event Code Group 800 (All GPCs Starting with 09/2012)Without QPR: Event Code Group 900 (All GPCs Starting with 09/2012)

Without QPR: Event Code Group 1000 (All GPCs Starting with 09/2012)With QuickPick® Remote: Events with Plain Text Display

Without QuickPickR Remote: Events with Plain Text Display

Repairing the ABM Traction MotorRepairing the ABM Traction MotorMaintaining the Crown Traction Motor

Repairing the Crown Traction MotorGeneral DC Motor Maintenance InstructionsRemoving and Installing the Steer Motor

Repairing the Steer Motor

Repairing Pump MotorsBattery Information

Battery Discharge Indicator (BDI)

Replacing the Batteries

Repairing the Contactor

Perform PMT TestSchematic DiagramsHydraulic SchematicComponentry

Hydraulic SystemDrive UnitElectrical SystemCylindersBraking SystemSteering

X10_Standard_grau_en_5A417753.pdf

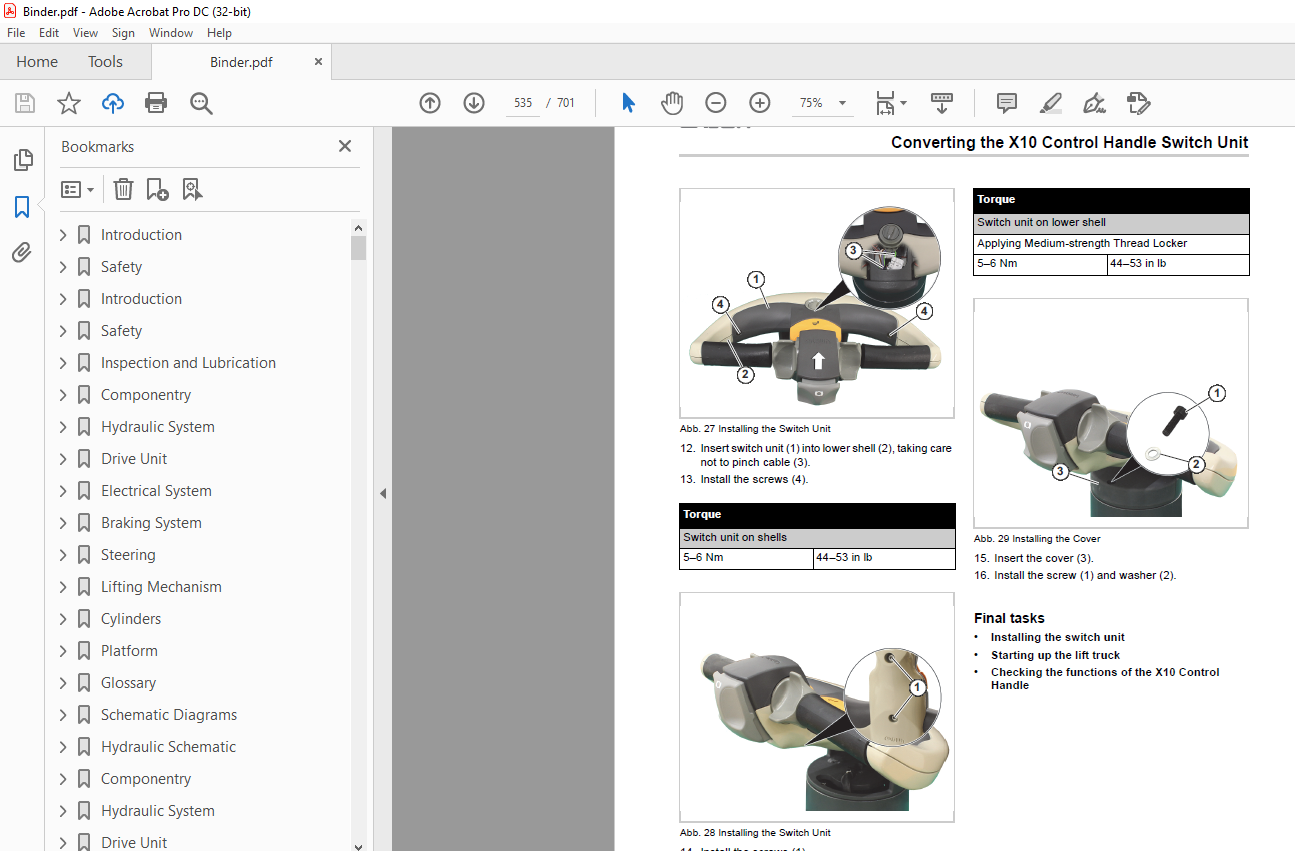

Replacing the Switch Unit of the X10 Control Handle

Previous tasks

Removing the Switch Unit

Abb. 17 Removing the Cover

1. Remove the screw (1) and washer (2).

2. Remove the cover (3).

Abb. 18 Removing the Switch Unit

3. Remove the screws (1).

Abb. 19 Removing the Switch Unit

Onnector (3)

for the fun winny maries and connecLUI (4)

10 the contro nanuit Cavic.

9. Remove the switch unit (1).

Abb. 21 Removing the Cover Cap

10. Remove the cover cap (1)

from the control handle (2)

by levering it into the small opening (arrow) with a suitable tool.

Abb. 22 Removing the Horn

11. Press the horn (1)

in and remove from the control handle (2).

12. Disconnect the connector (3)

and remove the horn (1).

Abb. 23 Removing the Cover Cap

13. Remove the cover cap (1)

from the control handle (2)

by levering it into the small opening (arrow) with a suitable tool. Abb. 24 Removing the Horn

14. Press the horn (1) in and remove from the control handle (2).

15. Disconnect the connector (3) and remove the horn (1).

Abb. 25 Removing the Control Handle

16. Remove the screw (1).

17. Carefully pull the control handle

(2) off the shells (3)

and guide the connector (4)

through the opening (arrow).

Abb. 26 Removing the Control Handle

18. Remove the screw (1).

19. Carefully pull the control handle (2)

off the shells (3)

and guide the connector (4)

through the opening (arrow).

Abb. 27 Removing the Upper Shell

20. Remove the screws (1).

IMAGES PREVIEW OF THE MANUAL: